Академический Документы

Профессиональный Документы

Культура Документы

Check Valves

Загружено:

Nilesh MistryАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Check Valves

Загружено:

Nilesh MistryАвторское право:

Доступные форматы

Check Valves

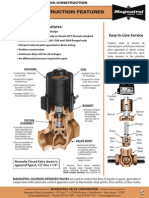

CV, CH, CO, CA, COA, CL and CW Series

FITOK Group

FITOK GmbH (Headquarter)

Sprendlinger Landstr. 115, 63069 Offenbach am Main, Germany

Tel.: +49 69 8900 4498

Fax: +49 69 8900 4495

FITOK, Inc.

13843 North Promenade Blvd., Suite 750, Stafford, Texas 77477, USA

Tel.: +1 281 888 0077

Fax: +1 281 310 8687

FITOK Incorporated

1-4F, Block C, Zone E, Yingtailong lndustrial Park, Dalang Street,

Longhua District, Shenzhen, 518109, China

Tel.: +86 755 2803 2500

Fax: +86 755 2803 2619

FITOK Middle East Oil Equipment Trading LLC

208-209, Makateb Tower, Airport Road, P.O.Box 185412, Deira, Dubai, UAE

Tel.: +971 4 2959 853

Fax: +971 4 2959 854

info@fitokgroup.com

www.fitokgroup.com

FK-IC-GV-03-EN-140821

www.fitokgroup.com

1 Check Valves

Check Valves 2

Cracking Pressure and Resealing Pressure

Check Valves

CV, CH, CO, CA, COA, CL and CW Series

Cracking pressure - the upstream pressure at which the first indication of flow occurs.

Reseal pressure - the pressure at which there is no indication of flow.

Series

Features

CV, CH and CO Series

COA Series

Compact, one-piece body

Fixed Cracking Pressures

Working pressure up to: 3000 psig (207 bar)

Working temperature: -10 F to 375F (-23C to 190C)

CH

1/3 (0.02)

1 (0.06)

3 (0.21)

10 (0.68)

25 (1.7)

0 to 3 (0 to 0.21)

0 to 4 (0 to 0.28)

1 to 5 (0.06 to 0.34)

7 to 15 (0.49 to 1.1)

20 to 30 (1.4 to 2.1)

Up to 6 (0.42) downstream pressure

Up to 5 (0.35) downstream pressure

Up to 2 (0.14) downstream pressure

3 (0.21) or higher upstream pressure

17 (1.2) or higher upstream pressure

CO

1/3 (0.02)

1 (0.06)

3 (0.21)

10 (0.68)

25 (1.7)

0 to 3 (0 to 0.21)

0 to 4 (0 to 0.28)

1 to 5 (0.06 to 0.34)

7 to 15 (0.49 to 1.1)

20 to 30 (1.4 to 2.1)

6 to 20 (0.42 to 1.4) downstream pressure

5 to 20 (0.35 to 1.4) downstream pressure

3 to 20 (0.21 to 1.4) downstream pressure

3 to 10 (0.21 to 0.68) downstream pressure

5 (0.35) or higher upstream pressure

CA

COA

3 to 50 (0.21 to 3.4)

50 to 150 (3.4 to 10.3)

150 to 350 (10.3 to 24.1)

350 to 600 (24.1 to 41.3)

Refer to the chart below

0 to 2 (0 to 0.14)

CW

Up to 2 (0.14) downstream pressure

Cracking Pressure and Resealing Pressure

CA and COA Series

50

100 150 200 250 300 350 400 450 500 550 600

350 400

450 500 550 600

10.3 13.8 17.2 20.7 24.1 27.6 31.0 34.5 37.9 41.4

6.9 10.3 13.8 17.2 20.7 24.1 27.6 31.0 34.5 37.9 41.4

6.9

3.4

1. Besides CL series, other check valves are all coated with lubricants like: silicone base and molybdenum disulfide base.

2. Contact the authorized representative or FITOK Group for

other materials.

3. PTFE coated spring is an option for CV, CO, CA, and COA series

check valves. For more details, please contact FITOK group or

authorized agent.

4. Every valve is tested with nitrogen for leak-tight performance

at its maximum working pressure.

3.4

200 250 300

CW Series

Working pressure up to: 3000 psig (207 bar)

Working temperature: -10F to 400F (-23C to 204C)

Cracking pressure: less than 2 psig (0.14 bar)

Variety of end connections and materials available

All-welded design for safety

-50

Resealing Pressure (psig)

Cracking Pressure (bar)

Resealing Pressure (bar)

-3.4

100 150

Working pressure up to: 6000 psig (414 bar)

Working temperature: -65F to 900F (-53C to 482C)

Rugged, all-stainless steel construction

Union bonnet design, all-stainless steel structure,

horizontal installation with bonnet nut on top

Reverse flow coefficient less than 0.1% of forward flow

coefficient

CA Series

Working pressure up to: 3000 psig (207 bar)

Working temperature: -10 F to 375F (-23C to 190C)

Cracking pressure: 3 to 600 psig (0.2 to 41.4 bar)

Variety of end connections and materials available

Up to 6 (0.42) downstream pressure

Up to 6 (0.42) downstream pressure

Up to 6 (0.42) downstream pressure

3 (0.21) or higher upstream pressure

17 (1.2) or higher upstream pressure

CL Series

CA and COA Series

Adjustable Cracking Pressures, Variety of Springs

Available

CV

0 to 3 (0 to 0.21)

0 to 4 (0 to 0.28)

1 to 5 (0.06 to 0.34)

7 to 15 (0.49 to 1.1)

20 to 30 (1.4 to 2.1)

50

CO Series

Compact, one piece body

Working pressure up to: 3000 psig (207 bar)

Working temperature: -10 F to 375F (-23C to 190C)

Cracking pressure: 1/3 to 25 psig (0.02 to 1.7 bar)

Variety of end connections and materials available

Variety of end connections and materials available

Resealing Pressure Range

psig (bar)

CH Series

Seat ring continuously cleaned by media, avoiding

secondary pollution

Working pressure up to: 6000 psig (414 bar)

Working temperature: -10F to 400F (-23C to 204C)

Cracking pressure: 1/3 to 25 psig (0.02 to 1.7 bar)

Variety of end connections and materials available

Cracking pressure: 3 to 600 psig (0.2 to 41.4 bar)

Cracking Pressure

Range

psig (bar)

1/3 (0.02)

1 (0.06)

3 (0.21)

10 (0.68)

25 (1.7)

Cracking Pressure (psig)

CV Series

Resilient O-ring seat design for leak free sealing

Working pressure up to: 3000 psig (207 bar)

Working temperature: -10F to 375F (-23C to 190C)

Cracking pressure: 1/3 to 25 psig (0.02 to 1.7 bar)

Variety of end connections and materials available

Nominal Cracking

Pressure

psig (bar)

3 Check Valves

Check Valves 4

Pressure vs. Temperature

CH Series

2 3 4 5

1 Inlet Body

Poppet

Temperature (C)

65

93

121 148 176

204

241

-33

37

93

148 204 260 315 371 426 482

7000

483

207

6000

414

2500

172

5000

345

2000

138

4000

276

1500

103

Pressure (psig)

3000

3000

207

1000

69

2000

138

500

35

1000

69

0

-10

0

100 150 200 250 300 350 400

50

Pressure (bar)

37

Temperature (C)

Pressure (bar)

Pressure (psig)

10

Component

CL Series

CV, CO, CA and COA Series

FKM Seat in 316 SS Body and Buna N in Brass Body

-23

3500

6 7

316 SS/A479

Fluorocarbon FKM - bonded 316 SS/A479

Poppet Stop

Spring

302 SS/A313

O-ring

Fluorocarbon FKM

Backup Ring

PTFE/D1710

Outlet Body

316 SS/A479

316 SS/A240

CO Series

1

Component

1 Body

2 Insert Locking Screw

3 Insert

4 O-ring

5 Poppet

6 Spring

-65 100 200 300 400 500 600 700 800 900

Temperature (F)

Temperature (F)

Valve Material Grade/ASTM Specification

Valve Material Grade/ASTM Specification

316 SS

Brass

316 SS/A479

Brass C36000/B16

316 SS/A276 or A479

Brass C36000/B16

316 SS/A479

Brass C36000/B16

Fluorocarbon FKM

Buna N

316 SS/A479

Brass C36000/B16

302 SS/A313

302 SS/A313

Brass

316 SS

CA Series

Component

CH Series

CW Series

FKM Seat in 316 SS Body

FKM Seat in 316 SS Body

10

37

65

93

121 148 176

6000

345

4000

276

3000

207

2000

138

1000

69

0

-10

-23

3500

Pressure (psig)

Pressure (psig)

204

483

414

5000

0

100 150 200 250 300 350 400

50

10

37

1 Inlet Body

2 Inlet Gasket

65

93

121 148 176

3 Insert

4 O-ring

204

241

3000

207

2500

172

2000

138

1500

103

1000

69

500

35

0

-10

0

50

1 2

3 4

Component

316 SS

Brass

316 SS/A479

Brass C36000/B16

Buna N

Poppet

Fluorocarbon FKM

316 SS/A479

Brass C36000/B16

Spring

302 SS/A313

302 SS/A313

Outlet Body

316 SS/A479

Brass C36000/B16

Inlet Body

O-ring

3

4

5

Brass C36000/B16

Buna N

Brass C36000/B16

302 SS/A313

302 SS/A313

7 Center Body

8 Adjusting Screw

316 SS/A479

Brass C36000/B16

316 SS/A276

316 SS/A276

316 SS/A276

316 SS/A276

PTFE-coated 316 SS/A240

PTFE-coated 316 SS/A240

316 SS/A479

Brass C36000/B16

Component

3 Insert

4 O-ring

5 Poppet

Valve Material Grade/ASTM Specification

PTFE-coated 316 SS/A240

316 SS/A479

316 SS/A479

1 Body

2 Insert Locking Screw

Standard Materials of Construction

3

PTFE-coated 316 SS/A240

COA Series

Contact the authorized representative or FITOK Group for curve graph of other materials

Brass

Brass C36000/B16

5 Poppet

6 Spring

11 Outlet Body

Temperature (F)

CV Series

316 SS

316 SS/A479

Fluorocarbon FKM

9 Locking Screw

10 Outlet Gasket

100 150 200 250 300 350 400

Temperature (F)

8 9 10 11

Temperature (C)

Pressure (bar)

-23

7000

Pressure (bar)

Temperature (C)

1 234 5 6

Valve Material Grade/ASTM Specification

Valve Material Grade/ASTM Specification

316 SS

316 SS/A479

Brass

Brass C36000/B16

316 SS/A479

Brass C36000/B16

316 SS/A479

Brass C36000/B16

Fluorocarbon FKM

Buna N

316 SS/A479

Brass C36000/B16

6 Spring

7 Adjusting Screw

302 SS/A313

302 SS/A313

316 SS/A276

316 SS/A276

8 Locking Screw

316 SS/A276

316 SS/A276

CL Series

1 2

3 4

Component

1

2

3

4

Bonnet Nut

Bonnet

Poppet

Body

Valve Material Grade/ASTM Specification

316 SS/A479

316 SS/A479

S17400/A564

316 SS/A479

5 Check Valves

Check Valves 6

CW Series

Part Number Description

1

Component

1

Body

Poppet

Guidance Wafer

Poppet Stop

Valve Material Grade/ASTM Specification

CVSS - FL8 - ML10 - B - 2SF2

316L SS/A479

Fluorocarbon FKM - bonded 316 SS/A479

Alloy X - 750/B637

316L SS/A240

Series Body Material

Dimensions

Inlet Type

CV

SS

6L

B

M

316 SS

316L SS

Brass

Alloy

FNS

NS

FRT

RT

FMS

MS

Connection Type and Size

Inlet

CV

Body Size

Outlet

Dimension, in. (mm)

FRP

BP

FL

CV-FL2-

1/8" FITOK

1/8" FITOK

0.10

2.14 (54.3)

CV-FL4-

1/4" FITOK

1/4" FITOK

0.47

2.35 (59.7)

CV-FL6-

3/8" FITOK

3/8" FITOK

1.47

3.17 (80.5)

B

5/8 (15.9)

ML

FO

FR

UMB

7/8 (22.2)

CV-FL8-

1/2'' FITOK

CV-FL12-

3/4" FITOK

1/2'' FITOK

1.68

3/4" FITOK

3.42 (86.9)

12

4.32 (110.0)

1 1/4 (31.8)

12

4.74 (120.0)

1 3/8 (34.9)

2.36 (59.9)

5/8 (15.9)

3.32 (84.3)

3.42 (86.9)

UFB

Female NPT

Male NPT

Female BSPT

Male BSPT

Female Metric

Thread (for RP-M)

Male Metric

Thread (for RG-M)

Female BSPP (for RP)

Male BSPP (for RG)

Fractional Tube

Fitting

Metric Tube Fitting

Male FO Fitting

Male FR Fitting

Nut+Gasket+Metric

Bulge Nipple

Nut+Gasket+

Fractional Bulge

Nipple

2 1/8"

4 1/4"

3/8"

6 or

6 mm

"

1

/2

8 or 8

mm

10 10 mm

3/4"

12 or

12 mm

16 1"

B

N

E

Z

1" FITOK

1" FITOK

CV-ML6-

6 mm FITOK

6 mm FITOK

CV-ML10-

10 mm FITOK

10 mm FITOK

CV-ML12-

12 mm FITOK

12 mm FITOK

CV-FNS2-

1/8 Female NPT

1/8 Female NPT

0.10

1.89 (48.0)

5/8 (15.9)

CV-FNS4-

1/4 Female NPT

1/4 Female NPT

0.47

2.15 (54.6)

3/4 (19.1)

CV-FNS6-

3/8 Female NPT

3/8 Female NPT

1.47

2.98 (75.7)

7/8 (22.2)

CV-FNS8-

1/2 Female NPT

1/2 Female NPT

1.68

3.58 (90.9)

1 1/16 (27.0)

CV-FNS12-

3/4 Female NPT

3/4 Female NPT

12

4.08 (104.0)

1 1/4 (31.8)

12

4.84 (123.0)

1 5/8 (41.3)

0.47

7/8 (22.2)

1.68

4.48

CV-FNS16-

1 Female NPT

1 Female NPT

CV-NS2-

1/8 Male NPT

1/8 Male NPT

0.10

1.71 (43.4)

CV-NS4-

1/4 Male NPT

1/4 Male NPT

0.47

2.09 (53.1)

CV-Ns6-

3/8 Male NPT

3/8 Male NPT

1.47

2.78 (70.6)

CV-NS8-

1/2 Male NPT

1/2 Male NPT

1.68

3.16 (80.3)

CV-NS12-

3/4 Male NPT

3/4 Male NPT

12

4.08 (104.0)

1 1/4 (31.8)

12

4.52 (115.0)

1 5/8 (41.3)

5/8 (15.9)

7/8 (22.2)

4.48

CV-NS16-

1 Male NPT

1 Male NPT

CV-FR4-

1/4" Male FR

1/4" Male FR

0.47

2.21 (56.1)

5/8 (15.9)

CV-FR8-

1/2" Male FR

1/2" Male FR

1.68

3.56 (90.4)

15/16 (23.8)

CV-FR12-

3/4" Male FR

3/4" Male FR

12

4.64 (118.0)

12

4.76 (121.0)

4.48

1" Male FR

1" Male FR

1 5/8 (41.3)

Fluorocarbon

FKM

Buna N

Neoprene

Ethylene

propylene

Kalrez

Same as Inlet

Specified in the

same way as the

inlet type and

size

4.48

CV-FL16-

CV-FR16-

Outlet Outlet

Seal

Type Size Material

Cracking

Pressure

Special

Application

Cleaning and

Packaging

A

B (Hex)

CV Series

Basic Ordering

Number

Inlet Size

1. Standard thread pitch for metric threads are as follows:

M10 and below: 1 mm

M12 to M24: 1.5 mm

Standard thread pitch should be ignored in the ordering number, others

should be specified.

2. For Oxygen-Riched Environment or dangerous media, please contact

FITOK group or authorized agent.

3. Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to

ensure compliance with product cleanliness requirement as stated in ASTM

G93 Level C.

4. The material in "Part Number Description" is general material, end connection

type & size is general standard. If other end connection is needed, please contact

FITOK group or authorized agent.

5. PTFE coasted gasket can be chosen to reduce the possibility of o-ring's moving in

system caused by the pressure fluctuations, vibration or pulsating, For the details,

please contact with FITOK company or authorized agents.

6. Check valve is unidirectional design with flow path, it can't be used as safety relief valve.

7. If the check valve is not opened during a period, its initial opening pressure may be

higher than set pressure.

3 psig

1 1/3 psig

2 1 psig

3 10 psig

4 25 psig

NO

NACE

S MR0175

FC-01

F2 FC-02

7 Check Valves

Check Valves 8

CH Series

Part Number Description

A

B (Hex)

CHSS - FL8 - ML10 - B - 2SF2

Series Body Material

Basic Ordering

Number

Connection Type and Size

Inlet

Outlet

CH-FL2-

1/8" FITOK

1/8" FITOK

CH-FL4-

1/4" FITOK

1/4" FITOK

Pressure

Rating at

100o F (37o C)

psig (bar)

CV

0.67

414 (6000)

3/8" FITOK

3/8" FITOK

CH-FL8-

1/2'' FITOK

1/2'' FITOK

CH-FL12-

3/4" FITOK

3/4" FITOK

344 (5000)

CH-FL16-

1" FITOK

1" FITOK

323 (4700)

CH-ML6-

6 mm FITOK

6 mm FITOK

CH-ML8-

8 mm FITOK

8 mm FITOK

CH-ML10-

10 mm FITOK

10 mm FITOK

CH-ML12-

12 mm FITOK

12 mm FITOK

CH-ML22-

22 mm FITOK

22 mm FITOK

337 (4900)

CH-ML25-

25 mm FITOK

25 mm FITOK

316 (4600)

CH-FNS4-

1/4 Female NPT

1/4 Female NPT

414 (6000)

CH-FNS6-

3/8 Female NPT

3/8 Female NPT

365 (5300)

CH-FNS8-

1/2 Female NPT

1/2 Female NPT

337 (4900)

CH-FNS12-

3/4 Female NPT

3/4 Female NPT

316 (4600)

CH-FNS16-

1 Female NPT

1 Female NPT

303 (4400)

CH-NS2-

1/8 Male NPT

1/8 Male NPT

CH-NS4-

1/4 Male NPT

1/4 Male NPT

CH-NS6-

3/8 Male NPT

3/8 Male NPT

CH-NS8-

1/2 Male NPT

1/2 Male NPT

CH-NS12-

3/4 Male NPT

3/4 Male NPT

CH-NS16-

1 Male NPT

1 Male NPT

CH-FRT4-

1/4 Female BSPT

1/4 Female BSPT

414 (6000)

0.67

CH-FRT8-

1/2 Female BSPT

1/2 Female BSPT

351 (5100)

1.8

CH-FRT12-

3/4 Female BSPT

3/4 Female BSPT

330 (4800)

CH-FRT16-

1 Female BSPT

1 Female BSPT

303 (4400)

CH-RT4-

1/4 Male BSPT

1/4 Male BSPT

CH-RT8-

1/2 Male BSPT

1/2 Male BSPT

CH-RT12-

3/4 Male BSPT

3/4 Male BSPT

CH-RT16-

1 Male BSPT

1 Male BSPT

CH-FR4-

1/4" Male FR

CH-FR8CH-FR12-

1.8

4.7

0.67

414 (6000)

1.8

4.7

0.67

1.8

4.7

0.67

414 (6000)

1.8

414 (6000)

4.7

4.7

0.67

1.8

2.27 (57.7)

2.43 (61.7)

2.75 (69.9)

B

11/16 (17.5)

1 (25.4)

2.96 (75.2)

16

3.52 (89.4)

16

3.88 (98.6)

2.43 (61.7)

2.70 (68.6)

2.80 (71.1)

2.96 (75.2)

16

3.48 (88.4)

16

3.88 (98.6)

2.13 (54.1)

2.55 (64.8)

1(25.4)

3.03 (77.0)

1 1/16 (27.0)

16

3.23 (82.0)

16

3.83 (97.3)

1.79 (45.4)

2.17 (55.1)

2.36 (59.9)

2.73 (69.3)

16

3.29 (83.6)

16

3.67 (93.2)

2.28 (57.9)

11/16 (17.5)

1 1/16 (27.0)

FL

1 (25.4)

1 5/8 (41.3)

UFB

11/16 (17.5)

1 5/8 (41.3)

11/16 (17.5)

1 (25.4)

1 5/8 (41.3)

16

3.83 (97.3)

2.17 (55.1)

11/16 (17.5)

1 (25.4)

16

3.67 (93.2)

2.28 (57.9)

1 5/8 (41.3)

4.7

1/4" Male FR

414 (6000)

0.67

1/2" Male FR

1/2" Male FR

296 (4300)

1.8

2.73 (69.3)

1 (25.4)

3/4" Male FR

3/4" Male FR

254 (3700)

4.7

16

3.78 (96.0)

1 5/8 (41.3)

CH-FO4-

1/4" Male FO

1/4" Male FO

0.67

1.98 (50.3)

11/16 (17.5)

CH-FO8-

1/2" Male FO

1/2" Male FO

1.8

2.35 (59.7)

1 (25.4)

CH-FO12-

3/4" Male FO

3/4" Male FO

CH-FO16-

1" Male FO

1" Male FO

2.90 (73.7)

1 5/8 (41.3)

344 (5000)

4.7

16

16

ML

FO

FR

UMB

3.55 (90.2)

3.35 (85.1)

FMS

11/16 (17.5)

3.29 (83.6)

2.73 (69.3)

FNS

NS

FRT

RT

1 5/8 (41.3)

SS 316 SS

6L 316L SS

M Alloy

FRP

BP

16

16

CH

MS

344 (5000)

414 (6000)

Inlet Size

Outlet Outlet

Seal

Type Size Material

Cracking

Pressure

Special

Application

Cleaning and

Packaging

Dimension, in. (mm)

A

CH-FL6-

344 (5000)

Body Size

Inlet Type

1 5/8 (41.3)

11/16 (17.5)

Female NPT

Male NPT

Female BSPT

Male BSPT

Female Metric

Thread (for RP-M)

Male Metric

Thread (for RG-M)

Female BSPP (for RP)

Male BSPP (for RG)

Fractional Tube

Fitting

Metric Tube Fitting

Male FO Fitting

Male FR Fitting

Nut+Gasket+Metric

Bulge Nipple

Nut+Gasket+

Fractional Bulge

Nipple

2 1/8"

4 1/4"

"

6 3/8

or 6 mm

/2"

8 1

or 8 mm

10 10 mm

"

12 3/4

or 12 mm

16 1"

22 mm or

22 M22 x 1.5

25 25 mm

B

N

E

Z

Fluorocarbon

FKM

Buna N

Neoprene

Ethylene

propylene

Kalrez

Same as Inlet

Specified in the

same way as the

inlet type and

size

1. Standard thread pitch for metric threads are as follows:

M10 and below: 1 mm

M12 to M24: 1.5 mm

M27 and above: 2 mm

Standard thread pitch should be ignored in the ordering number, others

should be specified.

2. For Oxygen-Riched Environment or dangerous media, please contact

FITOK group or authorized agent.

3. Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to

ensure compliance with product cleanliness requirement as stated in ASTM

G93 Level C.

4. The material in "Part Number Description" is general material, end connection

type & size is general standard. If other end connection is needed, please contact

FITOK group or authorized agent.

5. Check valve is unidirectional design with flow path, it can't be used as safety relief valve.

6. If the check valve is not opened during a period, its initial opening pressure may be

higher than set pressure.

3 psig

1 1/3 psig

2 1 psig

3 10 psig

4 25 psig

NO

NACE

S MR0175

FC-01

F2 FC-02

9 Check Valves

Check Valves 10

CO Series

CA Series

A

B (Hex)

B (Hex)

Connection Type and Size

Basic Ordering

Number

CV

Body Size

Connection Type and Size

Dimension, in. (mm)

Dimension, in. (mm)

Basic Ordering

Number

CA -FL4-

1/4" FITOK

1/4" FITOK

Inlet

Outlet

Inlet

Outlet

CO-FNS4-

1/4 Female NPT

1/4 Female NPT

0.35

2.41 (61.2)

3/4 (19.1)

CA -ML6-

6 mm FITOK

6 mm FITOK

CO-FNS8-

1/2 Female NPT

1/2 Female NPT

1.20

3.71 (94.2)

1 1/16 (27.0)

CA -ML8-

8 mm FITOK

8 mm FITOK

CO-NS4-

1/4 Male NPT

1/4 Male NPT

0.35

1.62 (41.1)

9/16 (14.3)

CA -FR4-

1/4" Male FR

1/4" Male FR

CO-NS8-

1/2 Male NPT

1/2 Male NPT

1.20

2.28 (57.9)

7/8 (22.2)

CO-FRT4-

1/4 Female BSPT

1/4 Female BSPT

0.35

CO-RT4-

1/4 Male BSPT

1/4 Male BSPT

2.54 (64.5)

3/4 (19.1)

1.62 (41.1)

9/16 (14.3)

Body Size

CV

3.23 (82.0)

0.37

5/8 (15.9)

3.32 (84.3)

3.09 (78.5)

Part Number Description

CASS - FL8 - ML10 - B - 2SF2

Part Number Description

COSS - FNS8 - NS8 - B - 2SF2

Series

Series Body Material

CO

SS

6L

B

M

316 SS

316L SS

Brass

Alloy

Inlet Type

FNS

NS

FRT

RT

Female NPT

Male NPT

Female BSPT

Male BSPT

Inlet Size

1/8"

1/4"

6 3/8"

8 1/2"

Outlet

Type

Outlet

Size

Seal Material

Same as Inlet

Specified in the

same way as the

inlet type and

size

B

N

E

Z

1. For Oxygen-Riched Environment or dangerous media, please contact

FITOK group or authorized agent.

2. Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to

ensure compliance with product cleanliness requirement as stated in ASTM

G93 Level C.

3. The material in "Part Number Description" is general material, end connection

type & size is general standard. If other end connection is needed, please contact

FITOK group or authorized agent.

4. Check valve is unidirectional design with flow path, it can't be used as safety relief valve.

5. If the check valve is not opened during a period, its initial opening pressure may be

higher than set pressure.

Fluorocarbon

FKM

Buna N

Neoprene

Ethylene

propylene

Kalrez

Cracking

Pressure

3 psig

1 1/3 psig

2 1 psig

3 10 psig

4 25 psig

Special

Application

NO

NACE

S MR0175

Cleaning and

Packaging

FC-01

CA

Body

Material

SS

6L

B

M

316 SS

316L SS

Brass

Alloy

Inlet Type

Fractional

Tube Fitting

Metric Tube

ML Fitting

Male FR

FR Fitting

FL

Inlet Size

1/4"

6 6 mm

8 8 mm

Outlet

Type

Outlet

Size

Seal Material

Same as Inlet

Specified in the

same way as the

inlet type and

size

B

N

E

Z

F2 FC-02

1. Standard thread pitch for metric threads are as follows:

M10 and below: 1 mm

Standard thread pitch should be ignored in the ordering number, others

should be specified.

2. For Oxygen-Riched Environment or dangerous media, please contact

FITOK group or authorized agent.

3. Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to

ensure compliance with product cleanliness requirement as stated in ASTM

G93 Level C.

4. The material in "Part Number Description" is general material, end connection

type & size is general standard. If other end connection is needed, please contact

FITOK group or authorized agent.

5. Check valve is unidirectional design with flow path, it can't be used as safety relief valve.

6. If the check valve is not opened during a period, its initial opening pressure may be

higher than set pressure.

Fluorocarbon

FKM

Buna N

Neoprene

Ethylene

propylene

Kalrez

Cracking

Pressure

Special

Application

3 to 50 psig

5 50 to 150 psig

6 150 to 350 psig

7 350 to 600 psig

Cleaning and

Packaging

NO

NACE

S MR0175

FC-01

F2 FC-02

11 Check Valves

Check Valves 12

COA Series

CL Series

B (Hex)

B

A

Basic Ordering

Number

Connection Type and Size

Dimension, in. (mm)

Body Size

CV

2.98 (75.7)

3/4 (19.1)

0.35

1.62 (41.1)

9/16 (14.3)

1.20

2.56 (65.0)

7/8 (22.2)

1/4 Male BSPT

0.35

1.62 (41.1)

9/16 (14.3)

1/2 Male BSPT

1.20

2.56 (65.0)

7/8 (22.2)

Inlet

Outlet

COA-FNS4-

1/4 Female NPT

1/4 Female NPT

0.35

COA-NS4-

1/4 Male NPT

1/4 Male NPT

COA-NS8-

1/2 Male NPT

1/2 Male NPT

COA-RT4-

1/4 Male BSPT

COA-RT8-

1/2 Male BSPT

Part Number Description

COASS - FL8 - ML8 - B - 2SF2

Series

COA

Body

Material

SS

6L

B

M

316 SS

316L SS

Brass

Alloy

Inlet Type

FNS Female NPT

NS Male NPT

RT Male BSPT

Inlet Size

1/4"

8 1/2"

Outlet

Type

Outlet

Size

Seal Material

Same as Inlet

Specified in the

same way as the

inlet type and

size

B

N

E

Z

1. Standard thread pitch for metric threads are as follows:

M10 and below: 1 mm

Standard thread pitch should be ignored in the ordering number, others

should be specified.

2. For Oxygen-Riched Environment or dangerous media, please contact

FITOK group or authorized agent.

3. Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to

ensure compliance with product cleanliness requirement as stated in ASTM

G93 Level C.

4. The material in "Part Number Description" is general material, end connection

type & size is general standard. If other end connection is needed, please contact

FITOK group or authorized agent.

5. Check valve is unidirectional design with flow path, it can't be used as safety relief valve.

6. If the check valve is not opened during a period, its initial opening pressure may be

higher than set pressure.

Fluorocarbon

FKM

Buna N

Neoprene

Ethylene

propylene

Kalrez

Cracking

Pressure

Special

Application

3 to 50 psig

5 50 to 150 psig

6 150 to 350 psig

7 350 to 600 psig

Cleaning and

Packaging

NO

NACE

S MR0175

FC-01

F2 FC-02

Basic

Ordering

Number

Inlet

Outlet

CL-FL4

1/4" FITOK

1/4" FITOK

CL-FL6

3/8" FITOK

3/8" FITOK

CL-FL8

1/2'' FITOK

1/2'' FITOK

CL-Fl12

3/4" FITOK

3/4" FITOK

CL-ML6

6 mm FITOK

6 mm FITOK

CL-FNS2

1/8 Female NPT

1/8 Female NPT

CL-FNS4

1/4 Female NPT

1/4 Female NPT

CL-FNS6

3/8 Female NPT

3/8 Female NPT

CL-FNS8

1/2 Female NPT

1/2 Female NPT

CL-TS4

1/4" TS

CL-TS6

CL-TS8

Dimension, in. (mm)

Connection Type and Size

CV

A

0.30

2.40 (61.0)

1.01 (25.7)

1.47 (37.3)

0.39 (9.9)

0.64

2.83 (71.9)

1.31 (33.3)

1.85 (47.0)

0.50 (12.7)

2.20

3.92 (99.6)

2.19 (55.6)

2.44 (62.0)

0.62 (15.7)

2.40 (61.0)

1.01 (25.7)

1.47 (37.3)

0.39 (9.9)

0.30

2.00 (50.8)

1.00 (25.4)

1.47 (37.3)

0.39 (9.9)

0.64

2.25 (57.2)

1.25 (31.8)

1.85 (47.0)

0.50 (12.7)

2.20

3.12 (79.2)

1.86 (47.2)

2.44 (62.0)

0.62 (15.7)

1/4" TS

0.30

1.81 (46.0)

0.90 (22.9)

1.47 (37.3)

0.39 (9.9)

3/8" TS

3/8" TS

0.64

2.25 (57.2)

1.25 (31.8)

1.85 (47.0)

0.50 (12.7)

1/2" TS

1/2" TS

2.20

3.13 (79.5)

1.88 (47.8)

2.44 (47.0)

0.62 (15.7)

CL-PB4

1/4 PB

1/4 PB

0.30

1.81 (46.0)

0.90 (22.9)

1.47 (37.3)

0.39 (9.9)

CL-PB6

3/8 PB

3/8 PB

0.64

2.25 (57.2)

1.25 (31.8)

1.85 (47.0)

0.50 (12.7)

CL-PB8

1/2 PB

1/2 PB

2.20

3.13 (79.5)

1.88 (47.8)

2.44 (62.0)

0.62 (15.7)

13 Check Valves

Check Valves 14

Part Number Description

CW Series

B (Hex)

CLSS - FL8 - ML10 - SF2

Series

CL

Body Material

SS 316 SS

Inlet Type

FNS

NS

FRT

RT

Female NPT

Male NPT

Female BSPT

Male BSPT

Female Metric

FMS Thread (for RP-M)

Male Metric

MS Thread (for RG-M)

FRP Female BSPP (for RP)

Male BSPP (for RG)

BP

Fractional Tube

TS

Socket Weld

MTS Metric Tube

Socket Weld

Inlet Size

2 1/8"

4 1/4"

"

6 3/8

or 6 mm

8 1/2"

Fractional Tube

Butt Weld

MTB Metric Tube

Butt Weld

Pipe Socket Weld

PS

Pipe Butt Weld

PB

Fractional Tube

FL

Fitting

ML Metric Tube Fitting

Nut+Gasket+

UFB Fractional Bulge

Nipple

FO

FR

Outlet

Size

Same as Inlet

Specified in the

same way as the

inlet type and

size

Basic

Ordering

Number

Cleaning and

Special

Application Packaging

NO

NACE

S MR0175

FC-01

F2 FC-02

12 3/4"

TB

UMB

Outlet

Type

Connection Type and Size

Inlet

Outlet

CW-TB4

1/4" TB

1/4" TB

CW-TB6

3/8" TB

3/8" TB

CW-TB8

1/2" TB

1/2" TB

CW-MTB6

6 mm MTB

6 mm MTB

0.55

CW-FR4

1/4" Male FR

1/4" Male FR

0.70

1.80 (45.7)

CW-FR8

1/2" Male FR

1/2" Male FR

0.70

2.06 (52.3)

1 (25.4)

CW-FL4

1/4" FITOK

1/4" FITOK

0.55

CW-ML6

6 mm FITOK

6 mm FITOK

0.55

1.96 (49.8)

7/8 (22.23)

0.55

1.24 (31.5)

0.70

7/8 (22.23)

1. FITOK means FITOK double ferrule tube fittings, FO means O-ring seal fittings, FR means metal gasket seal fittings, TB means

fractional tube butt weld, MTB means metric tube butt weld, TS means fractional tube socket weld, PB means pipe butt weld.

2. Sizes and types listed are standard. Other sizes and types are available upon request. For special sizes and types, refer to ordering

information.

3. Dimensions shown with FITOK nuts finger-tightened. All dimensions are for reference only and are subject to change. For

dimensions not shown above, contact the authorized representative or FITOK Group.

Part Number Description

CW6L - FL8 - ML10 - B - SF2

Nut+Gasket+Metric

Bulge Nipple

Male FO Fitting

Male FR Fitting

Series

1. Standard thread pitch for metric threads are as follows:

M10 and below: 1 mm

Standard thread pitch should be ignored in the ordering number, others

should be specified.

2. For Oxygen-Riched Environment or dangerous media, please contact

FITOK group or authorized agent.

3. Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to

ensure compliance with product cleanliness requirement as stated in ASTM

G93 Level C.

4. The material in "Part Number Description" is general material, end connection

type & size is general standard. If other end connection is needed, please contact

FITOK group or authorized agent.

Dimension, in. (mm)

CV

CW

Body Material

6L 316L SS

Inlet Type

Female NPT

Male NPT

Female BSPT

Male BSPT

Female Metric

FMS Thread (for RP-M)

Male Metric

MS Thread (for RG-M)

FRP Female BSPP (for RP)

BP Male BSPP (for RG)

Fractional Tube

FL

Fitting

ML Metric Tube Fitting

FO Male FO Fitting

FFR Female FR Fitting

Male FR Fitting

FR

Rotatable Male FR

RFR Fitting

FNS

NS

FRT

RT

Inlet Size

2 1/8"

4 1/4"

"

6 3/8

or 6 mm

/2"

8 1

or 8 mm

Outlet

Type

Outlet

Size

Same as Inlet

Specified in the

same way as the

inlet type and

size

Seal

Material

Fluorocarbon

FKM

B Buna N

N Neoprene

E Ethylene

propylene

Cleaning and

Special

Application Packaging

NO

NACE

S MR0175

FC-01

F2 FC-02

1. Standard thread pitch for metric threads are as follows:

M10 and below: 1 mm

Standard thread pitch should be ignored in the ordering number, others

should be specified.

2. For Oxygen-Riched Environment or dangerous media, please contact

FITOK group or authorized agent.

3. Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to

ensure compliance with product cleanliness requirement as stated in ASTM

G93 Level C.

4. The material in "Part Number Description" is general material, end connection

type & size is general standard. If other end connection is needed, please contact

FITOK group or authorized agent.

5. Check valve is unidirectional design with flow path, it can't be used as safety relief valve.

6. If the check valve is not opened during a period, its initial opening pressure may be

higher than set pressure.

15 Check Valves

Check Valves 16

Flow Data at 70O F (20O C)

CH Series

CV Series

Air Flow

(std L/min)

Air Flow

(std L/min)

Cracking Pressure (psig)

1

Inlet

Pressure

(psig)

10

25

10

Cv = 0.10

5

10

--

25

Cv = 0.47

--

114

--

--

Water Flow

(L/min)

Pressure

Drop

(psig)

5

10

25

Cv = 0.10

0.3

--

10

2.1

--

10

25

Cv = 0.67

Water Flow

(L/min)

Pressure

Drop

(psig)

Cracking Pressure (psig)

1

10

25

Cv = 0.67

--

--

0.2

--

--

10

80

--

--

1.9

--

--

25

Cv = 0.47

--

Inlet

Pressure

(psig)

Cracking Pressure (psig)

Cracking Pressure (psig)

--

25

160

200

--

10

5.7

--

--

180

200

--

12

7.5

0.2

--

10

29

--

--

157

36

--

10

1.2

--

--

6.1

--

--

40

12.5

38

11

--

176

150

--

12.5

1.4

0.3

--

6.5

6.5

--

60

600

390

180

20

--

1.4

--

--

80

900

880

640

26

--

2.9

--

7.5

0.9

3.4

15

25

48

23

72

62

--

196

253

170

--

--

18

15

20

1.6

0.7

1.9

1.2

--

6.9

--

7.8

6.9

7.8

--

95

1200

1060

830

36

--

--

1240

1020

50

--

--

30

78

--

17

279

--

146

27.5

2.3

1.7

0.2

--

--

1.2

110

35

85

--

34

309

--

330

35

2.6

2.3

0.9

--

--

5.0

128

--

1400

1200

60

--

--

5.6

--

7.5

140

--

--

1340

68

--

--

7.5

25

Water Flow

(L/min)

Pressure

Drop

(psig)

50

103

--

77

402

--

--

40

2.8

2.4

1.3

--

80

144

--

136

580

--

--

70

3.6

3.5

3.3

--

--

--

100

171

--

160

700

--

--

80

3.8

3.8

3.8

--

--

-Air Flow

(std L/min)

Air Flow

(std L/min)

Cracking Pressure (psig)

1

Inlet

Pressure

(psig)

10

25

10

Cv = 1.47

25

Cv = 1.68

Water Flow

(L/min)

Pressure

Drop

(psig)

10

25

Cv = 1.47

Inlet

Pressure

(psig)

Cracking Pressure (psig)

10

10

Cv = 1.8

--

25

Cv = 1.68

Cracking Pressure (psig)

--

--

1.5

Cracking Pressure (psig)

1

10

25

Cv = 1.8

--

--

--

10

620

--

--

5.0

14.4

--

--

520

--

7.5

20.4

--

--

10.0

22.5

--

--

2.0

--

325

--

--

460

--

--

2.5

4.6

--

--

7.4

--

--

25

1140

10

623

--

--

747

--

--

8.3

--

--

13.5

--

--

30

1320

720

190

1130

590

15

--

15

832

377

--

916

475

--

10

17.5

--

--

22.6

--

--

40

1620

25

1146

800

32

1255

939

40

11

--

3.3

--

--

6.8

--

50

1940

1520

1000

20

--

7.0

--

1900

1400

22

--

22.5

--

35

1440

1150

509

1594

1347

654

12.5

--

7.7

--

--

12.9

--

60

2250

50

1879

1686

1072

2101

1960

1230

15

--

13.1

--

--

20.0

--

78

2800

2520

2080

30

--

--

0.7

2800

2430

40

--

--

2.6

--

2800

45

--

--

22.5

80

2761

2756

2087

--

--

2400

20

--

20.0

--

--

--

--

86

--

100

--

--

2763

--

--

--

27.5

--

--

2.2

--

--

7.3

97

--

30

--

--

4.4

--

--

12

35

--

--

8.8

--

--

19.5

Air Flow

(std L/min)

Air Flow

(std L/min)

Cracking Pressure (psig)

1

Inlet

Pressure

(psig)

10

25

Cv = 4.48

5

468

--

Water Flow

(L/min)

Pressure

Drop

(psig)

10

Inlet

Pressure

(psig)

Cracking Pressure (psig)

25

Cv = 4.48

Cracking Pressure (psig)

10

25

Cv = 4.7

5

520

--

--

Water Flow

(L/min)

Pressure

Drop

(psig)

2.5

Cracking Pressure (psig)

1

10

Cv = 4.7

32

--

---

10

940

--

--

5.0

48

--

15

1240

540

--

7.5

58

--

---

--

2.5

29.5

--

45.0

--

--

20

1560

880

--

10.0

68

--

--

25

10

975

--

--

15

1208

491

--

10

59.3

--

--

25

1620

1100

--

11.0

75

10

--

65.8

65.8

--

30

1800

1325

420

12.0

86

75

--

72.3

72.3

--

35

2080

1520

720

30.0

--

--

--

13

20

1435

945

--

12.5

25

1658

1232

--

15

35

2122

1826

1059

20

85.4

85.4

--

40

2800

1760

980

32.5

--

50

2800

2678

1905

25.5

--

--

22

50

2280

2240

1800

35.0

--

--

21

60

--

--

38.0

--

--

86

2454

26

--

--

48

27

--

--

90

60

2560

2650

2280

17 Check Valves

Check Valves 18

CO Series

COA Series

Air Flow

(std L/min)

Inlet

Pressure

(psig)

Water Flow

(L/min)

Pressure

Drop

(psig)

Cracking Pressure (psig)

1

10

25

Cv = 0.35

Air Flow

(std L/min)

Cracking Pressure (psig)

1

10

25

Inlet

Pressure

(psig)

Cv = 0.35

12.5

85

--

--

7.5

2.6

--

--

25

201

121

--

15

5.3

0.9

--

50

400

327

212

22.5

2.9

--

75

600

539

431

30

7.7

--

0.6

100

800

--

750

--

653

60

--

5

--

750

90

--

--

6.7

112.5

Air Flow

(std L/min)

Inlet

Pressure

(psig)

Water Flow

(L/min)

Pressure

Drop

(psig)

Cracking Pressure (psig)

1

10

25

Cv = 1.2

3.7

Cracking Pressure (psig)

1

10

--

--

10.3

20

679

325

--

7.5

14.1

--

--

30

1027

706

237

10

--

1351

1064

664

15

17.3

--

--

40

2.3

--

13.2

1.0

17.8

--

2.6

1692

1433

1122

30

60

2924

1814

1561

37.5

---

75

Cracking Pressure (psig)

3

50

150

350

Cv = 0.37

Water Flow

(L/min)

Pressure

Drop

(psig)

9.8

150

350

Cv = 0.37

50

459

35

--

--

12.5

1.7

--

--

--

150

1424

851

40

--

25

4.3

--

--

--

250

1769

440

--

37.5

--

--

914

--

75

1.9

--

--

400

--

2800

--

6.6

--

--

350

2182

--

1173

303

150

--

6.4

--

--

500

--

--

1785

914

175

--

600

--

--

1512

250

700

--

--

2583

--

2121

CL Series

Air Flow

(std L/min)

Inlet

Pressure

(psig)

0.2

2

20

100

200

400

600

1000

Cv = 0.30

10

37

146

525

800

1495

2197

3842

Cv = 0.64

32

91

461

1404

2508

4246

5353

--

Cv = 2.20

96

350

1040

3523

5485

----

0.8

--

--

7.6

--

3.8

--

350

--

--

--

400

--

--

8.0

--

1.8

500

--

--

--

5.1

550

--

--

--

6.7

Water Flow

(L/min)

Pressure

Drop

(psig)

0.2

2

20

100

200

400

600

1000

Cv = 0.30

0.5

1.6

5.1

11.7

16.8

23.0

29.1

34.5

Cv = 0.64

1.3

4.0

13.3

28.9

38.5

53.6

67.0

81.8

350

Cv = 2.20

3.8

13.2

38.2

85.3

-----

Water Flow

(L/min)

Pressure

Drop

(psig)

Cracking Pressure (psig)

3

50

150

350

Cv = 0.35

50

323

--

--

--

12.5

1.5

--

--

--

150

1165

841

--

--

25

4.1

--

--

--

250

2039

1769

615

--

37.5

6.4

--

--

--

300

2425

2800

890

--

75

--

1.8

--

--

400

--

--

1502

246

150

--

6.3

--

--

500

--

--

2098

726

175

--

7.5

1.1

--

600

--

--

2692

1207

250

--

--

4.5

--

700

--

--

--

1700

350

--

--

8.6

--

400

--

--

--

1.8

500

--

--

--

5.1

550

--

--

--

6.7

Inlet

Pressure

(psig)

Cracking Pressure (psig)

50

150

Cv = 0.35

Air Flow

(std L/min)

CA Series

Air Flow

(std L/min)

Inlet

Pressure

(psig)

50

--

366

50

25

Cv = 1.2

--

10

--

Cracking Pressure (psig)

Cracking Pressure (psig)

3

50

150

350

Cv = 1.2

Water Flow

(L/min)

Pressure

Drop

(psig)

Cracking Pressure (psig)

3

50

150

350

Cv = 1.2

25

498

--

--

--

12.5

3.0

--

--

--

50

1553

--

--

--

25

9.3

--

--

--

75

2162

615

--

--

37.5

15.2

--

--

--

125

--

1682

--

--

75

--

5.3

--

--

175

--

2758

763

--

150

--

17.6

--

--

250

--

--

1859

--

175

--

21.4

2.5

--

300

--

--

2634

--

250

--

--

10.3

--

350

--

--

--

155

350

--

--

20.2

--

400

--

--

--

1665

400

--

--

--

4.4

450

--

--

--

2382

500

--

--

--

13.3

550

--

--

--

21.5

CW Series

Air Flow

(std L/min)

Inlet

Pressure

(psig)

Cv = 0.55

Cv = 0.70

Water Flow

(L/min)

Pressure

Drop

(psig)

Cv = 0.55

Cv = 0.70

0.1

9.5

27

0.1

0.66

1.2

0.2

14

34

0.2

0.88

1.5

0.4

20

50

0.4

1.3

2.1

0.6

26

64

0.6

1.6

2.6

1.0

35

85

1.0

3.4

56

130

4.6

86

190

6.5

140

470

5.1

7.9

10

170

590

10

6.5

11

50

450

1040

50

15

24

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Supplier Quality Assurance ManualДокумент29 страницSupplier Quality Assurance ManualNilesh Mistry0% (1)

- Resources Industrial Thomson ValveLineCard OnlineversionДокумент4 страницыResources Industrial Thomson ValveLineCard OnlineversionNilesh MistryОценок пока нет

- 2015 Q1 - Intertek - MalaysiaДокумент1 страница2015 Q1 - Intertek - MalaysiaNilesh MistryОценок пока нет

- Cat Acvbr9000Документ16 страницCat Acvbr9000Nilesh MistryОценок пока нет

- VS3 VS6 Instrumentation ValvesДокумент2 страницыVS3 VS6 Instrumentation ValvesNilesh MistryОценок пока нет

- WWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesДокумент10 страницWWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesNilesh MistryОценок пока нет

- L&T Gate Globe Check Valves API 602Документ12 страницL&T Gate Globe Check Valves API 602Nilesh MistryОценок пока нет

- Valve Con STR FeaturesДокумент1 страницаValve Con STR FeaturesNilesh MistryОценок пока нет

- Tech Ascend CNC Student ManualДокумент42 страницыTech Ascend CNC Student ManualabyzenОценок пока нет

- Instrumentation Tube: Tube and Tube AccessoriesДокумент4 страницыInstrumentation Tube: Tube and Tube AccessoriesNilesh MistryОценок пока нет

- Quick Release Coupling: CouplingsДокумент3 страницыQuick Release Coupling: CouplingsNilesh MistryОценок пока нет

- L&T Globe Control ValvesДокумент4 страницыL&T Globe Control ValvesNilesh MistryОценок пока нет

- 11 Why Sealexcel Tube FittingsДокумент20 страниц11 Why Sealexcel Tube FittingsNilesh MistryОценок пока нет

- 08 Push in Fittings For PneumaticДокумент20 страниц08 Push in Fittings For PneumaticNilesh MistryОценок пока нет

- 04 Two Three Way Ball Valves For CNG ApplicationsДокумент4 страницы04 Two Three Way Ball Valves For CNG ApplicationsNilesh MistryОценок пока нет

- 02 Precision Pipe FittingsДокумент28 страниц02 Precision Pipe FittingsNilesh MistryОценок пока нет

- ValvesДокумент13 страницValvesNilesh MistryОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Marioff 2021 07 01 EN Approval Matrix Marine Table - tcm986 148336Документ4 страницыMarioff 2021 07 01 EN Approval Matrix Marine Table - tcm986 148336Pavel DrugakovОценок пока нет

- CCO Rod Ring Prod. Lit. - en A4 - 030819Документ2 страницыCCO Rod Ring Prod. Lit. - en A4 - 030819SergeiОценок пока нет

- Ansi Fci70-2Документ3 страницыAnsi Fci70-2RafaelОценок пока нет

- HPM CatalogДокумент8 страницHPM CatalogNaser JahangiriОценок пока нет

- Sample ISO Tank 40ftДокумент7 страницSample ISO Tank 40ftAbu SuraisyОценок пока нет

- ENGINEERING DESIGN GUIDELINES Pump Sizing and Selection Rev Web PDFДокумент22 страницыENGINEERING DESIGN GUIDELINES Pump Sizing and Selection Rev Web PDFBkhari HaranОценок пока нет

- Service Brake Accumulator, Valve, Hoses and Fittings (640G, 648G, 740G and 748G) - ST325199Документ4 страницыService Brake Accumulator, Valve, Hoses and Fittings (640G, 648G, 740G and 748G) - ST325199Cesar Cauper CardenasОценок пока нет

- M5M BBДокумент22 страницыM5M BBfauzi endraОценок пока нет

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Документ1 страницаPipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Theodosios StergiouОценок пока нет

- BFD Dan PFDДокумент37 страницBFD Dan PFDIlham Kiki ShahilaОценок пока нет

- PNK Pump Catalogue R2 DT 25dec19Документ3 страницыPNK Pump Catalogue R2 DT 25dec19bmanojkumar16Оценок пока нет

- Water SystemДокумент9 страницWater SystemArun GuptaОценок пока нет

- Pump & Compressor PipingДокумент24 страницыPump & Compressor PipingDeven SutharОценок пока нет

- Compressor and Compressed Air SystemДокумент34 страницыCompressor and Compressed Air Systemrashm006ranjanОценок пока нет

- Binder1 PDFДокумент81 страницаBinder1 PDFkz_kamranОценок пока нет

- Manual Compresor 3707VДокумент100 страницManual Compresor 3707Vjose miguel quinteroОценок пока нет

- Falling Ball Viscometer: Abhishek Suman Department of Energy Science and Engineering IIT BombayДокумент12 страницFalling Ball Viscometer: Abhishek Suman Department of Energy Science and Engineering IIT BombayPratham sehgalОценок пока нет

- Compressed Air Conditioning: Filter Regulators C54 C55Документ6 страницCompressed Air Conditioning: Filter Regulators C54 C55abdulfetahОценок пока нет

- Lab Report 1 (Me160p-2, Bellen)Документ16 страницLab Report 1 (Me160p-2, Bellen)AndreОценок пока нет

- Bernoulli ExperimentДокумент4 страницыBernoulli ExperimentmahabubОценок пока нет

- Denis ANDRE: Hydraulic Diagram FalconДокумент2 страницыDenis ANDRE: Hydraulic Diagram FalconvestasvesОценок пока нет

- 06 Hydraulic PumpingДокумент71 страница06 Hydraulic PumpingAZDOLMANОценок пока нет

- Copia de STOCK Sem 13Документ8 страницCopia de STOCK Sem 13principepolОценок пока нет

- ProposedTIA1054NFPA13 - ProposedTIA1054NFPA13Документ7 страницProposedTIA1054NFPA13 - ProposedTIA1054NFPA13daniela hritucОценок пока нет

- Drill Floor / RT Level 0: 20 3/4 Bop 3K - Cameron - UДокумент9 страницDrill Floor / RT Level 0: 20 3/4 Bop 3K - Cameron - UEmad JamshidiОценок пока нет

- Section - III, Pipe SupportsДокумент2 страницыSection - III, Pipe SupportspalluraviОценок пока нет

- Submersible Pump Type & PriceДокумент1 страницаSubmersible Pump Type & PriceBudi MWОценок пока нет

- SC Gravel Pack SystemДокумент1 страницаSC Gravel Pack SystemCarlos Alberto Aguilera MendezОценок пока нет

- Experiment No. 3 Lab ManualДокумент9 страницExperiment No. 3 Lab Manualwasiq999Оценок пока нет

- Assignment - Trent 900Документ59 страницAssignment - Trent 900AzriSafwanRusli100% (3)