Академический Документы

Профессиональный Документы

Культура Документы

Report On Piled Foundations

Загружено:

hoangducmaiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Report On Piled Foundations

Загружено:

hoangducmaiАвторское право:

Доступные форматы

Final Design Report

Piled Foundations

SAIGON EAST WEST HIGHWAY

FINAL REPORT

PILE FOUNDATIONS

W. HOWKINS

April 2002

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

Final Design Report

Piled Foundations

DESIGN REPORT: PILE FOUNDATIONS.

TABLE OF CONTENTS

1

2

3

Overall soil conditions........................................................................................................................... 2

Soil parameters.................................................................................................................................... 2

Pile Capacities...................................................................................................................................... 5

3.1

Empirical method for granular soils............................................................................................... 5

a. Bored piles.................................................................................................................................... 6

3.2

Static method for granular soils..................................................................................................... 7

a. End bearing................................................................................................................................... 7

b. Shaft resistance............................................................................................................................. 9

3.3

Static method for cohesive soils.................................................................................................... 9

3.4

Adopted design parameters........................................................................................................ 10

4 Foundation Conditions........................................................................................................................ 12

4.1

NH1 Interchange......................................................................................................................... 12

4.2

Nuoc Len Bridge.......................................................................................................................... 12

4.3

Rach Cay Bridge......................................................................................................................... 13

4.4

Lo Gom Bridge............................................................................................................................ 13

4.5

Cha Va Bridge............................................................................................................................. 14

4.6

Calmette Bridge........................................................................................................................... 14

4.7

Khanh Hoi Bridge........................................................................................................................ 14

4.8

Ca Tre Lon Bridge....................................................................................................................... 15

4.9

Ca Tre Nho Bridge....................................................................................................................... 15

4.10 Hanoi Highway Flyover............................................................................................................... 15

4.11 Footbridges................................................................................................................................. 16

5 References:........................................................................................................................................ 19

TABLES

Table 1 Table 2 Table 3 -

Pile Capacity Calculation Sheet............................................................................................... 11

Major Bridges: estimated pile tip elevations.............................................................................17

Footbridges: estimated pile tip elevations................................................................................18

FIGURES

Figure 1 Figure 2 Figure 3 Figure 4 Figure 5 Figure 6 Figure 7 Figure 8 -

Profile of soft organic clays along the project road....................................................................2

SPT versus Unit Weight............................................................................................................. 3

SPT versus undrained strength................................................................................................. 3

SPT depth correction factor, CN................................................................................................. 4

Friction angle versus N60............................................................................................................ 5

Shaft friction factor for driven and bored piles.........................................................................6

Bearing capacity factor Nq from various sources.......................................................................8

Tomlinsons adhesion factor for piles in cohesive strata............................................................9

APPENDICES

1.

2.

3.

Comparison of pile design methods for granular soils

Major Bridges Pile Capacities

Footbridges Pile Capacities

DRAWINGS

01 10 Plan and Soils Profiles of Major Bridges

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

Final Design Report

Piled Foundations

OVER ALL SOIL CONDITIONS.

Beneath a thin surface layer of topsoil or fill, the uppermost natural soil layer, which was found across

almost the entire length of the road, was a very soft to soft, organic clay of medium to high plasticity. The

thickness of this layer, which is shown on Figure 1, was found to vary from 25 to 40 m between km 0 and

km 5.5 and then to change suddenly to less than 5 m along the bank of the Ben Nghe Canal up to km 14.

On the Thu Thiem side, the thickness of the organic clay was generally found to range between 10 and

20 m except between km 18.7 and 20.5 where it was generally less than 5 metres.

Figure 1 -

Profile of soft organic clays along the project road

Beneath the soft organic clay, medium dense sandy soils were mostly encountered down to elevation 30

to 40 m, where very stiff to hard clays were found to extend 15 to 20 m. The clay was found in turn to

overlie dense to very dense sands.

SOIL PAR AMETERS

The soft organic clay was found to have SPT N values of 0 to 3 blows/ft, and corresponding undrained

shear strengths typically about 10 to 20 kPa, reaching 30 to 40 kPa near the bottom of the layer. Moisture

contents were generally over 100 per cent in the upper part of the layer, well above the liquid limit.

Organic contents were found to be about 10 per cent.

The underlying medium dense sand layers had N values ranging from 12 to 30 blows/ft. This is not a

competent layer for the founding of piles. The very stiff to hard clay layer has generally high SPT

resistances of 30 to 50, corresponding to undrained shear strengths of 180 to 300 kPa. However, it is not

until the underlying sand layers are reached that a satisfactory end bearing capacity can be mobilised for

driven or bored piles.

The unit weight of the various soil layers depends predominantly on their natural moisture contents, and

thus their densities. In the pile calculations, the effective overburden pressure has been calculated

assuming the relationship between the unit weight and N value given in Figure 2 below. The plotted points

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

Final Design Report

Piled Foundations

in the Figure represent the approximate ranges of unit weight suggested by Meyerhof for different relative

densities.

2.4

Unit w eight - t/m3 .

2.2

2.0

= 0.2478.loge(N) + 1.1782

1.8

1.6

1.4

Points from empirical data

1.2

published by Mey erhof, Ref 1.

1.0

0

10

15

20

25

30

35

40

45

50

SPT 'N' - blow s/ft

Figure 2 -

SPT versus Unit Weight

Shear strengths of cohesive and granular soils have been correlated with SPT values by Terzaghi & Peck

and later modified by Meyerhof (1). Various undrained shear strength relationships are shown in Figure 3,

the upper being the Terzaghi & Peck relationship and the lower being that suggested in the British Code,

CP2004, 1972. The centre line has been drawn as a best fit of the vane test results carried out for the

project and the upper boundary of the unconfined compression tests carried out for this project, the Binh

Thuan Raod and the Maunsell tunnel borings 1 (2). The equation of this line is Su = 20 + 5.N, where Su is

measured in kPa. It should be noted that this line does not pass through the origin. This is consistent with

field results: the split spoon sampler may sink the full 45 cm under the weight of the rods and hammer

giving a zero N value, even though the clay have a shear strength of 20 kPa. This line has been used in

the pile capacity calculations.

300

Terzaghi & P eck

Design line

Tunnel borings (1997)

Vane tests EW Hwy

250

CP 2004, 1972

Binh Thuan Rd

EW Hwy

200

150

Vane tests

100

Unconfined tests

50

0

0

10

20

30

40

50

60

SP T - N

Figure 3 -

SPT versus undrained strength

The measured compressive strengths have been halved to give undrained shear strength.

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

Final Design Report

Piled Foundations

The unconfined tests all lie below the design line, and this is attributed to the normal degree of sample

disturbance which is to be expected. The vane tests results may be taken as the true measure of

undrained shear strength, and these points are both above and below the line.

In developing a relationship between the angle of friction of a cohesionless soil and the measured SPT

resistances, it was found that the N values should be corrected for overburden pressure which gives an

additional apparent resistance in deep borings which is not attributable to shear strength. The SPT

correction for both hammer efficiency and depth is given in the US Corps of Engineers Manual, EM 11101 (3) as follows:

N60 = CER..NSPT

equ. 1

where CER is the hammer energy correction factor (= 1 for a free fall hammer),

CN is the depth correction factor.

SP T Depth Correction Factor Cn

1.8

Correction factor - CN .

1.6

1.4

Cn =7.6873.p-0.4591

1.2

1

0.8

0.6

0.4

0.2

0

0

50

100

150

200

250

300

350

400

450

Overburden pressure p - kPa

Figure 4 -

SPT depth correction factor, CN

The relationship between CN and effective overburden pressure is given in the COE Manual on the basis

of data from Tokimatsu and Seed (4) as shown in Figure 4 and this was used in the spread sheets to

calculate N60 .

The relationship between N60 and friction angle, , is taken from the range of values proposed by

Meyerhof as given in Table 3-1 of the COE Manual. These values are plotted below in Figure 5, and were

found to give a good straight line fit when is plotted against log10 N. This line is defined by

= 4.1057.loge(N60) + 24.707

equ. 2

This relationship has been used in the spreadsheets to calculate the bearing capacity of piles in granular

strata.

The correlation between and SPT blow counts is difficult to verify since only disturbed samples can be

taken from the granular soil strata and triaxial tests can only be made on recompacted samples. Although

the use of SPT resistances to predict friction angles and relative densities is only approximate, it still

provides a rational method of estimating pile capacities. However, such estimates must be confirmed by

full scale load testing during construction.

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

Final Design Report

Piled Foundations

50

Friction angle -

45

40

35

= 4.1057loge(N60) + 24.707

30

25

20

1

10

100

N 60 - blows/ft

Figure 5 -

3

3.1

Friction angle versus N60

PILE C APACITIES

Empirical method for granular soils

a. Driven piles

Since it is difficult to measure the in-situ shear strength parameters of granular strata, an empirical

relationship was proposed by Meyerhof in 1976 (5) between the capacity of driven piles and SPT

resistance. This relationship, which is valid only for cohesionless soils, has become widely accepted as

giving a reasonable estimate of pile bearing capacity: it is quoted in Leonards, Foundation Engineering,

(6), the COE Manual EM 1110-1, the Navys Design Manual 7.02 (7), and Hsai-Yang Fangs Foundation

Engineering Handbook (8).

For driven piles, the ultimate bearing capacity is given by:

Total ultimate capacity

End bearing capacity

Shaft friction capacity

Shaft resistance

Qult = Qt + Qs

Qt = At.m.Nt

Qs = As.Lp.fs

fs = n.Nave

kN

kN

kN

kPa

equ. 3

equ. 3.1

equ. 3.2

equ. 3.3

Allowable capacity

Qall = (Qs + Qp)/F

kN

equ. 3.4

where

m, n are empirical coefficients,

At is the cross-sectional area of the pile at the tip (m 2),

As is the surface area of the pile per unit length (m 2),

Lp is the embedded length of the pile in bearing strata (m),

Nave is the average corrected SPT resistance over the length of the pile,

Nt is the SPT resistance at the pile tip.

F is the factor of safety, here set at 3.0.

It should be noted that the coefficients m and n are not dimensionless but have the dimensions of force

per unit area. Various references, compared in Appendix 1, give bearing resistances in tons/ft 2, some in

kips/ft2 and some in kPa. In the following text, the values of m and n are in kPa.

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

Final Design Report

Piled Foundations

There is a consensus among the references named above on the values of m and n for driven piles.

Expressed in SI units, for driven piles, m = 400 and n = 2. The end bearing capacity calculated by the

above equation was found to agree quite well with the capacities derived from the static formulae

described below. However, the shaft resistances for driven piles in medium dense soils were somewhat

lower than those calculated from the static formulae. In such cases, a better agreement was found by

using n = 3 since the empirical formula tends to underestimate the friction angle of looser soils. In denser

soils, there was good agreement between the static and empirical formulae using n = 2, and this value

was therefore adopted in the calculations.

In silty sands or very fine sands, Leonards recommends that the corrected SPT resistance, N, should be

used to estimate pile capacity. This is also corroborated by the Navy Manual, which recommends that m =

300 be used for silts. N is given by the formula:

N = 15 + (N 15)/2

where

for N > 15

equ. 4

N is the measured SPT driving resistance in blows/foot.

In applying the above equations, only dense granular soil strata should be considered. Where soft soil

strata overlie dense strata, the soft layers do not contribute to the piles capacity, and in some cases

detract from it due to negative skin friction from consolidation of the soft layers. Shaft resistance in these

soft strata is therefore ignored.

In cohesive strata, the empirical formulae are not valid and pile capacities are calculated based on the

measured or derived undrained shear strengths as described in Section 3.3 below.

a.

Bored piles.

With bored piles, no displacement or densification of soil occurs during installation and lower values of the

coefficients m and n are to be expected. For end bearing, Fang recommends m = 120, ie. 30 per cent of

the value for driven piles; the Navy Manual states that the bearing resistance is 1/3 of the value for driven

piles, ie. m = 128 in SI units. For shaft resistance, Fang recommends n = 1, ie. 50 per cent of the value

for driven piles, and this is also recommended by the US Navy. The Corps of Engineers does not give

empirical formulae for bored piles.

3.0

2.5

y = 3.276E-159.2999

Shaft friction factor -

Driven piles

Bored piles

2.0

1.5

1.0

y = 2.53E-1810.923

0.5

0.0

30

32

34

36

38

40

Friction angle -

Source: US, COE EM 1110-1

Figure 6 -

Shaft friction factor for driven and bored piles

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

Final Design Report

Piled Foundations

While the empirical coefficients for end bearing give results which are comparable with the static

formulae, correspondence is not so good with the shaft resistance. As shown in Figure 6, COE found that

shaft resistances for bored piles were about one third of those for driven piles. On the basis of these

considerations, the following m and n coefficients have been adopted:

Driven piles:

Bored piles:

3.2

a.

m = 400, n = 2

m = 133, n = 0.67

Static method for granular soils

End bearing

The end bearing capacity of a pile is given by the Terzaghi equation:

Qt = At ( c.Nc + ..B.N + .d.Nq)

equ. 5

where Nc, Ng, Nq are the dimensionless bearing capacity factors depending on the angle of

friction ,

c is the effective cohesion of the soil,

is the unit weight of the soil,

d is the depth of the pile tip.

For cohesionless soils, c = 0 and, for deep foundations, ..B.N is small compared with .d.Nq. The

above equation may therefore be simplified to:

Qt = At.qt

equ. 5.1

where qt = pt.Nq

equ. 5.2

and

pt is the effective overburden pressure at the pile tip.

The value of Nq, which is dependent on friction angle alone, has been studied by many researchers giving

a wide variety of results. Some of these, which have been quoted above, are shown in Figure 7.

The Terzaghi and Peck line, D, which was developed for shallow strip footings, was found to give very

conservative estimates of end bearing capacity for driven piles, but was found by Fang and Caltrans (9)

to give reasonable estimates for bored piles. This line has therefore been used for bored piles.

The COE Manual 1110-2 (10) recommends that end bearing capacities for driven piles be based on

values between curves B and C. Fang also gives tip bearing coefficients between these curves, shown

on the figure as single points. Curve B gives capacities about 1/3 higher than C, and the latter more

conservative values have therefore been adopted for calculating driven pile end bearing capacities.

In applying equation 5.1, many researchers have found that, although q t is directly dependent on pt up to

certain depths, there appears to be a limiting depth below which there is no increase in bearing

resistance. The COE Manual EM 1110-2 defines this critical depth beyond which the end bearing capacity

is constant as 10xB for loose sands, 15xB for medium dense sands and 20xB for dense sands, where B

is the width of the pile. The COE Manuals are not completely clear on where this depth should be

measured from if the bearing strata are overlaid by a thick soft clay stratum. In the Navy manual, it is

clearly stated that the critical depth should be taken as 20xB below the bearing stratum.

Fang is rather sceptical about the critical depth concept, both when applied to end bearing and also when

applied to shaft resistance. Referring to shaft friction, he writes It has been suggested that the above

effective stress relationship ceases to be valid at a certain critical depth equal to 10 to 20 pile diameters.

Below the critical depth, the unit shaft resistance would be constant and equal to the value at the critical

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

Final Design Report

Piled Foundations

depth. However, the concept of critical depth is unproven and in question. It should therefore be applied

with caution, if atall.

For the present calculations, the US Navy guidelines have been followed, with the critical depth being

measured from the bottom of the soft upper clay layers.

In COE Manual 1110-1, the Meyerhof method gives an upper limit for bearing capacity, independent of

depth and overburden pressure in the following equation:

QL = 48.At.Nqp.tan'

equ. 6

where Nqp is a limiting bearing capacity factor taken from Curve A.

This equation was found to give end bearing values of about half of those given by Equation 5.1 and

considerably below the values given by the empirical method.

Deep foundations - Bearing Capacity Factor N q

1000

A

'A' Meyerhof (high)

'B' Meyerhof (low )

'C' Tomlinson

'D' Terzaghi & Peck

'E' USN driven piles

'F' USN - bored piles

'G' Nordlund

Fang - Nt values

100

Nq

10

G

1

0

10

15

20

25

30

35

40

45

Friction angle - - degrees

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

Final Design Report

Figure 7 -

Piled Foundations

Bearing capacity factor Nq from various sources

Limiting values of ultimate end bearing resistance are given in various sources. Caltrans gives a

maximum qt value of 90 ksf (4,300 kPa) for bored piles and Tomlinson suggests a maximum of 11,000

kPa.

b.

Shaft resistance

The static formula for shaft resistance is:

Qs = L.As.po'.K.tan

equ. 7

where L is the length of a pile segment

As is the unit area of the pile circumference,

po' is the effective overburden pressure at the mid point of the pile segment,

K is the earth pressure coefficient, and

is the friction angle between the soil and the pile.

Driving displacement piles causes an increase in the lateral earth pressure due to displacement of the soil

and densification in medium of loose sands. The actual value of K depends both on the friction angle and

the overconsolidation ration of the stratum. A wide range of factors are quoted for K, from 0.5 for loose

sands to between 1.0 and 2.0 for dense sands. In the calculations for driven piles, a value 0.8 has been

selected. For bored piles, where there is no densification from the pile installation, 1/3 of this value has

been selected. This is in accordance with the curves for driven and bored piles shown in Figure 6.

3.3

Static method for cohesive soils

The empirical equations, 3.1 to 3.3, are not valid for cohesive soils and the static method based on

undrained shear strengths must be used in stead. The undrained shear strength, Su, of a cohesive layer

is derived from the relationship between Su and SPT N shown in Figure 3. The bearing capacity

equations for piles in cohesive strata are not dependent on overburden pressure so that the critical depth

factor does not apply. The end bearing capacity may then be calculated using the following equation:

Qt = At.Su.Nc

equ. 8

where Su is the undrained shear strength,

Nc is a bearing capacity factor depending on depth. For D/B > 4, N c = 9.

1.2

0.8

0.6

0.4

0.2

Fa =-6.28E-08Su3 +4.56E-05Su2 - 1.08E-02Su +1.156

0

0

50

100

150

200

250

300

Undrained shear strength - Su - kP a

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

Final Design Report

Piled Foundations

Figure 8 - Tomlinsons adhesion factor for piles in cohesive strata

Shaft resistance is given by the following equation:

Qs = (L.As.Su.Fa)

equ. 9

where Fa is the adhesion factor given in Figure 8.

The adhesion between the pile and the clay depends solely on the undrained shear strength of the clay.

For soft clays, the adhesion is equal to the undrained shear strength, but for stiffer clays, the adhesion

becomes progressively less than the shear strength. Tomlinsons (11) relationship between adhesion and

undrained shear strength, here shown in Figure 8 for concrete or timber piles, is widely accepted and has

been adopted in the calculations.

For bored piles, COE and Caltrans give a limiting value of 80 ksf (3,840 kPa) for end bearing resistance

and 5.5 ksf (264 kPa) for shaft friction, with special attention being paid to the effects of bentonite on the

adhesion factor.

3.4

Adopted design parameters

A comparison of the various methods of calculating pile capacities, which have been described in the

previous sections, is given in Appendix 1. This appendix also gives the parameters adopted in the

calculations.

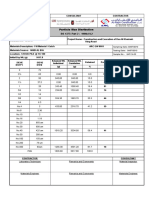

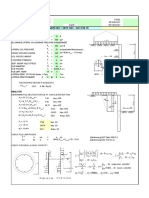

An example of the pile capacity calculation sheet is shown in Table 1. Where very soft soils are

encountered, no capacity is transferred to the pile. Where cohesive soils are encountered, C is entered

in the soil strata column and the undrained shear strength is used to calculate tip and shaft resistances as

described in Section 3.3. Where granular strata are encountered, G is entered in the soil strata column

and both the empirical and static methods are used to calculate pile capacity as described in Sections 3.1

and 3.2. Different Nq and shaft resistance factors are used for driven and bored piles.

The parameters may be summarised as follows:

Soil type

Driven piles

Cohesive strata

Granular

strata

Empirical

method

Static Method

Bored piles

Nc = 9

Fa from Fig. 8

m = 400

m = 133

n=2

n = 0.67

Nq from Fig. 7, Curve C

Nqp from Fig. 7, Curve A

K = 1.0, = 0.8

K = 0.33, = 0.8

In view of the considerable differences in bearing capacities that can be obtained using the various

methods described above, especially in the choice of Nq, some careful judgement is needed in

determining the design values.

In granular strata, the basis of the static method is the effective friction angle, which is inferred from the

SPT resistances. This relationship is only approximate and, in any case, the in-situ strength properties of

granular soils are very dependent on the type and installation method of the piles (ie. driven or bored).

Both the empirical method and the static method are thus dependent on empirical relationships based on

SPT values. Equal weight has therefore been placed on the results derived by both methods and the

required tip levels for driven piles have therefore been set by taking the average of the total capacity lines

derived by both methods.

For bored piles, the required tip elevation has been set according to shaft resistance. Again, an average

has been taken of the values derived by the static and empirical methods.

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

10

Table 1 - Pile Capacity Calculation Sheet

Lo Gom Bridge

Bridge

Boring

Station

Bored(b)/driven(d)

Pile width

B

Depth soft soil Ds

Critical depth Dc

Shaft area

As

Pile area

At

Depth

Lo Gom

LG1

4+501

D

0.45

41.7

50.7

1.80

0.20

m:

N

field

(blows/ft)

Strata

Depth

m

0.0

1.5

4.15

6

8

10

12

14

16

18

19.3

21.3

23.3

25

27

29

31

33

35

37

39

41

42.3

45

47

49

51

53

55

57

59

61

63

65

6

2

2

1

2

1

2

2

2

3

3

3

2

3

2

3

3

3

3

2

3

12

48

46

40

35

25

20

41

42

40

40

42

45x45cm driven piles

m

m

m

2

m /m

2

m

Radian factor

Soil

strata

F

F

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

SW

CH

CH

CH

CH

CL

CL

SW

SW

SW

SW

SW

G

C

C

C

C

C

C

G

G

G

G

G

unit wt

g

t/m3

Eff.o'burden

po'

kPa

1.90

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.45

1.79

2.14

2.13

2.09

2.06

1.98

1.92

2.10

2.10

2.09

2.09

2.10

6.50

19.74

31.43

39.60

48.42

57.25

66.08

74.90

83.73

92.56

98.30

107.13

115.97

123.47

132.31

141.13

149.97

158.80

167.64

176.47

185.30

194.13

204.26

234.37

256.48

277.90

298.68

317.82

335.87

357.42

379.08

400.50

421.93

443.59

Empirical formulae:

Qt = At. m. N

Qs = (L.As .n.N)

m

400

n

2

0.02

pdesign

N60

kPa

blows/ft

N'

corr.

blows/ft

N*

design

blows/ft

kPa

Su

19.74

31.43

39.60

48.42

57.25

66.08

74.90

83.73

92.56

98.30

107.13

115.97

123.47

132.31

141.13

149.97

158.80

167.64

176.47

185.30

194.13

204.26

234.37

256.48

277.90

277.90

277.90

277.90

277.90

277.90

277.90

277.90

277.90

12

3

3

1

2

1

2

2

2

3

3

3

2

2

2

2

2

2

2

1

2

8

30

28

23

20

14

11

21

21

20

19

20

6

2

2

1

2

1

2

2

2

3

3

3

2

3

2

3

3

3

3

2

3

12

48

46

40

35

25

20

41

42

40

40

42

50

30

30

25

30

25

30

30

30

35

35

35

30

35

30

35

35

35

35

30

35

260

250

220

195

145

120

-

Ad. factor

Fa

0.72

0.87

0.87

0.91

0.87

0.91

0.87

0.87

0.87

0.83

0.83

0.83

0.87

0.83

0.87

0.83

0.83

0.83

0.83

0.87

0.83

0.33

0.33

0.33

0.32

0.36

0.41

-

'

deg

DQs

kN

33.2

37.2

37.2

36.9

36.8

36.9

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

56

411

293

257

223

186

176

295

302

288

288

302

Empirical Formulae

Qs

Qt

kN

kN

max =

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

56

467

759

1017

1240

1426

1602

1898

2200

2488

2776

3078

Static formulae: granula strata

Qt = At. pt'.Nq (driven piles)

Qt = At. pt'.Nqb (bored piles)

QL = 48.At.Nqp.tan'

Qs = (L.As.p0'.K.tan)

Shaft resist. factorr Ffa

1.00

Static formulae: cohesive strata

Qt = At.qt = At.9.c

Qs = (L.As.Ca)

Ca = Su.Fa

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

972

474

456

401

355

264

219

3321

3402

3240

3240

3402

Qult

kN

Ngtv. friction

DQn

Qn

kN

kN

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1028

941

1215

1418

1595

1691

1821

5219

5602

5728

6016

6480

97

125

87

82

94

82

94

94

94

68

105

105

80

105

94

105

105

105

105

94

105

-

97

222

309

391

485

568

662

756

850

918

1023

1127

1207

1312

1406

1511

1615

1720

1825

1919

2023

-

Cohesive strata

DQs

Qt

kN

kN

max =

411

293

257

223

186

176

474

456

401

355

264

219

K.tand

DQs

kN

Nq

Granular strata

Nqp

Nqb

max =

Qt

kN

2227.5

QL

kN

0.37

178

41

106

26.8

1711

674

0.42

0.42

0.42

0.42

0.42

424

424

420

419

420

73

73

70

69

70

208

208

197

193

197

44.2

44.1

42.4

41.9

42.4

4104

4096

3916

3860

3921

1536

1532

1437

1407

1439

Figure 7, Curve C

Curve A

Curve D

DQs

kN

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

178

411

293

257

223

186

176

424

424

420

419

420

Static Bearing Capacities

Qs

Qt

Qult

kN

kN

kN

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

178

588

881

1138

1362

1548

1724

2148

2572

2992

3410

3830

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1711

474

456

401

355

264

219

4104

4096

3916

3860

3921

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1889

1062

1337

1539

1717

1812

1943

6252

6668

6908

7271

7751

Final Design Report

Piled Foundations

FOUND ATION CONDITIONS

There are 13 major bridges and 10 footbridges for which subsoil investigations were carried out. The soil

conditions at each bridge site has been assessed and pile capacities have been estimated in accordance

with the design procedures described in the previous section. The results of the pile bearing capacity

calculations for each bridge have been given in Appendices 2 and 3 and the required tip elevations are

summarised in Tables 2 and 3 at the end of this section.

For driven piles, the required tip elevations are determined from the total pile capacity, end bearing plus

shaft resistance. For 350 and 450 mm square piles, target ultimate capacities of 2,000 and 3,000 kN have

been set. For bored piles having larger diameters of 750, 1000 and 1500 mm, end bearing is only

mobilised at quite large settlements compared with shaft resistance. The required pile tip elevations have

accordingly been set where the shaft resistance on its own reaches the working load, here taken as 2,000

for the 750 mm diameter piles, 3,000 kN for 1000 mm diameter piles and 5,000 kN for 1500 mm diameter

piles.

The following paragraphs give brief descriptions of the soil conditions at each bridge site with reference

being made to the Reports on Soil Investigation prepared by the Consultants (12) under separate cover.

4.1

NH1 Interchange

The site of the interchange, shown on Drawing 01, is heavily built up on the north west side of the existing

road, but is open paddy land on the opposite side. Four borings were made at the interchange site: five

had originally been scheduled, but access was denied to the drilling team to carry out HI2. HI1 had to be

moved about 40 m away from its planned location due to access difficulties.

Beneath 0 to 2 m of fill, the borings encountered soft organic clay down to 20 to 22 m depth. SPT

resistances of 1 to 4 blows/foot were recorded with corresponding vane strengths of 17 to 48 kPa.

Beneath the soft upper clay stratum, medium to dense sands, clayey sands and sandy clays were

encountered to the end of the borings, at 40 to 60 metres depth. SPT resistances were generally between

25 and 30 blows/foot, with a few layers giving up to 40 blows. A 2 m clayey layer was encountered at 39

m depth in Boring HI3 where blow counts dropped to 15: a similar drop in blow count was recorded in

Boring HI4 at about the same depth. In Boring HI5, gravelly sand was encountered below 50 m depth

having SPT blow counts of 28 to 31.

The results of the pile capacity calculations are shown in Appendix 2.1. For driven 450 mm piles, the

required bearing of 3,000 kN is reached at about elevation 26 m, except at boring HI5, where piles

should be taken down below the sandy clay layer at 38 m. The required bearing is reached at 40 m.

Bored piles need to be taken down much further than the driven piles since the required shaft resistance

is not reached until tip levels of - 53 to 60 m have been reached. The same tip levels were estimated for

both sixes of bored pile.

Negative friction on the piles has been estimated due to settlements in the very soft clay under

embankment loads, such as may be expected at abutment approach ramps. For the 450 mm driven piles,

up to 1,160 kN may be expected, and up to 2,000 and 3,000 kN for the 1000 mm and 1500 mm bored

piles respectively.

4.2

Nuoc Len Bridge

Similar subsoil conditions to those described above were encountered at the Nuoc Len Bridge. The bridge

site, shown on Drawing 02, is low lying ground most excavated as fish ponds. Here, six borings were

made to between 30 and 60 m depth. The upper very soft organic clay was encountered from ground

level to depths of 22 to 25 m. SPT blow counts varied between 1 and 4 blows/foot and vane shear

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

13

Final Design Report

Piled Foundations

strengths varied between 19 and 52 kPa. A layer of firm plastic clay, 1.5 to 7 m thick, was encountered

under the soft clay in the three borings at the west end of the site having SPT resistances of 5 to 7

blows/foot.

Beneath the upper clay layers, medium to dense sands were encountered in all the borings to the depths

drilled. SPT resistances were generally fairly constant at 30 to 40 blows/foot, although in Borings NL3 and

NL4, looser sands were found down to about 45 m depth. In two of the borings, a 1m stiff sandy clay layer

was encountered at 37 to 41 m depth. Gravelly sand found at 53 m depth in Boring NL4.

The required tip elevations, shown in Appendix 2.2, are similar to those for the NH1 interchange. Driven

450 mm piles will reach their required bearing of 3,000 kN at about elevation - 30 to - 40 m. The deeper

levels are required under the centre of the channel, Borings NL3, NL4 and NL5, where the upper part of

the sand layer is less dense than at the other borings. Tip elevations for bored piles are estimated to vary

between 50 to 63 m, the lower levels also being estimated for Boring NL4.

As at the NH1 interchange, negative friction forces are also expected to be significant. These have been

estimated up to 1,100, 1,980 and 2,970 kN for the 450 mm driven and 1000 mm and 1500 mm bored

piles respectively.

4.3

Rach Cay Bridge

Two borings were made at the Rach Cay Bridge site as shown on Drawing 03. The very soft organic clay

was found to be 20 to 23 m thick, and to have vane shear strengths of 19 to 43 kPa. Three SPTs gave

blow counts of 1 blow/foot. Beneath the clay, loose clayey sand was encounterd down to 35 m depth with

SPT resistances of 3 to 7 blows/foot. Below the clayey sand, an 8 m layer of dense medium fine sand

was encountered in both borings. In Boring RC1, this was in turn underlain by a 9 m thick layer of very

stiff clay (N = 24 to 38) and dense medium fine sand (N = 27 to 31) down to the end of the boring at 60 m.

The required pile tip elevations for the driven 450 mm piles depend in this case on the depth of the very

stiff clay layer. The overlying dense sand is not considered sufficiently thick to develop the required full

ultimate capacity so that piles will need to be taken down into the very stiff clay. The required ultimate

capacity of 3,000 kN will probably be achieved in the middle of this layer, ie. at about 50 m. The bored

piles will need to be taken deeper to mobilise the required shaft resistance. They will therefore be founded

in the underlying dense sand at elevations 57 and 59 m for the 1000 and 1500 mm diameter piles

respectively. These estimated tip elevations are given in Appendix 2.3.

Negative friction forces have been estimated up to 875 kN for the 450 mm driven piles and up to 1,500

and 2,300 kN for the 1000 and 1500 mm bored piles.

4.4

Lo Gom Bridge

The Lo Gom Bridge has the most critical foundation conditions of any of the bridge sites. Six borings were

made to depths of 55 to 70 m, as shown on Drawing 04. The very soft organic clay was found to extend

down to depths of between 39 and 42 m below ground: SPT resistances varied between 1 and 4

blows/foot, and vane shear strengths varied from 16 to 43 kPa.

Beneath the very soft clay, a 1.5 to 6 m thick layer of medium to dense sand was found in which SPT

values of about 20 blows/foot were recorded. Below the sand, a 7 to 13 m layer of very stiff clay to sandy

clay was encountered in all the borings in which SPT resistances of 25 to over 50 blows were recorded.

Below the clay, dense sand was again encountered to the depths bored.

The foundation conditions are quite uniform across the bridge site. Piles will need to be taken down to the

dense sand layer beneath the very stiff clay to achieve sufficient bearing capacity. The estimated required

tip elevations, given in Appendix 2.4, were between 52 and 56 m for driven piles, and 54 and 64 m

for bored piles.

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

14

Final Design Report

Piled Foundations

Due to the 40 m thick layer of soft organic clay, high negative friction loads are likely to be caused by

consolidation settlements beneath the approach embankments. These are estimated to be up to 2,200

kN for 450 mm driven piles and up to 3,800 and 5,700 kN for 1000 and 1500 mm diameter bored piles.

4.5

Cha Va Bridge

The foundation conditions at the Cha Va Bridge site are much better than at the previous bridges, see

Drawing 05. 1.5 to 3 m of fill was found in the land borings, CV 4, CV2 and CV7, below which the soft

organic clay layer was only found to be 1.5 to 3 m thick and was not found at all in Boring CV4. Within the

next 10 m, firm sandy clays and clayey sands were found with SPT resistances of 9 to 16 blows/foot.

Beneath this, medium dense sands were encountered down to depths of 35 to 40 m with SPT blow

counts typically ranging from 10 to 20 blows/foot.

Beneath the medium dense sand stratum extending down to elevation 48 to 49 m, very stiff clay was

found in all the borings interspersed with a layer of stiff sandy clay. Beneath the clay, dense sand was

encountered to the depths bored.

The pile capacity calculations, given in Appendix 2.5, show that both driven and bored piles need to be

taken down to the very stiff clay layer to reach the required bearing capacities. The required tip elevations

for 450 mm driven piles were estimated to be between 41 and 49 m, while for bored piles, they were

estimated between 38 and 45 m.

Negative friction loads are not expected at this site, since the very soft clay stratum is less than 3 m thick

and this will be excavated during construction of the abutments.

4.6

Calmette Bridge

Seven borings were made at the Calmette Bridge site, shown on Drawing 06: five on the main line of the

bridge and two additional beneath the lateral approach ramps on the south side of the Ben Nghe Canal.

Beneath 1 to 2 m of fill, very soft organic clay was encountered down to depths of between 5 and 10 m.

Beneath this, medium dense sands interbedded with firm sandy clays and medium dense clayey sands

were found to extend down to elevation 38 m, where very stiff clay was encountered in all the borings.

The stiff clay layer extended down to 52 to 53 m, beneath which dense to very dense sand was found.

To obtain the required bearing capacities, both driven and bored piles will need to be taken down to the

very stiff clay layer below 38 m, although driven piles near Boring CF2 may refuse in the dense sand

just above this layer. Estimated tip elevations, given in Appendix 2.6, vary between 33 and 50 m for

the driven 450 mm piles and 41 to 48 for the 1000 and 1500 mm diameter bored piles.

Negative friction loads due to consolidation beneath abutment fill could reach 350 kN for the 450 mm

driven piles and 600 and 920 kN for the 1000 and 1500 mm bored piles respectively.

4.7

Khanh Hoi Bridge

Five borings were made at the Khanh Hoi Bridge site as shown on Drawing 07. 2 to 4 m of fill was

encountered in the land borings: beneath this and from the canal bed in Boring KH3, very soft to soft

organic clay was found to extend down to between 5 and 9 m depth. SPT resistances varied between 1

and 3 blows/foot and vane shear strengths of 18 to 55 kPa were recorded. Beneath the soft clay, a very

dense lateritic gravel or gravelly sand layer 4 to 6 m thick was encountered in Borings KH1 and KH2.

Beneath this, and below the soft clay in the other borings, medium dense silty and clayey sands and firm

sandy clays were encountered down to elevation 20 to 23 m. Below this level, clean medium dense

sands were found to extend down to a layer of very stiff to hard clay encountered at 29 to 33 m. This

stratum was found to be 17 m thick in Boring KH3, below which very dense gravelly sand was found.

The founding stratum in all the borings is the very stiff clay in which SPT resistances ranged from 27 to

over 50 blows/foot. To reach the set pile capacities, tip levels of 34 to 39 were estimated for the driven

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

15

Final Design Report

Piled Foundations

450 mm piles, and 34 to 41 for the bored piles, as shown in Appendix 2.7. Potential negative friction

loads of 460 kN are estimated for the driven 450 mm piles and 800 and 1200 kN for the 1000 and 1500

mm bored piles respectively.

4.8

Ca Tre Lon Bridge

Five borings were made at the Tre Lon Bridge site to depths of 50 to 65 m as shown on Drawing 08. The

site is in low-lying swampy ground with very soft organic clay encountered from the ground surface to

about 15 m depth. Vane shear strengths were measured at both abutment borings and showed the

strength to increase from 15 to 20 kPa near ground level to 30 to 35 kPa at the base of the layer. Below

the very soft clay, a 5 to 6 m thick layer of stiff to very stiff clay was encountered in all the borings with

SPT resistances of 12 to 18 blows/foot.

Beneath the stiff clay, medium dense clean sands, silty and clayey sands and sandy clays were found

interbedded in all the borings. SPT resistances were typically between 15 and 25 blows/foot. In Borings

TL1 and TL4, these sandy layers were underlain at about 52 m depth by a thin firm to stiff clay layer with

SPT blow counts dropping to as low as 9 blows/foot. Below this, dense sand was encountered in both

borings where SPT resistances were between 35 and 41 blows/foot .

The required pile tip elevations given in Appendix 2.8 were estimated at 31 to 33 m for the driven 450

mm piles. For the bored piles, required tip elevations varied from 48 to 54 m, with tip levels for the 1500

mm diameter piles being about 1 m lower than for the 1000 mm piles.

Potential negative friction loads are likely to be quite significant. They were estimated at up to 580 kN for

the 450 mm driven piles and 1,000 to 1,500 kN for the 1000 and 1500 mm bored piles.

4.9

Ca Tre Nho Bridge

Very similar conditions to the above were found at the Ca Tre Nho Bridge site where five borings were

made to depths of 50 to 67 m as shown on Drawing 09. Here the soft organic clay was encountered to

depths of 15 to 24 m, with vane shear strengths between 13 and 42 kPa. SPT resistances varied between

0 and 5 blows/foot. Beneath the organic clay, stiff clays and sandy clays were encountered down to

depths of 25 to 30 m with SPT blow counts of 7 to 18. Beneath this, a 7 to 10 m thick layer of very stiff to

hard clay was found to overlie interbedded layers of sandy clays, clayey to silty sands and clean sands.

These layers were medium dense to dense with SPT blow counts ranging between 10 and 40.

Pile tip elevations have been estimated as shown in Appendix 2.9. All piles need to be taken down

through the very stiff clay layer to the medium dense to dense sandy stratum encountered below -37m.

For the 450 mm driven piles, required tip elevations were found to vary from 39 m at the west abutment

to 48 m at the east abutment. For the bored piles, slightly shallower tip elevations were estimated: 35

and 37 m for the 1000 and 1500 mm piles at the west abutment to 44 and 47 m for the two pile sizes

at the east abutment.

Potential negative friction loadings on driven 450 mm piles also varied from 650 to 1,270 kN at the west to

east abutments respectively. Corresponding loads for the two bored pile sizes were estimated at 1,125

and 1,687 kN at the west abutment and 2,217 and 3,326 kN at the east abutment.

4.10 Hanoi Highway Flyover

Four borings were made to depths of 50 to 60 m at the site of the Hanoi Highway Flyover as shown on

Drawing 10. Beneath a fill layer 1 to 2 m thick, very soft organic clay was encountered down to depths of

10 to 12 m, with vane shear strengths of 11 to 46 kPa. SPT resistances varied from 1 to 3 blows/foot.

Beneath the organic clay, medium to stiff clay and sandy clay was encountered down to between 17 and

20 m depth with SPT blow counts of 5 to 15. Below this, medium dense to dense clean sands and clayey

sands occasionally interbedded with thin sandy clay layers were found down to the depths sampled. SPT

resistances in the sandy stratum ranged between 14 and 30 blows/foot. In Borings HHF1, HHF2 and

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

16

Final Design Report

Piled Foundations

HHF3, an intermediate 10 to 4 m thick layer of very stiff to hard clay or sandy clay was found at 37 to

43 m with SPT resistances of 20 to 44 blows/foot.

Required pile tip elevations are given in Appendix 2.10. For driven 450 mm piles, adequate bearing can

be derived from the upper medium dense to dense sandy stratum, and tip elevations vary from 24 to 27

m. The bored piles need to be taken deeper and founded in the lower sand layers. Here tip elevations of

between 37 and 47 m have been estimated for the 1000 and 1500 mm piles, the larger piles being

founded about 1 m below the smaller ones.

Potential negative friction loads of 430 to 530 kN were estimated for the 450 mm driven piles, 760 to 930

kN for the 1000 mm bored piles and 1,140 to 1,390 kN for the 1500 mm bored piles.

4.11 Footbridges

Ten footbridges have been investigated; three at the NH1 Interchange, four across the Ben Nghe Canal

and three at the Hanoi Highway Interchange. At each footbridge site, two borings were made to depths of

between 30 and 60 m.

The subsoil conditions for the six footbridges at the two interchanges are similar to the conditions

described for the main interchange structures in 4.1 and 4.10 above. The subsoil conditions for the four

footbridges across the Ben Nghe Canal are similar to those which have been described for the Cha Va

and Calmette bridges.

Smaller piles than those adopted for the major bridges have been selected for the footbridges: 350 mm

driven piles and 750 mm and 1000 mm bored piles. Charts showing the pile bearing capacities are given

for each bridge site in Appendix 3.1 to 3.10. The required pile tip elevations are given in Table 3.

At the NH1 interchange, the required tip elevations were estimated to vary from 32 m to 42 m for the

350 mm driven piles and from 57 m to 64 m for the bored piles. Along the Ben Nghe Canal, the tip

elevations ranged between 28 m and 45 m for the driven piles and between 38 m and 55 m for the

bored piles. At the Hanoi Highway Intersection, the driven piles need to be taken down to between 19

and 31 m and the bored piles to between 31 m and 46 m.

Table 3 also gives estimates of potential negative friction loads. These were found to be most critical at

the NH1 Interchange and at May Ruou where the soft organic clay layer is deepest. Here, negative

friction loads of 700 to 1,550 kN were estimated for the 350 mm driven piles and 1,220 to 2,680 kN for the

1000 mm bored piles. The other Ben Nghe footbridges had little or no negative friction forces. At the

Hanoi Highway, the negative friction loads were estimated to range between 300 and 625 kN for the

driven piles and 625 and 990 kN for the bored piles.

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

17

Final Design Report

Piled Foundations

Table 2 - Major Bridges: estimated pile tip elevations

Bridge

Boring

Station

NH1 Intersection

HI3

HI4

HI5

NL2

NL3

NL4

NL5

RC1

RC2

LG1

LG3

LG5

LG6

LG4

CV4

CV2

CV5

CV6

CV7

CF1

CF2

CF3

CF4

CF5

KH1

KH2

KH3

KH4

KH6

TL1

TL2

TL3

TL4

TL5

TN1

TN2

TN3

TN4

TN5

HHF1

HHF2

HHF3

HHF4

km

0+325

0+360

0+395

0+812

0+847

0+882

0+921

3+780

3+806

4+501

4+556

4+585

4+632

4+695

7+901

7+899

7+911

7+916

7+906

13+191

13+171

13+178

13+163

13+169

13+937

13+900

13+879

13+847

13+865

17+052

17+089

17+127

17+164

17+202

17+623

17+660

17+967

17+735

17+772

21+211

21+285

21+340

21+387

Nuoc Len

Rach Cay

Lo Gom

Cha Va

Calmette Flyover

Khanh Hoi

Ca Tre Lon

Ca Tre Nho

Hanoi Highway Flyover

Ground

level

m

1.30

1.50

0.30

0.90

-0.50

-1.90

1.00

1.20

1.00

1.30

1.10

-0.80

1.30

1.30

2.10

3.80

-0.90

-0.70

1.90

1.50

1.70

1.30

2.20

1.70

2.26

1.97

-2.44

2.75

2.35

0.61

0.83

-2.90

0.40

0.10

-1.05

0.58

-3.40

-0.07

0.10

1.42

1.51

1.78

1.83

Depth to

firm

stratum

m

21.8

21.5

21.7

22.0

23.0

21.5

27.0

20.6

23.2

41.7

38.5

41.5

41.5

39.0

5.3

0.0

1.5

1.5

3.5

10.4

5.1

6.2

5.9

10.5

5.0

7.2

5.5

8.8

8.7

14.5

14.1

11.5

14.5

16.8

15.3

16.5

15.6

19.6

17.5

12.0

11.5

11.5

10.0

Design Pile Tip Elevation

1000

1500

450x450

driven

bored

bored

m

m

m

-25.7

-55.7

-55.7

-25.5

-53.5

-53.5

-39.7

-59.7

-59.7

-32.1

-50.1

-52.1

-40.5

-55.5

-57.5

-37.9

-62.9

-62.9

-38.0

-56.0

-57.0

-50.8

-56.8

-58.8

-39.0

< -45

< -45

-55.7

-55.7

-57.7

-52.9

-53.9

-56.9

-51.8

< -57

< -57

-55.7

-60.7

-63.7

-52.7

-60.7

-63.7

-42.9

-38.9

-39.9

-43.2

-42.2

-42.2

-48.9

-43.9

-44.9

-41.7

-41.7

-42.7

-41.1

-38.1

-40.1

-44.5

-45.5

-46.5

-33.3

-41.3

-41.3

-44.7

-43.7

-44.7

-49.8

-46.8

-47.8

-42.3

-43.3

-44.3

-38.7

-39.7

-40.7

-34.0

-37.0

-38.0

-37.4

-34.4

-34.4

-39.3

-40.3

-41.3

-38.7

-35.7

-36.7

-31.4

-50.4

-50.4

-32.2

-53.2

-54.2

-32.9

-47.9

-48.9

-31.6

-51.6

-52.6

-30.9

-50.9

-51.9

-39.1

-35.1

-37.1

-37.4

-34.4

-35.4

-45.4

-39.4

-43.4

-42.1

-39.1

-41.1

-47.9

-43.9

-46.9

-25.6

-36.6

-38.6

-24.5

-38.5

-40.5

-27.2

-44.2

-45.2

-24.2

-46.2

-47.2

Negative Friction

1000

1500

450x450

driven

bored

bored

kN

kN

kN

956

1668

2502

994

1735

2603

1159

2023

3035

860

1501

2252

1134

1979

2969

935

1632

2448

1064

1857

2785

777

1356

2033

875

1528

2292

2023

3532

5297

1794

3131

4696

1995

3481

5222

2201

3842

5763

1871

3266

4899

352

614

921

187

327

491

259

451

677

248

427

641

352

614

921

462

807

1210

271

473

709

504

879

1319

462.4

807.1

1210.7

486

848

1272

486

848

1272

396

692

1038

500

872

1308

579

1011

1516

645

1125

1687

806

1407

2111

719

1254

1882

971

1695

2542

584

1408

2113

435

759

1139

483

843

1265

479

837

1255

532

928

1393

Design pile capacity criteria:

- 450x450 mm driven piles: Qt = 3,000 kN.

- 1000 mm bored piles: Qs= 3,000 kN.

- 1500 mm bored piles: Qs= 5,000 kN.

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

18

Final Design Report

Piled Foundations

Table 3 - Footbridges: estimated pile tip elevations

Depth to

Design Pile Tip Elevation

Negative Friction

firm

350x350 750 1000 350x350 750 1000

stratum

driven

driven

bored

bored

bored

bored

m

m

m

m

kN

kN

kN

Footbridge

Boring

Station

km

FB1

FB1-1

0+650

0.21

21.0

-31.8

~ -60

725

1221

FB2

FB1-2

FB2-1

0+650

0+107

0.22

1.73

22.0

22.0

-35.8

-34.3

897

834

1566

1456

FB3

FB2-2

FB3-1

0+154

0+503

1.48

1.39

26.4

24.5

-41.5

~34

-61.5

-

1052

1122

1836

1958

FB3-2

0+551

1.28

27.0

-33.7

-54.7

958

1671

MR1

MR3

5+177

5+179

1.50

1.50

30.0

33.0

-34.5

-33.5

1448

1535

2526

2679

U1

U3

5+932

5+934

1.80

1.40

5.6

5.4

-45.2

-43.6

-46.2

-45.6

-47.2

-46.6

230

213

402

372

603

558

Binh Tay

BT1

BT3

BH1

7+145

7+145

9+900

1.90

1.95

2.10

0.0

0.0

0.0

-29.1

-28.1

-27.9

1.9

-32.1

-37.9

1.9

-35.1

-38.9

BH3

B1-1

B1-2

9+900

21+263

21+014

1.63

1.63

1.05

0.0

11.3

11.0

-28.4

-19.4

-20.0

-38.4

-46.4

-43.0

-39.4

-

626

454

626

792

B2-1

B2-2

B3-1

B3-2

21+036

21+042

21+630

21+630

1.12

1.10

2.10

1.95

10.3

10.5

13.0

13.0

-20.9

-20.9

-30.9

-30.1

-40.9

-35.9

-30.9

-38.1

326

313

500

564

731

703

873

984

May Ruou

BH

B1

B2

B3

Ground

level

Design pile capacity criteria:

- 350x350 mm driven piles: Qt = 2,000 kN.

- 750 mm bored piles: Qs= 2,000 kN.

- 1000 mm bored piles: Qs= 3,000 kN.

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

19

Final Design Report

Piled Foundations

REFERENCES:

1. Meyerhof G.G. (1956), Penetration tests and bearing capacity of cohesionless soils, JSMF, Proc.

ASCE, 82, No. SM-1, pp 866-1 to 866-19.

2. Construction & Irrigation Services Company, Investigation & Design Enterprise (1997), Soil

Investigation Report on Saigon River Crossing, for Maunsell Vietnam.

3. US Army Corps of Engineers, Bearing Capacity of Soils, Manual EM 1110-1-1905, October 1992.

4. Tokimatsu and Seed (1984), Simplified Procedure for the Evaluation of Settlements in Sands due to

Earthquake Shaking, Report No. UCB/EERC-84/16, University of California, Berkeley.

5. Meyerhof G.G. (1976), Bearing Capacity and Settlement of Pile Foundations, ASCE Journal of the

Geotechnical Division, Vol. 102, G73, pp 197 228.

6. Leonards G.A. (1962), Foundation Engineering, McGraw-Hill Book Company.

7. US Navy, Naval Facilities Engineering Command, Foundations and Earth Structures, Manual DM

7.02, September 1986.

8. Hsai-Yang Fang (1991), Foundation Engineering Handbook, Van Nostrand Reinhold.

9. California Department of Transportation, Caltrans (2000), Bridge Design Specifications, Section 4

Foundations.

10. US Army Corps of Engineers, Design of Pile Foundations, Manual EM 1110-2-2906, January 1991.

11. Tomlinson M.J. (1957), The adhesion of piles driven in clay soils, Proc. 4 th ICSMFE, London, pp 66

71.

12. Saigon East West Highway Project, Reports on Soil Investigation,

Package 1A,

Package 1B,

Package 2A,

Package 2C, the Consultants, January April 2002.

/var/www/apps/conversion/tmp/scratch_1/269876001.doc

20

Вам также может понравиться

- Beginner Excel Cheat Sheet v1.3Документ6 страницBeginner Excel Cheat Sheet v1.3hoangducmaiОценок пока нет

- Concrete Structures in Fire PDFДокумент3 страницыConcrete Structures in Fire PDFsaman2580Оценок пока нет

- MS 114 - Substructure A5Документ25 страницMS 114 - Substructure A5hoangducmaiОценок пока нет

- TEMP WALL DESIGNДокумент27 страницTEMP WALL DESIGNhoangducmaiОценок пока нет

- TEMP WALL DESIGNДокумент27 страницTEMP WALL DESIGNhoangducmaiОценок пока нет

- Academic Vocabulary ListДокумент42 страницыAcademic Vocabulary ListHarunVeledarОценок пока нет

- Autodesk Building Design Suite FolletoДокумент4 страницыAutodesk Building Design Suite FolletoicreatiaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- PDFДокумент2 страницыPDFimran5705074Оценок пока нет

- Construction and Execution of Ras Al Khaimah Ring Road Fill Material Particle Size and Compaction Test ResultsДокумент7 страницConstruction and Execution of Ras Al Khaimah Ring Road Fill Material Particle Size and Compaction Test ResultsamesbОценок пока нет

- 10-9-366-727 MaldaДокумент5 страниц10-9-366-727 MaldaShambhu Nath MishraОценок пока нет

- Scope TC 9124Документ1 страницаScope TC 9124Esscon Engineering Services Pvt. Ltd.Оценок пока нет

- 10 ExpansiveSoil0.186Документ9 страниц10 ExpansiveSoil0.186Khaled HamdaouiОценок пока нет

- ScienceДокумент4 страницыScienceLloydDagsilОценок пока нет

- Grain Size Analysis: Axis TitleДокумент4 страницыGrain Size Analysis: Axis Titleajit karandikar100% (1)

- AGR 161 Horizon FormationДокумент5 страницAGR 161 Horizon FormationMus KingОценок пока нет

- Soil Types Lesson for Grade 5Документ3 страницыSoil Types Lesson for Grade 5Mikko Cadano75% (4)

- UU CD TestsДокумент24 страницыUU CD TestsDenver James RabaraОценок пока нет

- In - Situ Stresses (On - Site Stresses)Документ5 страницIn - Situ Stresses (On - Site Stresses)LYNETH ALEIA YAMBOTОценок пока нет

- Cyclic Triaxial Tert On Sands and Coarse Materials - Kokusho and Esashi (1981)Документ5 страницCyclic Triaxial Tert On Sands and Coarse Materials - Kokusho and Esashi (1981)Sebastian PalaciosОценок пока нет

- Foundation Engineering SlidesДокумент64 страницыFoundation Engineering SlidesAblodey AgbekoОценок пока нет

- Soil Moisture ProblemsДокумент32 страницыSoil Moisture ProblemsSecret DuhhhОценок пока нет

- History and Soil FormationДокумент36 страницHistory and Soil FormationTubal Ma. Aubrey G.Оценок пока нет

- Responsi 1 Mekanika Tanah 1Документ3 страницыResponsi 1 Mekanika Tanah 1Rene KurniadiОценок пока нет

- Project: Parwanoo - Solan Road Tunnel Engineering DocumentationДокумент9 страницProject: Parwanoo - Solan Road Tunnel Engineering DocumentationjitendraОценок пока нет

- Jurnal Teknik SipilДокумент8 страницJurnal Teknik SipilArif FadillahОценок пока нет

- Sheet Pile Wall Design Based On 2018 IBC / 2019 CBC / ACI 318-19Документ3 страницыSheet Pile Wall Design Based On 2018 IBC / 2019 CBC / ACI 318-19afvilavilanoriegaОценок пока нет

- The Construction, Commissioning and Maintenance of Infrastructure Works For Electrified Double Track Project Between Seremban and Gemas - Package Ii (KM 502.600 - KM 535.500)Документ46 страницThe Construction, Commissioning and Maintenance of Infrastructure Works For Electrified Double Track Project Between Seremban and Gemas - Package Ii (KM 502.600 - KM 535.500)Suhaidi AliasОценок пока нет

- Prediction of Swelling Potential and PreДокумент12 страницPrediction of Swelling Potential and PreMariaОценок пока нет

- 5E Lesson PlanДокумент3 страницы5E Lesson PlanMarian Alvarado100% (1)

- Visual Soil Classification LabДокумент13 страницVisual Soil Classification LabMatanog UnosОценок пока нет

- Compressibility of Soil: Review - Hydraulics and Geotechnical EngineeringДокумент6 страницCompressibility of Soil: Review - Hydraulics and Geotechnical EngineeringJustine Ejay MoscosaОценок пока нет

- 2.isolated FootingsДокумент47 страниц2.isolated Footingsjuliyet strucОценок пока нет

- Shear Strength of SoilДокумент13 страницShear Strength of SoilfitprawОценок пока нет

- Compaction Practice ProblemДокумент1 страницаCompaction Practice ProblemkakakarlОценок пока нет

- Retaining Walls Predesign and Design CalculationДокумент9 страницRetaining Walls Predesign and Design Calculationnkurunzizaapollinaire202Оценок пока нет

- (Dynamic Model Simulation of The Effects of Legume Cover Crops (LCC) On Runoff andДокумент18 страниц(Dynamic Model Simulation of The Effects of Legume Cover Crops (LCC) On Runoff andMUHAMMAD ZIKRON -Оценок пока нет

- Mass of Soil Retained (G) Cumulative Mass Retained Above Each SIEVE (G)Документ19 страницMass of Soil Retained (G) Cumulative Mass Retained Above Each SIEVE (G)jomari galiasОценок пока нет