Академический Документы

Профессиональный Документы

Культура Документы

Black Liquor Evaporation3-2

Загружено:

isosicaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Black Liquor Evaporation3-2

Загружено:

isosicaАвторское право:

Доступные форматы

Black Liquor Evaporation

Design & Operation

Jean-Claude Patel

A.H. Lundberg Associates, Inc.

Naperville, IL

Topics

Black Liquor Properties

What did we just learn?

What is critical for evaporator design?

Evaporation Technologies

Process Considerations at High Solids

Concentration Technologies

Multiple Effect Evaporators

Whats Black Liquor?

Complex mixture

Spent pulping chemicals (Inorganic salts, caustic, etc.)

Organic matter (Lignin) dissolved from the wood

Non-Process-Elements (NPE) such as K, Cl, etc.

Brought in with wood, water and fresh chemicals

No purge points: Constantly recycled

Black Liquor Properties

Chemical composition

Major role on the performance of the evaporators

Na2SO4, Na2CO3 co-precipitate at high solids

Risk of scale formation

Critical physical properties

Boiling Point Rise (BPR)

Viscosity which impacts heat transfer

Evaporation Technologies

Task of the evaporator

Take a waste stream (WBL) and turn it into fuel (SBL)

for the recovery boiler

Condense steam (or vapors) on one side of a heating

surface while boiling liquor on the other side

Process governed by the heat transfer law

Q = U x A x T

5

Evaporation Technologies

Q: Heat exchange amount which can be accomplished

A: Heat transfer surface

T: Temperature differential

T = Sat. Vapor T In Liquor T Out

U: Heat transfer coefficient, a measure of the

resistance to heat transfer

Depends on heating surface material & cleanliness

Depends on liquor properties & turbulence

6

Rising Film Evaporator (LTV)

Vapor outlet

Vapor (steam) inlet

Liquor product

NCG vent

Liquor feed

Condensate outlet

7

Rising Film Evaporator (LTV)

Liquor film formed by

generated vapors from boiling

liquor at the bottom of the

tubes

Poor turndown, cant handle

high viscosities, minimum T

requirement

Was the workhorse of the

Industry, now found only in

older mills

8

Rising Film Evaporator (LTV)

Low operating cost

Low propensity for foaming

Low liquor viscosity and high

flow-rate are ideal conditions

Only used today in WBL preevaporation where foaming

is an issue:

Blow Heat Recovery

Falling Film Evaporator

Recirculating

liquor

Vapor (steam) inlet

NCG vent

Condensate outlet

Liquor product

Vapor outlet

Liquor feed

10

Falling Film Evaporator

Film formed by mechanical

means (Distribution plate)

High turndown, can handle

higher viscosity (Gravity helps)

Primary technology worldwide

for concentrations up to 50%TS

11

Plate-type FF Evaporator

Vapor outlet

Distributor

Plate heating

element

Vapor

inlet

Liquor feed

Liquor product

NCG vent

Condensate

12

Falling Film Evaporator

Can operate at low T

Flexible (High turndown)

Good resistance to scaling

Moderate HP consumption

Easily automated

Foams easily at low %TS

13

Process Considerations at high solids

Precipitation of supersaturated components

Wt-% crystals in BLS

7

Total Na2SO4 + Na2CO3

= 8.2 wt-% of BLS

6

5

Dicarbonate

4

3

2

Burkeite

1

0

35

45

55

65

75

Dry solids content, wt-%

14

Process Considerations at high solids

Precipitation of supersaturated components

Units > ~ 50%TS must be designed as crystallizers

Control the precipitation process

Crystals form and grow within the liquor

Not as scale on the heat transfer surfaces

VS.

15

Process Considerations at high solids

High liquor viscosity

Impacts heat transfer due to low turbulence

Impediment to crystal growth

Pressurized storage or heat treatment needed?

Temperature becomes a critical design parameter

High temperatures enhance hard scaling risk

16

Process Considerations at high solids

Increased corrosion tendencies

Stress Corrosion Cracking in 300

series SS due to

High temperatures to control

viscosity

High alkalinity at high %TS

Duplex alloys required >75%TS

17

High Solids Technology

Enhanced FC

Crystallizer

FF

Crystallizer

Switching FF

Evaporator

18

Falling Film Concentrators

FF heat transfer

Evaporation takes place at the heat transfer surface

High supersaturation developed within the liquor

Potential for excessive crystal nucleation

Risk of uncontrolled scale formation

19

Falling Film Concentrators

1st approach: FF Crystallizer

Keep supersaturation low

Minimize evaporation/tube

Low Heat Flux (BTU/Sq.ft.)

Large surface area

High recirculation rate

High cost and HP usage

20

10

Falling Film Concentrators

2nd approach: Switching FF Evaps

Multiple rotating bodies with one on

wash at all times

As long as scale washes away faster

than it forms, you stay ahead

Complex piping arrangement

21

Falling Film Concentrators

High turndown capability

Moderate HP consumption

Easily automated

On-line washing (switching

type designs)

22

11

Falling Film Concentrators

Highly sensitive performance

Poor operation at high viscosity

Liquor chemistry changes

Soap and fiber

Distribution and heat transfer

Operation at high temperatures (Calcium scaling)

Liquor Heat Treatment (Expensive)

Product %TS swings (Switching type designs)

High risk of plugging (Non-switching designs)

23

Forced Circulation Crystallizer

24

12

Reynolds Enhanced Crystallizer (REX)

Spiral tube inserts disrupts the boundary

layer at the tube wall, highest resistance

to heat transfer

Apparent Reynolds number in the

turbulent region even at high liquor

viscosities

High U coefficient

Lower tube velocities

Lower HP

25

Forced Circulation Crystallizer

Boiling suppression

No evaporation during heat transfer very low

supersaturation levels developed

Crystallization point is never exceeded within the

heater Eliminates uncontrolled scale formation

Liquor viscosity

Not as much an issue: No film, no distribution device

Can be operated at lower temperatures Lower risk

for liquor decomposition and hard scale formation

26

13

Forced Circulation Crystallizer

Excellent resistance to scaling

Very infrequent washing

needed, if any

High tolerance to liquor

chemistry swings

High turndown capability

Moderate HP consumption

Easily automated

Simple and robust

27

Multiple Effect Evaporation

100,000 lbs of steam will evaporate only 100,000 lbs of

water from the liquor, if heat content is used only once

Economic operation dictates the multiple effective use

of the heat content of the steam used for evaporation

Venting, radiation and other losses prevent from ever

attaining full theoretical efficiency

28

14

Single Effect Operation

105k lb/hr vapor

116k lb/hr steam

45k lb/hr SBL

50% TS

116k lb/hr condensate

150k lb/hr WBL 15% TS

Steam Economy =

water evaporated

steam supplied

105

= 116

= 0.9

29

Two-Effect Operation

51k lb/hr vapor

57k lb/hr

steam

54k lb/hr

vapor

111k lb/hr

condensate

45k lb/hr

50% BL

99k lb/hr

23% BL

150k lb/hr

15% BL

Steam Economy = 105/57 = 1.8

30

15

Simple Six-Effect Evaporator Set

Steam

Condenser

Weak

black

liquor

Product

liquor

Steam Economy ~ 5

31

Typical Six Effect Set

25

25 vacuum

35 psig

Product

From soap skimming

To soap skimming

Feed

liquor

32

16

Multiple Effect Evaporation

Operating conditions in the MEE are set

Available live steam pressure (typ. 60 psig or less)

Vacuum in last effect and SC (typ. around 25 Hg)

Defines overall T available

Actual T much lower due to BPR

33

Cumulative BPR Impact on T

Temp., F

Temp., C

Steam temperature

274

134

Condenser temp.

132

56

T maximum

142

79

Sum of BPR's

43.7

24.3

T actual

98.3

54.6

Capacity loss

31%

31%

34

17

Multiple Effect Evaporation

Available T per effect

Six effect train: 98.3/6 = 16.4 F

Seven effect train: 98.3/7 = 14.0 F

Eight effect train: 98.3/8 = 12.3 F

Minimum T required with LTV Evaporators

Below 13-15F, LTV effects stall and behave poorly

35

Why the T/effect limit with LTVs?

Need to go back to Q = U x A x T

Low T implies large area A (i.e. many tubes)

Low evaporation per tube

Vapor generation per tube becomes too low for film

formation & for making it rise to the top

Some tubes flood and burp at random

Others percolate returning liquor to the bottom liquor

box (i.e. Mr. Coffee)

36

18

Rising Film (LTV) Multiple Effect Evaporation

T/effect limit

Sets number of LTV bodies

which fit within overall T

Sets steam economy

LTV trains

Six effects maximum

Few 7 effect trains around

Unstable & very twitchy

37

Rising Film (LTV) Multiple Effect Evaporation

Little turndown capability

At low capacities, T drops

below T/effect limit

Minimum operation

~ 70% of design rate

Older mills rely on several

LTV sets for flexibility.

38

19

Falling Film (FF) Multiple Effect Evaporation

Film created by mechanical means

Liquor recirculation and distribution device

No minimum T issues

Higher efficiencies achievable

39

Falling Film (FF) Multiple Effect Evaporation

Several 7 and 8 effect FF trains

in USA, Asia, Brazil and Europe

High turndown

~ 20% of design rate

Modern mills can rely on a

single line of FF evaporators

Easily matches evaporation

demand from production

40

20

Multiple Effect Evaporation

Integration of several evaporators (effects)

Vapors from one effect drive the next one

Entire train performance depends on the operation of

each single effect and surface condenser

The weak link governs

Optimizing performance will require working on one

weak link and then the next one, etc.

41

21

Вам также может понравиться

- Understanding Process Equipment for Operators and EngineersОт EverandUnderstanding Process Equipment for Operators and EngineersРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Design ChallengesДокумент52 страницыDesign ChallengesDrSurendra Pratap SinghОценок пока нет

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersОт EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Chemical Recovery Data BookДокумент100 страницChemical Recovery Data BookROHIT EINSTIENОценок пока нет

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsОт EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsОценок пока нет

- Interview Questions For Chemical EngineeringДокумент6 страницInterview Questions For Chemical EngineeringNikunj PatelОценок пока нет

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- Nalco Cooling Tower PresentationДокумент115 страницNalco Cooling Tower PresentationAnonymous ffje1rpa80% (10)

- Process Engineering: Facts, Fiction and FablesОт EverandProcess Engineering: Facts, Fiction and FablesРейтинг: 3 из 5 звезд3/5 (2)

- Presentation On Cooling TowersДокумент52 страницыPresentation On Cooling TowersMuhammad Haris HamayunОценок пока нет

- Cooling Tower Presentation - Brandon Rees - 2012-10-03 PDFДокумент67 страницCooling Tower Presentation - Brandon Rees - 2012-10-03 PDFAhmad Zulkifli100% (1)

- EvaporationДокумент21 страницаEvaporationMarvelous EkunОценок пока нет

- LDPE EloallitasaДокумент29 страницLDPE Eloallitasatatarey79Оценок пока нет

- Evaporation Principles & Black Liquor PropertiesДокумент15 страницEvaporation Principles & Black Liquor PropertiesNaveenGoyalОценок пока нет

- Presentation On Fluid Catalytic Cracking Unit: S.K.Mukherjee Technical ConsultantДокумент76 страницPresentation On Fluid Catalytic Cracking Unit: S.K.Mukherjee Technical ConsultantShankarMukherjeeОценок пока нет

- Steam Generation System OverviewДокумент35 страницSteam Generation System OverviewNevermoreОценок пока нет

- Gas Dehydration Using Glycol: Processes, Design, TroubleshootingДокумент25 страницGas Dehydration Using Glycol: Processes, Design, TroubleshootingBaha Eddine GharbiОценок пока нет

- Fouling of Heat Transfer SurfacesДокумент20 страницFouling of Heat Transfer Surfacessakshi_devi_mec14Оценок пока нет

- Co2 AshraeДокумент62 страницыCo2 Ashraegreerush100% (1)

- Cooling Tower DriveДокумент32 страницыCooling Tower DriveHassan KhanОценок пока нет

- RefrigerationДокумент65 страницRefrigerationUMA MAHESHОценок пока нет

- Tappi 3-1 Black Liquor Properties PDFДокумент6 страницTappi 3-1 Black Liquor Properties PDFserseh100% (1)

- Double Pipe Heat Exchanger - SsДокумент72 страницыDouble Pipe Heat Exchanger - SsNathanian100% (2)

- Using Separations in Chemical ProcessingДокумент30 страницUsing Separations in Chemical Processinggmrp2000Оценок пока нет

- Mass Transfer Operation BasicsДокумент37 страницMass Transfer Operation BasicspavijayaОценок пока нет

- Che 801 WHBДокумент51 страницаChe 801 WHBTaha Furkan GülОценок пока нет

- 1 EvaporationДокумент36 страниц1 EvaporationDoaa Badarneh100% (1)

- CO2 Refrigerant Guide for Industrial Refrigeration SystemsДокумент81 страницаCO2 Refrigerant Guide for Industrial Refrigeration Systemsmirali74Оценок пока нет

- 4 ReboilersДокумент33 страницы4 ReboilersĀĥMệd HĀşşan100% (3)

- Unit ConversionДокумент20 страницUnit ConversionHimanshu YadavОценок пока нет

- 03 EvaporatorsДокумент17 страниц03 EvaporatorsMarie RobertsОценок пока нет

- Super Critical BoilerДокумент32 страницыSuper Critical BoilerSyaiful Fuad89% (9)

- Effect of Fouling FactorДокумент5 страницEffect of Fouling FactorMehta Mehul100% (1)

- Dropwise and Filmwise CondensationДокумент20 страницDropwise and Filmwise CondensationRaviyank Patel100% (1)

- Main Differences - Oil & Gas DevtДокумент7 страницMain Differences - Oil & Gas DevtFemi DeleОценок пока нет

- 10d Troubleshooting Crude HeatersДокумент15 страниц10d Troubleshooting Crude HeatersTissa1969Оценок пока нет

- Operaciones - GlycolДокумент76 страницOperaciones - GlycolIsaac MuñozОценок пока нет

- Stripper Low EfficiencyДокумент14 страницStripper Low EfficiencyMuhammad Irfaan MeoОценок пока нет

- 2-Boiler Corrosion Issues-By Harmen Bouwman-SHELLДокумент65 страниц2-Boiler Corrosion Issues-By Harmen Bouwman-SHELLanand_basuri100% (1)

- Basic Deaerator Science RevealedДокумент50 страницBasic Deaerator Science RevealedMayur-03111986Оценок пока нет

- Heat Transfer Fundamentals - 19th JuneДокумент75 страницHeat Transfer Fundamentals - 19th JuneVivek RathodОценок пока нет

- Boiler Efficiency Improvement: Ankur Gaikwad B.E (Mechanical), Bits-PilaniДокумент36 страницBoiler Efficiency Improvement: Ankur Gaikwad B.E (Mechanical), Bits-PilaniAnonymous nw5AXJqjdОценок пока нет

- University of Tennessee - ChattanoogaДокумент49 страницUniversity of Tennessee - ChattanoogaMALIK ZARYABBABARОценок пока нет

- TEP10 Natural Gas Liquefaction - 2008Документ28 страницTEP10 Natural Gas Liquefaction - 2008viknesh100% (1)

- Flow AssuranceДокумент80 страницFlow AssuranceArief IhsanОценок пока нет

- Methanol Converter TypesДокумент43 страницыMethanol Converter TypesdigecaОценок пока нет

- Design and Operation of Black Liquor EvaporatorsДокумент0 страницDesign and Operation of Black Liquor EvaporatorsLissette Jeri AmaoОценок пока нет

- Mini Project StyereneДокумент25 страницMini Project StyereneMard Apik100% (1)

- Introduction to Condensing & Regenerative Systems THERMAL POWER PLANTДокумент57 страницIntroduction to Condensing & Regenerative Systems THERMAL POWER PLANTEzhil Vendhan Palanisamy100% (1)

- Generator ChemisДокумент86 страницGenerator ChemisVasudevan Krishnan100% (6)

- ALFA LAVAL Compact Heat Exchangers in HVAC SystemsДокумент27 страницALFA LAVAL Compact Heat Exchangers in HVAC SystemsvickersОценок пока нет

- University of Nottingham Butanol Project - Design Guide 1Документ6 страницUniversity of Nottingham Butanol Project - Design Guide 1Tom HartОценок пока нет

- 해양 자원 개발 시스템 개론Документ56 страниц해양 자원 개발 시스템 개론Sean PorterОценок пока нет

- FLUID DEGRADATION CAUSES AND EFFECTSДокумент1 страницаFLUID DEGRADATION CAUSES AND EFFECTSEng Kim WeiОценок пока нет

- Apparatus Dew PointДокумент4 страницыApparatus Dew PointS DasОценок пока нет

- Fouling FactorsДокумент3 страницыFouling FactorshurrikenОценок пока нет

- Kettle ChoiceДокумент5 страницKettle ChoiceHow Jie WeiОценок пока нет

- Heat Exchanger DesignДокумент48 страницHeat Exchanger DesignJose SotoОценок пока нет

- CO 2 Capture by Aqueous Na 2 CO 3 Integrated With High-Quality Caco3Документ9 страницCO 2 Capture by Aqueous Na 2 CO 3 Integrated With High-Quality Caco3isosicaОценок пока нет

- Flowserve General Product Guide PDFДокумент84 страницыFlowserve General Product Guide PDFSIMON S. FLORES G.Оценок пока нет

- Family eДокумент24 страницыFamily eisosicaОценок пока нет

- ExpressPCB2 PDFДокумент1 страницаExpressPCB2 PDFisosicaОценок пока нет

- Rows Numbering in ExcelДокумент5 страницRows Numbering in ExcelisosicaОценок пока нет

- ParChem - Hexachloroacetone Supplier DistributorДокумент10 страницParChem - Hexachloroacetone Supplier DistributorisosicaОценок пока нет

- Eric Clapton Wonderful Tonight Song LyricsДокумент1 страницаEric Clapton Wonderful Tonight Song LyricsisosicaОценок пока нет

- Problema - 1 (Op Aritm Simple)Документ1 страницаProblema - 1 (Op Aritm Simple)isosicaОценок пока нет

- Chemical Engineering and Processing: Process IntensificationДокумент10 страницChemical Engineering and Processing: Process IntensificationisosicaОценок пока нет

- Air - Composition and Molecular WeightДокумент4 страницыAir - Composition and Molecular WeightisosicaОценок пока нет

- IHS - August 2011Документ3 страницыIHS - August 2011isosicaОценок пока нет

- Funke Shell Tube He eДокумент24 страницыFunke Shell Tube He eisosicaОценок пока нет

- D:/Noi/Convertor CCIR-OIRT (PCB Design) /convertor - Express/convertor5.1.pcb (Top Layer, Bottom Layer)Документ1 страницаD:/Noi/Convertor CCIR-OIRT (PCB Design) /convertor - Express/convertor5.1.pcb (Top Layer, Bottom Layer)isosicaОценок пока нет

- Jinan Shandong, ChinaДокумент2 страницыJinan Shandong, ChinaisosicaОценок пока нет

- Cooling Towers Design Feb12 - CHENG PDFДокумент6 страницCooling Towers Design Feb12 - CHENG PDFisosicaОценок пока нет

- Chlormequat RedДокумент74 страницыChlormequat RedisosicaОценок пока нет

- Heat Exchanger DutyДокумент5 страницHeat Exchanger DutyisosicaОценок пока нет

- Hazard and Operability Study - WikipediaДокумент5 страницHazard and Operability Study - WikipediaisosicaОценок пока нет

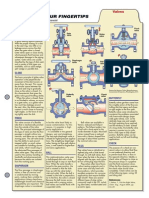

- Valves CHE Facts 0808Документ1 страницаValves CHE Facts 0808isosicaОценок пока нет

- Particle Size Reduction CHE - Facts - 1112 PDFДокумент1 страницаParticle Size Reduction CHE - Facts - 1112 PDFisosicaОценок пока нет

- Forbidden Chemistries Go Flow in API SynthesisДокумент8 страницForbidden Chemistries Go Flow in API SynthesisisosicaОценок пока нет

- Safety in Sulfuric Acid Storage Tanks - Chem. Eng. 11-2015Документ6 страницSafety in Sulfuric Acid Storage Tanks - Chem. Eng. 11-2015isosica100% (2)

- Metal Organic Frameworks (Mofs) :: Time For A Breakthrough in Material SupplyДокумент5 страницMetal Organic Frameworks (Mofs) :: Time For A Breakthrough in Material SupplyisosicaОценок пока нет

- Live Gold Price, Silver Price and Spot Precious Metals Quotes and ChartsДокумент5 страницLive Gold Price, Silver Price and Spot Precious Metals Quotes and ChartsisosicaОценок пока нет

- Metal Organic Frameworks (Mofs) :: Time For A Breakthrough in Material SupplyДокумент5 страницMetal Organic Frameworks (Mofs) :: Time For A Breakthrough in Material SupplyisosicaОценок пока нет

- MELF/mini-MELF/LL-34 Package Diode IdentificationДокумент2 страницыMELF/mini-MELF/LL-34 Package Diode IdentificationisosicaОценок пока нет

- London Metal Exchange Prices - Markets Data Center - WSJДокумент1 страницаLondon Metal Exchange Prices - Markets Data Center - WSJisosicaОценок пока нет

- Anti-Oxidant/pro-Oxidant Activity of Ascorbic AcidДокумент6 страницAnti-Oxidant/pro-Oxidant Activity of Ascorbic AcidisosicaОценок пока нет

- Optimal Design of Experiments: For The Identification of Kinetic Models of Methanol Oxidation Over Silver CatalystДокумент7 страницOptimal Design of Experiments: For The Identification of Kinetic Models of Methanol Oxidation Over Silver CatalystisosicaОценок пока нет

- The Challenges of Ecotox Testing of Nanomaterials and The BPRДокумент3 страницыThe Challenges of Ecotox Testing of Nanomaterials and The BPRisosicaОценок пока нет

- Biogeochemical CyclesДокумент31 страницаBiogeochemical CyclesJessica OliverОценок пока нет

- Hybrid Cooler Project PresentationДокумент13 страницHybrid Cooler Project PresentationJK COTTONОценок пока нет

- Science Specimen Paper 1 2012Документ20 страницScience Specimen Paper 1 2012siswaplus100% (2)

- Büchi Soxhlet E-500Документ14 страницBüchi Soxhlet E-500Cesmar AleniОценок пока нет

- Explanation Text - Reading Comprehensive - Text 1 To 3Документ4 страницыExplanation Text - Reading Comprehensive - Text 1 To 3DEA ANNОценок пока нет

- 3rd Quarter ModuleДокумент36 страниц3rd Quarter ModuleDela Cruz AraОценок пока нет

- 22-25 Vapour Absorption SystemДокумент50 страниц22-25 Vapour Absorption SystemAkshay GeraОценок пока нет

- EM65HHC 115 V 60 HZ 1Документ4 страницыEM65HHC 115 V 60 HZ 1Ricardo BarrosoОценок пока нет

- SpiraxSarco-B2-Steam Engineering Principles and Heat TransferДокумент186 страницSpiraxSarco-B2-Steam Engineering Principles and Heat Transferdanenic100% (4)

- Physics How Things WorkДокумент18 страницPhysics How Things WorkJosh LlarenaОценок пока нет

- Lesson 1 - Introduction To Water TreatmentДокумент5 страницLesson 1 - Introduction To Water TreatmentErica Nicole LabialОценок пока нет

- TÜV Industrie Service GmbH Waterside Scaling, Deposition and Corrosion in Steam GeneratorsДокумент19 страницTÜV Industrie Service GmbH Waterside Scaling, Deposition and Corrosion in Steam Generatorsking1qОценок пока нет

- Water Cycle WebquestДокумент6 страницWater Cycle Webquestapi-330037580100% (1)

- Lesson Plan Template Wac STD 1Документ2 страницыLesson Plan Template Wac STD 1api-510344957Оценок пока нет

- 4single Effect Evaporators ProblemsДокумент24 страницы4single Effect Evaporators Problemsananth2012100% (4)

- Astm D1078 PDFДокумент8 страницAstm D1078 PDFNok ChanОценок пока нет

- Chapter Test 3Документ2 страницыChapter Test 3Line Aban0% (1)

- Kinetic Molecular Theory Explains States of MatterДокумент31 страницаKinetic Molecular Theory Explains States of Matterashly jmgОценок пока нет

- Cambridge O Level: Physics 5054/12Документ20 страницCambridge O Level: Physics 5054/12maryy.army.77Оценок пока нет

- DLL Division DEMO Physical ChangeДокумент6 страницDLL Division DEMO Physical ChangeJR Pellejera100% (1)

- Spray DryerДокумент30 страницSpray Dryerrajesh kumar100% (1)

- 9701 s09 QP 5Документ12 страниц9701 s09 QP 5Hubbak KhanОценок пока нет

- Template Soal PAT B.ingg. Wajib XI 21Документ16 страницTemplate Soal PAT B.ingg. Wajib XI 21Fara AzzahraОценок пока нет

- Saint Louis School: Fire HazardsДокумент3 страницыSaint Louis School: Fire HazardsKimberly GonzalesОценок пока нет

- Water FormsДокумент8 страницWater FormsBasco Martin JrОценок пока нет

- SMEDA Aloe Vera ProcessingДокумент34 страницыSMEDA Aloe Vera ProcessingMuhammad Zargham Haider100% (2)

- 16 Gourdon F PDFДокумент8 страниц16 Gourdon F PDFJoão AlvesОценок пока нет

- Ccb2053 Assignment 1Документ2 страницыCcb2053 Assignment 1Yassin RoslanОценок пока нет

- Me Lab Assessment 1Документ10 страницMe Lab Assessment 1Emilio Joaquin FloresОценок пока нет

- Water Cycle Webquest Student Capture SheetДокумент5 страницWater Cycle Webquest Student Capture Sheetapi-268569185Оценок пока нет