Академический Документы

Профессиональный Документы

Культура Документы

Guidelines For Alloy Selection For Waters and Waste Water Service PDF

Загружено:

Vijayakumar AndiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Guidelines For Alloy Selection For Waters and Waste Water Service PDF

Загружено:

Vijayakumar AndiАвторское право:

Доступные форматы

Guidelines for Alloy Selection for Waters and Waste Water Service

http://www.nickelinstitute.org/NickelUseInSociety/MaterialsSelectio...

Nickel Institute > Nickel Use in Society > Materials Selection & Use > Water > Guidelines

for Alloy Selection

The most important considerations to achieve optimum corrosion performance are to:

choose the correct grade for the chloride content of the water;

avoid crevices when possible by good design;

follow good fabrication practices, particularly removing weld heat tint;

drain promptly after hydrotesting.

Stainless steels do not suffer uniform corrosion when exposed to water environments. On the

other hand, they can be susceptible to localised corrosion under certain circumstances which

designers and end users need to recognise and avoid. Such attack, if it occurs in water

environments, is usually localised as pits or in creviced areas. Design and good fabrication can

minimise such corrosion sites but this needs to be combined with correct alloy selection.

Pitting and crevice corrosion requires the presence of chlorides and, for a given chloride level,

the more highly alloyed stainless steels are more resistant. In general, the higher the chromium,

molybdenum and nitrogen contents of the steel, the better the corrosion resistance. While there

are other factors that have an effect on corrosion rate in waters, chloride content is a major

factor for selection of an appropriate grade and is easily measurable. As crevice corrosion tends

to occur at lower chloride levels and temperatures than pitting, it is normally the parameter

used to guide selection. The guidelines in Table 4 are based on laboratory tests and service

experience over many years.

Table 4. Suitability of Stainless Steels in Waters

Chloride Level ppm

Stainless Steel Grade

<200ppm

304L, 316L

200-1000ppm

316L,duplex alloy 2205

1000-3,600 ppm

Duplex alloy 2205

6%Mo super-austenitic, super-duplex

>3,600ppm

1 of 6

6%Mo super-austenitic, super-duplex

5/18/2015 9:25 AM

Guidelines for Alloy Selection for Waters and Waste Water Service

http://www.nickelinstitute.org/NickelUseInSociety/MaterialsSelectio...

15,000 26,000 ppm(seawater)6%Mo super-austenitic, super-duplex

For the chloride levels given in Table 4, crevice corrosion is rare at pH levels above 6 and

ambient temperatures, typical of most water industry environments. However, where conditions

are severe, e.g. very tight crevices, lower pH, higher temperatures, low flow rates and other

situations where there is a risk of local concentration of higher chloride levels - or just on

grounds of conservatism - 304L(1.4307) can be selected for chloride levels in the region of

50ppm and 316L(1.4404) for chloride levels up to 250ppm. Alternatively if the stainless steel

is cathodically protected, the waters are de-aerated, or there is only transient exposure to these

chloride levels then the requirements in Table 4 can be relaxed.

Machining grades of stainless steel contain high levels of non-metallic stringers which

significantly lower their resistance to pitting in waters. Therefore, free-cutting high sulphur or

selenium bearing grades such as alloy 303 and 303Se should not be used.

Care must be taken when adding chlorine compounds to various process streams. Serious

consideration needs to be given to ensuring that chlorine and aggressive chemicals, such as

ferric chloride (added for flocculation purposes), are added centrally into the stream for good

dispersion. Concentrated forms of these chemicals directed at or down the side of stainless steel

piping or equipment can result in localised attack.

Bacterial control and management is often achieved by chlorine dosing. Type 316L(1.4404)

stainless steel performs well and the molybdenum additions in this alloy provide greater pitting

and crevice corrosion resistance than its Type 304L(1.4307) counterpart. Data to evaluate

acceptable free chlorine levels is limited but that available for raw waters suggest up to 2ppm

for type 304L(1.4307) and 5ppm for type 316L(1.4404). However, stainless steel can tolerate

considerably higher levels of chlorine for short periods of time, as would be the case during

disinfection treatments e.g. AWWA Standards C651/652 where 25-50 ppm chlorine are held for

24-48 hours. It is important however that such levels are well flushed through the system

immediately after treatment.

Useful reference: Effect of Chlorine on Common Materials in Fresh Water. NI

Publication 14049

Ozonation has increased in popularity. This is a powerful oxidant with limited retention life. It

does not create ions or compounds which are as aggressive to stainless steel. However, a good

filter is preferred to remove sediment from the cooling water before it enters the generator to

avoid deposit build up on the tubes. Type 316L(1.4404) stainless steel is a standard material

used in ozone generation and for the handling of the ozonated water streams.

Stainless steels do not suffer from erosion corrosion and can operate at high flow rates, up to

around 40m/s without breakdown of the surface film. Flow rates of greater than 1m/s are

preferred in raw waters and greater than 0.6m/s in cleaner, treated waters to avoid deposit build

up.

2 of 6

5/18/2015 9:25 AM

Guidelines for Alloy Selection for Waters and Waste Water Service

http://www.nickelinstitute.org/NickelUseInSociety/MaterialsSelectio...

Prompt removal of stagnant water after hydrotesting requires particular attention. It is very

important to drain and dry stainless steel systems after hydrotesting, if the equipment is not

going into service directly. Alternatively, if this is not possible, maintaining regular flushing or

water recirculation of the system is good practice. Potable waters, steam condensates (where

available) or filtered waters should be used for hydrotesting rather than raw waters.

The above practices avoid long term stagnant conditions that occasionally can produce

colonisation of certain unsuitable types of bacteria as biomounds and tubercles which can lead

to microbiologically influenced corrosion (MIC). The bacteria causing MIC are more likely to

colonise in the area of welds that have not been cleaned of heat tint. Therefore, good

fabrication procedures which remove or avoid heat tint also greatly improve resistance.

Useful Reference: Microbiologically Influenced Corrosion of Stainless Steel by Water used

for Cooling and Hydrostatic Testing, NI Publication 10085

When fabricated and finished to suitable standards, the

type 304L(1.4307) and 316L(1.4404) can retain their bright appearance in atmospheric

exposure for many years particularly when any surface deposits which build up are removed by

a periodic wash down. In marine (within 5-15 miles of the coast depending on wind and

temperature) and chloride bearing or industrial polluted atmospheres, the 316L(1.4404) is

preferred where maximum life and good appearance are required.

(For more information on atmospheric exposure, particularly where an aesthetically pleasing

appearance is required, see Preventing Coastal Corrosion (Tea Staining) ASSDA

Publication

In enclosed plant atmospheres, where wet chlorine vapours collect and concentrate, acid

condensates can begin to stain and pit stainless steel. Good venting or regular washing down is

recommended in pipe galleries and other areas where chlorine gases can collect. However,

where this is not possible, a higher grade of stainless such as alloy 2205(1.4462) or super

stainless alloys may be required.

3 of 6

5/18/2015 9:25 AM

Guidelines for Alloy Selection for Waters and Waste Water Service

http://www.nickelinstitute.org/NickelUseInSociety/MaterialsSelectio...

It is often necessary to use a number of different alloys to construct a treatment plant or

processing system and the galvanic compatibility of these materials must be considered.

Galvanic corrosion can occur when 2 different alloys are in contact in a common electrolyte

(e.g. rain, condensation, fresh and treated waters and waste water) forming a galvanic corrosion

cell. If current flows between the two, the less noble alloy (the anode) corrodes at a faster rate

than it otherwise would if the alloys were not in contact.

Prediction of corrosion rates can be complicated by area ratios of the metals, temperature,

surface films and the electrical conductivity of the electrolyte and are not always easy to

accurately assess. Galvanic series are available to indicate which alloy is the least noble in a

metal couple but these are usually based on sea water as the electrolyte. Less information is

available about other waters but Galvanic Corrosion-A Practical Guide for Engineers by Roger

Francis published by NACE Press goes some way to assembling existing information.

A typical ranking for fresh water is:

ANODICLEAST NOBLE

Magnesium

Zinc

Aluminium

Carbon steel and cast iron

Copper Alloys

Stainless steels

Graphite

CATHODICMOST NOBLE

The greater the potential difference or, put more simply the vertical separation, between two

metals in the series, the greater the driving force for corrosion. Stainless steels are noble alloys

in this ranking and they are the protected component of the combination.

When the stainless steel is active such that the passive film is damaged or removed by localised

corrosion attack, its position in the series can change to between copper alloys and carbon steel

and thus become less noble.

In practice galvanic corrosion is particularly relevant when considering joining stainless steel

and carbon or low alloy steels. The risk of deep attack is greater if the stainless steel area is

large compared to the steel; for example, galvanised or steel fasteners in a stainless steel flange.

Methods of avoiding galvanic corrosion are:

Design to ensure the more noble area is small in comparison with the less noble area

Insulate the Joint e.g. insulating gaskets, sleeves and washers, paint and tapes.

Use of Isolation spools

Cathodic protection

Coating the joint region ensuring adequate coverage either side. If this is difficult coat

only the more noble metal. If the less noble metal alone is protected, then attack at any

coating defects will be severe.

Galvanic corrosion is also a reason why it is important to select a weld consumable that

4 of 6

5/18/2015 9:25 AM

Guidelines for Alloy Selection for Waters and Waste Water Service

http://www.nickelinstitute.org/NickelUseInSociety/MaterialsSelectio...

is at least as noble as the parent metal.

In fresh waters as opposed to sea water, copper base alloys are compatible with stainless steel

unless extreme stainless steel to copper area ratios exist for example copper alloy valves can be

used in stainless steel piping. However, steel, zinc and aluminium are significantly less noble

that stainless steel and generally should be insulated from stainless steel.

Useful Information: Stainless Steel in Waters: Galvanic Corrosion and its Prevention, A.E.

Bauer

Hydrogen sulphide gas can contribute to the general corrosion that occurs on copper alloys,

aluminium alloys and hot dipped galvanized steel, painted/unpainted steel in wastewater

treatment plants. In contrast, general corrosion rates of 304L(1.4307) and 316L(1.4404)

stainless steels in the atmosphere and in closed systems (e.g. pipework), where moist hydrogen

sulphide is present are negligible at near ambient temperatures. However in closed systems

there may be a propensity for localised corrosion attack (pitting and crevice corrosion) to occur

in 304L(1.4307) and 316L(1.4404) stainless steels if moist hydrogen sulphide and chlorides are

present together at elevated temperatures. The acidity of wastewaters may also be raised so that

they become more corrosive if condensates containing dissolved sulphur dioxide are generated,

forming sulphurous acid. These more corrosive environments may require higher molybdenum

austenitic stainless steels (e.g. alloy 904L/1.4539) or duplex stainless steels (e.g. alloy

2205/1.4462) to be considered as materials of construction.

Useful Guideline Reference:

Applications for Stainless Steel in the Water Industry, IGN 4-25-02, WRc. UK (1999)

Stainless Steel in Municipal Waste Water Treatment Plants, NI Publication 10076

Soil corrosivity towards stainless steels depends on many factors the more important of which

are soil resistivity, pH, chloride content and soil drainage. Resistivity provides a guideline to

the soils water retentiveness e.g clay; sand; loam. and the higher the resistivity, the better is the

drainage. Chlorides are affected by location; the more aggressive being coastal sites or near

roads salted for deicing. Selection of bedding can help with drainage away from piping,

especially in aggressive acidic and/or high chloride soils.

Coating protection, cathodic protection or both is often suggested for type 300 stainless steels

in conditions where the resistivity is less than 2,000 ohm.cm, pH is less than 4.5 and drainage

is poor. Between resistivities of 2000-5000 ohm.cm, stainless steels may require protection or

consideration given to higher alloys if the chloride level is high or soil acidity is of concern. In

the EuroInox paper, Stainless steels in Soils and Concrete at www.euro-inox.org

recommendations are given in more precise terms and provides guidance for material selection

vs chloride levels in the absence of coatings and or cathodic protection. A summary is given in

table 7.

Table 5. Stainless Steel Selection Criteria According to Soil Conditions

Stainless Steel Soil Conditions

5 of 6

5/18/2015 9:25 AM

Guidelines for Alloy Selection for Waters and Waste Water Service

http://www.nickelinstitute.org/NickelUseInSociety/MaterialsSelectio...

Articles

Volume 30-1

Socio-Economic Impact Assessment

Drinking water in Tokyo

News

Have you read the Nickel Magazine?

Publications

Nickel in the European Union

Nickel in Tomorrow's World

Steel Package Water & Waste Water Treatment Units

Knowledge Base

Nigel Ward at NiCoMo 2014

An Introduction to Environmental Quality Standards for Metals

Corrosion by Waters

Press Releases

Press Releases

Presentations

Stainless Steel in the Water Industry

Stainless Steel in the Water Industry

6 of 6

5/18/2015 9:25 AM

Вам также может понравиться

- Chloride Chlorine Levels and Stainless S PDFДокумент1 страницаChloride Chlorine Levels and Stainless S PDFSH1961Оценок пока нет

- Corrosion in Stainless Steel ! - Know The Facts !!Документ22 страницыCorrosion in Stainless Steel ! - Know The Facts !!faith23dbagulОценок пока нет

- 1.corrosion TheoryДокумент77 страниц1.corrosion Theoryamitvaze316100% (1)

- White Rust and Galvanized Cooling TowersДокумент2 страницыWhite Rust and Galvanized Cooling Towersnorrisherrington100% (1)

- Stainless SteelДокумент8 страницStainless SteelEdgarDavidDiazCampos100% (1)

- 2 - Low Temperature CorrosionДокумент65 страниц2 - Low Temperature CorrosiondennykvgОценок пока нет

- NclUni Lect1 1103Документ49 страницNclUni Lect1 1103Dino Peduto100% (1)

- Developments in Coatings For High Temperature Corrosion ProtectionДокумент9 страницDevelopments in Coatings For High Temperature Corrosion ProtectionRecep Vatansever100% (1)

- MARINE ConcreteДокумент12 страницMARINE ConcreteChristian Bar100% (1)

- GalvInfoNote - 3 - 1 How Zinc Protects SteelДокумент6 страницGalvInfoNote - 3 - 1 How Zinc Protects SteelKYAW SOE100% (1)

- Concrete Repair Q & A: by Bill Scannell and Ali SohanghpurwalaДокумент2 страницыConcrete Repair Q & A: by Bill Scannell and Ali SohanghpurwalaSiva Jothi100% (1)

- Repairing & Protective Coating System For Cooling Tower: SP Concare Pvt. LTDДокумент6 страницRepairing & Protective Coating System For Cooling Tower: SP Concare Pvt. LTDAnkita Baban Gavade100% (1)

- Truth and Consequences Solvent Entrapment and Osmotic Blistering PDFДокумент3 страницыTruth and Consequences Solvent Entrapment and Osmotic Blistering PDFCristian Cisternas100% (1)

- Surface & Coatings Technology: A. Rico, J. Gómez-García, C.J. Múnez, P. Poza, V. UtrillaДокумент8 страницSurface & Coatings Technology: A. Rico, J. Gómez-García, C.J. Múnez, P. Poza, V. UtrillaJhonatan GomezОценок пока нет

- Differential AerationДокумент1 страницаDifferential AerationPradeepОценок пока нет

- Interline 955 Performance Test Data ForДокумент2 страницыInterline 955 Performance Test Data ForMehman Nasibov100% (1)

- Engineering Failure Analysis: C.M.B. Martins, J.L. Moreira, J.I. MartinsДокумент7 страницEngineering Failure Analysis: C.M.B. Martins, J.L. Moreira, J.I. Martinspaneisan100% (1)

- Fusion Bond Epoxy (FBE) Coating RepairsДокумент4 страницыFusion Bond Epoxy (FBE) Coating Repairsyasi heeru100% (1)

- Interzinc 72 Performance Test Data For: Zinc Rich Epoxy PrimerДокумент2 страницыInterzinc 72 Performance Test Data For: Zinc Rich Epoxy PrimerShakir Ahmed Kalkundri100% (1)

- Standard Type of RT 50 Cooling Tower: Air Flow Water FlowДокумент5 страницStandard Type of RT 50 Cooling Tower: Air Flow Water FlowBapu612345100% (1)

- Corrosion TheoryДокумент10 страницCorrosion Theory7amada11100% (1)

- Barrier-Adhesion Principle For Corrosion PrtotectionДокумент10 страницBarrier-Adhesion Principle For Corrosion PrtotectionINRO Ingeníeria100% (1)

- Corrosion Protection Evaluation of Some Organic Coatings Incorrosion Protection EvaluationДокумент61 страницаCorrosion Protection Evaluation of Some Organic Coatings Incorrosion Protection EvaluationUsama Awad100% (1)

- T 18Документ10 страницT 18khuramluck100% (2)

- SPE-169195-MS Development, Test and Offshore Use of A Fouling Repellent Coating For Plate Heat ExchangersДокумент6 страницSPE-169195-MS Development, Test and Offshore Use of A Fouling Repellent Coating For Plate Heat ExchangersTangtang Guo100% (1)

- Fouling-Repellent Coating For Shell-And-Tube Heat ExchangersДокумент3 страницыFouling-Repellent Coating For Shell-And-Tube Heat Exchangersزيد عدنان عبد الحسين100% (1)

- Dr. Bugs Tan ADIPEC Conference PaperДокумент23 страницыDr. Bugs Tan ADIPEC Conference PaperDr Bugs Tan100% (1)

- CPT 1 ConcreteДокумент9 страницCPT 1 ConcreteJossef.ahsan Jossef.ahsan100% (1)

- 20160215042419-Ki Stahlsortenvergleich Rev0 eДокумент4 страницы20160215042419-Ki Stahlsortenvergleich Rev0 esanrexiОценок пока нет

- LW22Документ2 страницыLW22Nicolae MarinОценок пока нет

- 19 Civ Du 5240Документ18 страниц19 Civ Du 5240Bhatt100% (1)

- Whatever Is Updated and RevisedДокумент14 страницWhatever Is Updated and RevisedWan Ah-LunОценок пока нет

- Understanding Humidity and Humidity MeasurementvbДокумент5 страницUnderstanding Humidity and Humidity MeasurementvbPOOVENDHAN T100% (1)

- Water-Chemistry, Outage-Maintenance Best Practices Highlight Steam Plant WorkshopДокумент8 страницWater-Chemistry, Outage-Maintenance Best Practices Highlight Steam Plant Workshopnktiah1207Оценок пока нет

- Chloride Attack On Stainless SteelДокумент9 страницChloride Attack On Stainless SteelAnand GuptaОценок пока нет

- The Journal of Protective Coatings & Linings - Why Surface Preparation Is ImportantДокумент5 страницThe Journal of Protective Coatings & Linings - Why Surface Preparation Is ImportantSergio Daniel Barea Nuñez100% (1)

- Evaluation of Corrosion Protection Properties of Additives For Waterborne Epoxy Coatings On SteelДокумент9 страницEvaluation of Corrosion Protection Properties of Additives For Waterborne Epoxy Coatings On SteelJhon jairo100% (1)

- Performance Test Report - Novaguard 890 PDFДокумент2 страницыPerformance Test Report - Novaguard 890 PDFPeter Callán100% (1)

- Using Ultrasonic Coating Thickness GaugesДокумент4 страницыUsing Ultrasonic Coating Thickness GaugesAvijit Debnath100% (1)

- The Effect of Epoxy and Non-Epoxy Coating Treatment On The Corrosion Oflow Carbon Steel in Sodium Chloride Solutions - Dwinanda Et Al. 2021Документ6 страницThe Effect of Epoxy and Non-Epoxy Coating Treatment On The Corrosion Oflow Carbon Steel in Sodium Chloride Solutions - Dwinanda Et Al. 2021Luthfi Ady100% (1)

- BrederoShaw TP TropicEnvironment PDFДокумент8 страницBrederoShaw TP TropicEnvironment PDFMakrame BattazОценок пока нет

- Angels and Demons in The Realm of Protective CoatingsДокумент26 страницAngels and Demons in The Realm of Protective Coatingsaliabdulhamid100% (1)

- Brochure English - Pickling, Cleaning, PassivatingДокумент4 страницыBrochure English - Pickling, Cleaning, PassivatingSerge1976100% (1)

- Intra Laboratory Assessment of Commercial Test Kits For Quantifying Chloride On Steel SurfacesДокумент11 страницIntra Laboratory Assessment of Commercial Test Kits For Quantifying Chloride On Steel SurfacesAnonymous jw0enWB100% (1)

- Fouling Release Coatings Combat Fouling: Power Generation & Water Treatment FacilitiesДокумент22 страницыFouling Release Coatings Combat Fouling: Power Generation & Water Treatment Facilitiesthai avvai100% (1)

- 04 MaintenanceДокумент20 страниц04 MaintenanceCornelia Theodora100% (1)

- C CC CC: by Patrick J. Dunn, Associate Member ASHRAE, and Richard NorsworthyДокумент8 страницC CC CC: by Patrick J. Dunn, Associate Member ASHRAE, and Richard NorsworthyjamesОценок пока нет

- Abrasive Blasting COP August 2019Документ47 страницAbrasive Blasting COP August 2019Ian Flynn100% (1)

- Non Skid AreasДокумент2 страницыNon Skid AreasHossain AnwarОценок пока нет

- The Case of The Strange Blistering: Cases From The F-FilesДокумент5 страницThe Case of The Strange Blistering: Cases From The F-FilesSamsu Sams100% (1)

- Progress in Organic Coating-PaperДокумент22 страницыProgress in Organic Coating-Paperjibin k p100% (1)

- Research Progress in Organic Zinc Rich Primer Coatings For Cathodic Protection of MetalsДокумент18 страницResearch Progress in Organic Zinc Rich Primer Coatings For Cathodic Protection of MetalsJorge Suarez100% (1)

- A Simulations Test For The Selection of Coatings and Surface Treatments For Plastics Injection Moulding MachinesДокумент9 страницA Simulations Test For The Selection of Coatings and Surface Treatments For Plastics Injection Moulding MachinesCassioLopesОценок пока нет

- Coating IndiaДокумент53 страницыCoating Indiaagustinusset100% (1)

- 001CorrosionArticleAntiCorrosionTechWEIQ PDFДокумент3 страницы001CorrosionArticleAntiCorrosionTechWEIQ PDFJACK100% (1)

- Selecting Tubing Materials For Power Generation Heat ExchangersДокумент20 страницSelecting Tubing Materials For Power Generation Heat ExchangersPing Apiwat100% (1)

- Guidelines For Alloy Selection For Waters and Waste Water Service PDFДокумент6 страницGuidelines For Alloy Selection For Waters and Waste Water Service PDFssgentisОценок пока нет

- Hydrostatic Testing of Welded Ss FabricationsДокумент12 страницHydrostatic Testing of Welded Ss FabricationsKarin Soldatelli Borsato100% (1)

- Rouging Spec For SSДокумент16 страницRouging Spec For SStomcanОценок пока нет

- Article 510 - Corrosion Protection: California Groundwater AssociationДокумент5 страницArticle 510 - Corrosion Protection: California Groundwater AssociationmayasseenОценок пока нет

- Plant Commissioning Start Up ProcedureДокумент100 страницPlant Commissioning Start Up Proceduremsaad292% (124)

- Alpha Laval Emmie Oil SeparatorДокумент2 страницыAlpha Laval Emmie Oil SeparatorADITYA_PATHAKОценок пока нет

- Krinvanto VishwamaryamДокумент9 страницKrinvanto VishwamaryamADITYA_PATHAKОценок пока нет

- Material Conversion TableДокумент5 страницMaterial Conversion TableMilin DesaiОценок пока нет

- Dictionary of MetallurgyДокумент309 страницDictionary of MetallurgyADITYA_PATHAKОценок пока нет

- Balance Grades As Per ISO 1940Документ0 страницBalance Grades As Per ISO 1940ADITYA_PATHAKОценок пока нет

- Use of Gear Pumps For ExtrudersДокумент2 страницыUse of Gear Pumps For ExtrudersADITYA_PATHAKОценок пока нет

- Basic O-Ring ElastomersДокумент36 страницBasic O-Ring ElastomersADITYA_PATHAKОценок пока нет

- Maag Gear Pumps For PolymersДокумент12 страницMaag Gear Pumps For PolymersADITYA_PATHAK100% (1)

- PMI, Prince2 & IPMA ComparisonДокумент17 страницPMI, Prince2 & IPMA ComparisonADITYA_PATHAK100% (1)

- Elecon Scraper ReclaimerДокумент8 страницElecon Scraper ReclaimerADITYA_PATHAK100% (1)

- Haridwar Trains To&froДокумент2 страницыHaridwar Trains To&froADITYA_PATHAKОценок пока нет

- Fertilizer Storage GuidelinesДокумент8 страницFertilizer Storage GuidelinesADITYA_PATHAKОценок пока нет

- Paratherm Diathermic Oil OR MSDSДокумент4 страницыParatherm Diathermic Oil OR MSDSADITYA_PATHAKОценок пока нет

- TLT Covent Centrifugal Blower CatalogueДокумент12 страницTLT Covent Centrifugal Blower CatalogueADITYA_PATHAK0% (1)

- Bateman Stacker and ReclaimerДокумент31 страницаBateman Stacker and ReclaimerADITYA_PATHAK100% (2)

- Kito Electric Hoist CatalogueДокумент36 страницKito Electric Hoist CatalogueADITYA_PATHAKОценок пока нет

- JetMmixers Vs SideEntryPropellerДокумент2 страницыJetMmixers Vs SideEntryPropellerADITYA_PATHAKОценок пока нет

- Hermetic Pumpen Canned Motor Pumps Catalogue For Model CN - CNF - CNKДокумент16 страницHermetic Pumpen Canned Motor Pumps Catalogue For Model CN - CNF - CNKADITYA_PATHAKОценок пока нет

- 42CD4 MaterialДокумент1 страница42CD4 MaterialADITYA_PATHAK100% (1)

- Forced Draft Fan Sizing For Fired HeatersДокумент5 страницForced Draft Fan Sizing For Fired Heatersdlalameen4471Оценок пока нет

- TEAL Health HazardДокумент1 страницаTEAL Health HazardADITYA_PATHAKОценок пока нет

- 42CD4 MaterialДокумент1 страница42CD4 MaterialADITYA_PATHAK100% (1)

- Butyle RubberДокумент5 страницButyle RubberADITYA_PATHAKОценок пока нет

- Viscosity Effects On Pump PerformanceДокумент2 страницыViscosity Effects On Pump PerformanceADITYA_PATHAKОценок пока нет

- Final GB General Machining LR PDFДокумент82 страницыFinal GB General Machining LR PDFSamuel Aires LourencoОценок пока нет

- Worksheet Reactivity Series ks3Документ4 страницыWorksheet Reactivity Series ks3siau chingОценок пока нет

- Advanced Cast Products - Ductile Iron Specs-ASTM 897, ASTM A536, SAE J434Документ27 страницAdvanced Cast Products - Ductile Iron Specs-ASTM 897, ASTM A536, SAE J434George CharitouОценок пока нет

- Effect of Austenitizing Temperature and Cooling Rate On The Structure and Properties of A Ultrahigh Strength Low Alloy SteelДокумент10 страницEffect of Austenitizing Temperature and Cooling Rate On The Structure and Properties of A Ultrahigh Strength Low Alloy SteelMilena StajicОценок пока нет

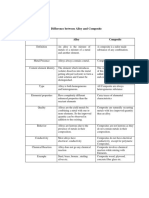

- Difference Between Alloy and Composite Word FinalДокумент2 страницыDifference Between Alloy and Composite Word FinalMehedi HasanОценок пока нет

- EN DX51D - 1.0226 - SteelNumber - Chemical Composition, Equivalent, PropertiesДокумент2 страницыEN DX51D - 1.0226 - SteelNumber - Chemical Composition, Equivalent, PropertiesliusfОценок пока нет

- Steel and Pipes For Africa Price ListДокумент1 страницаSteel and Pipes For Africa Price ListWynand Van ZylОценок пока нет

- Electrolytic Etching in Welding Metallography: ResearchДокумент6 страницElectrolytic Etching in Welding Metallography: ResearchBiju KОценок пока нет

- PSD CEU 180Sept11-Corrosion PDFДокумент17 страницPSD CEU 180Sept11-Corrosion PDFSam ChoiОценок пока нет

- Electron Configurations of The ElementsДокумент26 страницElectron Configurations of The ElementsTahsin MorshedОценок пока нет

- 6 - AceroДокумент76 страниц6 - AceroWilmer Junior Urango RomeroОценок пока нет

- Cutting Tool MetallurgyДокумент83 страницыCutting Tool MetallurgyMickloSoberanОценок пока нет

- Long Life Corrosion Protection of Steel by Zinc-Aluminium Coating Formed by Thermal Spray ProcessДокумент8 страницLong Life Corrosion Protection of Steel by Zinc-Aluminium Coating Formed by Thermal Spray ProcessmotokaliОценок пока нет

- Fabricating Inconel Alloy 625LCFДокумент8 страницFabricating Inconel Alloy 625LCFDet100% (2)

- TDS - Mulcoa - 47 - Rev 1Документ1 страницаTDS - Mulcoa - 47 - Rev 1유유재하Оценок пока нет

- Types of Gem Stone Setting - Jewellery DesigningДокумент30 страницTypes of Gem Stone Setting - Jewellery DesigningDr. Neeru jainОценок пока нет

- Copper Brass Bronze CW721R High Tensile Brass Manganese Bronze - CZ114Документ2 страницыCopper Brass Bronze CW721R High Tensile Brass Manganese Bronze - CZ114alextentwentyОценок пока нет

- iCE 3000 Series Detection LimitsДокумент1 страницаiCE 3000 Series Detection LimitsdudutwaeОценок пока нет

- ASTM F138 13aДокумент5 страницASTM F138 13aRiesma TasomaraОценок пока нет

- Fusealloy Fabrication Guidelines 2016Документ25 страницFusealloy Fabrication Guidelines 2016Vitor Rigueira de GodoyОценок пока нет

- Corrosion Coupons FinishДокумент2 страницыCorrosion Coupons FinishMohamed TallyОценок пока нет

- LF2 LCB LCC Carbon Steel Valve Material Low Temperature - Global Supply LineДокумент3 страницыLF2 LCB LCC Carbon Steel Valve Material Low Temperature - Global Supply LineheviОценок пока нет

- 3-Grooving&parting InsertsДокумент6 страниц3-Grooving&parting Insertssathiya priyaОценок пока нет

- Ams 4928Документ8 страницAms 4928REKHA100% (3)

- Surcharges Alloys 2018Документ21 страницаSurcharges Alloys 2018S Wa Sachin0% (1)

- Strictly For Private Circulation Amongst Members OnlyДокумент3 страницыStrictly For Private Circulation Amongst Members OnlyMohammed KhorakiwalaОценок пока нет

- NitridingДокумент32 страницыNitridingmurthy.kanulla660067% (3)

- 2 ,, 36Документ11 страниц2 ,, 36nareshОценок пока нет

- Cu-HCP: C10300 Industrial RolledДокумент7 страницCu-HCP: C10300 Industrial RolledpierocarnelociОценок пока нет

- Piping Material Specification-GeneralДокумент15 страницPiping Material Specification-GeneralTejas PatelОценок пока нет