Академический Документы

Профессиональный Документы

Культура Документы

E Coating

Загружено:

arpandevОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

E Coating

Загружено:

arpandevАвторское право:

Доступные форматы

Exactly what is E-Coat?

E-Coat is an electrically-applied paint coating. It is also known as electrocoat

ing, electronic coating, electronic painting, and electro photo coating. E-coati

ng was developed originally for the automotive industry because it is economical

and provides superior coverage, adhesion, and corrosion resistance. It coats an

y metal (aluminum, zinc, brass, steel) that conducts electricity.

Here is how E-coat works. The parts to be E-coated are first cleaned and treated

with a zinc phosphates conversion coating. The panels of your Dearborn Deuce Co

nvertible TM are moved to Oakley s assembly area with a thin film of oil remaining

on each panel from the stamping operation. The oil protects the freshly stamped

steel panel from rusting during shipping and assembly.

The parts to be E-coated are then attached to metal racks or placed in a coating

fixture. In our case, both the hemmed components and your Dearborn Deuce Conver

tible TM body each use a special coating fixture that is lifted by crane and put

onto a conveyor carriage system. The bodies are placed on a system designed to

carry truck frames.

The parts are immersed in an E-coat paint tank. A direct negative electrical cha

rge is applied to the carriage and the body and parts are electrically charged.

opposite direct positive electrical charge is applied to the paint bath.

An

For those of you who love the details, this process is known as cationic E-coat

and is used to provide a more corrosion-resistant film than the more common anio

nic E-coat process. The paint bath is filled with Cathodic Epoxy PPG 8000 E-coat

. Epoxy based E-coats are used in environments where corrosion protection is par

amount. Your charged parts attract the oppositely charged paint particles. As the

paint is deposited it begins to act as an insulator and deposition slows, stoppi

ng at a precisely predetermined thickness that is governed by the amount of volt

age applied during the process.

Even though deposition may have slowed or may be complete on one area on the sur

face of the part, deposition will continue on any uncoated or incompletely-coate

d area of the part until complete coverage is achieved.

Other benefits E-Coat offers are:

Cosmetic Appeal.

E-Coat paint applies a super-even

finish, no dripping, no pooling and no gaps.

Corrosion Protection.

All parts are coated evenly insi

de and out. Complex parts can be coated even after assembly.

Unbeatable Durability. Withstands the most rigorous salt

spray, adhesion, dialectric, acid resistance, and U.V. tests.

Super Adhesion.

Because of the very nature of th

e E-Coat process, a thin coat can be complete, uniform, tough, and attractive, w

hile

still maintaining close en

gineered tolerances.

E-coat is standard OEM practi

ce: it is corrosion-resist

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Project: Tapis Eor Brownfield Modifications & RetrofitsДокумент8 страницProject: Tapis Eor Brownfield Modifications & RetrofitsMohamad Azizi AzizОценок пока нет

- Grinding Polishing: Kiesow Dr. BrinkmannДокумент36 страницGrinding Polishing: Kiesow Dr. BrinkmannChoice OrganoОценок пока нет

- DC REGULATED POWER SUPPLY NP-9912 - Service - Manual PDFДокумент12 страницDC REGULATED POWER SUPPLY NP-9912 - Service - Manual PDFDa ElОценок пока нет

- Diagrama Electrico VespaДокумент1 страницаDiagrama Electrico Vespavetgesto3Оценок пока нет

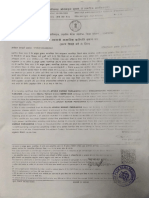

- Notificatio N (Rese Rvation) Gove Rnment: A Cu) UTДокумент1 страницаNotificatio N (Rese Rvation) Gove Rnment: A Cu) UT122-Ayush Kumar ParganihaОценок пока нет

- May PMДокумент45 страницMay PMR MathirajОценок пока нет

- FTNV-B FINAL - CatalogueДокумент8 страницFTNV-B FINAL - CatalogueAmodu Usman AdeyinkaОценок пока нет

- Series 3501 & 3503Документ4 страницыSeries 3501 & 3503Tim Stubbs100% (2)

- Rental Power 70 KW: Specification SheetДокумент4 страницыRental Power 70 KW: Specification SheetDulguunkherlen BudkhandОценок пока нет

- Reference Frame Theory PDFДокумент42 страницыReference Frame Theory PDFSubaragavanОценок пока нет

- Maryland Institute of Technology and Management, Jamshedpur Theory of Machine-Module: IIIДокумент12 страницMaryland Institute of Technology and Management, Jamshedpur Theory of Machine-Module: IIISourabh PradhanОценок пока нет

- ESB Networks Contractor Safety RegulationsДокумент68 страницESB Networks Contractor Safety RegulationsvhlactaotaoОценок пока нет

- Precast Capping Beam Formers DatasheetДокумент2 страницыPrecast Capping Beam Formers Datasheetsantoshgpr100% (1)

- Baseline Processing ReportДокумент17 страницBaseline Processing ReportMAMAN MAMANОценок пока нет

- SQAP For Pumps 2017Документ79 страницSQAP For Pumps 2017MukeshОценок пока нет

- Positector Calibration ProcedureДокумент6 страницPositector Calibration ProcedureluigimasterОценок пока нет

- KSB KWP: Non-Clogging Centrifugal PumpsДокумент12 страницKSB KWP: Non-Clogging Centrifugal PumpsalfredОценок пока нет

- ABB Isomax Circuit BreakersДокумент53 страницыABB Isomax Circuit BreakersAshish GuptaОценок пока нет

- Calculating The Maximum Attenuation For Optical Fiber LinksДокумент5 страницCalculating The Maximum Attenuation For Optical Fiber LinksMiguel LiceagaОценок пока нет

- Financial Auditor Job DescriptionДокумент8 страницFinancial Auditor Job Descriptionfinancemanagement702Оценок пока нет

- Understand and Troubleshoot Virtualized Domain Controller in Windows Server 8 BetaДокумент168 страницUnderstand and Troubleshoot Virtualized Domain Controller in Windows Server 8 BetaChiTownITОценок пока нет

- Behringer EPR900 Powered Speaker SchematicsДокумент14 страницBehringer EPR900 Powered Speaker SchematicsJimОценок пока нет

- Urethane UB-7 Catalog 2013Документ32 страницыUrethane UB-7 Catalog 2013yfontalvОценок пока нет

- Important RCC Questions-Short and LongДокумент15 страницImportant RCC Questions-Short and LongmailjoelsamuelОценок пока нет

- Cored Wires - ESAB - OK TubrodДокумент87 страницCored Wires - ESAB - OK TubrodElias KapaОценок пока нет

- HP4Документ88 страницHP4Alexander Neyra100% (4)

- ISTJ PersonalityДокумент2 страницыISTJ PersonalityMonalisa ChatterjeeОценок пока нет

- Vray Material Settings: COMP 423: Cadd For ArchitectureДокумент18 страницVray Material Settings: COMP 423: Cadd For ArchitectureMarvin GonzalesОценок пока нет

- HPSIM Command Line InterfaceДокумент107 страницHPSIM Command Line Interfacegverma80Оценок пока нет

- Material Turbina A GásДокумент47 страницMaterial Turbina A GásGetúlio RibeiroОценок пока нет