Академический Документы

Профессиональный Документы

Культура Документы

Us 4284248

Загружено:

KrozeАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Us 4284248

Загружено:

KrozeАвторское право:

Доступные форматы

'

Umted States Patent [191

[111

4,284,248

Adams

[45]

Aug. 18, 1981

[54]

PACKING PULVERIZER

[76] Inventor:

3,923,259

Harold R. Adaml, Rte. 1, St.

Francisville, 111- 62460

12/1975

Gorsha ........................... .. 241/278 R

Primary Examiner-Mark Rosenbaum

Attorney, Agent, or Firm-Glenn K. Robbins

[21] App]. No.: 23,847

[57]

[22] Film:

A packing pulverizer device for removing packing from

' Mu- 26 1979

[51] m. 01.1 ............................................ .. B02C 19/00

[52] US. 01. ........................ .. 241/278 R; 241/1691

[58] Field of Search ............ .. 241/98, 168, 169, 169.1,

ABSTRACT

cup-shaped packing glands having a valve stem passing

therethroush- The pulverizer device is particularly

adapted for use in valve stems con?ned inside yokes

241/277, 278 R, 283; 51/241 S, 241 VS, 245;

Where the ends are difficult to obtain access. The device

277/1, 9, 9.5; 408/67, 68, 203, 203.5, 204, 230;

is comprised of a semi-cylindrical housing which can be

425/376 R

opened and clamped loosely about the valve stem. The

[56]

Reference8 Cited

device has comminuting means at the bottom adapted to

grind up and comminute old packing within the cup

shaped gland. Spiral ?ute means are provided on the

U-S- PATENT DOCUMENTS

277,966

5/1883

531,546 12/1894

1,484,352

2/ 1924

gg'gg

Whiteside .......................... .. 408/204

exterior to remove the comminuted material. The de

Matthews

vice is provided with a handle for manual rotation and

277/9 X

hard . . . . . . . . . . . .

. . . . . . .. 408/204

"" "

grinding and also a gear train means which can

3:122:969

3/1964

Shames et al.

3,634,981

1/1972

Connor ............................. .. 51/241 5

. 241/1691 x

ployed for connection to a prime moving source.

-

6 Claims, 5 Drawing Figures

16

:

14

45

z

r

32

/

I8

2 E W

/-.

l0

48

44

22

34

2o

12

\\

\\\1\

58

46

em_

U.S. Patent

Aug. 18, 1981

Sheet 1 of 2

4242

34

3a2%;?

58

4,284,248

US. Patent

Aug. 18, 1981

Sheet 2 of2

BZVKM

J

I! /\ M

I \. / LU.

/ zz/ k30

NJ

n8

Il I

:E;i22,5%:Eg./5E2?

54

26

44

3 40.l

4,284,248

4,284,248

For the purpose of illustration of this invention there

is shown in the accompanying drawings a preferred

PACKING PULVERIZER

embodiment'thereof. It is to be understood that these

drawings are for the purpose of illustration only and

SUMMARY OF THE INVENTION

5 that the invention is not limited thereto.

Valves of one type or another and other types of

equipment are conventionally provided with cup

shaped packing glands in which a valve shaft or other

type of shaft is positioned for rotary or reciprocating

movement. The packing in the packing gland conven

tionally provides for lubrication and sealing to prevent

?uid loss in the valve. Such packing is of conventional

nature and commonly deteriorates and hardens over a

period of time and the packing must be replaced.

In various types of industrial gate valves used in the

process, petroleum, utilities and other types of heavy

industry such valves are quite large and expensive.

Further, the valves are exposed to the atmosphere,

industrial pollution and the like and the packing to be

removed presents a problem for the ef?ciency and

prompt and inexpensive removal. Such packing is par

ticularly dif?cult to remove in gate valves having a

yoke through which the valve stem passes and where in

the packing gland is positioned inside the yoke and is

IN THE DRAWINGS

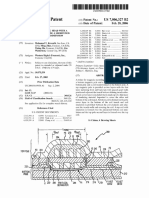

FIG. 1, is a top plan view of the pulverizing device.

FIG. 2, is a view in axial section through a packing

gland and the pulverizer device of this invention.

FIG. 3, is a bottom plan view of the pulverizing de

vice.

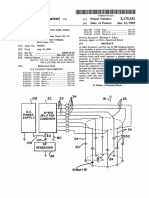

FIG. 4, is a top plan view similar to FIG. 2, but show

ing a modi?cation with the use of a handle rather than

the gear train of FIG. 2.

FIG. 5, is a view in vertical axial section of the em

bodiment of FIG. 4.

DESCRIPTION OF THE INVENTION

The pulverizing device of this invention is generally

indicated by the reference numeral 10 in FIGS. 1 and 2.

As there shown, 1t is employed, as particularly shown in

FIG. 2, in a cup-shaped packing gland 12 in which the

compression ?ange 14 has been removed. A valve stem

dif?cult to disassemble.

25 16 is shown passing through the gland.

By means of this invention there has been provided a

The pulverizer device is generally comprised of a

packing pulverizer which can be employed in various > cylindrical housing 18 having a bottom comminuting

types of gate valves and particularly those in which the

packing gland is con?ned within a yoke making the end

of valve stem not accessible. The packing pulverizer of

this invention is particularly adapted for use in such

member 20 and flute means 22 at the side of the housing.

The housing is comprisedv of two semi-cylindrical

members 24 and 26 which are adapted to be held to

gether by bolt members 28 and 30 ?tting through a top

bearing member 32. The bearing member is constructed

packing and removing it through ?ute means on the side

of two half portions held together by these bolts.

of the pulverizer device. The device may be operated

The housing is provided with a pair of semicircular

manually or through appropriate gearing by an external 35 comminuting plates connected by bolts 34 at the bottom

prime moving source.

of the housing. The comminuting plates are provided

Essentially the packing pulverizer of this invention is

with comminuting elements 36 which cut up the pack

comprised of a semi-cylindrical housing which is

ing as the housing is rotating.

cup-shaped packing glands accommodating the old

adapted to be opened and ?tted around a valve stem

In order to provide for powered rotational move

through a central opening provided in the housing. The 40 ment, a pair of semi-circular ring gear elements 38 and

housing is opened in the manner of a jaw and closed and

fastened together when ?tted around the valve stem.

The bottom of the housing is provided with cutting'

elements or comminuting elements which comminute

or cut up the old packing when the device is rotated.

40 are connected by bolts 42 and 44 to the housing. A

bevel gear 45 meshes with the ring gear and is con

nected to a shaft 46 which receives a power cable

adapted to be connected to an external power source to

provide powered rotary movement. A bearing block 48

Spiral ?ute means on the exterior of the housing are

designed to remove the comminuted debris from the

supports the bevel gear 45 and the power shaft 46. The

bolts 50 connect the support block to the bearing 32 at

packing gland to the outside.

the top of the cylindrical housing.

The housing is adapted to be rotated by means of a

In the modi?cation of FIGS. 4 and 5, the power

handle at the top which provides for manual operation 50 source is replaced by the manual handle 54. This handle

of the device. The device may also be ?tted with a gear

is formed as an extension of the support bearing 32 at

train comprised of a pair of semi-circular ring gears

the top of the housing and may be used for manual

?tted around the valve stem and connecting with the

rotation of the housing where an external power source

housing. The gear train means is also provided with a

is not available or is not desired.

bevel gear for rotating the ring gear by connection to an 55 Use

external power source. Thus, the device may be oper

The packing pulverizer device of this invention is

ated either manually or mechanically as desired.

very simply used in the ?eld. For removal of old pack

The pulverizing device of this invention is adapted to

ing 58 as shown in FIG. 2, the compression ?ange 14 is

be simply used in the ?eld by workmen removing pack

?rst conventionally disassembled from the packing

ing and providing maintenance on valves of one type or 60 gland and moved upwardly on the valve stem 16. When

another. The device is simply employed and provides

this has been effected, the two half members 24 and 26

of the cylindrical housing are then ?tted around the

for ef?cient and rapid removal of the dif?cult to break

valve stem and connected together. The device is then

up packing and such maintenance is simply effected as

ready for use either by powered operation through the

desired.

The above features are objects of this invention and 65 gear train of FIGS. 1 and 2 or through the manual

handle 54.

further objects will appear in the detailed description

Where the manual handle 54 is desired to be em

which follows and will be otherwise apparent to those

ployed, manual rotational movement is simply effected

skilled in the art.

4,284,248

t?.

and the comminuting elements 36 break-up or commi

housing being comprised of a plurality of members

nute the old packing. The packing is removed through

adapted to be removably ?tted around said valve stem.

the ?ute means 22 out of the cup-shaped housing. The

2. The packing pulverizer device of claim ll, in which

said housing is comprised of a pair of hemi-cylindrical

members having a central hemi-cylindrical opening and

close relationship of the exterior of the housing with the

internal diameter of the cup-shaped packing gland pro

vides a restricted path and efficiently effects the re

moval of the old cut-up or pulverized material. When

the comminuted material has been completely broken

up and removed, the pulverizing device is withdrawn

means are provided to fasten said members together

about said valve stem with said stem closely ?tting

through a cylindrical opening formed when said mem

bers are ?tted together.

from the cup-shaped opening in the packing gland and

3. The packing pulverizer of claim l in which the

simply disassembled and removed. New packing is then

housing has a transversely extending bottom wall pro

vided with comminuting elements comprising said com

minuting means, said housing is provided with a support

installed in a conventional fashion.

Where the power gear train is desired to be removed

of FIGS. 1 and 2, the split ring gear members 38 and W

member having bearing means supporting said housing

are utilized. The meshing of the bevel gear 45 within the 15 for rotary movement with respect to said valve stem,

ring gear and powering by the power shaft 46 from the

gear means connecting said housing through said bear

external power source effectively causes the ring gear

to rotate the connected housing. The rotational move

ing means to a source of power for rotating said hous

ing, said support member has a central opening receiv

ment of the housing provides comminutation through

ing said valve stem and said gear means is a ring gear

the cutter elements 36 in the same fashion but at a faster

having central opening receiving said valve stem and

said support member supports a prime moving gear

and more powerful rate than the manual means but

removal of the comminuted material is otherwise identi

cal.

element driven by said source of power at one side of

the valve stem engageable with said ring gear and said

Accordingly, there has been provided by this inven

support member and said ring gear are comprised of a

tion a very simply devised packing pulverizer device. 25 multiplicity of sections adapted to be ?tted around said

This device may be simply employed inside a valve

valve stem and connected together.

yoke where the ends of the valve stem are not accessible

4-. The packing pulverizer device of claim 3, in said

for use of the device. The device is provided for both

ring gear is positioned co-axially with the valve and the

manual and powered rotation and can be used with

prime moving gear is positioned with its axis perpendic

packing glands of various con?gurations. It will be

understood that although the packing pulverizing de

ular to the valve stem and meshes with the ring gear in

a bevel gear relationship.

vice is disclosed in semi-circular portions, it can be used

5. The packing pulverizer device of claim 1, in which

the housing has a transversely extending bottom wall

in multiple segments adapted to be connected together

or can even be made integral in valves where it can be

fitted over the end of the valve stem and made accessi 35 provided with comminuting elements comprising said

comminuting means, said housing has side walls pro

vided with spiral flute elements comprising said flight

means and said housing is comprised of a plurality of

members adapted to be removably ?tted around said

ble to the packing gland.

Various changes and modi?cations may be made

within this invention as will be readily apparent to those

skilled in the art. Such changes and modi?cations are

within the scope and teaching of this invention as de

valve stem.

6. The packing pulverizer device of claim 1, in which

said housing is provided with a support member having

bearing means supporting said housing for rotary move

?ned by the claims appended hereto.

What is claimed is:

1. A packing pulverizer device for removing packing

from cup-shaped packing glands having an axial valve

stem, said device comprising a cylindrical housing hav

ing a central opening for ?tting around said valve stem,

said housing having a bottom provided with packing

ment with respect to said valve stem, gear means con

necting said housing through said bearing means to a

source of power for rotating said housing and in which

said support member and said ring gear are comprised

of a multiplicity of sections adapted to be ?tted around

said valve stem and connected together.

comminuting means, ?ight means on side walls of said

housing for carrying comminuting packing from said

packing gland and means for rotating said housing, said

55

60

65

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Us 6250486Документ14 страницUs 6250486KrozeОценок пока нет

- United States Patent (19) : Kaye Oct. 15, 1996Документ44 страницыUnited States Patent (19) : Kaye Oct. 15, 1996KrozeОценок пока нет

- Us 3376803Документ26 страницUs 3376803KrozeОценок пока нет

- United States Patent: (21) Appl. N0.: 13/226,109 (Continued)Документ17 страницUnited States Patent: (21) Appl. N0.: 13/226,109 (Continued)KrozeОценок пока нет

- Aug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitДокумент6 страницAug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitKrozeОценок пока нет

- Us8608097 PDFДокумент10 страницUs8608097 PDFKrozeОценок пока нет

- Us 3616264Документ4 страницыUs 3616264KrozeОценок пока нет

- Dec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964Документ4 страницыDec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964KrozeОценок пока нет

- Us 6633161Документ21 страницаUs 6633161KrozeОценок пока нет

- United States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000Документ18 страницUnited States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000KrozeОценок пока нет

- Us 3195038Документ10 страницUs 3195038KrozeОценок пока нет

- United States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000Документ18 страницUnited States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000KrozeОценок пока нет

- Us 7006327Документ11 страницUs 7006327KrozeОценок пока нет

- United States Patent (19) : (45) Date of Patent: Oct. 12, 1999Документ17 страницUnited States Patent (19) : (45) Date of Patent: Oct. 12, 1999KrozeОценок пока нет

- United States Patent (19) : Nºzizi EДокумент11 страницUnited States Patent (19) : Nºzizi EKrozeОценок пока нет

- United States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000Документ18 страницUnited States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000KrozeОценок пока нет

- United States Patent (19) (11) Patent Number: 5,179,332Документ14 страницUnited States Patent (19) (11) Patent Number: 5,179,332KrozeОценок пока нет

- United States Patent (19) : Sinclair Et AlДокумент21 страницаUnited States Patent (19) : Sinclair Et AlKrozeОценок пока нет

- United States PatentДокумент25 страницUnited States PatentKrozeОценок пока нет

- Us 5818319Документ30 страницUs 5818319KrozeОценок пока нет

- United States PatentДокумент14 страницUnited States PatentKrozeОценок пока нет

- Us 4774914Документ25 страницUs 4774914KrozeОценок пока нет

- United States Patent (19) : Nºzizi EДокумент11 страницUnited States Patent (19) : Nºzizi EKrozeОценок пока нет

- Us 6577888Документ12 страницUs 6577888KrozeОценок пока нет

- United States PatentДокумент15 страницUnited States PatentKrozeОценок пока нет

- Us 4866424Документ14 страницUs 4866424KrozeОценок пока нет

- Us 5379832Документ16 страницUs 5379832KrozeОценок пока нет

- United States PatentДокумент15 страницUnited States PatentKrozeОценок пока нет

- United States Patent (19) (11) Patent Number: 5,207,074Документ18 страницUnited States Patent (19) (11) Patent Number: 5,207,074KrozeОценок пока нет

- United States Patent (19) : 16 VoltageДокумент12 страницUnited States Patent (19) : 16 VoltageKrozeОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Colour FastnessДокумент37 страницColour FastnessSivakumar K100% (1)

- ARK - Intel® Core™ I3-370m Processor (3M Cache, 2Документ3 страницыARK - Intel® Core™ I3-370m Processor (3M Cache, 2Delzi Guindra AdriОценок пока нет

- Compiled LecsДокумент24 страницыCompiled LecsNur SetsuОценок пока нет

- Test 2 Sku3023 A201 QuestionДокумент8 страницTest 2 Sku3023 A201 QuestionHafiz HafizanОценок пока нет

- 9A02502 Transmission of Electric PowerДокумент6 страниц9A02502 Transmission of Electric PowersivabharathamurthyОценок пока нет

- Vanish Magic Magazine VANISH MAGIC MAGAZINE 58 May 2019Документ118 страницVanish Magic Magazine VANISH MAGIC MAGAZINE 58 May 2019mick byrnes100% (1)

- Coding Decoding Sheet - 01 1678021709186Документ9 страницCoding Decoding Sheet - 01 1678021709186Sumit VermaОценок пока нет

- Resume: Satyam KumarДокумент3 страницыResume: Satyam KumarEr Satyam Kumar KrantiОценок пока нет

- Tokyo Guidelines 2018Документ115 страницTokyo Guidelines 2018Alik Razi100% (1)

- Investigation of Skew Curved Bridges in Combination With Skewed Abutments Under Seismic ResponseДокумент5 страницInvestigation of Skew Curved Bridges in Combination With Skewed Abutments Under Seismic ResponseEditor IJTSRDОценок пока нет

- Petersen Coils Basic 20principle and ApplicationДокумент3 страницыPetersen Coils Basic 20principle and ApplicationasotozuazuaОценок пока нет

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Документ2 страницыAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Khyle Laurenz DuroОценок пока нет

- 12-Week Off-Season Training Programme Junior Rugby (U18 - U21)Документ5 страниц12-Week Off-Season Training Programme Junior Rugby (U18 - U21)LeBron JamesОценок пока нет

- Prevailing Torque Locknut Technical SpecificationsДокумент3 страницыPrevailing Torque Locknut Technical SpecificationsLiu YangtzeОценок пока нет

- SOPДокумент16 страницSOPjerome marquezОценок пока нет

- Kinder DLL Week 8Документ15 страницKinder DLL Week 8Jainab Pula SaiyadiОценок пока нет

- EXAMPLE 8.6 Veneer Grades and RepairsДокумент2 страницыEXAMPLE 8.6 Veneer Grades and RepairsnickОценок пока нет

- Gaffin, Biblical Theology and Westminster StandardsДокумент16 страницGaffin, Biblical Theology and Westminster StandardstheoarticlesОценок пока нет

- Dna Adduct As Biomarker: Prof. Dr. Yahdiana Harahap, MS, AptДокумент68 страницDna Adduct As Biomarker: Prof. Dr. Yahdiana Harahap, MS, AptNadia AaqilahОценок пока нет

- Types of Loads Considered For Design of BridgeДокумент45 страницTypes of Loads Considered For Design of BridgeAbhishek100% (1)

- Maritime Management SystemsДокумент105 страницMaritime Management SystemsAndika AntakaОценок пока нет

- ContempoДокумент4 страницыContempoPrincess Jonette YumulОценок пока нет

- English Class Vii PDFДокумент101 страницаEnglish Class Vii PDFpannapurohitОценок пока нет

- WeeklyДокумент8 страницWeeklyivaldeztОценок пока нет

- Child DevelopmentДокумент15 страницChild Development4AndreeaОценок пока нет

- Us Navy To Evaluate Anti Submarine Warfare Training SystemДокумент2 страницыUs Navy To Evaluate Anti Submarine Warfare Training SystemVictor PileggiОценок пока нет

- Isulat Lamang Ang Titik NG Tamang Sagot Sa Inyong Papel. (Ilagay Ang Pangalan, Section atДокумент1 страницаIsulat Lamang Ang Titik NG Tamang Sagot Sa Inyong Papel. (Ilagay Ang Pangalan, Section atMysterious StudentОценок пока нет

- LinkageДокумент9 страницLinkageHarshu JunghareОценок пока нет

- AS and A Level: ChemistryДокумент11 страницAS and A Level: ChemistryStingy BieОценок пока нет

- 23001864Документ15 страниц23001864vinodsrawat33.asiОценок пока нет