Академический Документы

Профессиональный Документы

Культура Документы

Strain 95 j2

Загружено:

Ramprasad SrinivasanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Strain 95 j2

Загружено:

Ramprasad SrinivasanАвторское право:

Доступные форматы

To appear in Journal of Sound and Vibration

APPLICATION OF THE STRAIN ENERGY DAMAGE DETECTION

METHOD TO PLATE-LIKE STRUCTURES

Phillip Cornwell1

Rose Hulman Institute of Technology

5500 Wabash Ave.

Terre Haute, IN 47805

Scott W. Doebling2 and Charles R. Farrar3

Los Alamos National Laboratory

ESA-EA, MS P946

Los Alamos, NM 87545

Running headline: Strain Energy Method

Number of total pages: 36

Number of text pages: 14

Number of tables: 1

Number of figures: 19

Person for correspondence:

Scott Doebling

Los Alamos National Laboratory

ESA-EA, MS P946

Los Alamos, NM 87545

Phone: (505) 667-6950

FAX: (505) 665-2137

doebling@lanl.gov

Associate Professor, Dept. of Mechanical Engineering, Phillip.J.Cornwell@Rose-Hulman.edu

Technical Staff Member, Engineering Analysis Group, doebling@lanl.gov

Materials Behavior Team Leader, Engineering Analysis Group, farrar@lanl.gov

1/37

To appear in Journal of Sound and Vibration

ABSTRACT

In this paper the problem of using measured modal parameters to detect and locate damage in platelike structures is investigated. Many methods exist for locating damage in a structure given the

modal properties before and after damage. Unfortunately, many of these methods require a correlated

finite element model or mass normalized mode shapes. If the modal properties are obtained using

ambient excitation then the mode shapes will not be mass normalized. In this paper a method based

on the changes in the strain energy of the structure will be discussed. This method was originally

developed for beam-like structures, that is, structures characterized by one-dimensional curvature. In

this paper the method will be generalized to plate-like structures that are characterized by twodimensional curvature. This method only requires the mode shapes of the structure before and after

damage. To evaluate the effectiveness of the method it will be applied to both simulated and

experimental data.

1

INTRODUCTION

Significant work has been done in the area of detecting damage in structures using changes in the

dynamic response of the structure. Because the natural frequencies and mode shapes of a structure

are dependent on the mass and stiffness distributions any subsequent changes in them should,

theoretically, be reflected in changes in the frequency and mode shapes of the structure. The problem

of using measured frequencies and mode shapes and their sensitivity to damage is a question not to

be addressed in this paper. An extensive literature review [1] of the state of the art of damage

detection and health monitoring from vibration characteristics has recently been published. From this

review it is clear that there are a large number of proposed methods of detecting damage from

vibration characteristics but, unfortunately, many of these methods require a correlated finite element

model and/or mass normalized mode shapes. If the modal properties are obtained using ambient

excitation, as would most likely be the case for a remote, automated health monitoring system, then

the mode shapes will not be mass normalized. The method proposed in this paper avoids both of

these requirements.

Pandey, et. al. [2] demonstrated that absolute changes in mode shape curvature can be a good

indicator of damage for the FEM beam structure they considered. Stubbs, et. al. [3] presented a

2/37

To appear in Journal of Sound and Vibration

method based on the decrease in modal strain energy between two structural degrees of freedom as

defined by the curvature of the measured mode shapes. This method was has been successfully

applied to data from a damaged bridge [4] and has been compared to several other methods [5-6].

Several other researches have also used changes in mode shape curvature to detect damage [7-10]

In this paper an extension of the method proposed by Stubbs [3], [4] will be presented. This method

requires that the mode shapes before and after damage be known, but the modes do not need to be

mass normalized and only a few modes are required. The original formulation by Stubbs and Kim is

inherently limited to structures that are characterized by one-dimensional curvature (i.e. curvature

that is uniquely a function of one independent spatial variable). In other words, the 1-D strain energy

method can only be applied to structures that behave globally in a beam-like manner or can be

decomposed into beam elements. (It should be noted that the 1-D strain energy method has been

successfully applied to 2-D and 3-D structures, but only by decomposing them into beam-like

elements.) In this paper the method will be generalized to plate-like structures that are characterized

by two-dimensional curvature. To examine limitations of the method it will be applied to several sets

of simulated data and comparisons will be made between applying the original formulation to a

series of slices of the structure verses the true two-dimensional formulation.

2

THEORY

For completeness the derivation of the damage indicator will be shown for both beam-like and platelike structures.

2.1 Beam-like structures

The strain energy of a Bernoulli-Euler beam is given by

2

"

2w

1

U = EI 2 dx

2 0 x

(1)

where EI is the flexural rigidity of the beam. For a particular mode shape, i (x ) , the energy

associated with that mode shape is

3/37

To appear in Journal of Sound and Vibration

2

"

2

1

U i = EI 2 i dx

2 0 x

(2)

If the beam is subdivided into Nd divisions as shown in Figure 1, then the energy associated with

each sub-region j due to the ith mode is given by

1

U ij =

2

a j +1

aj

2 i

(EI )j 2 dx

x

(3)

The fractional energy is therefore

U ij

Fij =

(4)

Ui

and

Nd

ij

=1

(5)

j =1

Similar quantities can be defined for a damaged structure and are given by Eq. (6-9)

2

"

2 i*

1

dx

U = EI *

2

20

x

*

i

1

U =

2

*

ij

a j +1

aj

F =

*

ij

(6)

2 *

(EI ) 2 i dx

x

*

j

U ij*

(7)

(8)

U i*

4/37

To appear in Journal of Sound and Vibration

and

Nd

Nd

j =1

j =1

Fij = Fij* = 1

(9)

where ( )* indicates a quantity calculated using the damaged mode shapes, i* .By choosing the subregions to be relatively small, the flexural rigidity for the jth sub-region, EIj is roughly constant and

Fij* becomes

a j +1

(EI )

*

j

F =

aj

*

ij

2 i*

dx

2

x

*

Ui

(10)

If we assume that the damage is primarily located at a single sub-region then the fractional energy

will remain relatively constant in undamaged sub-regions and Fij* = Fij . For a single damaged

location at sub-region j=k we find

a k +1

(EI )k

ak

2 i

x 2

Ui

dx

a k +1

(EI )

*

k

ak

2 i*

x 2

U i*

dx

(11)

If we assume that EI is essentially constant over the length of the beam for both the undamaged and

damaged modes Eq. (11) can be rearranged to give an indication of the change in the flexural rigidity

of the sub-region as shown in Eq. (12)

5/37

To appear in Journal of Sound and Vibration

a k +1

(EI )k

(EI )*k

ak

a k +1

ak

2 i*

x 2

dx

2 i

x 2

dx

2 i*

0 x 2

dx

2 i

0 x 2

dx

"

"

f ik*

f ik

(12)

In order to use all the measured modes, m, in the calculation, the damage index for sub-region k is

defined to be

m

k =

f

i =1

m

*

ik

(13)

ik

i =1

One advantage to the formulation shown in Eqs. 12 and 13 is that the modes do not need be

normalized. Assuming that the collection of the damage indices, k, represent a sample population of

a normally distributed random variable, a normalized damage index is obtained using Eq. (14)

Zk =

k k

k

(14)

where k and k represent the mean and standard deviation of the damage indices, respectively. In

this paper it will be assumed that normalized damage indices with values greater than two are

associated with potential damage locations. The preceding derivation was originally presented by

Stubbs, et al. [3],[4].

2.2 Plate-like structures

The strain energy of a plate is given by Eq. 15 [11].

6/37

To appear in Journal of Sound and Vibration

2

b a

2 w 2 w

2w

D 2w 2w

dxdy

U = 2 + 2 + 2 2 2 + 2(1 )

2 0 0 x y

x y

xy

where D= Eh3

12(1 2 )

(15)

is the bending stiffness of the plate. For a particular mode shape, i ( x, y) , the

energy associated with that mode shape is

b a

D 2 i

U i =

2 0 0 x 2

2 i

+

2

y

2 i

+ 2

2

2 i

2

y

2 i

+ 2(1 )

xy

dxdy

(16)

If the plate is subdivided into Nx subdivisions in the x direction and Ny subdivisions in the y

direction as shown in Figure 2 then the energy associated with sub-region jk for the ith mode is given

by

U ijk =

D jk

2

bk +1 a j +1

bk

aJ

2 i

2

x

2 i

+

2

2 i

+ 2

x 2

2 i

2

y

2 i

+ 2(1 )

xy

dxdy

so

Ny Nx

U i = U ijk

(18)

k =1 j =1

and the fractional energy at location jk is defined to be

F ijk =

U ijk

(19)

Ui

and

Ny Nx

ijk

=1

k =1 j =1

7/37

(20)

(17)

To appear in Journal of Sound and Vibration

Similar expressions can be written using the modes of the damaged structure, i* . Using arguments

similar to the ones used for beam-like structures a ratio of parameters can be determined that is

indicative of the change of stiffness in the structure as shown in Eq. 21-22.

D jk

D*jk

f ijk*

(21)

f ijk

where

bk +1 a j + 1

f ijk =

bk

aJ

ba

(22)

i i

i

+ 2 + 2 2 i 2 i + 2(1 )

dxdy

2

y

x y

xy

0

2

x

0

2 i 2 i

2 2

2 i

2 + 2 + 2 2 i 2 i + 2(1 )

dxdy

x y

x y

xy

2

and an analogous term f ijk* can be defined using the damaged mode shapes. In order to account for

all measured modes, the following formulation for the damage index for sub-region jk is used

m

jk =

*

ijk

i =1

m

f

i =1

(23)

ijk

Once again a normalized damage index can be found using Eq. (14).

3

SIMULATION RESULTS

Both algorithms discussed in the theory section can be applied to detect damage in plate-like

structures. The algorithm derived assuming plate-like behavior (two-dimensional curvature) can be

applied directly. To use the algorithm formulated assuming one-dimensional curvature the structure

must be divided into slices and the algorithm needs to be applied to each slice individually. The

normalized damage index is then determined using the average and standard deviation of all the

8/37

To appear in Journal of Sound and Vibration

damage indices from all the slices. The slicing algorithm is presented here for comparison only,

because that would be the only way to apply the 1-D strain energy method to a plate-like structure. It

is not expected that the slicing algorithm will perform well as it does not preserve the torsional

stiffness between slices. Regardless of the method chosen several additional parameters must be

chosen including the number of modes and the number of subdivisions to be used.

Several sets of simulated data were used to investigate the effectiveness of both approaches in

locating damage in plate-like structures as well as to study the effect of changing the number of

modes and subdivisions. The data were generated using a finite element model of a pinned-pinned

plate with several elements reduced in stiffness to model damage. The finite element mesh is shown

in Fig. 3. The plate was given pinned boundary conditions at y=-300 and y=300. The elements in the

location of reduced stiffness are indicated in Fig. 3. The reduced stiffness was in the region 48<x<96,

and 84<y<132 with the center of the damage being located at x=72, y=108. All the analysis was done

using MATLAB.

The first case studied had the stiffness of four elements reduced by 25%. The results from this case

are shown in Figs. 4-7. In all of these figures the normalized damage index is shown as a 3-D bar

graph with values greater than 2 drawn in a darker color and are the likely locations of damage.

In Fig. 4 the damage index is shown by dividing the structure into slices in the longitudinal direction

of the plate, that is, slices with constant x values, with 20 divisions per slice and using just one

mode. It is clear from Fig. 4 that the algorithm does a fairly good job of locating the damage. The

largest peak in Fig. 4 has its center at a location of (72,105). Increasing the number of modes to five

did not noticeably change the results. In Fig. 5 the number of divisions per slice was increased to 40

and four modes are used. The results did not improve by increasing the divisions and the location of

the damage was found to be roughly the same. When the structure was divided into slices in the

transverse direction (i.e. constant y), 20 divisions/slice and using four modes, the damage was once

again located as shown in Figure 6.

In Figure 7 the damage indices calculated using the algorithm derived for plate-like structures, one

mode, and 20 divisions in each direction, are shown. Once again the damage is located fairly

accurately. The two peaks in Fig. 7 are located at (64.8,105) and (79.2,105). Clearly the choice of the

9/37

To appear in Journal of Sound and Vibration

number of divisions will affect the location of the peak. Once again, increasing the number of

divisions and modes does not significantly improve the results.

An example in which the method of dividing the structure into slices has several problems is

examined in the second set of simulated data. In this case the stiffness was reduced by only 10%. The

results of dividing the structure into longitudinal slices with 20 divisions/slice and using one and four

modes are shown in Fig. 8 and 9 respectively. In this case the region of reduced stiffness was not

located when using just one mode and when additional modes were included the damage indices

were found to be large along the node line of the second natural mode. In Fig. 10-11 the results using

the algorithm for plate-like structures is shown. In Fig. 10 only one mode was used and 20 divisions

were used in both the x and y directions. From Fig. 10 it is clear that the area of reduced stiffness

was not located. In Fig. 11 four modes and 20 divisions in each direction were used in the 2-D

algorithm and clearly the general location of the damage has been identified.

In all of the examples used thus far it was assumed that the mode shapes were known exactly on a

very fine grid of sensors. In actual practice this will obviously not be the case. A reduced set of data

was used to determine how the results change using a coarser grid of sensors. In this case the

stiffness was reduced 25% and the number of sensor locations was reduced from 338 to 56. The

results from dividing the structure into longitudinal slices with 20 divisions/slice and using four

modes are shown in Figure 12. Once again, when more than one mode is used, the algorithm

incorrectly identified damage as being along a node line. Also, the resolution of this method is

clearly limited by the number of slices that are available. Results from using the algorithm for 2-D

curvature with four modes and 20 divisions in each direction are shown in Fig. 13 and the general

area of the damage can be clearly seen.

One of the major difficulties associated with implementing the algorithms discussed in this paper

was the calculation of the derivatives and integrals when the mode shape is known at a relatively

small number of discrete locations. In both algorithms additional intermediate points were calculated

by curve-fitting the data. The derivatives and integrals required by the algorithms were then

calculated numerically.

10/37

To appear in Journal of Sound and Vibration

Experimental Setup and Results

To demonstrate the new technique experimentally, a 17 83 "1814 " 83 " aluminum plate was tested

before and after a cut was made at two locations in the plate. The cut was made with a jewelers saw

and each end of the plate was clamped to an air bearing as shown in Figure 14. The use of air

bearings was an attempt to have consistent boundary conditions throughout all the tests. Thirty-one

accelerometers were glued to the plate in the configuration shown in Figure 15. The impact location

is also shown in Figure 15. Sawing diagonally at damage location one as shown in Figure 15

provided the initial damage for the structure. After this first cut additional damage was added to the

plate at a second location, damage location two, as shown in Figure 15. A brief description of the

eight damage cases studied is given in Table 1.

The test equipment used in this study consisted of a Hewlett-Packard (HP) 3566A dynamic data

acquisition system including a model 35650 mainframe, 35653A source module, four 35653A 8channel input modules which provided power for accelerometers and performed the analog to digital

conversion of accelerometer signals, and a 35651C signal processing module that performed the

needed Fast Fourier Transform calculations. A Toshiba Tecra 700CT Laptop was used for data

storage and as a platform for the HP software that is the user interface for the data acquisition

system.

The dynamic range for data acquisition was set by experimenting with different excitation levels and

then setting the range so that response overloads were avoided. Wilcoxen Research model 736T

accelerometers were used for the vibration measurements. This accelerometer has a nominal

sensitivity of 10 mV/g, an operating frequency of about 5 to 15000 Hz, and an amplitude rate of 50

gs. Lengths of MicroDot cable were used to connect the accelerometers to the input modules.

The system samples the analog signal from the accelerometers at approximately 32 kHz (regardless

of the frequency range being analyzed), passes the signal through an analog anti-aliassing filter,

digitizes it, then passes the data though a digital anti-aliassing filter with the cutoff frequency based

upon the Nyquist frequency for the specified sampling parameters. The signal is then decimated

based on the particular sampling parameters.

11/37

To appear in Journal of Sound and Vibration

The data acquisition system was set up to measure acceleration-time histories and a force-time

history of the input, and to calculate the Frequency-Response Functions (FRFs) of these time

histories. Testing parameters were specified as 10 averages discretized with 1024 samples. A force

window was applied to the signal from the impact hammers force transducer and an exponential

window was applied to the signal from the accelerometers. The 1024 time samples yielded 512

spectral points, but because of the rolloff in the anti-aliassing filters, only 401 spectral points are

displayed.

The curve fitting and modal extraction was done using the software program, DIAMOND [12].

Although a variety of methods are available in this code (ERA, rational polynomial, and complex

exponential), the rational polynomial method was the only one used.

The structure was tested several times in an undamaged state and then again after each saw cut. The

strain energy method was applied to the data and the results for are shown in Figure 16, Figure 17,

Figure 18, and Figure 19.

This method clearly identified both damage locations for damaged case 8, but only identified the 1st

damage location for damage case 7. Evidently the change in mode shape curvature due to the damage

at the first location dominated the results until the damage at the 2nd location was roughly

comparable in severity. This indicates that this method has problems identifying multiple damage

locations of different degrees of severity. The smallest case of damage that was identified was

damage case 3. Clearly in damage case 2 the damage is not identified and some false positives

appear at locations other than the damage location. Without prior knowledge there is no way to

determine which is the true damage and which is a false positive.

Overall, the 2-D strain energy method performed comparably to the historical performance of the 1D strain energy method [5]. Specifically, the method showed a propensity for false-positive results

(especially at low levels of damage), but generally performed well as the level of damage increased.

5

CONCLUSIONS

A damage detection algorithm derived for structures whose modes are characterized by onedimensional curvature has been generalized for plate-like structures that are characterized by two12/37

To appear in Journal of Sound and Vibration

dimensional curvature. The method only requires the mode shapes of the structure before and after

damage and the modes do not need to be mass normalized making it very advantageous when using

ambient excitation. The algorithm was found to be effective in locating areas with stiffness

reductions as low as 10% using relatively few modes. The algorithm was also demonstrated

successfully using experimental data.

6

ACKNOWLEDGMENTS

Funding for this research was provided by the Department of Energy through the Los Alamos

National Laboratorys Laboratory Directed Research and Development (LDRD) program.

7

[1]

REFERENCES

S.W. Doebling, C.R. Farrar, and M.B. Prime 1998 The Shock and Vibration Digest, 30(2),

91-105. A Summary Review of Vibration-Based Damage Identification Methods.

[2]

A.K. Pandey, M. Biswas, and M.M. Samman 1994 Journal of Sound and Vibration, 154(2),

321-332. Damage Detection from Changes in Curvature Mode Shapes.

[3]

N. Stubbs, J.-T. Kim and K. Topole 1992 Proceedings of the ASCE Tenth Structures

Congress, 543-546. An Efficient and Robust Algorithm for Damage Localization in Offshore

Platforms.

[4]

N. Stubbs, J.-T. Kim, and C. R. Farrar 1995 Proceedings of the 13th International Modal

Analysis Conference, 210-218. Field Verification of a Nondestructive Damage Localization

and Sensitivity Estimator Algorithm.

13/37

To appear in Journal of Sound and Vibration

[5]

D.V. Jauregui and C.R. Farrar 1996 Proceedings of the 14th International Modal Analysis

Conference, 119-125. Damage Detection Algorithms Applied to Numerical Modal Data from

a Bridge.

[6]

D.V. Jauregui and C.R. Farrar 1996 Proceedings of the 14th International Modal Analysis

Conference, 1423-1429. Comparison of Damage Identification Algorithms on Experimental

Modal Data from a Bridge.

[7]

J. Chance, G.R. Tomlinson, and K Worden 1994 Proceedings of the 12th International

Modal Analysis Conference, 778-785. A Simplified Approach to the Numerical and

Experimental Modeling of the Dynamics of a Cracked Beam.

[8]

I. Kondo and T. Hamamoto 1994 Proceedings of the 4th International Offshore and Polar

Engineering Conference, 4, 400-407. Local Damage Detection of Flexible Offshore

Platforms Using Ambient Vibration Measurements.

[9]

O.S. Salawu and C. Williams 1994 Proceedings of the 12th International Modal Analysis

Conference, 933-939. Damage Location Using Vibration Mode Shapes.

[10]

D.I. Nwosu, A.S.J. Swamidas, J.Y. Guigne, and D.O. Olowokere 1995 Proceedings of the

13th International Modal Analysis Conference, 1122-1128. Studies on Influence of Cracks on

the Dynamic Response of Tubular T-Joints for Nondestructive Evaluation.

[11]

D. Young 1956 Journal of Applied Mechanics, 448-453. Vibration of Rectangular Plates by

the Ritz Method.

14/37

To appear in Journal of Sound and Vibration

[12]

S.W. Doebling, C.R. Farrar, and P.J. Cornwell 1997 Proc. of Sixth International Conference

on Recent Advances in Structural Dynamics, 399-412. DIAMOND: A graphical user

interface toolbox for comparative modal analysis and damage identification.

15/37

To appear in Journal of Sound and Vibration

FIGURE AND TABLES

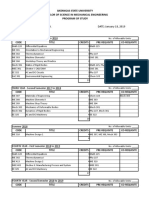

Table 1: Description of the damage cases studied for the plate

Figure 1:-

A schematic illustrating a beams Nd sub-divisions.

Figure 2:--

A schematic illustrating a plates Nx x Ny sub-regions.

Figure 3:- -

Finite element mesh of a pinned-pinned plate with an area of reduced stiffness.

Figure 4:--

Damage index for a plate with a region of 25% reduced stiffness. The plate was

divided into longitudinal slices, 20 divisions per slice, and one mode was used in the

algorithm.

Figure 5:--

Damage index for a plate with a region of 25% reduced stiffness. The plate was

divided into longitudinal slices, 40 divisions per slice, and four modes were used in

the algorithm.

Figure 6:-

Damage index for a plate with a region of 25% reduced stiffness. The plate was

divided into transverse slices, 20 divisions per slice, and four modes were used in the

algorithm.

Figure 7:-

Damage index for a plate with a region of 25% reduced stiffness. The plate was

divided into 20 divisions in each direction and the 2-D algorithm was used with one

mode.

Figure 8:-

Damage index for a plate with a region of 10% reduced stiffness. The plate was

divided into longitudinal slices, 20 divisions per slice, and one mode was used in the

algorithm.

Figure 9:-

Damage index for a plate with a region of 10% reduced stiffness. The plate was

divided into longitudinal slices, 20 divisions per slice, and four modes were used in

the algorithm.

Figure 10:-

Damage index for a plate with a region of 10% reduced stiffness. The plate was

divided into 20 divisions in each direction and the 2-D algorithm was used with one

mode.

Figure 11:-

Damage index for a plate with a region of 10% reduced stiffness. The plate was

divided into 20 divisions in each direction and the 2-D algorithm was used with four

modes.

Figure 12:-

Damage index for a plate with a region of 25% reduced stiffness using a reduced

number of sensors. The plate was divided into longitudinal slices, 20 divisions per

slice, and four modes were used in the algorithm.

16/37

To appear in Journal of Sound and Vibration

Figure 13:-

Damage index for a plate with a region of 10% reduced stiffness. The plate was

divided into 20 divisions in each direction and the 2-D algorithm was used with four

modes.

Figure 15:-

Experimental Schematic of Plate for Damage Identification Tests

Figure 16:-

Experimentally determined damage index for damage case 8. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with 12 modes.

Figure 17:-

Experimentally determined damage index for damage case 7. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with 11 modes.

Figure 18:-

Experimentally determined damage index for damage case 3. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with 12 modes.

Figure 19:-

Experimentally determined damage index for damage case 2. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with 12 modes.

17/37

To appear in Journal of Sound and Vibration

Table 1: Description of the damage cases studied for the plate

Number

Description

1 long cut at location 1

2 long cut at location 1

Cut extends to 1/4 from the edge of the

plate at location 1

Cut is all the way through the edge at

location 1

0.75 cut at location 2

1.75 cut at location 2

Cut extends to 1/4 from the edge of the

plate at location 2

Cut is all the way through the edge at

location 2

18/37

To appear in Journal of Sound and Vibration

...

0

Figure 1:-

Nd

...

aj aj+1

A schematic illustrating a beams Nd sub-divisions.

19/37

To appear in Journal of Sound and Vibration

b

(1,Ny )

(Nx ,Ny )

bk+1

(j,k)

bk

Figure 2:--

(1,1)

...

...

aj

(Nx ,1)

aj+1

A schematic illustrating a plates Nx x Ny sub-regions.

20/37

To appear in Journal of Sound and Vibration

Pinned Edge

Elements with

reduced stiffness

y

300

0

Pinned Edge

-300

-144

144

Figure 3:- - Finite element mesh of a pinned-pinned plate with an area of reduced stiffness.

21/37

To appear in Journal of Sound and Vibration

Damage Index

15

10

5

0

-5

400

200

0

-200

Y

-400

-200

-100

100

200

Figure 4:-- Damage index for a plate with a region of 25% reduced stiffness. The plate was divided

into longitudinal slices, 20 divisions per slice, and one mode was used in the algorithm.

22/37

To appear in Journal of Sound and Vibration

Damage Index

15

10

5

0

-5

400

200

0

-200

Y

-400

-200

-100

100

200

Figure 5:-- Damage index for a plate with a region of 25% reduced stiffness. The plate was divided

into longitudinal slices, 40 divisions per slice, and four modes were used in the

algorithm.

23/37

To appear in Journal of Sound and Vibration

Damage Index

15

10

5

0

-5

400

200

0

-200

Y

Figure 6:-

-400

-200

-100

100

200

Damage index for a plate with a region of 25% reduced stiffness. The plate was divided

into transverse slices, 20 divisions per slice, and four modes were used in the algorithm.

24/37

To appear in Journal of Sound and Vibration

Damage Index

15

10

5

0

-5

400

200

0

-200

Y

Figure 7:-

-400

-200

-100

100

200

Damage index for a plate with a region of 25% reduced stiffness. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with one mode.

25/37

To appear in Journal of Sound and Vibration

Damage Index

6

4

2

0

-2

-4

400

200

0

-200

Y

Figure 8:-

-400

-200

-100

100

200

Damage index for a plate with a region of 10% reduced stiffness. The plate was divided

into longitudinal slices, 20 divisions per slice, and one mode was used in the algorithm.

26/37

To appear in Journal of Sound and Vibration

Damage Index

10

5

0

-5

-10

400

200

0

-200

Y

Figure 9:-

-400

-200

-100

100

200

Damage index for a plate with a region of 10% reduced stiffness. The plate was divided

into longitudinal slices, 20 divisions per slice, and four modes were used in the

algorithm.

27/37

To appear in Journal of Sound and Vibration

Damage Index

4

2

0

-2

-4

400

200

0

-200

Y

-400

-200

-100

100

200

Figure 10:- Damage index for a plate with a region of 10% reduced stiffness. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with one mode.

28/37

To appear in Journal of Sound and Vibration

Damage Index

10

-5

400

200

0

-200

Y

-400

-200

-100

100

200

Figure 11:- Damage index for a plate with a region of 10% reduced stiffness. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with four modes.

29/37

To appear in Journal of Sound and Vibration

Damage Index

-5

-10

400

200

0

-200

Y

-400

-200

-100

100

200

Figure 12:- Damage index for a plate with a region of 25% reduced stiffness using a reduced

number of sensors. The plate was divided into longitudinal slices, 20 divisions per slice,

and four modes were used in the algorithm.

30/37

To appear in Journal of Sound and Vibration

Damage Index

6

4

2

0

-2

400

200

0

-200

Y

-400

-200

-100

100

200

Figure 13:- Damage index for a plate with a region of 10% reduced stiffness. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with four modes.

31/37

To appear in Journal of Sound and Vibration

Figure 14:- Experimental Configuration of Plate for Damage Identification Tests

32/37

To appear in Journal of Sound and Vibration

Impact location

Damage Location #2

Accelerometer locations

17 3/8

Damage Location #1

Figure 15:- Experimental Schematic of Plate for Damage Identification Tests

33/37

To appear in Journal of Sound and Vibration

Figure 16:- Experimentally determined damage index for damage case 8. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with 12 modes.

34/37

To appear in Journal of Sound and Vibration

Figure 17:- Experimentally determined damage index for damage case 7. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with 11 modes.

35/37

To appear in Journal of Sound and Vibration

Figure 18:- Experimentally determined damage index for damage case 3. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with 12 modes.

36/37

To appear in Journal of Sound and Vibration

Figure 19:- Experimentally determined damage index for damage case 2. The plate was divided

into 20 divisions in each direction and the 2-D algorithm was used with 12 modes.

37/37

Вам также может понравиться

- Mechanics of Composite BeamsДокумент21 страницаMechanics of Composite BeamskhazarhayatОценок пока нет

- MAC13Документ16 страницMAC13rompnadegasОценок пока нет

- Bertero Bozorgnia, Paper Damage Spectrum.Документ8 страницBertero Bozorgnia, Paper Damage Spectrum.mariocp310Оценок пока нет

- Finite Element With No FORTRANДокумент84 страницыFinite Element With No FORTRANNora MostafaОценок пока нет

- Analysis of Truss-Cable StructuresДокумент9 страницAnalysis of Truss-Cable StructuresKtk ZadОценок пока нет

- 1994 - SCHARDT - Generalized Beam Theory - An Adequate Method For Couple Stability ProblemsДокумент20 страниц1994 - SCHARDT - Generalized Beam Theory - An Adequate Method For Couple Stability ProblemsJanaína Souza AlvesОценок пока нет

- Shear Band Formation in Granular Materials: A Micromechanical ApproachДокумент7 страницShear Band Formation in Granular Materials: A Micromechanical ApproachgeoanagoОценок пока нет

- Flexural Analysis of Thick Beams Using Single Variable Shear Deformation TheoryДокумент13 страницFlexural Analysis of Thick Beams Using Single Variable Shear Deformation TheoryIAEME PublicationОценок пока нет

- Determination of Dipping Contacts UsingДокумент20 страницDetermination of Dipping Contacts UsingRoland Rawlins IgaborОценок пока нет

- The Variation of The Modal Propagation Constant With Temperature in Coupled Bent Optical FibersДокумент5 страницThe Variation of The Modal Propagation Constant With Temperature in Coupled Bent Optical Fibersebi1205Оценок пока нет

- Dynamic Analysis of A Planar Rigid-Link Mechanism WithДокумент11 страницDynamic Analysis of A Planar Rigid-Link Mechanism Withyangee1201Оценок пока нет

- Piezoelectric MaterialДокумент12 страницPiezoelectric MaterialanandadiОценок пока нет

- Hutchinson Fracture Delamination of Beams Under Transverse Shear and BendingДокумент10 страницHutchinson Fracture Delamination of Beams Under Transverse Shear and BendingTashi MalhotraОценок пока нет

- Energy BasedДокумент13 страницEnergy BasedEdy GalvisОценок пока нет

- On The Relative and Absolute Transmissibility of A Vibration Isolation System Subjected To Base ExcitationДокумент10 страницOn The Relative and Absolute Transmissibility of A Vibration Isolation System Subjected To Base ExcitationNaveen SaharanОценок пока нет

- Describing Functions For Effective StiffnessДокумент11 страницDescribing Functions For Effective Stiffnessryan rakhmat setiadiОценок пока нет

- 3 AnnДокумент16 страниц3 AnnDilleswararao ChintalaОценок пока нет

- Dynamics of Cracked BeamsДокумент4 страницыDynamics of Cracked BeamsPrakash InturiОценок пока нет

- Estimation of Response of 2-DOF RCC Base Isolated Building To Earthquake LoadingДокумент9 страницEstimation of Response of 2-DOF RCC Base Isolated Building To Earthquake LoadingRamana ReddyОценок пока нет

- Article SUR CHAMP MAGNETIQUEДокумент10 страницArticle SUR CHAMP MAGNETIQUEpape diopОценок пока нет

- LW1 Test ExampleДокумент4 страницыLW1 Test ExampleBalta AndreiОценок пока нет

- Smart Materials and Structures: International WorkshopДокумент10 страницSmart Materials and Structures: International WorkshopPartha SarathiiОценок пока нет

- Extended Abstract (R)Документ3 страницыExtended Abstract (R)Eshwar G PawarОценок пока нет

- Stability Analysis of Composite Panels With Stiffeners and Circular CutoutsДокумент13 страницStability Analysis of Composite Panels With Stiffeners and Circular CutoutsSaad Al HelyОценок пока нет

- Sensors 18 01307 v2Документ18 страницSensors 18 01307 v2Harshal NejkarОценок пока нет

- Energy PDFДокумент20 страницEnergy PDFVictorTintayaMedinaОценок пока нет

- Analytical Solution For Static Analysisof Composite Laminates Induced by Piezoelectric ActuatorsДокумент6 страницAnalytical Solution For Static Analysisof Composite Laminates Induced by Piezoelectric Actuatorsbluemoon1172Оценок пока нет

- Sensors: Effect of External Vibration On PZT Impedance SignatureДокумент14 страницSensors: Effect of External Vibration On PZT Impedance SignatureSai SivaОценок пока нет

- Analysis of Tapered Beam Piezoelectric Energy HarvestersДокумент4 страницыAnalysis of Tapered Beam Piezoelectric Energy HarvestersshikhamaharanaОценок пока нет

- AFLДокумент4 страницыAFLoadipphone7031Оценок пока нет

- EMI TechniqueДокумент0 страницEMI Techniqueluvjoshi1989Оценок пока нет

- Vibration Energy Harvesting Using Single and Comb-Shaped Piezoelectric Beam Structures: Modeling and SimulationДокумент7 страницVibration Energy Harvesting Using Single and Comb-Shaped Piezoelectric Beam Structures: Modeling and SimulationAmir JoonОценок пока нет

- Structural Analysis: Worsak Kanok-NukulchaiДокумент9 страницStructural Analysis: Worsak Kanok-NukulchaiAdam ZulkifliОценок пока нет

- Response Spectrum: Ahmed ElgamalДокумент20 страницResponse Spectrum: Ahmed ElgamalAnonymous 5VwQ0KC3Оценок пока нет

- Soil - Structure Interaction & Foundations VibrationsДокумент53 страницыSoil - Structure Interaction & Foundations Vibrationscasanovavn100% (1)

- Short Pile DesignДокумент9 страницShort Pile DesignScooby Doo100% (1)

- Journal of Mechanical Engineering Science 1978 Rao 271 82Документ13 страницJournal of Mechanical Engineering Science 1978 Rao 271 82mehtabpathanОценок пока нет

- Comparative Study of Air-Core and CoaxialДокумент15 страницComparative Study of Air-Core and CoaxialajaykumarОценок пока нет

- RRCM 0003Документ21 страницаRRCM 0003Rahul N SagarОценок пока нет

- Estimation of Peak Roof Displacement of Degrading StructuresДокумент10 страницEstimation of Peak Roof Displacement of Degrading StructuresFawad NajamОценок пока нет

- A 3D FDTD Code Implemented in MATLABДокумент38 страницA 3D FDTD Code Implemented in MATLABAli Mhd100% (2)

- Crack Detection in Beam Type Structure Using FrequДокумент37 страницCrack Detection in Beam Type Structure Using FrequjayaОценок пока нет

- Hoa 1979Документ13 страницHoa 1979Ciprian ComanОценок пока нет

- Electric Field Stress Calculation For Different Spacer Types in Bus DuctДокумент6 страницElectric Field Stress Calculation For Different Spacer Types in Bus DuctijsretОценок пока нет

- Scaling of Optical Forces in Dielectric Waveguides: Rigorous Connection Between Radiation Pressure and DispersionДокумент3 страницыScaling of Optical Forces in Dielectric Waveguides: Rigorous Connection Between Radiation Pressure and DispersionDenis JaissonОценок пока нет

- Seismic Design of Structures With Supplemental Maxwell Model-Based Brace-Damper SystemsДокумент8 страницSeismic Design of Structures With Supplemental Maxwell Model-Based Brace-Damper SystemsDac PiОценок пока нет

- Finite Element Analysis of A Cracked Cantilever Beam: Research PaperДокумент5 страницFinite Element Analysis of A Cracked Cantilever Beam: Research PaperSanketОценок пока нет

- 8NCEE Vargas BruneauДокумент10 страниц8NCEE Vargas BruneauJuan Pablo Lemus IbacacheОценок пока нет

- Mutual Inductance and Force Exerted Between Thick Coil Slobodan Babic PIER - 102 - HALДокумент15 страницMutual Inductance and Force Exerted Between Thick Coil Slobodan Babic PIER - 102 - HALcristian1961Оценок пока нет

- CM A04 MauPoudelДокумент30 страницCM A04 MauPoudelCarolina RibeiroОценок пока нет

- Capacity Spectra For Lead Rubber Bearing Capacity Spectra For Lead Rubber Bearing Seismic Isolation SystemsДокумент8 страницCapacity Spectra For Lead Rubber Bearing Capacity Spectra For Lead Rubber Bearing Seismic Isolation SystemsDoby KamburovaОценок пока нет

- CH 10Документ25 страницCH 10Mohammed AliОценок пока нет

- Stiffness and Mass RatioДокумент9 страницStiffness and Mass RatioMahnooranjumОценок пока нет

- Modeling of Large Deformations of Hyperelastic MaterialsДокумент4 страницыModeling of Large Deformations of Hyperelastic MaterialsSEP-PublisherОценок пока нет

- Numerical Fracture MechanicsДокумент4 страницыNumerical Fracture Mechanicsg401992Оценок пока нет

- Integrated Imaging of the Earth: Theory and ApplicationsОт EverandIntegrated Imaging of the Earth: Theory and ApplicationsMax MoorkampОценок пока нет

- Method of Moments for 2D Scattering Problems: Basic Concepts and ApplicationsОт EverandMethod of Moments for 2D Scattering Problems: Basic Concepts and ApplicationsОценок пока нет

- Electron Beam-Specimen Interactions and Simulation Methods in MicroscopyОт EverandElectron Beam-Specimen Interactions and Simulation Methods in MicroscopyОценок пока нет

- An Alternative Assumed Strain Method: Luo Yunhua, Anders ErikssonДокумент15 страницAn Alternative Assumed Strain Method: Luo Yunhua, Anders ErikssonRamprasad SrinivasanОценок пока нет

- Certification of Engine Usage Monitoring SystemsДокумент12 страницCertification of Engine Usage Monitoring SystemsRamprasad SrinivasanОценок пока нет

- SD Article 6Документ4 страницыSD Article 6Ramprasad SrinivasanОценок пока нет

- Structural Response of Composite BeamsДокумент28 страницStructural Response of Composite BeamsRamprasad SrinivasanОценок пока нет

- 451Документ30 страниц451Ramprasad SrinivasanОценок пока нет

- Lessons Learned During Solutions of Multidisciplinary Design Optimization ProblemsДокумент8 страницLessons Learned During Solutions of Multidisciplinary Design Optimization ProblemsRamprasad SrinivasanОценок пока нет

- Extraction of Ritz Vectors Using A Complete Flexibility MatrixДокумент6 страницExtraction of Ritz Vectors Using A Complete Flexibility MatrixRamprasad SrinivasanОценок пока нет

- Akbar and BirbalДокумент1 страницаAkbar and BirbalRamprasad SrinivasanОценок пока нет

- SD Article 2Документ15 страницSD Article 2Ramprasad SrinivasanОценок пока нет

- Appendix B A Review of State-of-the-Art Techniques For Real-Time Damage Assessment of BridgesДокумент25 страницAppendix B A Review of State-of-the-Art Techniques For Real-Time Damage Assessment of BridgesRamprasad SrinivasanОценок пока нет

- NASA 2001 Ices SCFДокумент6 страницNASA 2001 Ices SCFRamprasad SrinivasanОценок пока нет

- 9701wel1 PDFДокумент5 страниц9701wel1 PDFrs0004Оценок пока нет

- 2990 Bombardier Success StoryДокумент4 страницы2990 Bombardier Success StoryRamprasad SrinivasanОценок пока нет

- Cooper 1Документ24 страницыCooper 1sumatrablackcoffee453Оценок пока нет

- Least SquaresДокумент163 страницыLeast SquaresRamprasad SrinivasanОценок пока нет

- Substructural Identi®cation Using Neural Networks: Chung-Bang Yun, Eun Young BahngДокумент12 страницSubstructural Identi®cation Using Neural Networks: Chung-Bang Yun, Eun Young BahngRamprasad SrinivasanОценок пока нет

- A Neural Network For Structural Re-Analysis: W.M. JenkinsДокумент12 страницA Neural Network For Structural Re-Analysis: W.M. JenkinsRamprasad SrinivasanОценок пока нет

- Corresponding AuthorДокумент20 страницCorresponding AuthorRamprasad SrinivasanОценок пока нет

- Neural Network Design For Engineering Applications: M.Y. Ra®q, G. Bugmann, D.J. EasterbrookДокумент12 страницNeural Network Design For Engineering Applications: M.Y. Ra®q, G. Bugmann, D.J. EasterbrookRamprasad SrinivasanОценок пока нет

- Neural Networks in Mechanics of Structures and Materials New Results and Prospects of ApplicationsДокумент16 страницNeural Networks in Mechanics of Structures and Materials New Results and Prospects of ApplicationsRamprasad SrinivasanОценок пока нет

- Application of Neural Networks To The Seismic Analysis of StructuresДокумент11 страницApplication of Neural Networks To The Seismic Analysis of StructuresRamprasad SrinivasanОценок пока нет

- 00377970Документ9 страниц00377970Ramprasad SrinivasanОценок пока нет

- NNFTДокумент9 страницNNFTRamprasad SrinivasanОценок пока нет

- IMAC00 Unsupervised PDFДокумент7 страницIMAC00 Unsupervised PDFrs0004Оценок пока нет

- Acrm PDFДокумент17 страницAcrm PDFrs0004Оценок пока нет

- 306Документ14 страниц306Sam SamouraОценок пока нет

- Non-Local Continuum Mechanics and Fractional Calculus: K.A. LazopoulosДокумент5 страницNon-Local Continuum Mechanics and Fractional Calculus: K.A. Lazopoulosrs0004Оценок пока нет

- Applied Neural Networks For Predicting Approximate Structural Response Behavior Using Learning and Design ExperienceДокумент15 страницApplied Neural Networks For Predicting Approximate Structural Response Behavior Using Learning and Design ExperienceRamprasad SrinivasanОценок пока нет

- Comparative Damid Part2Документ12 страницComparative Damid Part2Ramprasad SrinivasanОценок пока нет

- Additional Mathematics Project Work 2014 (Sabah)Документ16 страницAdditional Mathematics Project Work 2014 (Sabah)Shelyn HiewОценок пока нет

- Three Phase Transformer TrainerДокумент20 страницThree Phase Transformer TrainerHaroon AsadОценок пока нет

- FRM Course Syl Lab Us Ip DownloadДокумент2 страницыFRM Course Syl Lab Us Ip DownloadYatish PujaraОценок пока нет

- UNIT 8 ThermodynamicsДокумент9 страницUNIT 8 ThermodynamicsHimadhar SaduОценок пока нет

- Simplified Feynman DiagramsДокумент23 страницыSimplified Feynman Diagramssid_senadheera50% (2)

- Indian Standard: Application Guide For Voltage Transformers (Документ16 страницIndian Standard: Application Guide For Voltage Transformers (Pardeep KhosaОценок пока нет

- Phy122 Em1 2023Документ1 страницаPhy122 Em1 2023Resego lentsweОценок пока нет

- Liquid Vapor EquilibriumДокумент4 страницыLiquid Vapor EquilibriumDoge WoweОценок пока нет

- Sci 09 Sample QPДокумент8 страницSci 09 Sample QPkvindhraОценок пока нет

- Installation Operation & Maintenance of 33kV & 11kV SwitchgearДокумент23 страницыInstallation Operation & Maintenance of 33kV & 11kV SwitchgearSaff MdОценок пока нет

- Economic Operation of Power SystemДокумент45 страницEconomic Operation of Power SystemDogbey BrightОценок пока нет

- 1988 Analysis and Design of Single Pole Transmission StructureДокумент12 страниц1988 Analysis and Design of Single Pole Transmission StructureChandara KOEMОценок пока нет

- Precise Finite-Element Model For Pulleys Based On The Hamiltonian Form of ElasticityДокумент13 страницPrecise Finite-Element Model For Pulleys Based On The Hamiltonian Form of ElasticityShamik ChowdhuryОценок пока нет

- Changes That Matter Undergoes: Physical and Chemical ChangeДокумент10 страницChanges That Matter Undergoes: Physical and Chemical ChangeKaye Jean VillaОценок пока нет

- Transmission Electron Microscopy and Its ApplicationsДокумент12 страницTransmission Electron Microscopy and Its ApplicationsMoayad TeimatОценок пока нет

- Discovery of New ElementsДокумент5 страницDiscovery of New ElementsTyler DickinsonОценок пока нет

- شيت مختبر الاسس PDFДокумент23 страницыشيت مختبر الاسس PDFMohamad AlhadithyОценок пока нет

- How To Build A BombДокумент11 страницHow To Build A Bombgpduf100% (1)

- United States Patent (19) : SSNSN SnssnsДокумент6 страницUnited States Patent (19) : SSNSN SnssnsMihai RobertОценок пока нет

- LT 3 - Nuclear ChemДокумент2 страницыLT 3 - Nuclear Chemaj eneriaОценок пока нет

- Strength of Material 2Документ12 страницStrength of Material 2mjdalenezi100% (1)

- CUMBIA Theory and User GuideДокумент44 страницыCUMBIA Theory and User GuideSiul OnarbmazОценок пока нет

- A Comparison of Finite Element Slope Stability AnalysisДокумент8 страницA Comparison of Finite Element Slope Stability AnalysisYoseph BirruОценок пока нет

- Performance of Heat ExchangersДокумент10 страницPerformance of Heat ExchangersJusztinAquinoОценок пока нет

- PosДокумент3 страницыPosAndre De VillaОценок пока нет

- Enthuse SRG TEST-8 FinalДокумент26 страницEnthuse SRG TEST-8 FinalremorevdrakeОценок пока нет

- Rinsing - A Critical Process in Contamination RemovalДокумент6 страницRinsing - A Critical Process in Contamination Removalfreebee12345Оценок пока нет

- Science 2004Документ5 страницScience 2004yilongwei.comОценок пока нет

- FSI Manuscript Rev05Документ9 страницFSI Manuscript Rev05ADITYA SINGH PATELОценок пока нет

- Light Emitting Diode (LED) - Working, Construction and Symbol - DiodeДокумент19 страницLight Emitting Diode (LED) - Working, Construction and Symbol - DiodehavejsnjОценок пока нет