Академический Документы

Профессиональный Документы

Культура Документы

Wire Bond Encapsula1on For The CMS Forward Pixel Upgrade

Загружено:

Sam Higginbotham0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров1 страницаAPS poster that describes the encapsulation of wirebonds for the CMS forward pixel phase 1 Upgrade.

Оригинальное название

WirebondEncapsulationPosterV3

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документAPS poster that describes the encapsulation of wirebonds for the CMS forward pixel phase 1 Upgrade.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров1 страницаWire Bond Encapsula1on For The CMS Forward Pixel Upgrade

Загружено:

Sam HigginbothamAPS poster that describes the encapsulation of wirebonds for the CMS forward pixel phase 1 Upgrade.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

Wire

Bond Encapsula1on for the CMS

Forward Pixel Upgrade

Introduc1on

The pixel detectors used in the CMS experiment at

CERN will be replaced by an upgraded detector

system in 2016. Modules consis=ng of a pixel sensor

and 16 readout chips are being assembled at Purdue

with electrical connec=ons to the support circuits

made using aluminum wire bonds. We have

developed a process to encapsulate these wire

bonds in a silicone compound to provide mechanical

protec=on and to prevent electroly=c corrosion.

Presented here are the techniques developed for

deposi=ng this viscous compound with a precision of

100 m.

Module Assembly

Purdue is responsible for delivering at least 500

modules for the phase-1 upgrade of the CMS

detector. These modules consist of an array of silicon

pixels (sensor) that are bump-bonded to silicon read

out chips (ROCs) and glued to a high density

interconnect (HDI) circuit. There are 560 wire bonds

that make electrical connec=ons between the ROCs

and the HDI on each module.

HDI

Sensor

ROCs

Figure 1: Forward pixel detector module stack up.

A Devoltek F&K 6400 ultrasonic wire bonder is used

with 38 m wire to place the wire bonds. Sylgard

186, a silicone based elastomer, is used to

encapsulate the wire bonds. Sylgard is a very viscous

polymer before curing, and aber curing has

exibility, high shear strength, and excellent

dielectric proper=es.

Equipment

To encapsulate at the 100 m precision, Purdue uses

an Aerotech AGS10000 robo=c gantry system which

is capable of 1 m posi=oning precision over large

distances. An Edmund OpAcs machine vision camera

with 2560 x 1920 resolu=on is used to index the wire

bonds to the gantry.

Figure 2: Indexing the last wire bond of a line.

The cameras precision allows the operator to gather

posi=ons of wire bonds in any congura=on in all

three dimensions. To deposit the encapsulant at high

pressure, an EFD UlAmus V pressure control

dispenser with pressure mul=plier is used.

Sam

Higginbotham

Prof.

MaIhew

Jones

Purdue

High

Energy

Physics

Precision Dispensing

Purdue takes advantage of the gantrys precision by

xing a 150 micron inner diameter dispensing =p to

an EFD dispensing pressure mul=plier mounted on

the gantry head. To interface with the hardware, a

LabVIEW program performs the vector algebra to

systema=cally deposit encapsulant with enough

degrees of freedom to account for variance of parts

and posi=ons.

Figure 3: Token bit manager encapsula=on

The Token Bit Manager (TBM) is a custom integrated

circuit on the HDI that is responsible for coordina=ng

readout of data from the ROCs. Wire bonds on the

TBM are placed at Fermilab and are encapsulated at

Purdue. The geometry of the chip poses a challenge

for encapsula=on because of the ne pitch of the

wires. We prefer to encapsulate only the feet of the

wire bonds which achieves the main objec=ves while

avoiding encapsulant encroaching on unwanted

places. For example, encapsulant seeping into the

gap between the sensor and a ROC has been seen to

slightly alter the electrical proper=es of the pixels

that are in contact with the encapsulant.

The mo=on of the dispensing =p is piecewise linear

and the LabVIEW program is used to acquire points

along its path from the absolute coordinate system

of the gantry. With the precise op=cs of the gantry,

a 3D point can be measured with the XY posi=ons

based on the image and the Z posi=on from the

focus of the Camera. In conjunc=on with the

acquired posi=ons of the wire bond feet, a CAD

model of the part is used to deposit encapsulant in 8

sets of 35 bonds in a single opera=on. Movements

such as retrac=ng, shown below, are used to ensure

an even glue deposi=on.

5 mm

0.75mm

6.5 mm

Figure 4: Needle retract movement (not to scale)

Figure 5: ROC to HDI encapsula=on results

Benets of Encapsula1on

For the CMS Forward Pixel detectors, there are three

main reasons for encapsula=on:

Mechanical protec=on

Preven=on of electroly=c corrosion

Resonance damping

The encapsulant provides mechanical protec=on for

the wire bonds, ensuring the longevity of the part

once it has been installed at the center of the CMS

detector, where access is imprac=cal.

The encapsulant also prevents water and other

electroly=c catalysts from accelera=ng the entropic

corrosion process [1].

Figure 6: Wire bond resonance from Lorentz force

and wire bond breaking at the heel.

Forced harmonic oscilla=ons in the wire bonds can

result from currents on some wire bonds in the

presence of the 3.8 Tesla magne=c eld used in CMS

[2]. Periodic currents at a resonant frequency can

result in large amplitude mechanical vibra=ons

which could eventually result in bond failures, as

shown in Figure 6 [3]. The encapsulant damps these

resonances, preven=ng large amplitude vibra=ons

from developing.

Conclusion

We have developed a process for the selec=ve

encapsula=on of wire bonds used in the phase-1

upgrade of the CMS forward pixel detector. Using an

Aerotech robo=c gantry system, Purdue can

encapsulate a module with 100 m precision in

approximately 20 minutes. Encapsula=on provides

mechanical protec=on, prevents electroly=c

corrosion, and damps mechanical vibra=ons. This

process will be used throughout 2015 in the

produc=on of approximately 500 sensor modules.

References

1.

2.

3.

D.R. Sparks, Chemically-accelerated corrosion tests for

aluminum metallized ICs. Thin Solid Films 235 (1993) 108-111.

S. Chatrchyan, et al. (CMS collabora=on.) The CMS experiment

at the CERN LHC, JINST 3 (2008) S08004.

G. Bolla, et al., Wire-bonds failures Induced by resonant

vibraAons in the CDF silicon detector. IEEE NSS 3 (2003)

1641-1645.

Вам также может понравиться

- Solution To Einstein Equations For Perfect Fluid in Circularly Symmetric 2+1 D MetricДокумент14 страницSolution To Einstein Equations For Perfect Fluid in Circularly Symmetric 2+1 D MetricSam HigginbothamОценок пока нет

- 07 Bubble BreakДокумент25 страниц07 Bubble BreakWeb LogueandoОценок пока нет

- 3d Floorplanning - ReviewPaperДокумент6 страниц3d Floorplanning - ReviewPaperMayank ChoudharyОценок пока нет

- Busbar Protection - A ReviewДокумент5 страницBusbar Protection - A ReviewPrajiWazharyОценок пока нет

- Optical Ring-Coupler Simulation Using CST MICROWAVE STUDIOДокумент3 страницыOptical Ring-Coupler Simulation Using CST MICROWAVE STUDIONgô Cự MạnhОценок пока нет

- Application in Mobile CommДокумент4 страницыApplication in Mobile CommAnandita MalikОценок пока нет

- Reliability Assessment of Delamination in Chip-to-Chip Bonded MEMS PackagingДокумент26 страницReliability Assessment of Delamination in Chip-to-Chip Bonded MEMS Packagingshruthig29111988Оценок пока нет

- 1 s2.0 S0924424795011935 MainДокумент7 страниц1 s2.0 S0924424795011935 MainGuillem RoperОценок пока нет

- CST Flyer EMC Web RfmsДокумент4 страницыCST Flyer EMC Web Rfmsfahadned5717Оценок пока нет

- 10-Gbps 5.3-MW Optical Transmitter and Receiver Circuits in 40-Nm CMOSДокумент19 страниц10-Gbps 5.3-MW Optical Transmitter and Receiver Circuits in 40-Nm CMOSali hadi amhazОценок пока нет

- A MMW Perpendicular Coax-To-microstrip TransitionДокумент4 страницыA MMW Perpendicular Coax-To-microstrip Transitionagmnm1962Оценок пока нет

- EMC Design and Interconnection Techniques: Cable Routing and ConnectionДокумент27 страницEMC Design and Interconnection Techniques: Cable Routing and ConnectionMurali MohanОценок пока нет

- Energies 14 02477 v2Документ29 страницEnergies 14 02477 v2Hasmat MalikОценок пока нет

- Mems For Sysem On Chip ConectivtetyДокумент29 страницMems For Sysem On Chip ConectivtetyPrashanth Kumar KodamОценок пока нет

- Pnas 201219068siДокумент7 страницPnas 201219068siSneider LandinezОценок пока нет

- Optimization of Guard Ring Structures To Improve Latchup Immunity in An 18 V DDDMOS ProcessДокумент6 страницOptimization of Guard Ring Structures To Improve Latchup Immunity in An 18 V DDDMOS ProcessKEVIN CHENОценок пока нет

- Finite Element Modeling of Capacitive Micromachined Ultrasonic TransducersДокумент10 страницFinite Element Modeling of Capacitive Micromachined Ultrasonic TransducersCesar ManОценок пока нет

- Introduction To Common Printed Circuit Transmission Lines: Guiding The WaveДокумент6 страницIntroduction To Common Printed Circuit Transmission Lines: Guiding The WaveHabib Ur RehmanОценок пока нет

- Antenna Ratio Definition For Vlsi Circuits Plasma Etch DamageДокумент5 страницAntenna Ratio Definition For Vlsi Circuits Plasma Etch DamageShin Tsz JianОценок пока нет

- Next Generation VLSI CircuitsДокумент5 страницNext Generation VLSI CircuitssudhaaishОценок пока нет

- Brooke ThesisДокумент4 страницыBrooke Thesismaritzapetersonpaterson100% (2)

- Efecto PielДокумент9 страницEfecto PielMilena AlarconОценок пока нет

- Design of A PCB Rogowski Coil Based On The PEEC MethodДокумент7 страницDesign of A PCB Rogowski Coil Based On The PEEC MethodNacho NavajasОценок пока нет

- Use of Nano-Mechanical Relays For FPGA Power ReductionДокумент6 страницUse of Nano-Mechanical Relays For FPGA Power ReductionMegha Gupta ChaudharyОценок пока нет

- Smart Pixel ArraysДокумент25 страницSmart Pixel ArraysSupriya Nagane-Gaikwad100% (1)

- Design of A CMOS Tapered Cascaded Multistage Distributed AmplifierДокумент10 страницDesign of A CMOS Tapered Cascaded Multistage Distributed Amplifierindresh.vermaОценок пока нет

- 2014 MR - Metal-Layer Capacitors in The 65 NM CMOS Process and The Application For Low-Leakage Power-Rail ESD Clamp CircuitДокумент7 страниц2014 MR - Metal-Layer Capacitors in The 65 NM CMOS Process and The Application For Low-Leakage Power-Rail ESD Clamp CircuitspaulsОценок пока нет

- Research Paper On Power System ProtectionДокумент5 страницResearch Paper On Power System Protectioniakoasulg100% (1)

- The Last BarrierДокумент13 страницThe Last BarrierGdv Santhosh KumarОценок пока нет

- Fail Safe Operation of Audio Frequency Track Circuits For Railway SignallingДокумент6 страницFail Safe Operation of Audio Frequency Track Circuits For Railway SignallingKrittapop SaleechanОценок пока нет

- Iot Based Underground Cable Fault Detector: Mr. N. SampathrajaДокумент11 страницIot Based Underground Cable Fault Detector: Mr. N. SampathrajaOladipo David OluwablessmeОценок пока нет

- Cable Harness EMC EMI FinalДокумент7 страницCable Harness EMC EMI FinalSerci35Оценок пока нет

- Complex Antenna System Simulation Uses EM Software: ElectronicsДокумент4 страницыComplex Antenna System Simulation Uses EM Software: Electronicshamid_arjmandОценок пока нет

- Optimal Positions of Twists in Global On-Chip Differential InterconnectsДокумент9 страницOptimal Positions of Twists in Global On-Chip Differential InterconnectsSudhakar SpartanОценок пока нет

- ACES Journal February 2011 Paper 06Документ10 страницACES Journal February 2011 Paper 06yasmineОценок пока нет

- Loosely Coupled Wireless Charging of Footwear-Based Sensor SystemДокумент3 страницыLoosely Coupled Wireless Charging of Footwear-Based Sensor SystemVI VekОценок пока нет

- Simulation of Automotive EMC Emission Test Procedures Based On Cable Bundle MeasurementsДокумент4 страницыSimulation of Automotive EMC Emission Test Procedures Based On Cable Bundle MeasurementsSajid NaseebОценок пока нет

- 10 - 2015 - FIO - Experimental Investigation of A Nanoplasmonic Air-Slot Coupler Toward Dense Optical Integrated CircuitsДокумент2 страницы10 - 2015 - FIO - Experimental Investigation of A Nanoplasmonic Air-Slot Coupler Toward Dense Optical Integrated CircuitsRami WahshehОценок пока нет

- Iot Based Underground Cable Fault Detector: Mr. N. SampathrajaДокумент11 страницIot Based Underground Cable Fault Detector: Mr. N. SampathrajaRenu RaiОценок пока нет

- Andre Carpenter 02072014 Tracked VersionДокумент6 страницAndre Carpenter 02072014 Tracked VersionnikhatskhanОценок пока нет

- Grounded Coplanar Waveguide With Coaxial Transition 39Документ4 страницыGrounded Coplanar Waveguide With Coaxial Transition 39CNEMWОценок пока нет

- Design Challenges in Subthreshold Interconnect CircuitsДокумент19 страницDesign Challenges in Subthreshold Interconnect CircuitsshastryОценок пока нет

- VLSI: Techniques For Efficient Standard Cell Placement: Aditi Malik Deepak Kumar Arora Sanjay KumarДокумент5 страницVLSI: Techniques For Efficient Standard Cell Placement: Aditi Malik Deepak Kumar Arora Sanjay KumarKumar KumarОценок пока нет

- Modeling and Simulation of Next-Generation Multimode Fiber LinksДокумент14 страницModeling and Simulation of Next-Generation Multimode Fiber LinksDeepihaОценок пока нет

- Clamp-Force Estimation For A Brake-by-Wire System: A Sensor-Fusion ApproachДокумент10 страницClamp-Force Estimation For A Brake-by-Wire System: A Sensor-Fusion ApproachHsan HaddarОценок пока нет

- An Intensity-Based Optical Fibre Sensor For Fatigue Damage Detection in Advanced Fibre-Reinforced CompositesДокумент9 страницAn Intensity-Based Optical Fibre Sensor For Fatigue Damage Detection in Advanced Fibre-Reinforced CompositessreekanthОценок пока нет

- Force Calc BusbarsДокумент7 страницForce Calc BusbarsVimal Puthusseri100% (1)

- Algorithm For Digital Low ImpedanceДокумент8 страницAlgorithm For Digital Low ImpedanceJanen AhujaОценок пока нет

- Reliability Analysis and Optimization of Power-Gated IcsДокумент12 страницReliability Analysis and Optimization of Power-Gated Icskaushik_gupta_4Оценок пока нет

- Distance Relay ModellingДокумент10 страницDistance Relay ModellingpavanrajhrОценок пока нет

- Sensor Design For Leakage Current Measurement On ADSS Fiber-Optic Cable PDFДокумент6 страницSensor Design For Leakage Current Measurement On ADSS Fiber-Optic Cable PDFUdriste DanielОценок пока нет

- The Basics of Fiber OpticsДокумент7 страницThe Basics of Fiber OpticsKishan GuptaОценок пока нет

- Vision Inspection of Wire Bonding Position of Leadframe ICДокумент12 страницVision Inspection of Wire Bonding Position of Leadframe IClive yourdreamОценок пока нет

- Electronic Devices in MTL Annual Report 1998Документ20 страницElectronic Devices in MTL Annual Report 1998tbsuirОценок пока нет

- A 0.35Μm Cmos 1.9Ma Vco-Core With Off-Chip Inductance On Ltcc For System-In-A-Package Solutions Of A 5-Ghz-Wlan TransceiverДокумент4 страницыA 0.35Μm Cmos 1.9Ma Vco-Core With Off-Chip Inductance On Ltcc For System-In-A-Package Solutions Of A 5-Ghz-Wlan TransceiverMohamed SaidОценок пока нет

- Analytical Studies: and TransmissionДокумент10 страницAnalytical Studies: and TransmissionMj Tichy HОценок пока нет

- DVR Based ThesisДокумент5 страницDVR Based Thesistinajordanhuntsville100% (1)

- Practical Evaluation of Fault Countermeasures On An Asynchronous DES Crypto ProcessorДокумент6 страницPractical Evaluation of Fault Countermeasures On An Asynchronous DES Crypto ProcessorVinayak KumarОценок пока нет

- Fiber ObticsДокумент57 страницFiber ObticsMs RawatОценок пока нет

- Noets On ThermodynamicsДокумент94 страницыNoets On ThermodynamicsSam HigginbothamОценок пока нет

- Fresnel and Fraunhofer DiffractionДокумент9 страницFresnel and Fraunhofer DiffractionSam HigginbothamОценок пока нет

- Real Analysis NotesДокумент141 страницаReal Analysis NotesSam Higginbotham100% (4)

- Vector CalcДокумент96 страницVector CalcSam Higginbotham100% (1)

- General Chem BuffersДокумент10 страницGeneral Chem BuffersSam HigginbothamОценок пока нет

- Expert To Novice Presentation Assignment SpecificationsДокумент1 страницаExpert To Novice Presentation Assignment SpecificationsSam HigginbothamОценок пока нет

- Sam Higginbotham PHYS 422: Free OscillationsДокумент2 страницыSam Higginbotham PHYS 422: Free OscillationsSam HigginbothamОценок пока нет

- UNIT1-Demand Management in Supply Chain Demand Planning and ForecastingДокумент20 страницUNIT1-Demand Management in Supply Chain Demand Planning and Forecastingshenbha50% (2)

- Mac On FigДокумент449 страницMac On Figvuk_vucko_vukovicОценок пока нет

- Yohimbine InjectionДокумент1 страницаYohimbine InjectionKasidit SornchaiОценок пока нет

- LSM330DLДокумент54 страницыLSM330DLalexanderОценок пока нет

- Math 9 Textbook AnswersДокумент43 страницыMath 9 Textbook AnswersMehak GillОценок пока нет

- Selecting EquipmentДокумент7 страницSelecting EquipmentZara ShireenОценок пока нет

- Astm Parte 5Документ5 страницAstm Parte 5Jimmy David Espinoza MejiaОценок пока нет

- TFT SDK ManualДокумент107 страницTFT SDK ManualRenier ServenОценок пока нет

- 8051 Serial CommunicationДокумент35 страниц8051 Serial CommunicationSanthosh CricketОценок пока нет

- DPP 01 Periodic Table JH Sir-3576 PDFДокумент5 страницDPP 01 Periodic Table JH Sir-3576 PDFChessОценок пока нет

- Replica User ManualДокумент7 страницReplica User Manualjefz2607Оценок пока нет

- Instant Download Trauma Contemporary Directions in Theory Practice and Research 1st Edition Ebook PDF PDF FREEДокумент33 страницыInstant Download Trauma Contemporary Directions in Theory Practice and Research 1st Edition Ebook PDF PDF FREErichard.rosas835100% (41)

- Programming: Simon ScheideggerДокумент90 страницProgramming: Simon ScheideggerRuben KempterОценок пока нет

- Hemoglobin A1c: A) MES 2-Morpholinoethane Sulfonic Acid B) TRIS Tris (Hydroxymethyl) - AminomethaneДокумент6 страницHemoglobin A1c: A) MES 2-Morpholinoethane Sulfonic Acid B) TRIS Tris (Hydroxymethyl) - Aminomethanejoudi.jou95Оценок пока нет

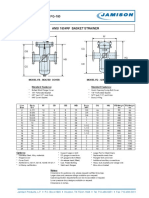

- FB-150 FQ-150 Basket StrainerДокумент1 страницаFB-150 FQ-150 Basket Strainerklich77Оценок пока нет

- Reliability Analysis Center: Practical Considerations in Calculating Reliability of Fielded ProductsДокумент24 страницыReliability Analysis Center: Practical Considerations in Calculating Reliability of Fielded ProductsNg Wei LihОценок пока нет

- All Intervals From G For Guitar (Ear Training Exercise)Документ1 страницаAll Intervals From G For Guitar (Ear Training Exercise)dalcha100% (1)

- Design and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionДокумент4 страницыDesign and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionGoitom HaileОценок пока нет

- Engineering Properties of Soil PDFДокумент55 страницEngineering Properties of Soil PDFJam Apizara Chaizalee100% (1)

- 13 EGWDC 2012 CompresscoДокумент17 страниц13 EGWDC 2012 CompresscoVeky Pamintu100% (1)

- Sensor Gaurd Installation and Maintenance ManualДокумент57 страницSensor Gaurd Installation and Maintenance ManualCapacitacion TodocatОценок пока нет

- Transmission Line TowersДокумент3 страницыTransmission Line TowersSoumik Dandapat100% (2)

- Modern Age Waste Water ProblemsДокумент364 страницыModern Age Waste Water Problemsromaehab201912Оценок пока нет

- 6FM134 XДокумент2 страницы6FM134 XSua Heo100% (1)

- Sc3 Lecture Short CKT Currents BMR Feb.03, 2021Документ11 страницSc3 Lecture Short CKT Currents BMR Feb.03, 2021Khizer AminОценок пока нет

- Ece R13Документ36 страницEce R13DilipReddiarОценок пока нет

- La 3391p Rev0.3novo DesbloqueadoДокумент48 страницLa 3391p Rev0.3novo DesbloqueadoRogeriotabiraОценок пока нет

- Sri Chaitanya: KEY SheetДокумент13 страницSri Chaitanya: KEY SheetMODALAVALASA SRIHARSHAОценок пока нет

- Tarea Stereonet-HelpДокумент32 страницыTarea Stereonet-HelpJosueHuillcaPortilloОценок пока нет