Академический Документы

Профессиональный Документы

Культура Документы

002-MS Nitrogen Filling, Cyrogenic Vaporizer PDF

Загружено:

Köksal PatanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

002-MS Nitrogen Filling, Cyrogenic Vaporizer PDF

Загружено:

Köksal PatanАвторское право:

Доступные форматы

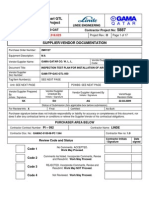

Pearl GTL

Project

LINDE ENGINEERING

Shell Project No: HP-3000-QAT

Project Document Number: T-4.305.139

Purchase Order Number:

2MH127

Tag/Item Number(s):

0E-2091 A

0E-2091 B

0E-2091 C

0E-2091 D

0E-2091 E

0E-2091 F

0E-2091 G

0E-2091 H

0E-2091 J

0E-2091 K

0E-2091 L

0E-2091 M

0E-2091 N

0E-2091 P

0E-2091 R

0E-2091 T

0E-2091 U

0E-2091 V

0E-2091 W

0E-2091 X

Unit(s):

ASU

PCWBS:

Contractor Project No :

Project Rev.: O

0E-2092 A

0E-2092 B

0E-2092 C

0E-2092 D

0E-2092 E

0E-2092 F

0E-2094 A

0E-2094 B

0E-2094 C

0E-2094 D

0E-2094 E

0E-2094 F

0E-2094 G

0E-2094 H

Page 2

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

Issued for Company Comments

OD

MEY

AG

ICC

Issued for Review

OD

MEY

AG

IFR

Issued for Internal Review

OD

MEY

AG

IIR

GAMA

Rev.

Project

Rev

No.

No.

Date

Prepared Checked Approved

By

By

By

Description

Status

ORIGINATOR

Document Title:

METHOD STATEMENT NITROGEN FILLING,

CRYOGENIC VAPORIZER

LINDE ENGINEERING AG

Document No.

Contractor

Gama Qatar Co. W. L. L.

GAM

MTS

PRE

GTL

002

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.305.139

LOC470

Vendor Code

Rev No.: O

Doc. Title

Q A T A R

GAM-MTS-FSI-GTL-002 Rev. C

Method Statement Nitrogen Filling,

Cryogenic Vaporizer

Date/Rev. No :

TABLE OF CONTENTS

1

INTRODUCTION ____________________________________________________________________ 5

1.1

1.2

GENERAL ____________________________________________________________________ 5

SCOPE AND PRECAUTION _______________________________________________________ 5

HSSE ____________________________________________________________________________ 5

REFERENCES _____________________________________________________________________ 6

DEFINITIONS ______________________________________________________________________ 6

RESPONSIBILITIES _________________________________________________________________ 6

5.1

5.2

5.3

5.4

SITE MANAGER _______________________________________________________________

FSI MANAGER ________________________________________________________________

CLEANLINESS & PRESERVATION ENGINEER _________________________________________

LIFT SPECIALIST ______________________________________________________________

RESOURCES ______________________________________________________________________ 7

6.1

EQUIPMENT & MANPOWER _______________________________________________________ 7

6.1.1

6.1.2

7

EQUIPMENT________________________________________________________________ 7

MANPOWER _______________________________________________________________ 8

METHOD OF EXECUTION _____________________________________________________________ 8

7.1

PRE-COMMENCEMENT WORKS ____________________________________________________ 8

7.1.1

7.1.2

7.1.3

8

6

6

7

7

WORK PERMIT _____________________________________________________________ 8

TRAFFIC MANAGEMENT PLAN ________________________________________________ 8

EQUIPMENT AND PERSONNEL________________________________________________ 8

MEASURING AND FILLING PROCEDURE __________________________________________________ 8

8.1

8.2

8.3

GENERAL ____________________________________________________________________ 8

ASSEMBLY AND CHARGING ______________________________________________________ 9

DISASSEMBLY AND DELIVERY ____________________________________________________ 9

QUALITY ASSURANCE ______________________________________________________________ 10

10

ATTACHMENTS ___________________________________________________________________ 10

10.1

10.2

JOB SAFETY ANALYSIS ________________________________________________________ 10

TAGS AND SIGNS (SAMPLE) _____________________________________________________ 10

GAM-MTS-PRE-GTL-002

Page 4 of 10

Doc. Title

Q A T A R

GAM-MTS-FSI-GTL-002 Rev. C

Method Statement Nitrogen Filling,

Cryogenic Vaporizer

Date/Rev. No :

1 INTRODUCTION

1.1 GENERAL

This document describes the methods proposed to be used for checking the pressure of and

filling with nitrogen (as required) of Cryogenic Vaporizer as part of the preservation activities at

ASU area that shall be carried out as part of ASU Construction works of Qatar Shell GTL Plant

(Pearl) in Ras Laffan Industrial City (RLIC) of Qatar including similar works up to the time of

commissioning.

The preservation shall be performed at ASU Area. The nitrogen filling and tagging activities

shall be carried out by GAMA QATAR in coordination with the Contractor.

All parties (LINDE Contractor, GAMA Logistics, Mechanical and FSI disciplines) involved

in the preservation of the Cryogenic Vaporizer will conduct minuted coordination meetings as

required.

1.2 SCOPE AND PRECAUTION

N2 (Nitrogen) is hazardous, especially in confined spaces. All measures will be taken prior to

start of operations.

During the work on and in the vicinity of open flange connections, care will be taken so that

dust and moisture can not get inside the equipment.

Nitrogen filling will be performed by the GAMAs Cleanliness and Preservation Engineer.

The methodology will be presented to the Contractor and will be approved prior to execution.

Wind intensity and velocity is to be taken into consideration. It is important in order to be able

to decide if certain works can be carried out safely.

Area influenced by the operation of the man-basket will be taken into consideration.

Competency of personnel to execute the works on the equipment will be assessed.

Availability and safety of man-basket, operator, hand-tools, measuring equipment, connectors,

hoses and the N2 Bottle will be ensured.

2 HSSE

All works shall be in compliance with the State of Qatar laws and regulations, Ras Laffan

Industrial City and International standards, codes, LINDE ENGINEERING AG and QSGTL

and/or its PMC requirements and instructions.

In addition all employees and GAMA subcontractor employees on site will have gone through

GAMA Qatar Site Safety Induction, LINDE ENGINEERING AG Site Safety Induction and

QSGTL Safety induction for site safety, health, environmental and security prior to resuming

work activities at site. Other training courses (i.e. Working in Confined Spaces, Working at

Heights, etc.) will be attended as required by LINDE ENGINEERING AG or QSGTL and/or

PMC.

Risk Assessment will have been prepared by the Risk Assessment Team (RAT) ranking the

hazards associated with project works and control measures to be taken to mitigate the

hazards to an acceptable level.

Each scope work or task will have a completed and approved Job Safety Analysis (JSA)

GAM-MTS-PRE-GTL-002

Page 5 of 10

Doc. Title

Q A T A R

GAM-MTS-FSI-GTL-002 Rev. C

Method Statement Nitrogen Filling,

Cryogenic Vaporizer

Date/Rev. No :

identifying the potential hazards and control measures that will be implemented to protect

people and environment.

The JSA (RA) will be used by Supervisor as the basis of conducting his daily TSTI meeting

and his weekly Tool Box Talk.

For additional safety requirements for a particular or specific task please refer to the JSA

prepared for that task.

All personnel will have PPE required for their specific tasks in addition to the minimum PPE

(coveralls, safety goggles, safety shoes, high-visibility vests, gloves) at site at all times as

required.

3 REFERENCES

T-4.233.760

T-4.233.891

T-13.376.921

T-13.377.539

:

:

Cryogenic Vaporizer Steam Heated-O2 Vaporizer and

Condensate Vessel

Cryogenic Vaporizer Air Heated N2 Vaporizer Preservation

Procedure

Preservation of New Equipment, Technical Specification

Flawless Start-up

4 DEFINITIONS

Company

Contractor

Sub Contractor

Contract

QCP

ITP

QA/QC

HSSE

JSA (RA)

FSI

CA

:

:

:

:

:

:

:

:

:

:

:

Package Unit

CV

ASU

MSDS

:

:

:

QSGTL and/or its PMC

Linde Engineering AG

GAMA QATAR Co. W.L.L.

QSGTL Pearl Project C2 ASU Construction Works

Quality Control Procedure

Inspection and Test Plan

Quality Assurance / Quality Control

Health, Safety, Security and Environmental

Job Safety Analysis (Risk Assessment)

Flawless Start-up Initiative

Construction Area

Major components assembled at the manufacturers plant e.g.

Linde Engineering AG

Cryogenic Vaporizer

Air Separation Unit

Material Safety Data Sheet

5 RESPONSIBILITIES

5.1 SITE MANAGER

The Site Manager will provide inputs to the project execution plan to ensure that strategies &

philosophy of the project are properly addressed.

5.2 FSI MANAGER

The FSI Manager is responsible for the overall management of the Preservation Team to

ensure that safe and effective operations are conducted and properly documented.

GAM-MTS-PRE-GTL-002

Page 6 of 10

Doc. Title

Q A T A R

GAM-MTS-FSI-GTL-002 Rev. C

Method Statement Nitrogen Filling,

Cryogenic Vaporizer

Date/Rev. No :

5.3 CLEANLINESS & PRESERVATION ENGINEER

He will be overall responsible for planning and safe execution of the whole job including:

Organizing of equipments, material and tools needed for the job.

Confirming the preservation location.

Assigning skilled personnel for the job.

Conducting TSTI with the concerned work force prior to start of work.

Ensuring that relevant work permits and Method Statement for the job are obtained prior to

start of work and made available at site.

Conducting of activities to be carried out for the work in a safe manner as per this method

of statement.

Tagging of the vessel(s) and keeping the records. Records are auditable by Company.

Conduct inspection and surveillance.

Notify to Contractor engineer for inspection as applicable.

Ensure that all Contractor and Company regulations are followed.

Ensure that all personnel involved are in safe working condition at all times.

5.4 LIFT SPECIALIST

Shall be operating the man-basket (if and as required), to achieve a safe measuring and filling

of N2 gas in the Cryogenic Vaporizers.

6 RESOURCES

6.1 EQUIPMENT & MANPOWER

A list of equipment and manpower is given below.

6.1.1 EQUIPMENT

Manometer

T-piece

Hose

Gas Pressure Regulator

Atmospheric Monitoring Equipment

Nitrogen Bottle

Holding Clamps

Hand Tools

Full PPE and Safety Harness

Aerial Platform/ Manlift/ Man Basket

GAM-MTS-PRE-GTL-002

Page 7 of 10

Doc. Title

Q A T A R

GAM-MTS-FSI-GTL-002 Rev. C

Method Statement Nitrogen Filling,

Cryogenic Vaporizer

Date/Rev. No :

6.1.2 MANPOWER

Site Manager

FSI Manager

Cleanliness & Preservation Engineer

Man-Basket Operator

HSSE Personnel

Helpers

7 METHOD OF EXECUTION

7.1 PRE-COMMENCEMENT WORKS

7.1.1 WORK PERMIT

The measuring of internal pressure and filling with Nitrogen gas of the Cryogenic

Vaporizer starts with the preparation of Method Statement and issuance of a Permit to

Work.

7.1.2 TRAFFIC MANAGEMENT PLAN

Area will be soft barricaded and secured.

Access road to operation area and enough space for movement of man-basket during

operation will be arranged and made available.

7.1.3 EQUIPMENT AND PERSONNEL

All equipment shall be inspected, tested and approved by the CONTRACTOR.

All equipment and tools shall be available at the site.

All personnel shall be inducted and trained before they commence work on site and

have sufficient knowledge.

All personnel shall be competent to execute all the works pertaining measuring N2

pressure and filling as required of Cryogenic Vaporizer.

8 MEASURING AND FILLING PROCEDURE

8.1 GENERAL

The Cryogenic Vaporizer is filled with N2 gas to avoid oxidation of internals and needs to be

kept at this state during storage and after erection up to the time of commissioning.

The N2 pressure will be checked at intervals of one month by the CONTRACTOR, and will be

refilled as required to achieve 0.5 bar internal pressure.

Observations will be properly recorded, and copies will be forwarded to COMPANY.

The vessel(s) (Cryogenic Vaporizer) and or the container will be tagged appropriately after

GAM-MTS-PRE-GTL-002

Page 8 of 10

Doc. Title

Q A T A R

GAM-MTS-FSI-GTL-002 Rev. C

Method Statement Nitrogen Filling,

Cryogenic Vaporizer

Date/Rev. No :

each inspection and/ or refilling to reflect the status of preservation. (See Attachment-2 for

samples).

8.2 ASSEMBLY and CHARGING

Read the dials supplied on Cryogenic Vaporizer and record the readings.

If the readings are below 0.5 bar (50 kPa/ 7.25 psi/ 0.5 atm) fill as required.

Perform Gas Testing if the Cryogenic Vaporizer is in a confined space.

Adjust the filling nozzle to properly connect with filling equipment.

Position the N2 Bundle securely on ground.

Do not expose the N2 Bundle to direct sun-light for elongated durations.

Operate and position the man-lift so that the measuring and filling operation can be

performed safely and effectively.

Remove the plug on the Ball Valve on a suitable charging nozzle.

Attach the T-Piece on the Ball Valve.

Install the Manometer on one of the free ends of the T-Piece.

Connect the hose to the other end of the T-Piece.

Connect the other end of hose to the Isolation Valve. Ensure the Isolation Valve is at

closed position.

Connect the Isolation Valve to the Gas Pressure Regulator. Check that Gas Pressure

Regulator is at its lowest setting.

Connect the Gas Pressure Regulator to the N2 Cylinder .

Turn the Ball Valve (existing valve on the vessel) open.

Record the internal pressure displayed on the Manometer.

If it is less than 0.5 bar, open N2 Cylinder valve slowly to avoid pressure shock.

Increase output of the Gas Pressure Regulator to 0.5 bar. Turn the Isolation Valve

slowly to open position.

Check the Manometer to read 0.5 bar.

Turn the Isolation Valve off, when 0.5 bar is reached.

Turn the Ball Valve on the vessel off.

8.3 DISASSEMBLY and DELIVERY

Disconnect the T-Piece from the Ball Valve.

Plug the Ball Valve with the previously removed plug and use a gasket to ensure

tightness.

Dismantle the arm of the Ball Valve and using a duct tape attach on or near to the Ball

Valve to alleviate future operations.

Affix (if missing) an A4 size easily readable danger notice (supplied) on all sides of

the vessel or on to the door of container, as required to ensure visibility at both sides of

the vessel.

Affix (if missing) an A4 size easily readable warnings (supplied) on all sides of the

vessel or on to the door of container, as required to ensure visibility at both sides of the

vessel.

Affix (if missing) an 10cm X 10cm size easily visible safety signs (supplied) on all

sides of the vessel or on to the door of container, as required.

Store the N2 Bundle as instructed on MSDS.

GAM-MTS-PRE-GTL-002

Page 9 of 10

Doc. Title

Q A T A R

GAM-MTS-FSI-GTL-002 Rev. C

Method Statement Nitrogen Filling,

Cryogenic Vaporizer

Date/Rev. No :

9 QUALITY ASSURANCE

A Quality Assurance System shall be operated conforming to related standards.

10 ATTACHMENTS

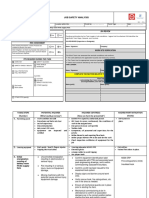

10.1 JOB SAFETY ANALYSIS

10.2 TAGS and SIGNS (Sample)

GAM-MTS-PRE-GTL-002

Page 10 of 10

Q A T A R

JOB SAFETY ANALYSIS / RISK ASSESSMENT

JSA Number: T-4.305.139

NEW

Page No: 1 of 5

REVISED

Job being analysed: NITROGEN FILLING, MOLECULAR SIEVE ADSORBER

JSA Members: Mr. Oguz Baskoylu, Mr. Emre Yazc

Department/Section doing JSA: HSSE & Mechanical Dept.

Job Performers: Mr. Osman Davaslgil, Mr. Seyfettin Bayrak

Normal Approvals:

Name

Signature

Date

General job requirements / Common Personnal

Protective Equipment.

JSA by:

Job Supervisor:

Mr.Emre Yazc

23.09.2008

Mr. Osman Davaslgil

23.09.2008

Additional Approvals (Determined by Job Supervisor in correlation with LINDE HSSE Manager).

Name

Signature

Discipline Superindent(LINDE)

SHES Representative(LINDE)

OTHERS (List Below):

Date

1. The following Personal Protective Equipment

shall be worn while installing manbasket: Approved

coveralls, safety glasses, safety helmet, safety steel

toe shoes and gloves.

2. Permit To Work.

Approval required for hazardous work detailed in the LINDE work permit procedure.

Changing conditions and emergency procedures: Stop work. Switch of equipment.Supervisor directs personnel to nearest and safest muster point considering wind direction. Supervisor counts all employees. Missing

employees are reported to LINDE HSSE Dept. When all clear is given check with LINDE HSSE before returning to work.

LINDE EMERGENCY TELEPHONE NO.

HSSE MANAGER:

RLIC HOT LINE :

583 40 72

474 88 88

Note: 1) If any of the tasks involves biological, physical or chemical hazards, then The LINDE Industrial Hygienist must also approve the work.

2) Use additional sheets as necessary.

3) Details on safety (PPE,Hazard etc) and environmental requirements can be found in LINDE and shell Safety and Environment Procedures.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

T-4.305.139

JSA Number:

QT- 4.xxx.yyy

A T A

Q A T A R

Job Performers: Mr. Osman

Davaslgil, Mr. Seyfettin

Bayrak

ITE

M

ACTIVITY

Using of Manlift

HAZARD / POTENTIAL

CONSEQUENCES

1,1

Initial Risk

P C

CURRENT

CONTROLS

RISK

RANK

Mechanical Breakdown

Equipment shall be serviced

1.1.1.1

maintained and inspected as per set

maintenance and inspection program.

Ensure equipment to be provided

with controls of the dead man type,

which only allow movement of the

machine to take place whilst they

are actually being operated.

1.1.2

Ensure E-Stop is in place through the 1.1.1.2

control system.

Perform equipment daily check prior 1.1.1.3

to use.

Supervisor shall ensure that work will

be properly supervised as per work

method statement.

Dead man controls automatically

return to the neutral position.

Appropriate trained & certified

persons only to use equipment.

1.1.4

1.1.5

Improper use of

equipment

1.2.1

3 #####

ADDITIONAL

CONTROLS

1.1.1

## 3 ##### 1.1.3

1,2

SCOPE : METHOD STATEMENT FOR

NITROGEN FILLING, CRYOGENIC VAPORIZER

1.2.2

1.2.3

Ensure an emergency stop should be

provided on the platform control

panel.

Manlift shall not be used as cranes or 1.2.1.1

jacks unless they have specifically

been designed for this purpose by

their manufacturers.

Leaning out of the platform will not be 1.2.1.2

allowed.

Colour code sticker to be available on 1.2.1.3

the equipment.

Residual Risk

P C

3 #####

3 #####

Ensure equipment is inspected,

approved & colour coded as per

colour code chart.

Current inspection sticker must be

in place.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

T-4.305.139

JSA Number:

QT- 4.xxx.yyy

A T A

Q A T A R

Job Performers: Mr. Osman

Davaslgil, Mr. Seyfettin

Bayrak

ITE

M

ACTIVITY

HAZARD / POTENTIAL

CONSEQUENCES

1,3

Initial Risk

P C

CURRENT

CONTROLS

RISK

RANK

Untrained personnel

1.3.1

1.3.2

B

3 #####

## 3 ##### 1.3.3

1.3.4

1,4

Fall of personnel

1.4.1

SCOPE : METHOD STATEMENT FOR

NITROGEN FILLING, CRYOGENIC VAPORIZER

5 #####

1.4.2

Ensure platforms must only be used

by authorized personnel who have

been trained in the operation of the

type of platform in use.

Initial training should cover operating

principles, machine controls and

environmental conditions, which are

likely to be encountered.

Training and practice in this type of

work undertaken is essential.

Ensure that equipment operator is

certified by third party, valid

certificates.

Safety harness shall be provided for

the use of all personnel working from

mobile work platforms so that in the

event of any advertent movement of

the platform they are working from,

they will not be thrown from it.

ADDITIONAL

CONTROLS

1.3.1.1

1.4.1.1

Boxes, hop-ups or ladders will not be 1.4.1.2

used to gain additional height or reach

from the platform of manlift machine

work platform.

Residual Risk

P C

Ensure supervisor/foreman who

will be using the manlift should be

particularly aware of the hazards

which may be encountered whilst

using these machines and of the

precautions which may be taken to

eliminate or minimize the hazards. A

3 #####

3 #####

4 #####

Discuss working at height hazards

in TSTI.

Supervisor shall ensure that work

will be properly supervised at all

times as per work method

statement.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

T-4.305.139

JSA Number:

QT- 4.xxx.yyy

A T A

Q A T A R

Job Performers: Mr. Osman

Davaslgil, Mr. Seyfettin

Bayrak

ITE

M

ACTIVITY

HAZARD / POTENTIAL

CONSEQUENCES

1,5

Initial Risk

P C

CURRENT

CONTROLS

RISK

RANK

Overturning of Machine

Ensure no excessive force by the

operator on the platform by

introducing an element of side load.

1.5.2

The outriggers or stabilizers, when

1.5.1.2

fitted, shall be fully extended and in

position, before the platform or boom

is raised.

The platform shall not be overloaded 1.5.1.3

exceeding the regulated safe working

load.

Ensure the machine will be located to

the most suitable position for the job

to be carried out before any slewing

takes place.

Slewing of the boom to the extent that

causes the machine to overturn shall

be avoided.

Ensure all vehicle movement to be

guided by competent banks men with

high visibility vests.

Ensure that each piece of equipment

is fitted with an automatic reverse

alarm and beacon or strobe light.

4 ##### 1.5.3

1.5.4

1.5.5

1,6

Vehicle Movement

1.6.1

ADDITIONAL

CONTROLS

1.5.1

## 3 #####

B

SCOPE : METHOD STATEMENT FOR

NITROGEN FILLING, CRYOGENIC VAPORIZER

3 ##### 1.6.2

1.5.1.1

When a manlift needs work in a

congested area, an approval for

the operation shall be obtained

from HSSE dept of Gama/Linde

authorized personnel's.

Considering the effects of the

acceleration and deceleration of

the manlift.

Discuss in TSTI.

Residual Risk

P C

3 #####

4 #####

3 #####

JOB SAFETY ANALYSIS / RISK ASSESSMENT

T-4.305.139

JSA Number:

QT- 4.xxx.yyy

A T A

Q A T A R

Job Performers: Mr. Osman

Davaslgil, Mr. Seyfettin

Bayrak

ITE

M

ACTIVITY

Transportation of

nitrogen bottle

HAZARD / POTENTIAL

CONSEQUENCES

2,1

Initial Risk

P C

Moving of the

nitrogen bottle to the

"filling position" via

man-lift

RANK

2.1.1

A

CURRENT

CONTROLS

RISK

Damaging of cylinder

4 #####

3,1 Dropped bottle

3.1.1

##

C 3

5 #####

#####

3.1.2

Nitrogen filling

4,1

Dropped tools

4,2

Gas Leakage

4,3

Inhaling nitrogen

4.1.1

A

4 #####

4 #####

B

4,3

Handling pressurized

equipment

ADDITIONAL

CONTROLS

Ensure the bottle is securly tied to the 2.1.1.1

vehicle.

2.1.1.2

Ensure that the nitrogen bottle is tied 3.1.1.1

to the basket rails of the man-lift using

metal or plastic clamps.

Barricade and secure the working

area with sign boards to prevent

unauthorized entry.

Ensure that all hand tools are carried

in a tool box or attached to the

personnel.

Perform Gas Testing prior to start of

operation.

4,3,1 Ensure that the operation is carried

5 #####

out in a well ventilated area or out

doors.

4,4,1 Ensure that valve protection cap is in

place.

2 #####

SCOPE : METHOD STATEMENT FOR

NITROGEN FILLING, CRYOGENIC VAPORIZER

Ensure the driver is warned to

avoid abrubt manouvers.

Ensure that the people are

instructed to avoid to drop the

bottle while carrying.

Discuss in TSTI.

4.1.1.1

Install barricades "exclusion zone"

with sign boards indicating

nitrogen filling works in progress to

prevent unauthorized entry.

4.3.1.1

Install "INERT GAS WARNING"

signs, as necessary.

4.4.1.1

Remove protection cap only to

connect the bottle to the filling

point.

Use a check-valve.

Residual Risk

P C

4 #####

A

A

3

4 #####

#####

3 #####

4,2,1

Ensure the regulator is connected to 4.4.1.2

the bottle and operational.

Ensure that the bottle is kept under 50 4.4.1.3

degrees Celcius and not in elongated

direct contact with sunlight.

Ensure that the bottle valve is opened

slowly to avoid pressure shock.

Ensure backfeed is not allowed into

the bottle.

Isolate cylider (bottle) at cylinder

valve when not in use.

Doc. Title

Q A T A R

Date/Rev. No :

GAM-MTS-FSI-GTL-002 Rev. C

Method Statement Nitrogen Filling,

Cryogenic Vaporizer

Вам также может понравиться

- Asme Sec V A-10-2006 PDFДокумент24 страницыAsme Sec V A-10-2006 PDFMuhammed Abo-FandoodОценок пока нет

- Cutting HandlingДокумент25 страницCutting HandlingWalid AmdouniОценок пока нет

- Installation of Underground 2"stainless Steel (1sdou) .Документ8 страницInstallation of Underground 2"stainless Steel (1sdou) .AldrinОценок пока нет

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisДокумент15 страницSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda BukshОценок пока нет

- Suppressor Engineering 101Документ6 страницSuppressor Engineering 101Irma Knutt83% (6)

- 016-CIVIL - MS Anchor Bolt Installation PDFДокумент14 страниц016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 041 - ITP For Painting (Building) PDFДокумент12 страниц041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- JSA For Cathodic Protection Installation For PipelineДокумент15 страницJSA For Cathodic Protection Installation For PipelineAmeerHamzaWarraich100% (1)

- 048-Itp For Installation of Hvac Unit PDFДокумент8 страниц048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 043-ITP FOR Water Proofing (Buildings) PDFДокумент13 страниц043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- Jsa FormДокумент3 страницыJsa Formmiaicarba100% (1)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFДокумент23 страницы014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanОценок пока нет

- JSA Building WorksДокумент9 страницJSA Building WorksMon Trang Nguyễn100% (1)

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFДокумент25 страниц007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanОценок пока нет

- Equipment Nitrogen Purging Procedure PDFДокумент13 страницEquipment Nitrogen Purging Procedure PDFKUMAR100% (2)

- Conduit BKM 7102Документ9 страницConduit BKM 7102Utku Can Kılıç100% (1)

- Hot & Cold Work PermitДокумент10 страницHot & Cold Work PermitSubratОценок пока нет

- 015-MS For Night Works PDFДокумент16 страниц015-MS For Night Works PDFKöksal Patan80% (5)

- Jsa For Pipe Fabrication ErrectionДокумент5 страницJsa For Pipe Fabrication Errectionjithin shankarОценок пока нет

- Breather Valve CalcДокумент12 страницBreather Valve CalczamijakaОценок пока нет

- Drilling Engineering 2 Course (1 Ed.)Документ34 страницыDrilling Engineering 2 Course (1 Ed.)Aoun FatehОценок пока нет

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFДокумент10 страниц045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- HIRA 013 Working Over Water.Документ2 страницыHIRA 013 Working Over Water.srinibas mohapatra100% (1)

- Jsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementДокумент13 страницJsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementKhuda Buksh100% (1)

- Pre Comm ProcedureДокумент8 страницPre Comm ProcedurewahyuОценок пока нет

- 050-Itp For Installation of Air Intake Filter PDFДокумент17 страниц050-Itp For Installation of Air Intake Filter PDFKöksal PatanОценок пока нет

- Risk Assessment - Pipe Fit Up - Hot WorkДокумент7 страницRisk Assessment - Pipe Fit Up - Hot WorkHanu JemberОценок пока нет

- JSA HCK MOC Hot Tap Drilling Rev1Документ6 страницJSA HCK MOC Hot Tap Drilling Rev1Ijaz Hussain100% (2)

- JSA For Confined Space 20 12 2019 - TS3Документ5 страницJSA For Confined Space 20 12 2019 - TS3narasimhamurthy414Оценок пока нет

- Molecular Sieve Sizing Sheet: Input Particle Type Data Particle Type Selection CalculationДокумент3 страницыMolecular Sieve Sizing Sheet: Input Particle Type Data Particle Type Selection CalculationreninbabaskiОценок пока нет

- Job Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentДокумент5 страницJob Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentlokreddiОценок пока нет

- Hazzaz Sir Merged PDFДокумент301 страницаHazzaz Sir Merged PDFMahmud ShetuОценок пока нет

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFДокумент16 страниц012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- Execution Procedure For Pipe Connection Tie in and Hot TapzДокумент7 страницExecution Procedure For Pipe Connection Tie in and Hot TapzyuwantoniОценок пока нет

- 039-Itp For Embedded Plate PDFДокумент7 страниц039-Itp For Embedded Plate PDFKöksal PatanОценок пока нет

- 040-ITP For Repair of Steam Distribution Manifold PDFДокумент11 страниц040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanОценок пока нет

- 049-Itp For Lighting and Small Power (Building) PDFДокумент15 страниц049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 044-ITP For Installation of Gypsum Board (Buildings) PDFДокумент10 страниц044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- Section 7Документ64 страницыSection 7WlopezaОценок пока нет

- Jsa For TIE INS in Accommodation BlockДокумент4 страницыJsa For TIE INS in Accommodation BlockAliОценок пока нет

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFДокумент17 страниц010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanОценок пока нет

- 014-MS For General Scaffolding PDFДокумент33 страницы014-MS For General Scaffolding PDFKöksal Patan100% (2)

- Commissioning ActivitiesДокумент1 страницаCommissioning ActivitiesthinkpadОценок пока нет

- Jsa For Intallation of Sub Pipe Rack Incuding Grinding Cutting and Welding Near Condensate DrumsДокумент6 страницJsa For Intallation of Sub Pipe Rack Incuding Grinding Cutting and Welding Near Condensate DrumsMohammed MinhajОценок пока нет

- JSA Pile Concrete Works OkДокумент9 страницJSA Pile Concrete Works OkMon Trang NguyễnОценок пока нет

- 4..pipe Spool Air Blowing & Cleaning JSA 04Документ2 страницы4..pipe Spool Air Blowing & Cleaning JSA 04Francis Vinoj100% (1)

- Job Safety Analysis: 1. Removing Spool From Existing Pipe LinesДокумент5 страницJob Safety Analysis: 1. Removing Spool From Existing Pipe Lineskaremkoko100% (2)

- 047-Itp For Oxygen Lines Fabrication and Installation PDFДокумент28 страниц047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanОценок пока нет

- AST JSA Excavations.Документ3 страницыAST JSA Excavations.md_rehan_2Оценок пока нет

- Tanks Confined Space JSAДокумент5 страницTanks Confined Space JSAkosoko100% (1)

- 011-Method Statement For Repair of Concrete Works PDFДокумент25 страниц011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 011-Method Statement For Repair of Concrete Works PDFДокумент25 страниц011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- Method of Statement For Bus Duct InstallationДокумент11 страницMethod of Statement For Bus Duct InstallationMohd MuksinОценок пока нет

- Chemical Cleaning and Steam Blowing Application Sheet Rev.1Документ12 страницChemical Cleaning and Steam Blowing Application Sheet Rev.1Eslam ShiblОценок пока нет

- JSA For Blower Cyclone and Duct Installation - Revision 004Документ8 страницJSA For Blower Cyclone and Duct Installation - Revision 004WilsonОценок пока нет

- 10 Precommissioning & Commissioning HSE Procedure 10Документ31 страница10 Precommissioning & Commissioning HSE Procedure 10riyazaliОценок пока нет

- AGA Report 7 Turbine Gas MeterДокумент42 страницыAGA Report 7 Turbine Gas MeterO100% (12)

- Detailed Lesson Plan Boyle's LawДокумент9 страницDetailed Lesson Plan Boyle's LawTeacher Derick Daet86% (7)

- JSA Tank Modification and Repair Work 1683009539 PDFДокумент12 страницJSA Tank Modification and Repair Work 1683009539 PDFLabroratoirОценок пока нет

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFДокумент23 страницы008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanОценок пока нет

- PP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0Документ14 страницPP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0ibrahimОценок пока нет

- Cat Loading by Sock Method in Inert AtmosphereДокумент5 страницCat Loading by Sock Method in Inert Atmospherevishal bailurОценок пока нет

- 009-Method Statement - Main Erection Sequence For Acc PDFДокумент68 страниц009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- JHA Vessel EntryДокумент2 страницыJHA Vessel EntryRiyadh SalehОценок пока нет

- Jsa For Tie-In Tp-950Документ11 страницJsa For Tie-In Tp-950rexivyОценок пока нет

- 008-CIVIL-MS Backfilling Works PDFДокумент16 страниц008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 013-MS For Mass Concrete Works PDFДокумент26 страниц013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 05 Capillary PressureДокумент15 страниц05 Capillary PressureMohamed Tarek100% (1)

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFДокумент18 страниц012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanОценок пока нет

- JSA For Piping-Hydro TestДокумент10 страницJSA For Piping-Hydro TestMuthu AlaguRajОценок пока нет

- Method Statement For Hot Tapping Rev 0 PDFДокумент9 страницMethod Statement For Hot Tapping Rev 0 PDFsharif339Оценок пока нет

- 015-Method Statement For Painting Works (Building) PDFДокумент21 страница015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 015-Method Statement For Painting Works (Building) PDFДокумент21 страница015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- SOP-10 Pre Commissioning and Commissioning ActivitiesДокумент14 страницSOP-10 Pre Commissioning and Commissioning ActivitiesVineet AgrawalОценок пока нет

- 010-MS For Grouting PDFДокумент33 страницы010-MS For Grouting PDFKöksal PatanОценок пока нет

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFДокумент18 страниц046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanОценок пока нет

- Medical Gas Piping SpecДокумент22 страницыMedical Gas Piping Specvvg100% (1)

- 22.MS For HydrotestДокумент9 страниц22.MS For HydrotestASHWANIОценок пока нет

- 038-Itp For Coldboxes PDFДокумент25 страниц038-Itp For Coldboxes PDFKöksal PatanОценок пока нет

- 017-CIVIL-MS For Installation of Fence & Gate PDFДокумент18 страниц017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 009-Civil-Ms Concrete Works PDFДокумент27 страниц009-Civil-Ms Concrete Works PDFKöksal PatanОценок пока нет

- 013-MS Utilization of Hilti DX 76 PDFДокумент51 страница013-MS Utilization of Hilti DX 76 PDFKöksal PatanОценок пока нет

- What You Should Know About Liquid Thermal ExpansionДокумент3 страницыWhat You Should Know About Liquid Thermal ExpansionBacelis100% (3)

- TR-CA-MS-001 - B Demolishing and Debris Removal-Sent To HibaДокумент17 страницTR-CA-MS-001 - B Demolishing and Debris Removal-Sent To Hibasamer8saifОценок пока нет

- Jha JOHN DEERE Engine PumpДокумент4 страницыJha JOHN DEERE Engine Pumpperquino oasanОценок пока нет

- 4 Jsa (Sie-Hse-005-F11 r1) - Precomm Ess001Документ3 страницы4 Jsa (Sie-Hse-005-F11 r1) - Precomm Ess001Jannuar Ilham100% (2)

- HVAC Fans Initial Energisation Battery RoomДокумент3 страницыHVAC Fans Initial Energisation Battery RoomMajdiSahnoun0% (1)

- Tonnering JSAДокумент4 страницыTonnering JSAboyettОценок пока нет

- Jsa Insulation WorkДокумент20 страницJsa Insulation WorkazerОценок пока нет

- Safety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksДокумент1 страницаSafety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksRísês ÃfrözОценок пока нет

- Jha New - PWHTДокумент6 страницJha New - PWHTSalam AlkataluniОценок пока нет

- JSA-01 WeldingДокумент7 страницJSA-01 WeldingAlfian Novialdi LaksonoОценок пока нет

- JSA - Winstar Pipeline CrossingДокумент6 страницJSA - Winstar Pipeline CrossingRidha BennasrОценок пока нет

- Doku - Pub Risk-AssessmentДокумент10 страницDoku - Pub Risk-AssessmentUlviyye ElesgerovaОценок пока нет

- Health & Safety Hazard Identification/ Risk Assessment/ Operational PlanДокумент20 страницHealth & Safety Hazard Identification/ Risk Assessment/ Operational PlanRebekah SchmidtОценок пока нет

- Environmental, Health and Safety Risks AnalysisДокумент2 страницыEnvironmental, Health and Safety Risks AnalysisKrishna PatilОценок пока нет

- MS-ASU-052 MS For Perlite On-Site Expansion and Filling R1Документ11 страницMS-ASU-052 MS For Perlite On-Site Expansion and Filling R1LamineОценок пока нет

- Confined Space Rescue Plan: Description of The WorkДокумент2 страницыConfined Space Rescue Plan: Description of The Workidigiti100% (1)

- Steam BoilerДокумент3 страницыSteam BoilerMohammad AzlanОценок пока нет

- MEIL Rigging Plan For Unloading LoaderДокумент4 страницыMEIL Rigging Plan For Unloading LoaderGyanendra Narayan NayakОценок пока нет

- Jsa n2 Purging PDF FreeДокумент1 страницаJsa n2 Purging PDF FreeSKH CultureОценок пока нет

- Lecture 1 Aerodynamics - Introduction To Fundamentals of AerodynamicsДокумент52 страницыLecture 1 Aerodynamics - Introduction To Fundamentals of Aerodynamicsyusuf harunaОценок пока нет

- Fluid Transport in Thin Film Polymer ProcessorsДокумент9 страницFluid Transport in Thin Film Polymer ProcessorsshirinОценок пока нет

- Oil Well ControlДокумент15 страницOil Well ControlSunder Singh BishtОценок пока нет

- Terms of Reference For Foundry RoofingДокумент25 страницTerms of Reference For Foundry RoofingImags GamiОценок пока нет

- LevelДокумент12 страницLevelAqilahJazuliОценок пока нет

- Experiment: To Verify Boyle's LawДокумент3 страницыExperiment: To Verify Boyle's Lawheheh100% (1)

- Fluid Mech. 2Документ32 страницыFluid Mech. 2Leslie Owusu MensahОценок пока нет

- Degrees of Freedom Analysis in Process Control: PergamonДокумент7 страницDegrees of Freedom Analysis in Process Control: PergamonPriyam NayakОценок пока нет

- 1617 Level L Chemistry Revision Sheet T1 Wk11Документ8 страниц1617 Level L Chemistry Revision Sheet T1 Wk11Hisham El KanayatiОценок пока нет

- Aspiration EffectДокумент13 страницAspiration EffectSavio Jain100% (3)

- Class 7-Physics-Worksheet-PressureДокумент3 страницыClass 7-Physics-Worksheet-Pressureenosh.sinhaОценок пока нет

- Xav 545Документ4 страницыXav 545ALIОценок пока нет

- Pascal LawДокумент4 страницыPascal LawpratishgnairОценок пока нет

- Conversion FormulasДокумент1 страницаConversion Formulaslokesc100% (11)

- Classnotesforyou, 1Документ26 страницClassnotesforyou, 1Robin RappaiОценок пока нет

- LNG Tanker MannualДокумент49 страницLNG Tanker MannualJohn CabiativaОценок пока нет

- Soln Class Problems CH 1-4 Spring 2017Документ4 страницыSoln Class Problems CH 1-4 Spring 2017Syed Qassam Mustafa SadiqullahОценок пока нет

- F520Документ2 страницыF520Marcos AldrovandiОценок пока нет