Академический Документы

Профессиональный Документы

Культура Документы

010-MS For Welding and Hot Works For General Activities at TSF Area PDF

Загружено:

Köksal PatanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

010-MS For Welding and Hot Works For General Activities at TSF Area PDF

Загружено:

Köksal PatanАвторское право:

Доступные форматы

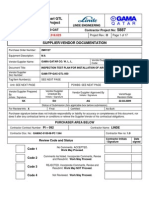

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T.4.250.905

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No :

Project Rev.: O

Page 2 of 16

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

25.03.2008

Issued for Company Comments

RO

EE

ZG

ICC

19.03.2008

Issued for Review

RO

EE

ZG

IFR

16.03.2008

Issued for Internal Review

RO

EE

ZG

IIR

Date

Description

GAMA

Rev.

No.

Project

Rev

No.

Prepared Checked Approved

By

By

By

ORIGINATOR

Status

Document Title:

LINDEGINEERING AG

METHOD STATEMENT FOR WELDING AND HOT

WORKS FOR GENERAL ACTIVITIES AT TSF AREA

Document No.

Contractor

Gama Qatar Co. W. L. L.

LOC470

GAM

MTS

MEC

GTL

010

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T.4.250.905

Vendor Code

Rev No: O

Doc. Title

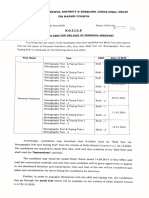

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WELDING AND HOT

WORKS FOR GENERAL ACTIVITIES AT TSF AREA

GAM-MTS-MEC-GTL-010, 25 March 2008, REV-C

TABLE OF CONTENTS

1

INTRODUCTION .......................................................................................................... 5

1.1

PURPOSE

1.2

SCOPE

REFERENCE................................................................................................................ 5

DEFINITIONS ............................................................................................................... 5

RESPONSIBILITIES..................................................................................................... 5

PRE-COMMENCEMENT WORKS ............................................................................... 6

5.1

WORK PERMIT

5.2

EQUIPMENTS AND PERSONNEL

ReSOURCES................................................................................................................ 6

6.1

PERSONNEL

6.2

CONSTRUCTION EQUIPMENT AND MAJOR TOOLS TO BE MOBILIZED

HSSE ............................................................................................................................ 7

ACTIVITIES DESCRIPTION AND DETAIL METHOD.................................................. 7

wELDING...................................................................................................................... 8

9.1

GENERAL

9.2

PREPARATION OF BASE METAL

9.3

ASSSEMBLY

9.4

FILLER METAL

9.5

PREHEAT AND INTER-PASS TEMPERATURE

9.6

WELDING procedure

9.6.1 GENERAL ________________________________________________________________________9

9.6.2 WELDING CONTROL _______________________________________________________________9

9.7

10

11

INSPECTION TOLERANCES AND CORRECTIONS FOR WELDING

nON-DESTRUCTIVE EXAMINATIONS ....................................................................... 9

iNSTRUCTIONS ......................................................................................................... 10

11.1

CUTTING AND BURNING

10

11.2

ARC WELDING

10

11.3

COMPRESSED GAS CYLINDERS

11

11.4

TRAINING (GRINDING WORKS)

11

11.5

LIFTING SLINGS

12

12

QUALITY ASSURANCE ............................................................................................ 12

13

ATTACHMENTS......................................................................................................... 12

13.1

JOB SAFETY ANALYSIS

T.4.250.905 REV-O

12

Page 4 of 16

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WELDING AND HOT

WORKS FOR GENERAL ACTIVITIES AT TSF AREA

GAM-MTS-MEC-GTL-010, 25 March 2008, REV-C

1 INTRODUCTION

1.1

PURPOSE

This document describes the methods proposed to be used for the support activities that will

be carried out as part of ASU construction works and open workshop at TSF area.

1.2

SCOPE

The scope of this method statement identifies the general steps, arrangement & precautions

during the execution of hot metal works at the open workshop of TSF area. The metal works

consists of cutting, grinding, welding and hot works for fabricating supporting tools.

2 REFERENCE

T-4.234.542

T-4.219.591

: Project Quality Plan

: Welding and Cutting

T-4.250.930

: Quality Control procedure for cleanliness

T-13.377.360

: Flawless Start-up Initiative (FSI)

T-4.234.084

: Method Statement for Lifting

T-4.129.872

: Heat Stress Disorder Prevention Procedure

T-4.095.303

: HSSE Plan Construction

T.4.250.938

: General Welding Procedure

T-4.129.860

: Manual handling

T-4.129.863

: Welding and Flame Cutting

T-4.129.859

: Lifting Operations

T-4.219.660

: Permit to Work Handover Implementation Plan

T-4.129.861

: Working with Electricity

T-4.129.656

: Construction Waste Management Plan

T.4.250.931

: Welding Consumable Control

T.4.250.940

: Weld Repair Procedure

T-4.250.915

: Calibration Procedure

Other specifications and procedures of contractor, Company and RLIC.

3 DEFINITIONS

Company

Contractor

Sub Contractor

Contract

TSF

: QSGTL or its PMC

: LINDE ENGINEERING AG

: GAMA QATAR

: QSGTL Pearl Plant C2 ASU Project

: Temporary Site Facility

4 RESPONSIBILITIES

As per organization chart, starting from Site Manager and ends at welding, steel structure,

foremen level, including QC personnel, all the people within this link is responsible for

execution of this method statement.

T.4.250.905 REV-O

Page 5 of 16

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WELDING AND HOT

WORKS FOR GENERAL ACTIVITIES AT TSF AREA

GAM-MTS-MEC-GTL-010, 25 March 2008, REV-C

Site Manager and Mechanical Works Coordinator are responsible for the fulfilment of this

procedure.

5 PRE-COMMENCEMENT WORKS

5.1

WORK PERMIT

Before the start of each day's operation, all necessary permits shall be obtained from LINDE /

SHELL (or) its PMC.

5.2

EQUIPMENTS AND PERSONNEL

All equipment shall be inspected before using on the job, whether they are good in condition or

not and all personnel's shall be safety inducted and trained before mobilization. Only skilled/

competent worker shall be used.

6 RESOURCES

6.1

PERSONNEL

As per the schedule requirements, the construction activities in different areas shall be

carried out simultaneously. The structural construction team will be structured under

sufficient groups, such as;

Construction Team for structural and general works.

Welder Team

Lifting and Transportation Team

In addition to the groups given herein above, a planning team, QA/QC team and

HSSE team shall be established to service to the above mentioned groups.

Classification of welder for construction of TSF facilities:

Welder who can make structural steel welding of mild carbon steel shall be qualified

as per project specification & AWS D1.1.

6.2

CONSTRUCTION EQUIPMENT AND MAJOR TOOLS TO BE MOBILIZED

WHEREVER REQUIRED

Crane, approximate capacity min. 20Tons

Arc-weld-Mach, GMAW and/or SMAW and/or OAW and/or FCAW and

GTAW

Vertical Bench Type Drilling Machine

Portable Drill

Portable Plate Cutting Machine Oxy-acetylene

Profile Cutter

Saw Machine

Electrical Hand Grinders (115-230) mm

Oxy-Acetylene set

T.4.250.905 REV-O

min.1

min.1

Each

each

min.1

min.2

min.1

min.1

min.1

min.2

min.1

each

each

each

each

each

each

each

Page 6 of 16

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WELDING AND HOT

WORKS FOR GENERAL ACTIVITIES AT TSF AREA

GAM-MTS-MEC-GTL-010, 25 March 2008, REV-C

Magnetic Drilling Machine

Overhead Crane(for pipe prefabrication shops)min.3 tons

Forklift

Transpalet,min.1 ton

Boom truck, min. two tons

Other Supporting Tools and Machineries

Baking Oven & Quiver

min.1

min.2

min.1

min.1

min.1

min.1

each

each

each

each

each

Set

7 HSSE

All works shall be in compliance with the State of Qatar laws and regulations, Ras Laffan

Industrial City and International standards, codes, LINDE ENGINEERING AG and QSGTL

and/or its PMC requirements and instructions.

In addition all employees and GAMA subcontractor employees on site will have through

GAMA Qatar Site Safety Induction, LINDE ENGINEERING AG Safety induction and

QSGTL Safety Induction for site safety, health, environmental and security prior to work

activities. Other training courses will be attended as required by LINDE ENGINEERING AG

or QSGTL and/or its PMC as required.

At a minimum a generic Risk Assessment (RA) will be prepared and rank the hazards

associated with the project works and control measures to be taken to mitigate the hazards

to an acceptable level.

Each work scope or task will have a completed and approved JSA identifying the potential

hazards and control measures that will be implemented to protect people and environment.

The JSA (RA) will be used by Supervisor as the basis of conducting his daily TSTI meeting

and his weekly TBT.

In addition to the above, employees conducting survey works will wear required PPE and

highly visible vest where traffic or other hazards may exist. For additional safety

requirements for a particular or specific task please refer to the JSA prepared for that task.

8 ACTIVITIES DESCRIPTION AND DETAIL METHOD

The Structural items shall be fabricated in assigned fabrication area.

All necessary lifting and rigging tools, precautions used for proper lifting operations are

explained in the specific work method statement T-4.234.084 for lifting general respectively.

Housekeeping at job site shall be performed daily and subject to be checked daily by site

engineer and HSSE personnel.

It is essential that all materials shall be controlled and identified throughout the construction

processes. Non-conformity report shall be prepared by the GAMA material handling

supervisor for any material received out of conformance.

T.4.250.905 REV-O

Page 7 of 16

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WELDING AND HOT

WORKS FOR GENERAL ACTIVITIES AT TSF AREA

GAM-MTS-MEC-GTL-010, 25 March 2008, REV-C

9 WELDING

9.1

GENERAL

Approved welding procedure specifications and procedure qualification records

(WPS & PQR) will be used. Ref. T-4.250.938.

Qualified welders are used for the welding activities at TSF area.

Welding shall not be done when the ambient temperature and weather conditions

is below specified temperature without preheating; when surfaces to be welded

are wet or exposed to rain, or high winds; nor when the welders are exposed to

inclement conditions.

Random visual inspection of all welds shall be performed during execution of

works.

The welding process shall be SMAW and /or GMAW, and/or OAW, and /or FCAW

and/or GTAW.

9.2

PREPARATION OF BASE METAL

Surfaces and edges to be welded shall be free from loose scale, slag, rust, grease,

paint, and any other foreign matter and mill scale.

9.3

ASSSEMBLY

Those parts to be joined by fillet welds, and separations between laying surfaces

to lap joint and of butt welds landing on a backing shall be brought into as close

contact as practicable.

Those parts to be joined by groove welds shall be brought into correct alignment.

Those members to be welded shall be held in the correct position by bolts,

clamps, wedges, guy lines, struts, or other suitable devices, or by tack welds, until

welding has been completed. The use of jigs and fixtures is recommended where

practical.

Tack welds shall be subject to the same quality requirements as final welds.

Temporary welds made for erection purpose shall be sufficiently strong to

withstand all anticipated erection loads.

All structural steelwork shall remain accurately aligned during bolting and welding

work,

Ladders, lugs and hooks welded to structures for the purpose of erection and

safety in accordance with the construction drawings shall not be removed, unless

otherwise specified or requested.

9.4

FILLER METAL

All filler metals that have been removed from its original packaging shall be handled

so that they do not absorb moisture. Wet electrodes shall not be used. Low-Hydrogen

electrodes shall be dried in accordance with the manufacturer's instructions before

use.

Electrodes shall be kept in a quiver, which prevent them from atmospheric moisture.

Ref.: T.4.250.931.

T.4.250.905 REV-O

Page 8 of 16

Doc. Title

Q A T A R

9.5

Date/Rev. No :

METHOD STATEMENT FOR WELDING AND HOT

WORKS FOR GENERAL ACTIVITIES AT TSF AREA

GAM-MTS-MEC-GTL-010, 25 March 2008, REV-C

PREHEAT AND INTER-PASS TEMPERATURE

Prior to welding, the base metal shall be preheated as required to the applicable WPS

& project specification.

Where the base metal temperature is below 5C, the base metal shall be preheated to

at least 50C and that temperature shall be approximately maintained during welding.

Temperature control can be carried out by Tempile stick, (or) digital pyrometers,

calibrated according to calibration procedure T-4.250.915.

9.6

WELDING PROCEDURE

GENERAL

9.6.1

WELDING CONTROL

9.6.2

9.7

Arc strikes outside the area of permanent welds not permitted on any base

metal.

Before making the subsequent welding pass, all slag shall be removed and

adjacent base metal shall be brushed clean.

Groove welds shall be terminated at the ends of a joint in a manner that will

ensure sound welds. Where possible, this shall be done by using extension

bars or run-off plates.

Steel backing, if used, shall be made continuous for the full length of the weld.

The classification and size of electrodes, electrode-arc length, voltage, and

amperage shall be specially selected to suit the thickness of the materials

being welded, type of groove, welding position, and other circumstances

relevant to the work. Welding electrodes, which are suitable for each steel

grades, shall be selected by manufacturer's recommendation.

When welding in the vertical position, the progression of all passes shall be

upwards.

The root of groove welds with no backing plate shall be gouged back and rewelded to produce sound metal fusion throughout the entire cross section.

INSPECTION TOLERANCES AND CORRECTIONS FOR WELDING

Assembly and weld tolerances shall be based on the supplier drawings and AWS

D.1.1 the alignment, groove angle, root opening, and cleanliness of the surfaces to be

welded shall be inspected prior to welding for compliance with the tolerances.

Members distorted by welding shall be straightened by mechanical means or by

carefully supervised application of a limited amount of local heating.

10 NON-DESTRUCTIVE EXAMINATIONS

Dye Penetrant Testing or Magnetic Particle Test shall be done on 10% of all butt-welding.

The procedure shall be according to section 6.14 of AWS D.1.1, unless otherwise

specified.

T.4.250.905 REV-O

Page 9 of 16

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WELDING AND HOT

WORKS FOR GENERAL ACTIVITIES AT TSF AREA

GAM-MTS-MEC-GTL-010, 25 March 2008, REV-C

11 INSTRUCTIONS

Welding and cutting normally produce fumes, gases & heat and may result in ultra-violet

radiation.

The main sources of hazard likely to be encountered are:

High temperature causing burns and fires

Electric shock, which could be fatal

Fumes and gases, liable to cause injury to health

Airborne of metal slugs from cutting / grinding Eye injuries.

Thermal radiation causing burns and arc eye.

Gas leaks from Oxy/Acetylene bottle/Fire/Explosion.

11.1 CUTTING AND BURNING

Follow safety precautions listed below:

All employees engaged in oxygen / Acetylene welding, or torch cutting must wear

appropriate protective coverall clothing, long leather gloves, safety steel toe shoes, etc.

The assistant must wear a minimum of goggles for eye protection, and gloves.

Oxygen and acetylene cylinders in use must be secured to a welding cart, or other

suitable structure.

All oxy/acetylene equipment must be inspected prior to use including regulators, hoses,

flash back arrestors, torches, etc.

Hot work permits must be obtained prior to welding and / or torch cutting where any

flammable liquid and/or gas exist. Sometimes gas test must be carried out prior to

welding and the area must be clear of flammable gas/liquid. Especially it's mandatory

when working on pipelines for repairing jobs.

Other combustible materials such as paper, plastic trash, etc must be moved out of the

area before welding or cutting.

Cylinder caps must be replaced on oxygen and acetylene cylinders prior to moving to a

new location.

Flash back arrestors must be on all gauges (sometime fitted on the cutting outfit if hose

is too long).

Take precautions to prevent oil and grease from getting inside oxygen regulators or on

oxygen valve threads.

Use forced air ventilation when welding or cutting is done in any confined space.

Use isolation booth to prevent sparks from flying.

11.2 ARC WELDING

Follow safety precautions listed below:

Proper coverall, steel tip shoes, long leather gloves, face mask must be used during all

welding works. Other protection, such as a welder's jacket may be necessary. The

welder's assistant will have to wear goggles for eye protection and the remaining PPE

stands same as the welders.

Ensure that appropriate hot work permits have been issued and a copy has been issued

to the supervisor in charge.

Some times gas test must be carried out prior to welding and the area must be clear of

flammable gas/liquid. Especially it's mandatory when working on pipeline for repairing

T.4.250.905 REV-O

Page 10 of 16

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WELDING AND HOT

WORKS FOR GENERAL ACTIVITIES AT TSF AREA

GAM-MTS-MEC-GTL-010, 25 March 2008, REV-C

jobs. Other combustible material such as paper, plastic trash, etc, must be moved out of

the area before welding or cutting.

Install welding screens to prevent other persons getting flash when possible.

If welding above ground level, contain hot slag with suitable sheeting and Fire

extinguishers are within the work area.

Ensure ground return clamps are in good conditions and located as close as possible to

the work position.

Ensure that all drains within 20 meters are covered.

In confined spaces ensure there is adequate ventilation, and use respiratory protection

whenever necessary & the appropriate permits are in place.

Ensure the welding generators are grounded properly when in use.

Use forced air ventilation when welding or cutting is done in any confined space.

11.3 COMPRESSED GAS CYLINDERS

Compressed gas cylinders must be handled with care and stored in a secure upright

position.

Cylinders caps must be in place when cylinders are not in use, especially when cylinders

are being transported.

Cylinders should be stored securely to prevent cylinders from falling over.

Regulators should be inspected daily. Inspection should cover whether the gauges are

accurate, dents or cracks in the gauge covers, hose connections, flash back arrestors to

be fitted to all gauges, etc.

Cylinders should never be used while lying on their side. Cylinders in use should be

secured in an upright position.

Never oil or grease cylinder valves and/or regulators.

11.4 TRAINING (GRINDING WORKS)

Only competent persons are permitted to operate tools utilising abrasive wheels, cutting

discs abrasive tips and flappers.

Training and instruction must be provided before any person can be authorised to mount

wheels on pedestal grinders or change abrasive wheels, cutting discs tips or flappers.

Supervisor to ensure right disk for the job is used. i.e. cutting disc, grinding disc.

The correct personal protective equipment must be used at all times when using any

grinding or abrasive tools. This consists of proper gloves, goggles, steel tip toes shoe, etc.

Double eye protection to be worn when cutting or grinding (Safety glass & Face shield).

Ear plugs to be worn for ear protection.

Care must be taken to minimise the risk of fire by removing all potential flammable

materials from the immediate work area. Precautions must also be taken to control or

contain sparks and suitable fire fighting equipment must be readily available at site or

working area.

T.4.250.905 REV-O

Page 11 of 16

Doc. Title

Q A T A R

Date/Rev. No :

METHOD STATEMENT FOR WELDING AND HOT

WORKS FOR GENERAL ACTIVITIES AT TSF AREA

GAM-MTS-MEC-GTL-010, 25 March 2008, REV-C

11.5 LIFTING SLINGS

There are two types of lifting slings used on this job, wire slings and webbing slings. It is

very important that they are used and stored correctly.

Always use the right slings for the job, each sling has its safe working load (SWL) printed

or attached to the sling. Never try to make up, prefabricate lifting equipment.

Do not use a sling if there is no SWL written or attached, remove the sling and give it to

your supervisor.

Never tie knots in webbing or wire slings. This will damage the sling and it will need to be

discarded.

Always check a sling before use, look for tears, cuts and broken wires and if you have

any doubts about the sling show it to your supervisor. Wire slings must not have more

than five broken wires in one lay and must not be crushed or kinked. Nylon slings must

not be knotted or torn in the centre of the sling.

Never drag a sling from under a load if it is not free.

Webbing slings should not be dragged through oil or along the ground. Store the sling in

a rolled position making sure the sling is dry and stored in a dry place.

Be careful not to wrap the edges of the sling on sharp corners. Use packing materials

rubber, wood, cloth anything that will keep the slings surfaces away from sharp edge.

Always attach the sling properly to the load. Do not use a combination of wire and

webbing slings together, webbing will be cut by the wire sling.

All lifting equipment must be inspected, documented and colour coded.

12 QUALITY ASSURANCE

A Quality Assurance System shall be operated conforming to related standards.

13 ATTACHMENTS

13.1

JOB SAFETY ANALYSIS

T.4.250.905 REV-O

Page 12 of 16

Q A T A R

JOB SAFETY ANALYSIS FORM

Page No: 1 of 3

JSA For: T-4.250.905

Job being analysed: MS - WELDING AND HOT WORKS GENERAL AT TSF

JSA Members: Mr. Syd Osborne, Mr. Raci Onelge,

Department/Section doing JSA: HSSE & Mechanical works

Job Performers: Mr. Raci Onelge

Normal Approvals:

Name

Signature

JSA by:

Mr. Raci Onelge

23.03.08

Mr. Tej Prakash

Job Supervisor:

Additional Approvals (Determined by Job Supervisor in correlation with Linde HSSE Manager).

Name

Date

Signature

Discipline Superintendent (Linde)

23.03.08

Date

General job requirements / Personal

Protective Equipment.

1. The following Personal Protective

Equipment shall be worn:

Approved coveralls, safety goggles,

safety helmet, safety steel toe shoes and

leather gloves. Hearing protection must

be worn.

HSSE Representative (Linde)

2. Permit To Work.

OTHERS (List Below):

3. Gas test if / when required.

Approval required for hazardous work detailed in the Linde Work Permit Procedure.

Changing conditions and emergency procedures

Stop work. Switch off equipment. Supervisor directs personnel to nearest and safest muster point considering wind direction. Supervisor counts all employees.

Missing employees are reported to Linde HSSE Dept. When all clear is given, check with Linde HSSE before returning to work.

LINDE EMERGENCY TELEPHONE NO.

HSSE MANAGER:

Pearl HOT LINE :

583 40 72

474 88 88

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.250.905

Q A T A R

ITEM

1

ACTIVITY

Fit-up and Hot

works (Welding,

Grinding, Cutting)

HAZARDS / POTENTIAL

CONSEQUENCES

1.1 Burn Injury

Initial Risk

RISK

P C

RANK

1.2

1.4

MED

Electrical Shock

1.3

LOW

Fire Hazards

C

MED

LOW

Tripping Hazard

SCOPE : METHOD STATEMENT WELDING

AND HOT WORKS GENERAL AT TSF

Residual Risk

MAIN

CONTROLS

1.1.1 Wearing of protective coverall,

safety jackets, Long leather

gloves, Goggles, welding apron,

etc.

1.1.2 Drop zone should be provided

with barricade and warning signs

to warn the workers.

ADDITIONAL

CONTROLS

1.1.1.1 100% body protection/welding

apron. Welding blanket shall be

used to prevent welding slag's

from falling on people working

below and to avoid fire incident.

1.2.1 Check electrical equipment prior

1.2.1.1 All Welding cables and air hose

to its use. Ensure it is color coded

must be properly elevated to

and properly documented for the

avoid damage from heavy

month.

objects, damage from sharp

1.2.2 Ensure proper grounding.

objects and hot metals.

Grounding cable must be clamped

near the joint to be welded.

Welding cables, electrical cords

must be properly insulated.

1.2.3 Discuss at TBT Meeting.

1.3.1 Fire extinguisher shall be located

near the welding machine and on

welding operation.

1.3.2 Fire blanket must be used as

enclosure to eliminate hot slag's

from flying to adjacent work area.

1.4.1 All electrical cords, extension

cords must be elevated and

rolled-up after use.

1.4.2 All materials should be stored at

designated area.

1.4.3 Remove scrap and unnecessary

materials regularly.

1.4.4 House keeping to be done daily.

1.3.1.1 Do not store combustible and

flammable materials at work

area.

1.3.1.2 House keeping to be done daily.

LOW

LOW

LOW

LOW

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.250.905

Q A T A R

ITEM

ACTIVITY

HAZARDS / POTENTIAL

CONSEQUENCES

1.5 Head, Eye, Hand Injury,

leg injury, hearing loss

1.6

Initial Risk

P C RISK

MED

MED

Fall of Compressed

Gas

MAIN

SCOPE : METHOD STATEMENT WELDING

AND HOT WORKS GENERAL AT TSF

ADDITIONAL

1.5.1 100% Hard Had with welding

1.5.1.1 Supervisor/Forman shall ensure

Mask, Face shield with helmet,

TSTI is properly executed

safety goggles and leather hand

before work starts and discuss

gloves, safety steel capped shoes

the hazards.

and hearing protection.

1.5.2 Keep away hands, fingers and

feet from moving parts.

1.6.1 Oxygen Cylinder valves/fittings to 1.6.1.1 Empty cylinders must be

be kept free from oil/grease.

removed immediately from work

1.6.2 All Cylinders must be secured with

area and kept at the designated

chain on upright position.

area.

Protective caps to be used for all

full & empty cylinders and stored

at designated area away from hot

works activities.

1.6.3 Flash back arrestors to be fitted at

two ends of hoses and flow check

valve near cutting torch. Use torch

lighter to light the cutting torch.

1.6.4 Gas hoses and gauges to be

maintained in a safe condition.

Inspection to be done on a daily

basis. Defective gauges and

hoses to be replaced immediately.

1.6.5 Always check valves and

regulators and all fittings for leaks.

Residual Risk

P C

R

LOW

LOW

JOB SAFETY ANALYSIS / RISK ASSESSMENT

FOR T-4.250.905

Q A T A R

ITEM

2

ACTIVITY

Manual handling

HAZARDS / POTENTIAL

CONSEQUENCES

2.1 Personal injury, back

injuries, muscle strains,

sprains.

Initial Risk

RISK

P C

RANK

2.1.1

2.1.2

C

MED

2.2 Slip, Trip & Fall from

same level

2.1.3

2.1.4

2.1.5

2.2.1

2.2.2

LOW

2.3 Hand and finger injuries.

2.2.3

2.2.4

2.3.1

C

MED

2.3.2

SCOPE : METHOD STATEMENT WELDING

AND HOT WORKS GENERAL AT TSF

MAIN

ADDITIONAL

CONTROLS

CONTROLS

Worker to wear appropriate

2.1.1.1 Provision for lifting aids when

gloves.

practical.

Break the load into manageable

portions.

Lift with your legs not your back.

Use the buddy system, Get help.

Provide pictorial sign boards with

correct lifting position.

Adequate stacking of materials.

2.2.1.1 Remove unnecessary materials

Regular housekeeping practices

in the work place.

and removal of trash and

unnecessary items.

Maintain access and walk paths.

Housekeeping shall be a priority,

walk and work areas shall be kept

free of materials and supplies.

Wear approved PPE with leather 2.3.1.1 Supervisor/foreman shall

gloves.

ensure that the TSTI is properly

Keep away hand and finger from

executed at the work front and

moving parts.

hazards discussed.

Residual Risk

RISK

P C

RANK

LOW

LOW

LOW

Вам также может понравиться

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- 002-MS Nitrogen Filling, Cyrogenic Vaporizer PDFДокумент18 страниц002-MS Nitrogen Filling, Cyrogenic Vaporizer PDFKöksal PatanОценок пока нет

- 032-Procedure For Shop and Field Painting Work On Site PDFДокумент26 страниц032-Procedure For Shop and Field Painting Work On Site PDFKöksal Patan100% (1)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFДокумент23 страницы014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanОценок пока нет

- 004-Civil - MS Construction of Temporary Roads PDFДокумент17 страниц004-Civil - MS Construction of Temporary Roads PDFKöksal Patan100% (2)

- 001-MS For Structural Steel Assembly and Erection PDFДокумент28 страниц001-MS For Structural Steel Assembly and Erection PDFKöksal Patan100% (1)

- 015-Method Statement For Painting Works (Building) PDFДокумент21 страница015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 034-Pro For Building PDFДокумент36 страниц034-Pro For Building PDFKöksal Patan0% (1)

- 037-Procedure For Cleanliness PDFДокумент21 страница037-Procedure For Cleanliness PDFKöksal PatanОценок пока нет

- 008-CIVIL-MS Backfilling Works PDFДокумент16 страниц008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 014-MS For General Scaffolding PDFДокумент33 страницы014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 015-MS For Night Works PDFДокумент16 страниц015-MS For Night Works PDFKöksal Patan80% (5)

- MS of Concrete FoundationДокумент18 страницMS of Concrete FoundationSainbayar SBОценок пока нет

- 2.3 Hot WorkДокумент9 страниц2.3 Hot Workvishal bailurОценок пока нет

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Документ7 страницINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- Conduit BKM 7102Документ9 страницConduit BKM 7102Utku Can Kılıç100% (1)

- Execution Procedure For Pipe Connection Tie in and Hot TapzДокумент7 страницExecution Procedure For Pipe Connection Tie in and Hot TapzyuwantoniОценок пока нет

- Scaffolding ProcedureДокумент3 страницыScaffolding Proceduremd ruman100% (2)

- Job Safety Analysis Risk Summary SheetДокумент10 страницJob Safety Analysis Risk Summary SheetMohammad Fazal KhanОценок пока нет

- 15.5b - Pre-Qualification Questionnaire (Sample)Документ8 страниц15.5b - Pre-Qualification Questionnaire (Sample)karthikeyan elangoОценок пока нет

- Installation Method StatementДокумент6 страницInstallation Method StatementgururajОценок пока нет

- Pre-Commissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose ReelДокумент2 страницыPre-Commissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose ReelDong VanraОценок пока нет

- TR-CA-MS-001 - B Demolishing and Debris Removal-Sent To HibaДокумент17 страницTR-CA-MS-001 - B Demolishing and Debris Removal-Sent To Hibasamer8saifОценок пока нет

- HSE-Method Statement ScaffoldingДокумент32 страницыHSE-Method Statement ScaffoldingihsanОценок пока нет

- Cms 710 01 PR 03600 Substance Abuse ProgramДокумент8 страницCms 710 01 PR 03600 Substance Abuse Programandruta1978Оценок пока нет

- Method Statement For Painting of ValvesДокумент4 страницыMethod Statement For Painting of ValvesRashid Kayum100% (1)

- Method Statement of Ipa-227 Piping WorksДокумент5 страницMethod Statement of Ipa-227 Piping WorksPramod kumarОценок пока нет

- Litz Safe Work Procedures 2011Документ195 страницLitz Safe Work Procedures 2011Naz ッ WanyОценок пока нет

- Petrochina International Jabung Ltd. Job Safety Analysis: T On Ppe Required For A Safe JobДокумент5 страницPetrochina International Jabung Ltd. Job Safety Analysis: T On Ppe Required For A Safe JobYosua SitumorangОценок пока нет

- 30) Method Statement For Loading & Unloading PlatformДокумент3 страницы30) Method Statement For Loading & Unloading Platformmanoj50% (2)

- PR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionДокумент37 страницPR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionAffandy MMdОценок пока нет

- TIMAS-PR-PI-001 - Hot Tapping ProcedureДокумент11 страницTIMAS-PR-PI-001 - Hot Tapping ProcedureMechanical Static WRKОценок пока нет

- METHOD STATEMENT - PipingДокумент12 страницMETHOD STATEMENT - PipingAnonymous M5rHHKОценок пока нет

- S 1153824 CST G01 0008 MS For Maintenance ToolДокумент9 страницS 1153824 CST G01 0008 MS For Maintenance ToolDedy SupriadiОценок пока нет

- For Information For Review For Approval For Construction As-BuiltДокумент21 страницаFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçОценок пока нет

- JSA-Steel Structure Erection-NДокумент4 страницыJSA-Steel Structure Erection-NVivek Naik100% (2)

- JSA NO 2-Piling WorkДокумент3 страницыJSA NO 2-Piling WorkKarthik GanesanОценок пока нет

- Method Statement For Fabrication, Installation and Testing of PipeworkДокумент31 страницаMethod Statement For Fabrication, Installation and Testing of PipeworkNaveed Ahmed Get-Info100% (1)

- Method Statement For Excavation01Документ12 страницMethod Statement For Excavation01Basem DoniaОценок пока нет

- 4..pipe Spool Air Blowing & Cleaning JSA 04Документ2 страницы4..pipe Spool Air Blowing & Cleaning JSA 04Francis Vinoj100% (1)

- Method Statement For Hydro TestДокумент3 страницыMethod Statement For Hydro TestSandeep kumar100% (1)

- Operation and Maintenance Considerations For Oil and Gas SeparatorsДокумент2 страницыOperation and Maintenance Considerations For Oil and Gas SeparatorsJatin RamboОценок пока нет

- Safe Work Method StatementДокумент15 страницSafe Work Method StatementSampath AhОценок пока нет

- EHS Alert 008 - Tremmie Pipe Blockage AccidentДокумент1 страницаEHS Alert 008 - Tremmie Pipe Blockage AccidentAbdulKatherОценок пока нет

- 07 Method Sytatement For Drilling MachineДокумент5 страниц07 Method Sytatement For Drilling MachineNishar Balkavade100% (1)

- JSA - Erection Boiler Install (SFILEДокумент35 страницJSA - Erection Boiler Install (SFILEHilman NugrahaОценок пока нет

- Civil Work Method StatementДокумент18 страницCivil Work Method Statementغيثمحمود100% (1)

- JSA23 Hydro Static Pressure Testing Various Pipe AuxiliariesДокумент5 страницJSA23 Hydro Static Pressure Testing Various Pipe AuxiliariesslmLSU100% (3)

- 033-Itp For Piping Installation Ag and Ug PDFДокумент13 страниц033-Itp For Piping Installation Ag and Ug PDFKöksal Patan75% (4)

- Mechanical Completion Check ListДокумент6 страницMechanical Completion Check Listmanish2089Оценок пока нет

- Safety Method Statement TemplateДокумент1 страницаSafety Method Statement TemplatemaninderpreetОценок пока нет

- 049-Itp For Lighting and Small Power (Building) PDFДокумент15 страниц049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- SWP 013 Oxy Acetylene WeldingДокумент4 страницыSWP 013 Oxy Acetylene WeldingBajaj NitinОценок пока нет

- Jsa Nitrogen Purging PDFДокумент2 страницыJsa Nitrogen Purging PDFBISWA RANJAN SAHOOОценок пока нет

- Work Method Bridge Sleeper Replacement - 2014Документ8 страницWork Method Bridge Sleeper Replacement - 2014Irham M AFОценок пока нет

- HIRADC Installation PipeДокумент4 страницыHIRADC Installation PipeamizanОценок пока нет

- Job Procedure 05 For CABLE LAYING & TERMINATIONДокумент6 страницJob Procedure 05 For CABLE LAYING & TERMINATIONSoumik KarОценок пока нет

- Method Statement Template - Rev01Документ18 страницMethod Statement Template - Rev01Senthilkumaran VenkatasamyОценок пока нет

- Site Erection ManualДокумент11 страницSite Erection Manualjohney2Оценок пока нет

- 035-Procedure Structural Steel Repair Works at Site PDFДокумент14 страниц035-Procedure Structural Steel Repair Works at Site PDFKöksal Patan100% (1)

- 017-CIVIL-MS For Installation of Fence & Gate PDFДокумент18 страниц017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 015-Method Statement For Painting Works (Building) PDFДокумент21 страница015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 015-MS For Night Works PDFДокумент16 страниц015-MS For Night Works PDFKöksal Patan80% (5)

- 014-MS For General Scaffolding PDFДокумент33 страницы014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 016-CIVIL - MS Anchor Bolt Installation PDFДокумент14 страниц016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 048-Itp For Installation of Hvac Unit PDFДокумент8 страниц048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 050-Itp For Installation of Air Intake Filter PDFДокумент17 страниц050-Itp For Installation of Air Intake Filter PDFKöksal PatanОценок пока нет

- 013-MS Utilization of Hilti DX 76 PDFДокумент51 страница013-MS Utilization of Hilti DX 76 PDFKöksal PatanОценок пока нет

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFДокумент18 страниц012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanОценок пока нет

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFДокумент16 страниц012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 040-ITP For Repair of Steam Distribution Manifold PDFДокумент11 страниц040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanОценок пока нет

- 013-MS For Mass Concrete Works PDFДокумент26 страниц013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 049-Itp For Lighting and Small Power (Building) PDFДокумент15 страниц049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 043-ITP FOR Water Proofing (Buildings) PDFДокумент13 страниц043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 047-Itp For Oxygen Lines Fabrication and Installation PDFДокумент28 страниц047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanОценок пока нет

- 011-Method Statement For Repair of Concrete Works PDFДокумент25 страниц011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 044-ITP For Installation of Gypsum Board (Buildings) PDFДокумент10 страниц044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFДокумент10 страниц045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 010-MS For Grouting PDFДокумент33 страницы010-MS For Grouting PDFKöksal PatanОценок пока нет

- 041 - ITP For Painting (Building) PDFДокумент12 страниц041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 009-Civil-Ms Concrete Works PDFДокумент27 страниц009-Civil-Ms Concrete Works PDFKöksal PatanОценок пока нет

- 009-Method Statement - Main Erection Sequence For Acc PDFДокумент68 страниц009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFДокумент18 страниц046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanОценок пока нет

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFДокумент23 страницы008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanОценок пока нет

- 039-Itp For Embedded Plate PDFДокумент7 страниц039-Itp For Embedded Plate PDFKöksal PatanОценок пока нет

- 008-CIVIL-MS Backfilling Works PDFДокумент16 страниц008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFДокумент25 страниц007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanОценок пока нет

- 038-Itp For Coldboxes PDFДокумент25 страниц038-Itp For Coldboxes PDFKöksal PatanОценок пока нет

- Manual - Submersible PumpДокумент4 страницыManual - Submersible PumpcodersriramОценок пока нет

- Chapter 5 SupplementsДокумент5 страницChapter 5 SupplementsGabriela MironОценок пока нет

- Mica PDFДокумент2 страницыMica PDFomarОценок пока нет

- Multibio BrochureДокумент1 страницаMultibio Brochuree-ComfortUSAОценок пока нет

- CG FlexconnectДокумент32 страницыCG FlexconnectSantanuMannaОценок пока нет

- Mazda rx7Документ3 страницыMazda rx7Jon WestОценок пока нет

- Kevin Colcomb, Matthew Rymell and Alun Lewis: Very Heavy Fuel Oils: Risk Analysis of Their Transport in Uk WatersДокумент12 страницKevin Colcomb, Matthew Rymell and Alun Lewis: Very Heavy Fuel Oils: Risk Analysis of Their Transport in Uk WatersSidney Pereira JuniorОценок пока нет

- CarДокумент5 страницCarHarish GundaОценок пока нет

- 4 Leed Open SpaceДокумент6 страниц4 Leed Open SpaceswapnilupgadeОценок пока нет

- The Hydraulic Pumping SystemДокумент12 страницThe Hydraulic Pumping SystemCarlos Lopez DominguezОценок пока нет

- Antonio Stradivari, Cello, Cremona, 1726, The 'Comte de Saveuse' - TarisioДокумент1 страницаAntonio Stradivari, Cello, Cremona, 1726, The 'Comte de Saveuse' - TarisioUrko LarrañagaОценок пока нет

- Chapter 5 Hydraulic JumpДокумент31 страницаChapter 5 Hydraulic JumpUsman AliОценок пока нет

- Crane GBLДокумент2 страницыCrane GBLbudi setiawanОценок пока нет

- Customer Interface Publication: KCH CIP015Документ8 страницCustomer Interface Publication: KCH CIP01560360155Оценок пока нет

- RC4 Vector Key Based Conditional Access System in Pay-TV Broadcasting SystemДокумент5 страницRC4 Vector Key Based Conditional Access System in Pay-TV Broadcasting SystemAlad Manoj PeterОценок пока нет

- Checklist For Buying A Better Used Car in MalaysiaДокумент2 страницыChecklist For Buying A Better Used Car in MalaysiaSurendra KumarОценок пока нет

- Development Processes and OrganizationsДокумент41 страницаDevelopment Processes and OrganizationsPuneet GoelОценок пока нет

- Fuse Box Diagram JeepДокумент7 страницFuse Box Diagram JeepSumedin Nisic100% (1)

- Control Systems Vs Machine LearningДокумент2 страницыControl Systems Vs Machine LearningSufiyan N-YoОценок пока нет

- Power Profile - Armor Powers PDFДокумент6 страницPower Profile - Armor Powers PDFlolo1972100% (2)

- Indian CyberSecurity Product Landscape PDFДокумент56 страницIndian CyberSecurity Product Landscape PDFShaik InayathОценок пока нет

- Brochure 7900E EN PDFДокумент16 страницBrochure 7900E EN PDFabvs97Оценок пока нет

- Prime Vision Security Solutions - Company ProfileДокумент11 страницPrime Vision Security Solutions - Company ProfileAbdul QayyumОценок пока нет

- UTDEC 2020: Sub: Skill Test/Typing Test For The Post of Personal AssistantДокумент2 страницыUTDEC 2020: Sub: Skill Test/Typing Test For The Post of Personal Assistantneekuj malikОценок пока нет

- ANDROID Workshop MaheshДокумент72 страницыANDROID Workshop MaheshPradeepCool100% (2)

- Instalare Auxiliar in For CD-70 NaviДокумент6 страницInstalare Auxiliar in For CD-70 Navipolyrain0% (1)

- Acquisitions Bentley SystemsДокумент3 страницыAcquisitions Bentley SystemsPramit Kumar SenapatiОценок пока нет

- CIV211 - Module1Документ49 страницCIV211 - Module1Dayalan JayarajОценок пока нет

- 108 Names English Ucchista Ganapati SanskritДокумент5 страниц108 Names English Ucchista Ganapati Sanskritakshay patriОценок пока нет

- Skills, Techniques and Production in Contemporary Art HANDOUT PDFДокумент4 страницыSkills, Techniques and Production in Contemporary Art HANDOUT PDFKeyy TaezaОценок пока нет

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОт EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОценок пока нет

- Analog Design and Simulation Using OrCAD Capture and PSpiceОт EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceОценок пока нет

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureОт EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceОт EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceРейтинг: 4 из 5 звезд4/5 (19)

- Laws of UX: Using Psychology to Design Better Products & ServicesОт EverandLaws of UX: Using Psychology to Design Better Products & ServicesРейтинг: 5 из 5 звезд5/5 (9)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsОт EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsОценок пока нет

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsОт EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsРейтинг: 4 из 5 звезд4/5 (2)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsОт EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsРейтинг: 5 из 5 звезд5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchОт EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchРейтинг: 4 из 5 звезд4/5 (10)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableОт EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableОценок пока нет

- Practical Troubleshooting of Electrical Equipment and Control CircuitsОт EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsРейтинг: 4 из 5 звезд4/5 (5)

- 507 Mechanical Movements: Mechanisms and DevicesОт Everand507 Mechanical Movements: Mechanisms and DevicesРейтинг: 4 из 5 звезд4/5 (28)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tОт EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tРейтинг: 4.5 из 5 звезд4.5/5 (27)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersОт EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersРейтинг: 4 из 5 звезд4/5 (13)

- Understanding Automotive Electronics: An Engineering PerspectiveОт EverandUnderstanding Automotive Electronics: An Engineering PerspectiveРейтинг: 3.5 из 5 звезд3.5/5 (16)

- Design for How People Think: Using Brain Science to Build Better ProductsОт EverandDesign for How People Think: Using Brain Science to Build Better ProductsРейтинг: 4 из 5 звезд4/5 (8)

- Basic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesОт EverandBasic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesРейтинг: 3 из 5 звезд3/5 (1)