Академический Документы

Профессиональный Документы

Культура Документы

Kit Procedure - FM4-8409-000 - PDF

Загружено:

Shadamyen NomyenИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Kit Procedure - FM4-8409-000 - PDF

Загружено:

Shadamyen NomyenАвторское право:

Доступные форматы

Prroocceedduurree ttoo iinnssttaallll tthhee IITTBB iim

P

mp

prroov

veem

meen

ntt k

kiitt

((FFM

M4

4--8

84

40

09

9))

2. Remove thee tension sprring [10].

[[1100]]

[N

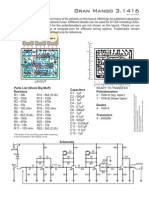

Necessary iteems]

A. Super lube grease (FY99-6005-000)

B. ITB improvvement kit (FFM4-8409)xx 1 set

Parts

P in the ITB improvvement kit

22

11

66

44

55

33

77

88

3. Remove the retaining part [4] whhich retainss the

tennsion springg [3] at the rear and applys tensioon to

thee ITB [2].

Att this time, remove

r

the 2 screws [6].

*[55] is a retainning part at the front.

[[44]]

99

1. Tension

T

springg (with no parrt number)[[2233]] x 2 pieces- Shape

S

chaange

2. Cam

C spacer (FCC0-4882-000)[[2211]]-- New part

3. Rear

R transfer arm,

a 2(FL3-5416-010)[[2222]]--Shaape change

4. Upper

U

steering cam (FC8-44744-000) [[1166]]

5. Lower

L

steering cam (FC8-44755-000) [[1177]]

[[55]]

6. Roller

R

cam (FC8-4487-000)[[1188]]

[[44]]

7. (A)

( Belt retainiing sheet (FC9--7914-000) [[3355]]

8. Secondary

S

trannsfer inner rolleer(FC8-4402-0000)[[2277]]

9. Identification

I

l

label

(black coolor) (with no part number) [[3366]]-New

w part

[Stteps]

1.RRemove the ITB unit [1]] from the main

m body.

Reemove the transfer cleeaner [37] to remove the

ITB[2].

[[22]]

[[11]]

[[66]]

4. Remove thee tension sprring [3] at thhe rear.

Discard [3].

*D

[[44]]

[[33]]

[[3377]]

Pub No: FT2-0018-0

F

000

6/10

5. Remove the retaining part [5] at the front in the

same way as in the step at the rear.

10. Remove the E-ring [11] and the washer [12].

[[55]]

[[66]]

[[1122]]

[[1111]]

6. Remove the tension spring [3] at the front.

*Discard [3].

[[55]]

[[33]]

7. Remove the 3 screws to remove the harness guide

[7] of the electric contacts. [[77]]

8. Remove the screw to remove the sheet metal part

[8].

[[88]]

9. Remove the 3 screws to remove the old type of

the rear transfer arm, 2 [9].

*Discard [9].

11. Remove the spring [13] to remove the cam

assembly [14].

*Discard [13].

[[1133]]

[[1144]]

12. Remove the 2 screws [15] from the cam assembly

[14].At this time, the upper steering cam [16] and the

upper steering cam [17] are separated.

* Keep the 2 screws [15] somewhere so that they

should be used again later.

*Discard [16] and [17].

[[1144]]

[[1166]]

[[1177]]

[[1155]]

[[99]]

Pub No: FT2-0018-000

7/10

13. Replace thhe roller cam

m (FC8-44877-000)[18] with a

new one.*Disccard removedd [18].

[[1188]]

[[1144]]

166. Inset thee cam spaceer (FC0-48882-000)[21] into

thee gap betweeen the cam assembly [114] and the shaft

s

[199].

[[2211]]

w upper steering cam

14. Prepare the new

t new low

wer steering cam

(FCC8-4474-0000) [16] and the

(FCC8-4475-0000) [17].

Unnite [16] andd [17] by usinng the 2 screews kept in Step

12.

Make sure noot to make the

t screw hoole loose as the

t 2

*M

scrrews [15] aree self tappinng and the hoole for [17] is not

tappped.

* Do

D not retighhten the scrrew once thee screw has been

tigghtened to prevent

p

the screw holee from becom

ming

looose.

[[1155]]

[[1199]]

[[1144]]

177. Apply the grease to thhe sliding suurface [A] of

o the

neew type of thhe rear trannsfer arm, 2 (FL3-5416--010)

[222].

Grrease: Superr lube greasee (FY9-6005-000)

Appplication quantity:

q

thhe size of a rice graiin (2

loccations)

[[2222]]

[[AA]]

[[1166]]

[[1144]]

[[1177]]

15. Insert the shaft [19] into

i the new

w cam assem

mbly

[144] assembleed earlier. At

A this timee, assemblee the

rolller cam [18]] to be locked into the grroove [20].

188. Mount thee new rear trransfer arm,, 2

(FLL3-5416-0100) [22], the ssheet metal assembly

a

[8]] and

thee harness guide

g

[7] of the electricc contacts too the

ITB unit [1] inn a reverse oorder of Stepp 6, 7 and 8.

[[88]]

[[77]]

[[2222]]

[[1199]]

[[1144]]

[[1188]]

[[2200]]

Pub No: FT2-0018-0

F

000

8/10

19. Prepare the new type of the tension spring [23]

and insert it to the ITB unit [1].

Note: Make sure to correctly insert the tension spring

[23] into the boss [24].

[[2233]]

22. Remove the bearing retaining part [25] to remove

the bearing [26]. Slide aside the second transfer inner

roller [27] to remove it. Prepare the new second

transfer inner roller [27] and assemble it in reverse

order of the above.

N

Noottee:: AAppppllyy tthhee rriissee--ggrraaiinn--ssiizzeedd ggrreeaassee ttoo tthhee eeddggeess ooff

tth

hee ffrroon

ntt ssh

ha

afftt [[2288]] aanndd tthhee rreeaarr sshhaafftt [[2299]] ooff tthhee nneew

w

sseeccoonndd ttrraannssffeerr iinnnneerr rroolllleerr [[2277]] bbeeffoorree tthhee

rreep

plla

acceem

meen

ntt.. W

Wiitth

hoou

utt tth

hee g

grreea

assee aapppplliiccaattiioonn,, tthhee

sshhaafftt m

ma

ayy cchhiipp--ooffff,, ccaauussiinngg EE007755 eerrrroorr..

Grease: SSuuppeerr lluubbee ggrreeaassee ((FFYY99--66000055--000000))

*Discard the removed [27].

[[2244]]

[[2233]]

[[2288]]

[[2299]]

20. Mount the retaining part [4] to complete fixing

the tension spring [23].

* Secure the tension spring [23] at the front in the

same way as in the step at the rear.

[[2277]]

[[44]]

[[2255]]

[[2277]]

21. Mount the E-ring [11] and the washer [12] to the

cam assembly [14]. Mount the tension spring [10].

[[2266]]

23. Rotate the ITB sub pressure release lever [30]

from the state [B] to the state [C], making the ITB

unit pressurized condition.

[[3300]]

[[1144]]

[[1100]]

[[1122]]

[[1111]]

[[BB]]

Pub No: FT2-0018-000

[[CC]]

9/10

24. Clean with alcohol while rotating the drive roller

[31], the tension roller [32], the primary transfer

auxiliary roller [33] and the idler roller [34]. Return

the ITB sub pressure release lever [30] to the position

[B] after cleaning.

27. Return the removed ITB and others to the unit,

and assemble the ITB unit to the main body.

28. Perform ITB equilibrium position detection.

[Steps in Service Mode]

Check that the value of ITB equilibrium position

detection is in the range between -200 and +350.

First, perform ITB equilibrium position detection.

((LLeevveell11))CCO

OP

PIIE

ERR>>FFU

UN

NCCTTIIO

ON

N>>M

MIIS

SCC--PP>>IITTBB--IIN

NIITT

[[3311]]

Then, check the position of the ITB belt.

(Level1)COPIER>DISPLAY>MISC>ITB-POS

The work is completed if the value of ITB-POS is in

the range between --220000 aanndd ++335500.

If the value of ITB-POS is not in the above range, go

to Step 29.

[[3333]]

[[3322]]

29. Adjust the adjuster

[[3344]]

How to adjust ITB-POS by adjuster

When ITB-POS is -200 or less

When ITB-POS is +350 or more

(When it needs to be shifted to + side)

(When it needs to be shifted to side)

25. Replace the belt retaining sheet with the new

sheet (A) (FC9-7914-000) [35].

*Reference of attachment: [D] and [E]

[F] is plastic rib. The edge of [F] is the location of [E].

*Discard the removed [35].

[[EE]]

[[D

D]]

[[3355]]

Rotate the adjuster in the front

left of the machine

clockwise for twice.

Rotate the adjuster in the front

right of the machine

clockwise for twice.

below -200

After ITB-INIT

Reverse the belt

-200 to +350

OK

over +300

After ITB-INIT

Rotate the adjuster

-200 to +350

one more time.

After ITB-INIT

-200 to +350

OK

OK

After ITB-INIT

-200 to +350

OK

The work is completed.

[[FF]]

26. Attach the identification label ( black color) [36] to

the ITB unit.

[[3366]]

Position to attach

Pub No: FT2-0018-000

10/10

Вам также может понравиться

- GK 19 Ur PDFДокумент50 страницGK 19 Ur PDFDavid DiehlОценок пока нет

- Canon MF5650-007 - Service BulletinДокумент1 страницаCanon MF5650-007 - Service BulletinSMART REFILLОценок пока нет

- EECD0001Документ36 страницEECD0001Sergey Gusev100% (3)

- Gemini-BPM500 PreampДокумент12 страницGemini-BPM500 PreampAristoteles CarreñoОценок пока нет

- 3512 Diag - Engine - 1243-06 - SisДокумент8 страниц3512 Diag - Engine - 1243-06 - Sisshashank715Оценок пока нет

- ENG1002 - Project 2 Specification 2018 S2Документ8 страницENG1002 - Project 2 Specification 2018 S2Sara Uyen TranОценок пока нет

- Service Bulletin: Issued by Canon Europa N.VДокумент6 страницService Bulletin: Issued by Canon Europa N.Valfred vivien bossonОценок пока нет

- Disassembling and Reassembling - Fixing Unit - TP07-168Документ9 страницDisassembling and Reassembling - Fixing Unit - TP07-168shamilbasayevОценок пока нет

- Parts Catalog: Imagerunner1750/1740/ 1730 SeriesДокумент90 страницParts Catalog: Imagerunner1750/1740/ 1730 SeriescollionsОценок пока нет

- Products Affected / Serial Numbers Affected:: TP12 253.pdf 08-03-12Документ5 страницProducts Affected / Serial Numbers Affected:: TP12 253.pdf 08-03-12Andi PrengaОценок пока нет

- Imagerunner Advance c5051 Series PC Rev1 111110Документ264 страницыImagerunner Advance c5051 Series PC Rev1 111110JamesОценок пока нет

- Skew Adjustment Single Pass DADF-C1Документ4 страницыSkew Adjustment Single Pass DADF-C1Copier ServicesОценок пока нет

- Products Affected / Serial Numbers Affected: Subject: GeneralДокумент3 страницыProducts Affected / Serial Numbers Affected: Subject: GeneralAndi PrengaОценок пока нет

- Service Bulletin: Issued by Canon Europa N.VДокумент2 страницыService Bulletin: Issued by Canon Europa N.Vcopiadoras manuelОценок пока нет

- Ir4570 026Документ3 страницыIr4570 026Indah Bunda CantixsОценок пока нет

- TP10 PDFДокумент7 страницTP10 PDFCopiopolis FiestaОценок пока нет

- Ir6000 027Документ3 страницыIr6000 027katem1Оценок пока нет

- Service Bulletin: Issued by Canon Europa N.VДокумент1 страницаService Bulletin: Issued by Canon Europa N.VanthonypardoОценок пока нет

- Compudiskette Abril ListaДокумент33 страницыCompudiskette Abril ListaJuan Carlos SalazarОценок пока нет

- General Timing Chart / General Circuit Diagram: Ir1018/1019/1022/1023 SeriesДокумент18 страницGeneral Timing Chart / General Circuit Diagram: Ir1018/1019/1022/1023 SerieslogostilОценок пока нет

- Product: All Title: Changing Configuration of A Point and Print DriverДокумент8 страницProduct: All Title: Changing Configuration of A Point and Print DriveranthonypardoОценок пока нет

- Service Bulletin: Model: GP160F No.Документ20 страницService Bulletin: Model: GP160F No.Mohamed SamirОценок пока нет

- Products Affected / Serial Numbers Affected:: Description Imagerunner Lbp5460Документ3 страницыProducts Affected / Serial Numbers Affected:: Description Imagerunner Lbp5460Eder AgrazОценок пока нет

- HP LaserJet Enterprise M725MFP Repair Manual PDFДокумент366 страницHP LaserJet Enterprise M725MFP Repair Manual PDFfefotroncito0% (1)

- Saddle Finisher q2 q4 GTC GCDДокумент20 страницSaddle Finisher q2 q4 GTC GCDutilscОценок пока нет

- Products Affected / Serial Numbers Affected:: TP10 332.pdf 11-17-10Документ2 страницыProducts Affected / Serial Numbers Affected:: TP10 332.pdf 11-17-10Andi PrengaОценок пока нет

- HP Toner Inkjets: Printers PrintersДокумент7 страницHP Toner Inkjets: Printers PrintersTecnoprint Sevilla CentroОценок пока нет

- Service Bulletin: CopierДокумент2 страницыService Bulletin: CopiertraminerОценок пока нет

- 020A-010B Jam CodesДокумент3 страницы020A-010B Jam CodestraminerОценок пока нет

- General Timing Chart / General Circuit Diagram: Finisher, Sorter, Deliverytray Punch Unit-U1Документ10 страницGeneral Timing Chart / General Circuit Diagram: Finisher, Sorter, Deliverytray Punch Unit-U1ereslomaximo2014Оценок пока нет

- Ir3200 TP03-1Документ11 страницIr3200 TP03-1COLOR50Оценок пока нет

- Canon Service LetterДокумент2 страницыCanon Service LetterFinito TheEndОценок пока нет

- Canon Image Runner 2200 - 2800 - 3300 Reference GuideДокумент358 страницCanon Image Runner 2200 - 2800 - 3300 Reference GuidejunktownhawkОценок пока нет

- imageRUNNER 2016 2020 PC DU7-3142-000Документ112 страницimageRUNNER 2016 2020 PC DU7-3142-000oleg-spbОценок пока нет

- IR-6570 Remove Drum Cleaning UnitДокумент5 страницIR-6570 Remove Drum Cleaning UnitbongОценок пока нет

- Introduction of ImagePRESS C6000-6000VPДокумент32 страницыIntroduction of ImagePRESS C6000-6000VPshamilbasayevОценок пока нет

- Cat A LogoДокумент14 страницCat A LogoJanaina JacobsОценок пока нет

- Canon I Sensys LBP5300 5360Документ192 страницыCanon I Sensys LBP5300 5360GonzaloОценок пока нет

- Instructional Manual Continuous Ink System For Use in HP Deskjet 3320,3323,3325,3420,3425 With CartridgesДокумент4 страницыInstructional Manual Continuous Ink System For Use in HP Deskjet 3320,3323,3325,3420,3425 With CartridgesleijuliaОценок пока нет

- HP LaserJet Enterprise MFP M631, M632, M633 and HP LaserJet Managed MFP E62555, E62565, and E62575 - Control Panel Message Document (CPMD)Документ254 страницыHP LaserJet Enterprise MFP M631, M632, M633 and HP LaserJet Managed MFP E62555, E62565, and E62575 - Control Panel Message Document (CPMD)JeralAntonioLisboaCarranzaОценок пока нет

- Despec Romania Stoc Printing Imaging 19.04.2012Документ12 страницDespec Romania Stoc Printing Imaging 19.04.2012fansistem1Оценок пока нет

- Asus F80L - F80Q SchemeДокумент59 страницAsus F80L - F80Q Schemecyper8Оценок пока нет

- Saddle Finisher q2 q4 CDДокумент46 страницSaddle Finisher q2 q4 CDutilscОценок пока нет

- Ir5000/6000 Series: Service BulletinДокумент2 страницыIr5000/6000 Series: Service Bulletinkatem1Оценок пока нет

- E069 PDFДокумент4 страницыE069 PDFvishwajitОценок пока нет

- Samsung SP0411N HDD TutorialДокумент9 страницSamsung SP0411N HDD TutorialBibhuti BibhakerОценок пока нет

- Products Affected / Serial Numbers Affected:: TP10 003a.pdf 03-02-10Документ2 страницыProducts Affected / Serial Numbers Affected:: TP10 003a.pdf 03-02-10Hamidullah Asady WardakОценок пока нет

- Pixma - Ip4200 Service ManualДокумент58 страницPixma - Ip4200 Service ManualPepeОценок пока нет

- iRC5180 Color Shift Prevention & CorrectionДокумент5 страницiRC5180 Color Shift Prevention & CorrectionrsqnetОценок пока нет

- Products Affected / Serial Numbers Affected:: TP06 036.pdf 01-30-06Документ3 страницыProducts Affected / Serial Numbers Affected:: TP06 036.pdf 01-30-06xm1Оценок пока нет

- CanonДокумент747 страницCanonnafeesОценок пока нет

- IMS Ink ManualДокумент40 страницIMS Ink ManualAli Aleem0% (1)

- Whirlpool Polar PDT 839 Service ManualДокумент14 страницWhirlpool Polar PDT 839 Service ManualAnonymous 2GVabYh40WОценок пока нет

- Canon PIXMA MP170 MP450 Parts CatalogДокумент28 страницCanon PIXMA MP170 MP450 Parts CatalogtangocharliepdxОценок пока нет

- Measure To Prevent A False Size Detection at The Reader Assembly PDFДокумент8 страницMeasure To Prevent A False Size Detection at The Reader Assembly PDFereslomaximo2014Оценок пока нет

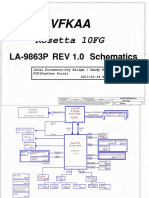

- LA-9863P VFKAA r10 PDFДокумент56 страницLA-9863P VFKAA r10 PDFn nnОценок пока нет

- TP08 178c iPF Parts Replacement Per Model PDFДокумент16 страницTP08 178c iPF Parts Replacement Per Model PDFciphardОценок пока нет

- Service Bulletin: CopierДокумент2 страницыService Bulletin: CopierAmer RafiqueОценок пока нет

- Calibration Process IPC1Документ30 страницCalibration Process IPC1Nick GumbaОценок пока нет

- Bootrom Dcon Rcon PCB Dimm Chart 05222012Документ2 страницыBootrom Dcon Rcon PCB Dimm Chart 05222012Deepak BukhrediwalОценок пока нет

- w58 RebuildДокумент49 страницw58 RebuildtfphoenixОценок пока нет

- F2 Manual Transmission/Manual Transaxle: To IndexДокумент21 страницаF2 Manual Transmission/Manual Transaxle: To IndexKwun Hok ChongОценок пока нет

- Installing The 266-8480 Temperature Control Kit (Manual) On 300 Series B Excavators (7304)Документ12 страницInstalling The 266-8480 Temperature Control Kit (Manual) On 300 Series B Excavators (7304)alfredОценок пока нет

- Reglaje de ValvulasДокумент15 страницReglaje de ValvulasJuan Antonio Ochoa PadronОценок пока нет

- Speedometer Fuel Gauge and Fuel Gauge Sender: Macam - Macam Instrument PanelДокумент2 страницыSpeedometer Fuel Gauge and Fuel Gauge Sender: Macam - Macam Instrument PanelWahyu PОценок пока нет

- Anixter Wire and Cable Cold Temperature Ratings Wire Wisdom enДокумент2 страницыAnixter Wire and Cable Cold Temperature Ratings Wire Wisdom enFelipe GustavoОценок пока нет

- T2500Документ2 страницыT2500kylegazeОценок пока нет

- Feednet: ManualДокумент56 страницFeednet: ManualRobot 3TОценок пока нет

- The Shark: Slickline Measurement Device With Combined Depth/TensionДокумент34 страницыThe Shark: Slickline Measurement Device With Combined Depth/TensionFabio ParceroОценок пока нет

- Measure of Pump Efficiency, Head and DischargeДокумент15 страницMeasure of Pump Efficiency, Head and DischargeHaikal HarithОценок пока нет

- In 14 6TubeClock en V1.2Документ14 страницIn 14 6TubeClock en V1.2Enéas BaroneОценок пока нет

- Zelio Timer Relays - RUZC2MДокумент5 страницZelio Timer Relays - RUZC2MFredy Aparco IngaОценок пока нет

- 27.classroom Objects BДокумент21 страница27.classroom Objects BAleksandra VuОценок пока нет

- 480 Volt Corner Grounded Delta - Friend or Foe PDFДокумент8 страниц480 Volt Corner Grounded Delta - Friend or Foe PDFRajuОценок пока нет

- Manual M3PRO 80Документ2 страницыManual M3PRO 80Aziz el materziОценок пока нет

- Panel Schedule TemplateДокумент1 страницаPanel Schedule TemplateJefri Yan SipahutarОценок пока нет

- Orca Share Media1522536164379Документ4 страницыOrca Share Media1522536164379Jesus Alfredo Soria Sanchez100% (1)

- Expression 1640XL PDFДокумент13 страницExpression 1640XL PDFfefotroncitoОценок пока нет

- Tonepad BigmuffДокумент2 страницыTonepad BigmuffWasabiRockОценок пока нет

- PLC Based Automatic Control of Uniflocka10 Machine in Altex: CertificateДокумент60 страницPLC Based Automatic Control of Uniflocka10 Machine in Altex: CertificateFìrœ Lōv MånОценок пока нет

- fILE PERSIAPAN UKKДокумент4 страницыfILE PERSIAPAN UKKLuqman Pramana SudibyaОценок пока нет

- Camara Espia Manual Español e InglesДокумент4 страницыCamara Espia Manual Español e InglesAnonymous rvAn04wk1YОценок пока нет

- Install An Alarm Bell, Back Box, and Bell Guard in 6 Easy StepsДокумент9 страницInstall An Alarm Bell, Back Box, and Bell Guard in 6 Easy StepsSofiqОценок пока нет

- Zinc-Coated Steel Wire Rope and Fittings For Highway GuardrailДокумент2 страницыZinc-Coated Steel Wire Rope and Fittings For Highway GuardrailmjgutierrezperaltaОценок пока нет

- AEL5 Series Electric Linear Actuators For DN15 To DN100 Control Valves-Technical InformationДокумент9 страницAEL5 Series Electric Linear Actuators For DN15 To DN100 Control Valves-Technical InformationNguyen Xuan QuangОценок пока нет

- BOBCAT E26 7348752 SM PreviewДокумент41 страницаBOBCAT E26 7348752 SM Previewmonica SoluguelОценок пока нет

- 11 CVC 01 INLET VANE CONTROL DAMPER Flamgard Calidair Product Data Sheet1Документ2 страницы11 CVC 01 INLET VANE CONTROL DAMPER Flamgard Calidair Product Data Sheet1Nguyễn LinhОценок пока нет

- DL Manual - Com Vs Controller Gs Driver p100 Operating ManualДокумент124 страницыDL Manual - Com Vs Controller Gs Driver p100 Operating ManualThiago Teixeira PiresОценок пока нет

- Price ListДокумент519 страницPrice Listabrar nurtata100% (1)

- Status Report Rinnen Foreuse C9 MBD08641 La Totale - PSRPT - 2021-07-20 - 14.03.53Документ4 страницыStatus Report Rinnen Foreuse C9 MBD08641 La Totale - PSRPT - 2021-07-20 - 14.03.53Jean DiscretОценок пока нет