Академический Документы

Профессиональный Документы

Культура Документы

1 s2.0 S0255270112001389 Main

Загружено:

NopparutОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1 s2.0 S0255270112001389 Main

Загружено:

NopparutАвторское право:

Доступные форматы

Chemical Engineering and Processing 61 (2012) 815

Contents lists available at SciVerse ScienceDirect

Chemical Engineering and Processing:

Process Intensication

journal homepage: www.elsevier.com/locate/cep

Hybrid hydrocyclone process operating with natural water

Chaiyaporn Puprasert b , Vorasiri Siangsanung a,b , Christelle Guigui a ,

Cline Levecq c , Gilles Hbrard a,

a

Universit de Toulouse, INSA, UPS, INP, Laboratoire dIngnierie des Systmes Biologiques et des Procds (LISBP), 135 Avenue de Rangueil, 31077 Toulouse, France; INRA, UMRA792,

LISBP, 31400 Toulouse, France; CNRS, UMR5504, LISBP, 31400 Toulouse, France

b

Department of Environmental Engineering, Faculty of Engineering, Chulalongkorn University, Patumwan Road, Bangkok 10330, Thailand

c

Anjou Recherche, Chemin de la digue, BP 76, F-78603 Maisons-Laftte cedex, France

a r t i c l e

i n f o

Article history:

Received 24 November 2011

Received in revised form 3 July 2012

Accepted 7 July 2012

Available online 16 July 2012

Keywords:

Hybrid process

Water treatment

Hydrocyclone

Coagulation

Flocculation

Natural water

a b s t r a c t

This research deals with a hybrid hydrocyclone process, involving micro-bubbles injection generated by

the dissolved air otation technique; the micro-bubbles allow the aerated ocs formed by coagulation

and occulation to be separated inside the hydrocyclone. The oc separation is induced by centrifugal

force. The lighter phase moves toward the center of the hydrocyclone and the heavier one to the wall.

This hybrid process is intended for natural water or industrial raw water and would be performed as

an industrial water treatment process. For this study, the hybrid hydrocyclone process was performed

under steady state conditions with natural water coming from the river Marne. Efciencies of 61 4% for

turbidity decrease and 77 20% for suspended solids removal were obtained. The separation efciency

between the claried water and the ocs reached 95 10%. This process achieved continuous operation

with 1000 L/h inlet ow. In industrial wastewater treatment, which requires a reliable, compact and

efcient process, this hybrid technology shows strong potential, with a signicant reduction of the plant

footprint.

2012 Elsevier B.V. All rights reserved.

1. Introduction

Removing suspended solids is a common goal of most water

treatment processes. Although ltration has commonly been used

for this purpose, alternative processes, such as hydrocycloning,

have been proposed. Menezes et al. [1] worked on coagulation and

occulation in a dynamic separator based on a swirling motion to

remove silica (500 mg/L) and clay particles (50 mg/L). Their study

used a coagulation process in conjunction with a dynamic separator to separate the solid phase (silica and clay) from the water

phase. Rubio and Rosa [2] used a occulation and otation process

to produce aerated polymeric ocs of an emulsied oil dispersion

followed by separation in a centrifuge cell. Nowadays, no compact

system combines simultaneous coagulation, occulation, otation

and separation in a single device. Most of the previous studies used

only synthetic raw water but never tested real raw water of very

low turbidity. The hybrid hydrocyclone process evaluated during

this study combines coagulation, occulation, otation and hydrocycloning. It was tested using natural waters.

Corresponding author at: Universit de Toulouse, INSA, UPS, INP, Laboratoire

dIngnierie des Systmes Biologiques et des Procds (LISBP), 135 Avenue de

Rangueil, 31077 Toulouse, France. Tel.: +33 0561559789; fax: +33 0561559760.

E-mail address: gilles.hebrard@insa-toulouse.fr (G. Hbrard).

0255-2701/$ see front matter 2012 Elsevier B.V. All rights reserved.

http://dx.doi.org/10.1016/j.cep.2012.07.001

This work was achieved as a continuation of a thesis by Puprasert

[3]. He studied the feasibility of a hybrid process with a hydrocyclone 5 cm in diameter and 50 cm in height. In its pilot process,

three valves were located at the bottom of the system: two lateral

valves for tangential injection, one used for the raw water ow and

the other for the occulants, and one vertical valve for the upward

ow of micro-bubbles. He has shown that centrifuge forces created

by the tangential ow injection lead to strong velocity gradients

at the wall, which promote the coagulation and occulation phenomenon. The presence of micro-bubbles causes the aerated and

the lighter ocs to be dragged by the vortex effect toward the center, where a weaker velocity gradient exists. He has shown that

aerated ocs containing micro-bubbles inside their structure can

be obtained in an unsteady state condition.

Following Pupraserts work, Siangsanun [4] studied the parameters affecting the process in a steady state condition and also

investigated conical and cylindrical hydrocyclone geometries. The

conical geometry hydrocyclone achieved a vortex ow through

the hydrocyclone axis, but there was still no separation. With

these operating conditions, micro bubble coalescence occurred and

reduced the aerated oc production. The process was also inuenced by coagulant and occulant concentration and by the air

fraction. During her PhD, Bamrungsri [5] continued Siangsanuns

investigations; she studied the hydrodynamic characteristics inside

three hydrocyclone geometries and found the optimum operating

C. Puprasert et al. / Chemical Engineering and Processing 61 (2012) 815

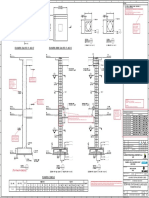

Fig. 1. Pilot plant schematic diagram.

conditions for the hybrid process. The velocity proles obtained

with a conical hydrocyclone [6,7] showed the downow of water

along the cyclone axis and its coalescence effect on micro-bubbles.

Moreover, from her PhD conclusions, Siangsanun [8] recommended

increasing the cylindrical hydrocyclone diameter from 5 cm to

10 cm in order to improve the separation efciency. So after several years of experience, the optimum hybrid process conditions

found were: air volume fraction from 0.0082 to 0.0100, 34 mg/L

of occulant polymer, and 250 L/h inlet owrate.

From the reliable results obtained in the previous studies, a

hydrocyclone reactor (Fig. 1(a)), 10 cm in diameter and 1 m in

height, was then selected and designed; its efciency was tested

in the treatment of a continuous ow of raw tap water. The general objective of this project was to evaluate the performance of the

innovative hybrid hydrocylone process applied to natural surface

waters. With the technical support of the Veolia research center

of Annet in France, the hybrid hydrocyclone process was tested

on natural raw water from the river Marne. The operation was

run continuously for at least 1 h to ensure stable operation. A jar

test was integrated to nd the optimum coagulant and occulant

concentrations assuming equal retention times.

The rst part of this paper presents the experimental devices,

the operating conditions tested and the different methods used to

perform the work. The second part deals with the results obtained

on natural water with the jar test and the hybrid hydrocyclone process, in terms of turbidity and suspended solids removal efciency.

2. Materials and methods

2.1. Pilot plant description

The pilot plant presented in Fig. 1(a) was designed for treating

the natural water from the river Marne in France. The four parts

contributing to the process are described below.

2.1.1. Coagulation

The coagulation process used aluminum sulfate WAC HB in

liquid form and a Fluidcontrol static mixer (PMS15-4-316LDIN2576, IMP 3419), as shown in Fig. 1(a). The raw water was

pumped through the static mixer at 1000 L/h in order to obtain

the best shear stress to perform the initial occulation. Meanwhile,

the coagulant solution was injected into the system before the raw

water passed the static mixer. The 35-m-long tube of diameter

2.54 cm provided 1 min of retention time before the ocs entered

the hydrocyclone reactor, in order to ensure the start of oc growth.

2.1.2. Flocculation

The occulant solution was prepared with anionic polymer

AN905, which was injected directly into the bottom of the hydrocyclone at a ow rate calculated to give the required concentration

(0.10.5 mg/L). This step was expected to start the occulation process, and the retention time inside the hydrocyclone was 30 s (with

1000 L/h).

2.1.3. Micro-bubbles generation

The air-saturated water or bubble generation system used the

dissolved air otation (DAF) technique. It is accomplished in a saturation tank with the air at 45 bars pressure and the water at

4.3 bars. The retention time was set at around 10 min to ensure

that the air would dissolve in the water. The inlet aperture was

installed vertically underneath the hydrocyclone and close to the

wall. The diaphragm relief valve decreased the pressure, allowing

the air dissolved in the water to form micro-bubbles entering the

hydrocyclone. A mean bubble size of 70 m was determined using

a laser granulometer (Malvern Spraytech). Thus, the micro-ocs

produced in the coagulation and occulation process contained

embedded micro-bubbles. We call them aerated ocs. The ow

meter was installed before the releasing valve to measure the airsaturated water ow rate in order to compare the ow ratio of the

conventional otation process to that of the hybrid process.

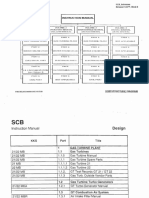

2.1.4. Hydrocyclone reactor

The hydrocyclone reactor used in this study was 1000 mm high

and 100 mm in diameter. It was made of transparent acrylic resin so

that the phenomena inside the reactor could be observed. The oc

growth and separation process was expected to occur inside the

reactor. In the lower part, the ow was injected tangentially to the

hydrocyclone wall at a rate of 1000 L/h corresponding to an outlet

velocity of 3.54 m/s, causing vortex ow. Only one tangential inlet,

10 mm in diameter, is used for raw water and coagulant injection,

and one vertical inlet, which is designed for the air-saturated water

injection as shown in Fig. 2. A central vertical tube was placed to

drain the system. The top part was designed for sample collection.

In the central zone, the efuent water or oc sludge swirled and

drained out from the two upper horizontal tubes, while the claried

water drained out from two horizontal tubes below the oc efuent.

10

C. Puprasert et al. / Chemical Engineering and Processing 61 (2012) 815

Table 2

Jar test experimental conditions with various raw water turbidity values.

Fig. 2. Hydrocyclone reactor, front, upper and lateral view.

Varied parameter

Experimental value

Raw water turbidity

Coagulant concentration

Flocculant concentration

Flocculation stage time

5.68, 6.13, 6.17, 10.05, 15.60 NTU

28, 30, 40, 50, 60 mg/L

0.1, 0.5 mg/L

30 s, 1 min, 15 min (45 rpm)

a occulator (FLOCUMATIC P, SELECTA, maximum mixing speed

210 rpm, round beakers volume: 1 L). The rapid mixing time for the

coagulation process was 1 min. It was equal to the rapid mixing time

in the hydrocyclone static mixer and the retention time in the 35m-long tube with 1000 L/h inlet ow rate. The jar test impeller rate

was maintained at 160 rpm for the rapid mixing time. The jar test

slow mixing time was varied considering the experimental retention time of the hydrocyclone (30 s, 1 min, 15 min). The speed was

maintained at 45 rpm. The sedimentation time was 10 min, after

which the supernatants were collected for analysis.

Table 2 illustrates the experimental steps used for testing the

coagulant concentration effect and the inuence of the occulation time. The parameters that were varied are listed with their

corresponding values. The coagulant concentrations are calculated

considering the total molecular weight of the coagulant. The lowest

mixing time was chosen to be 30 s because the hydrocyclone reactor has 30 s of retention time. Then, 1 min was used to analyze the

inuence of the slow mixing time. The conventional occulation

contact time was 15 min.

2.2. Experiments

The study worked with natural water from the river Marne. The

experiments were performed during two summer months at the

Veolia research center of Annet in France. The Marne water quality

during the entire period was quite good with very low turbidity

ranging between 5 and 15 NTU, a pH ranging between 7.9 and 8.31

and a temperature close to 22 C. Each assay with the hybrid hydrocyclone lasted 1 h and each one was triplicated for the different

parameters under test reported in Table 1. The jar test helped to

characterize and dene the best operating conditions, and the ow

characterization evaluated the hydrodynamic conditions suited to

operation with natural water. Each step is described in detail below.

2.2.1. The jar test experiment

This jar test approach was a preliminary study for the hybrid

process to predict the coagulation and occulation that could occur

in the hybrid process. However, in a jar test, the micro-bubbles are

not taken into account. The phenomenon would not be exactly the

same, but it is hypothesized that the jar test study is efcient for

determining suitable coagulant and occulant concentrations for

the hybrid hydrocyclone process.

The jar test was performed in order to study the conditions that

could be expected to exist in the hydrocyclone, to nd the optimum

coagulation and occulation concentration, and to test the effect of

coagulation and occulation time. The tests were conducted using

Table 1

Parameters under test for the hybrid process study with Marne river water.

Experimental steps

Parameters studied

1. Jar test

- Raw water turbidity coagulant concentration

- Flocculant concentration

- Flocculation time

- Vortex ow intensity and micro bubble size

- Flow partition between center and wall zone

- Coagulant concentration

- Flocculant concentration

- Air-saturated water ow rate

2. Hybrid process on

Marne river water

2.2.2. Vortex ow intensity, micro bubble size, and ow partition

in the hydrocyclone reactor

It was important to observe the vortex ow needed for efcient separation within the hydrocyclone process. Each operating

condition was tested with tap water to visually control the vortex

presence and intensity at the top of the hydrocyclone. Moreover,

the injection of micro-bubbles from the DAF system was tested to

nd the optimum air-saturated water ow, required in the hybrid

hydrocyclone to obtain aerated ocs without generation of coalescence phenomena. Then, the air-saturated water ow was varied:

50, 100, 150 and 200 L/h in order to observe whether a micro bubble

coalescence phenomenon was induced by a downward owstream

appearing in the central area of the hydrocyclone, as reported by

Bamrungsri [5] in the conical hydrocyclone. Flow partition between

the central and wall zones was tested by modifying the diameter

and the position of the upper water outlet tube.

2.2.3. Hybrid hydrocyclone process with Marne river water

The anionic occulant polymer AN905 was injected directly at

the hydrocyclone inlet. The retention time inside the reactor was

30 s (at 1000 L/h inlet ow rate), which is the retention time for

the occulation process. Table 3 reports the experimental conditions that were varied and controlled to determine the treatment

efciency of the hybrid process on the natural water. Aluminum

Table 3

Operating conditions tested in hybrid process performed with natural water.

Parameter varied

Experimental values

Raw water turbidity

Coagulant concentration

Flocculant concentration

Air-saturated water ow rate

(Air fraction)

5.50, 5.80, 6.25, 6.30, 6.31, 6.52, 8.46 NTU

30, 70 mg/L

0.1, 0.5 mg/L

50, 100, 200 L/h

(0.0030, 0.0058, 0.0106)

Parameter controlled

Experimental values

Raw water ow rate

Operating time

1000 L/h

1h

C. Puprasert et al. / Chemical Engineering and Processing 61 (2012) 815

Non Filtered% Optical Densitydecreasewith 0.1 ppm

polymer

% Turbidity removal with 0.1 ppm polymerconcentration

10

% Optical Density

decrease

70

100

90

80

70

60

50

40

30

20

10

0

removal

% Turbidity

11

60

50

40

30

20

10

20

30

40

50

60

70

Coagulant concentration (mg/L)

30 seconds

1 minute

15 minutes

The turbidity removal with 0.1 ppm polymer

concentration

0

0

10

20

30

40

50

60

Coagulant concentration (mg/L)

30 seconds

1 minute

70

15 minutes

Non filtered optical density removal with 0.1 ppm

polymer

Fig. 3. Jar test turbidity and optical density removals with 0.1 ppm polymer at different occulation times.

sulfate WAC HB was used as a coagulant. Two doses were selected

on the preliminary jar testing. The lower concentration (30 mg/L)

was selected because it achieved coagulation in jar test. The higher

value of concentration was 70 mg/L, chosen because it provided

the highest percentage of turbidity decrease in the jar test and was

sufciently different from 30 mg/L to distinguish the effect of the

concentration parameter on treatment efciency. The occulant

polymer concentration was kept unvaried at 0.1 mg/L or 0.5 mg/L

as in the jar test. In each experiment, three samples were taken

during the continuous hybrid process operation. Fig. 1(b) presents

the different outlet positions where the sampling was performed.

The efuent water was sampled at 15 min, 30 min and 50 min during 1 h of operation. The claried water was sampled from the wall

zone and the turbid water was sampled from the central zone. Each

sample was analyzed with three measurements: the turbidity, the

suspended solid concentration and the UV 254 nm absorbance.

2.3. Analysis method

Turbidity, suspended solids and absorbance were analyzed on

inlet and outlet water samples in order to evaluate the performance

of the hybrid hydrocyclone process.

2.3.1. Turbidity and suspended solids (SSs) measurement

The turbidity was measured with a turbidity meter (HACH

2100N IS TURBIDIMETER). The suspended solid concentration was

analyzed by the method of drying at 103105 C: 100 mL of sample were ltered on 0.45 m lter paper (PALL LIFE SCIENCES, LE

TUFFRYN 47 mm diameter). The lter papers were then dried in

the oven for 2 h and the solid weight measured with an accurate

balance (0.1 mg).

2.3.2. UV-254-nm absorbance (ltered optical density)

The UV-254-nm absorbance was used to indicate the reduction

in dissolved organic matter provided by the coagulation process in

the hybrid process. The samples were ltered on the 0.45 m lter

paper and the ltered water was analyzed for dissolved organic

matter. A 5 cm3 cell was lled with the ltered water and the

UV-254-nm absorbance was measured with a UV-254-nm spectrometer (HACH LANGE DR5000).

2.3.3. Efciencies

The performance of the hybrid hydrocyclone process with

respect to water quality was assessed by calculating the reductions

(as %) in UVA, turbidity and suspended solids observed between

the raw waters and the efuent collected at the wall zone. The performance of the hybrid hydrocyclone with respect to its ability to

reduce suspended solids was evaluated by calculating the reduction

(as %) in turbidity and suspended solids between the wall and aerated zones (central zone). This was done in order to account for the

addition of coagulant/occulation within the treatment process. To

calculate the suspended solids reductions, the ow rate partition

ratio (30:70) was considered.

3. Results and discussion

3.1. Identication of proper operating conditions

3.1.1. Coagulation and occulation

The jar test experiment was carried out setting the coagulation and occulation times equal to the conditions that occur in

a hydrocyclone reactor. The coagulation process was followed by

the UV 254 nm absorbance at 1 min of coagulation mixing. For the

occulation process, the experiment was accomplished by varying the occulation time. Result examples are reported in Fig. 3(a)

and (b) for turbidity and absorbant removals, respectively (occulant 0.1 mg/L). It showed that 30 s of occulation could remove

80% of the turbidity (coagulant 50 mg/L). Moreover, increasing the

coagulant and occulant concentration up to 50 mg/L and 0.5 mg/L,

respectively, led to higher turbidity and organic matter removals. In

order to explain the unexpected drop observed in Fig. 3 at 60 mg/L,

it is important to mention that during the experiments conducted

on the water quality of La Marne river, the inlet raw water turbidity

could daily change. For example, with the jar test results reported in

Fig. 3(a) and (b), the raw water turbidity for 50 mg/L coagulant concentration condition was 15.6 NTU, while it was 5.7 NTU at 60 mg/L.

Consequently, the lower raw water turbidity was more difcult

to agglomerate and form the oc even though the coagulant concentration was higher [10]. However, others jar test experiments

performed with a constant water quality showed that an optimum

coagulant concentration was obtained at 70 mg/L.

In any case, this part of the study indicated that 1 min of coagulation stage and 30 s of occulation stage could remove the turbidity

and the organic matter if suitable coagulant and occulant concentrations were used; it suggested that it could work in the hybrid

hydrocyclone process.

3.1.2. Flotation and ow partition inside the hydrocyclone

The optimum ow rate of the air-saturated water was 100 L/h,

which was 10% of the raw inlet ow rate. The air-saturated water

12

C. Puprasert et al. / Chemical Engineering and Processing 61 (2012) 815

Fig. 4. Percentage decreases of ltered UV absorbance at center and wall zones with

0.1 mg/L occulant and for different coagulant concentrations.

Fig. 5. Percentage separation of turbidity and suspended solids between claried

water and raw water with 0.1 mg/L occulant and for different coagulant concentrations.

3.2. Performance on surface water

Fig. 5 reports the percentage reduction of turbidity and the suspended solids removal for the two coagulant concentrations tested

and 0.1 mg/L as occulant concentration. The percentage reduction

reported in Fig. 5 considered the water treatment process by comparing claried water with the raw inlet water. It can be seen that

70 mg/L coagulant concentration gives high decrease of turbidity

and suspended solids removal (61 4% and 77 20%, respectively).

Note that, for a coagulant concentration of 30 mg/L, the suspended

solids experimental error is very important (more than 50%), and it

can lead to positive or negative values of % removal close to zero. So

we can assume that small removal efciency occurs for suspended

solid particles. At this low concentration, two parameters can justify this high uncertainty: the raw water inlet had low turbidity

(less than 10 NTU) and only 100 mL of sample was used to analyze

suspended solids in this study, which was not enough for good accuracy at low coagulant concentration with the ltration method. It

would be advisable to increase the volume of the sample in future

work to achieve greater accuracy on the mass of suspended solids

in the raw water.

Fig. 6 reports the turbidity and suspended solids separation

efciency measured for the two coagulant concentrations under

test with a constant occulant concentration of 0.1 mg/L. Considering the separation performed by the hybrid process described in

Fig. 1(b), the oc concentration measured in water samples from

the central zone is compared with that related to the wall zone. Separation efciencies for turbidity and suspended solids were each

calculated as the difference between the center zone and the wall

zone over the center zone. It can be seen from the measured turbidity that the separation phenomena occurred with these two

coagulant concentrations. With 70 mg/L coagulant concentration,

3.2.1. Inuence of the coagulant concentration on hybrid process

efciencies

Fig. 4 reports the percentage decrease of UV-254-nm absorbance

with respect to natural water for the two coagulant concentrations

under test, with 0.1 mg/L as occulant concentration, for the central

zone and the wall zone. The results obtained show that a decrease

of UV-254-nm absorbance occured in both zones and at all concentrations, which implies that the coagulation process occurred

within the hybrid process and was able to reduce the amount of

dissolved organic matter in the water. Increasing the coagulant

concentration increased the coagulation process slightly in terms

of the UV absorbance. The decrease of UV-254-nm absorbance

ranged between 25 and 35% in this study, which corresponded to

the results of the jar test. Taking into account the relatively good

standard errors of the experiments (1% and 2%), it could be concluded that the hybrid process performed with these two coagulant

concentrations achieved the desired coagulation.

Fig. 6. Percentage separation efciency for two coagulant concentrations (at

0.1 mg/L constant occulant concentration).

from the pilot system could function continuously during 1 h of

operation. All the ow rates gave micro-bubbles inside the hydrocyclone and there was no micro bubble coalescence. The vortex ow

appeared at the top of the reactor as it depended on the raw water

inlet ow rate (1000 L/h). From this observation, 100 L/h of pressurized ow rate gave a large quantity of micro-bubbles and a smaller

bubble size than 50 L/h, and the water was observed to look whiter.

The higher ow rates (150 L/h and 200 L/h) induced unacceptable

levels of uctuations, although the coagulation and occulation

performances were not impacted. All the following data presented

in Sections 3.2.1 and 3.2.2 were obtained with an inlet ow rate of

1000 L/h and a pressurized ow rate of 100 L/h.

Before working with the hybrid process, the throughput ratio

between the center zone and the wall zone has to be considered.

From the water treatment point of view, it is important to maximize the throughput ratio between the wall zone (clear water) and

the center one (ocs sludge). In the hybrid process, there are two

parameters that can affect the throughput ratio. The rst one is the

level difference existing between the outow wall zone and the

outow center zone. The higher the upper central weir, the greater

will be the ratio. The second parameter is the outlet tube internal

diameter; however in our experiments we used a constant 50 mm

diameter. The results of pre-experiments where the level difference

was varying showed a maximum ratio of 70:30, with a difference

of 5 cm between the outow wall zone and the center; this was

the maximum ratio that the hybrid process could achieve and we

applied it to any operating conditions.

C. Puprasert et al. / Chemical Engineering and Processing 61 (2012) 815

13

% Turbidity decrease

100

90

80

70

60

50

40

30

20

10

0

0.1 mg/L

0.2 mg/L

0.5 mg/L

Flocculant concentration

Fig. 7. Percentage turbidity decrease with different occulant concentrations (at

constant coagulant concentration 70 mg/L).

separation is obviously good: 95 10% separation efciency for

suspended solids and 61 6% separation efciency for turbidity.

This result for separation is very satisfactory in continuous operation. The hybrid process succeeded in creating aerated ocs that

were transported to the hydrocyclone axis where velocity gradients

are weaker. The claried water from the 70 mg/L coagulant condition presented a constant turbidity efuent (3.30 NTU obtained at

the wall zone during 1 h), since the sample had been collected at

three different times (15 min, 30 min and 55 min). It also indicated

that this hybrid process was able to operate continuously, which

is very important if the process is to be developed at the industrial

level.

3.2.2. Inuence of the occulant concentration in the hybrid

process

Fig. 7 reports the turbidity decrease versus the occulant concentration for a constant coagulant concentration of 70 mg/L. From

Fig. 7, it clearly appears that polymer occulant concentration plays

an important role in the water treatment process. The percentage turbidity decrease is highest with 0.1 mg/L polymer (61 4%).

The polymer concentrations used in this experiment were 0.1, 0.2

and 0.5 mg/L. They were high concentrations compared to those in

conventional water treatment processes. From the results, it can

be seen that 0.1 mg/L occulant gave better performance in the

hybrid process than the other concentrations, even though the 0.2

and 0.5 mg/L concentrations were expected to perform better. This

phenomenon can be explained in two ways. Firstly, using an overdose of polymer can cause the restabilization mechanism to operate

because many polymer molecules link with the same colloid particle (Metcalf and Eddy [9]). Secondly, 30 s of occulation mixing

time in the hybrid process was not enough to achieve maximum

polymer performance. There was no signicant difference when

the polymer occulant dosage was increased.

Fig. 8 reports the separation efciency in turbidity and suspended solids measured for three occulant concentrations tested

at a constant coagulant concentration of 70 mg/L. As shown in Fig. 8,

the polymer occulant concentration effect is not simple to interpret. The separation efciency on suspended solids is very high

(95 10%) with 0.1 mg/L and 0.5 mg/L, but the percentage separation efciency on suspended solids at 0.5 mg/L polymer was in

sharp contrast with the percentage turbidity removal. This could

be due to the turbidity of the occulant itself, which increases with

concentration and can affect strongly the efciency values, particularly when the difference between the center and the wall is very

weak. However, the results obtained on suspended solids removal

are very satisfactory, as they certify the separation phenomenon

occurring in the hybrid process during continuous operation.

Fig. 8. Percentage separation of turbidity and suspended solids between center and

wall zone (at constant coagulant concentration of 70 mg/L).

As observed from the results for the previous conditions

(70 mg/L coagulant concentration, 0.1 mg/L polymer concentration

and 100 L/h air-saturated water ow rate), it was remarkable that

there was a separation in the continuous operation, which yielded

more satisfactory results than the other operations.

3.2.3. Inuence of the air-saturated water ow rate on the hybrid

process

This part of the study tested the effect of the air-saturated water

(air fraction) variation on the hybrid process efciency. The pressurized air/water ow rate was chosen at three values, 50, 100 and

200 L/h pressurized water, i.e. 0.0030, 0.0058 and 0.0106 air fraction, respectively. Fig. 9 reports the percentage reduction and the

separation efciency of turbidity and suspended solids removal for

three air-saturated water ow rates tested with the best coagulant

and occulation concentrations determined previously (70 mg/L

coagulant concentration and 0.1 mg/L polymer concentration).

As reported in Fig. 9, no reduction in turbidity or suspended

solids was observed with the 50 L/h air-saturated water ow rate

(0.0030 air fraction), but percentage reductions were observed

with the other two conditions. All three operating conditions used

Fig. 9. Percentage reduction and separation efciency with various air-saturated

water ow rates.

14

C. Puprasert et al. / Chemical Engineering and Processing 61 (2012) 815

the same occulant polymer (0.1 mg/L), indicating that not only

the occulant polymer but also the air-saturated water ow rate

plays an important role in the occulation process. The 50 L/h airsaturated water ow rate did not produce aerated ocs that could

be separated by the vortex ow.

The 100 L/h air-saturated water ow gave excellent percentage turbidity reduction and suspended solids removal (61 4%

and 77 20%, respectively), while 200 L/h led to 48 4% turbidity

decrease and 58 20% suspended solids removal. The hybrid process achieved good water treatment and was able to remove the

oc particles in the water.

Varying the pressurized air ow rate affected the separation

efciency in the hybrid process as shown in Fig. 9. These conditions show that differences in turbidity and suspended solids exist

between the wall zone and the central zone. This means that the

idea of creating aerated ocs that can be separated by the vortex

ow inside the hydrocyclone is valid. The reproducibility of the turbidity values implies stable operation, as the samples were taken

at different times during 1 h of operation.

The 50 L/h air-saturated water ow rate gave 15 6% separation

efciency on turbidity and 27 10% for suspended solids, while

there was no percentage reduction at this ow rate. Apparently,

this low air-saturated water ow rate could not produce enough

micro-bubbles to support the separation process in the sense of

creating aerated ocs.

In contrast, the 200 L/h air-saturated water ow rate, i.e. 20% of

the raw water ow rate, provided the proper separation conditions,

i.e. thickening in the central zone and clarifying in the wall zone. It

resulted in 55 6% separation efciency on turbidity and 83 10%

separation efciency on suspended solids.

The 100 L/h pressurized air/water ow rate produced 61 6%

separation efciency in turbidity and 95 10% separation efciency

on suspended solids. It was found that a higher air-saturated water

ow rate (200 L/h) gave poorer results than 100 L/h. This shows that

there is a certain optimum pressurized air ow rate that leads to

a good embedding mechanism between the micro bubble and the

oc.

Additionally, the ow rate ratio of 1000 L/h of treated water to

100 L/h of air-saturated water was satisfactory because the 1:10

ratio of air-saturated to raw water ow rate does not exceed the

ratio corresponding to the classical otation process. In conventional DAF, the typical proportion of air-saturated water in treated

water is 1550% (0.150.50 air fraction) and operating pressures

can vary in the range of 37 bars (Monod [10]; Kiuru and Vahala

[11]). This is an advantage in the hybrid process from the economics point of view. Another advantage of the hybrid process is

the retention time: 1 min and 30 s. It shows that the process is very

compact compared to conventional water treatment coagulation,

occulation and separation, which takes at least 30 min.

Overall, in experiments performed with natural water from the

river Marne, the application of the hybrid process with coagulation, occulation and otation performed in a single hydrocyclone

contactor, was successful. The aerated ocs occurring in the process

had a low mass density and could improve separation by the hydrocyclone mechanism. The minimum outlet water turbidity obtained

from continuous operation of the hybrid process reached 3.30 NTU.

This value is successful if we consider our initial objective of hybrid

process validation in continuous operation; however, it is perhaps

still not low enough to justify industrial hybrid hydrocyclone development.

The difculty of this process was to nd the optimum coagulant

and occulant concentrations, the optimum air fraction and also

the best hydrodynamics inside the system. The optimum oc size is

necessary to produce aerated ocs. Then, the aerated oc should be

able to rise and be separated by the vortex ow inside the hydrocyclone. This cannot happen if ocs are large or heavy. The occulant

polymer concentration used in this study was high (0.10.5 mg/L).

It was imposed by the small retention time for the occulation

process. To develop the hybrid process using lower polymer concentrations, the hydrocyclone geometry should be reconsidered in

order to increase the retention time for the occulation stage.

It is also important to note that the raw water tested in this study

(river Marne water) contained a low concentration of suspended

solids and its turbidity was very low. If raw water containing

more suspended solids with higher turbidity were considered, the

obtained percentage reduction and removal efciencies in suspended solids and turbidity could be higher. Moreover, pollutants

that are more hydrophobic and less heavy (oil pollution for example) could show improved separation, with special ocs dense in

micro-bubbles and thus lighter.

4. Conclusions

The experiments performed with natural water from the river

Marne successfully demonstrated the idea of the hybrid process:

coagulation, occulation and otation performed in a single hydrocyclone contactor. The hybrid process was successfully developed

in terms of creating and separating aerated ocs. The minimum outlet water turbidity obtained in continuous operation of the hybrid

process was 3.30 NTU (from 8.46 NTU in raw water), which signies 61 4% turbidity removal, 77 20% suspended solids decrease

and 95 10% suspended solids separation efciency. The ratio of

efuent ow in the wall zone to that in the central zone (claried

water to concentrated oc) was 70:30. These results are satisfactory

with respect to the hybrid process but they remain scale dependent.

A nal scale-up will be required before the hybrid process can be

applied in the eld of industrial tap water treatment. In any case, we

have demonstrated in this work that the hybrid hydrocyclone can

work with natural surface water under steady state conditions. The

range of operating conditions in this study were 1000 L/h raw water

inlet ow rate, 70 mg/L coagulant WAC HB, 0.10.2 mg/L anionic

polymer occulant AN905, 100 L/h pressurized air-saturated water

ow rate (1020% of the raw water) and 0.00550.0104 air fraction.

Acknowledgements

The authors gratefully acknowledge the nancial support given

by the French Ministry of Higher Education and the Thai Ministry of Higher Education, via the Franco-Thai Cooperation Program

in Higher Education and Research. They gratefully acknowledge

nancial and technical support from the Veolia research center of

Annet, France.

References

[1] F.M. Menezes, R. Amal, D. Luketina, Removal of particles using coagulation and

occulation in a dynamic separator, Powder Technology 88 (1996) 2731.

[2] J. Rubio, J.J. Rosa, The FF (occulationotation) process, Mineral Engineering

18 (2005) 701707.

[3] C. Puprasert, Contribution la mise au point dapplications spciques des

hydrocyclones en traitement des eaux, Ph.D. Thesis, Gnie des Procds

de lEnvironnement, Institut National des Sciences Appliques de Toulouse,

France, 2004.

[4] V. Siangsanun, Hybrid Process: Hydrocyclone, Coagulation-occulation and

Flotation in Water Treatment Process, Masters Degree Thesis, Department of

Environmental Engineering, Faculty of Engineering, Chulalongkorn university,

Thaland, 2006.

[5] P. Bamrungsri, Hybrid Process: Hydrocyclone, Coagulation-Flocculation and

Floatation in Water Treatment Process, Ph.D. Thesis, Gnie des Procds de

lEnvironnement, INSA de Toulouse and NRC-EHWM, Graduate school, Chulalongkorn university, 2008.

[6] P. Bamrungsri, C. Puprasert, C. Guigui, P. Marteil, P. Brant, G. Hbrard, Development of a simple experimental method for the determination of the liquid

eld velocity in conical and cylindrical hydrocyclones, Chemical Engineering

Research and Design 86 (2008) 12631270.

[7] V. Siangsanun, J. Morchain, C. Puprasert, C. Guigui, P. Marteil, P. Brant, C. Levecq, G. Hbrard, Velocity measurement in hydrocyclone by oil droplet, Doppler

C. Puprasert et al. / Chemical Engineering and Processing 61 (2012) 815

untrasound velocimetry and CFD modeling, The Canadian Journal of Chemical

Engineering 89 (4) (2010) 725733.

[8] V. Siangsanun, Hybrid Process: Hydrocyclone, Coagulation-occulation and

Flotation in Water Treatment Process, Ph.D. Thesis, Laboratoire dIngnierie

des Systmes Biologiques et Procds, INSA de Toulouse (France) and Department of Environmental Engineering, Faculty of Engineering, Chulalongjkorn

university, Bangkok, Thaland, 2010.

15

[9] Metcalf, Eddy, Wastewater Engineering Treatment and Reuse, 4th ed.,

McGraw-Hill, New York, 2004.

[10] J. Monod, Water Treatment Handbook, vol. 1, 6th ed., Rueil-Malmaison, Degrmont, 1991, pp. 136145.

[11] H. Kiuru, R. Vahala, Dissolved air otation in water and waste water treatment,

Water Science Techology 43 (2009) 815.

Вам также может понравиться

- Design Simple Support Beam With 2-Load (Created by Bundit S.)Документ2 страницыDesign Simple Support Beam With 2-Load (Created by Bundit S.)Nopparut100% (1)

- Blank Thickness CalculatorДокумент1 страницаBlank Thickness CalculatorNopparutОценок пока нет

- Design CalДокумент4 страницыDesign CalNopparutОценок пока нет

- AAA Variable Spring Hangers CatalogДокумент31 страницаAAA Variable Spring Hangers CatalogNopparut0% (1)

- Nema SM23-1991 PDFДокумент64 страницыNema SM23-1991 PDFmarsulex67% (9)

- Welding SignДокумент20 страницWelding SignNopparutОценок пока нет

- Autopipe New Features & Enhancements (v9.61 To v6.20)Документ17 страницAutopipe New Features & Enhancements (v9.61 To v6.20)NopparutОценок пока нет

- 050 - Inspection Paint ReportДокумент2 страницы050 - Inspection Paint ReportNopparutОценок пока нет

- Mechanics of Materials: Third EditionДокумент17 страницMechanics of Materials: Third EditionNopparutОценок пока нет

- Command Prompt TutorialДокумент11 страницCommand Prompt TutorialNopparutОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- C A 2018 ET HP DesigninfoДокумент9 страницC A 2018 ET HP DesigninfoJonathan DouglasОценок пока нет

- 327101-BJ81-C-RCC-0007 Rev.00 - Client MarkupДокумент1 страница327101-BJ81-C-RCC-0007 Rev.00 - Client MarkupGokulprabhuОценок пока нет

- Mine Survey CertificationДокумент37 страницMine Survey CertificationAgustin Eliasta Ginting100% (1)

- GRE Sentence CompletionДокумент3 страницыGRE Sentence Completionapi-3699142Оценок пока нет

- Fire Risk of Cold Room PanelДокумент6 страницFire Risk of Cold Room Paneldarby1028Оценок пока нет

- Assessing The Feasibility of Using The Heat Demand-Outdoor Temperature Function For A Long-Term District Heat Demand ForecastДокумент5 страницAssessing The Feasibility of Using The Heat Demand-Outdoor Temperature Function For A Long-Term District Heat Demand ForecastmohammedelamenОценок пока нет

- Specification For Piping MaterialДокумент9 страницSpecification For Piping MaterialAgus SupriadiОценок пока нет

- Design Report For Proposed 3storied ResidentialbuildingДокумент35 страницDesign Report For Proposed 3storied ResidentialbuildingMohamed RinosОценок пока нет

- Huawei Antenna and Antenna Line Products Catalogue (General Version) 2014 01 (20131228)Документ380 страницHuawei Antenna and Antenna Line Products Catalogue (General Version) 2014 01 (20131228)Rizky JuliadiОценок пока нет

- Project Management Resume ExampleДокумент2 страницыProject Management Resume ExampleGuino VargasОценок пока нет

- Foreword by Brett Queener - Agile Product Management With Scrum - Creating Products That Customers LoveДокумент3 страницыForeword by Brett Queener - Agile Product Management With Scrum - Creating Products That Customers LoveJoao Paulo MouraОценок пока нет

- CHEN3000 Process Plant Engineering: Semester 2 2016Документ30 страницCHEN3000 Process Plant Engineering: Semester 2 2016Max Yee Min JueyОценок пока нет

- DPM Engineering WorksДокумент34 страницыDPM Engineering WorksAkash SinghОценок пока нет

- Gas Turbine Manual PDFДокумент721 страницаGas Turbine Manual PDFZakki Afifi100% (2)

- FB131Документ7 страницFB131Hoangvinh DuongОценок пока нет

- Larsen and Toubro RVNL Bid Document Rock Bolts PDFДокумент240 страницLarsen and Toubro RVNL Bid Document Rock Bolts PDFSubhash Kedia100% (1)

- br604 PDFДокумент5 страницbr604 PDFmartinpellsОценок пока нет

- Example Pump CalcsДокумент4 страницыExample Pump CalcsSourav ChattopadhyayОценок пока нет

- Automobile Manufacturing Process (17403) : Chapter 1. ForgingДокумент87 страницAutomobile Manufacturing Process (17403) : Chapter 1. ForgingPramod DhaigudeОценок пока нет

- ASTM D445-Viscoz Cinematica PDFДокумент9 страницASTM D445-Viscoz Cinematica PDFCorina StanculescuОценок пока нет

- Nachi Special SteelsДокумент20 страницNachi Special SteelsBambang MulyantoОценок пока нет

- Johnloomis Org Ece563 Notes Geom Resize ImresizeДокумент10 страницJohnloomis Org Ece563 Notes Geom Resize ImresizeAdrian Jose Costa OspinoОценок пока нет

- NSX Battle Card - FinalДокумент2 страницыNSX Battle Card - FinalElias Bezulle100% (1)

- IEEE Recommended Practice For Exc. Sys Models 2Документ4 страницыIEEE Recommended Practice For Exc. Sys Models 2Emmanuel ZamoranoОценок пока нет

- Saep 1116Документ5 страницSaep 1116Anonymous 4IpmN7OnОценок пока нет

- Exact Solution Tank DrainageДокумент8 страницExact Solution Tank DrainageFelipe CastОценок пока нет

- D60 70S-5 (Sb1112e02)Документ346 страницD60 70S-5 (Sb1112e02)goxmadОценок пока нет

- Python ScriptingДокумент2 страницыPython ScriptingRavikumar TumuluriОценок пока нет

- KX Tde600 FeatureДокумент460 страницKX Tde600 Featureabg121Оценок пока нет