Академический Документы

Профессиональный Документы

Культура Документы

SFRA Sensitivity Towards Detection of Transformer Insulation Damage

Загружено:

Sergio OrtegaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SFRA Sensitivity Towards Detection of Transformer Insulation Damage

Загружено:

Sergio OrtegaАвторское право:

Доступные форматы

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 4, April 2013)

SFRA Sensitivity Towards Detection of Transformer Insulation

Damage

Shubhangi Patil1, Prof. (Dr.) B. E. Kushare2

1

Crompton Greaves Limited, Mumbai

Electrical Engineering Department, K. K. W. Institute of Engineering and Research, Nasik

These issues can damage mechanical structure of

transformer system and without knowing such internal

damages; they can cause high performance loss. Such

situations may worsen the condition till it fails at site.

Many dielectric and mechanical failures in large power

transformers are generally due to mechanical damage .at

core and winding structure. If a transformer experiences

higher mechanical shock than the suggested G levels can

damage internal parts like, core and winding distortion,

inter turn insulation blocking arrangement, loosened

clamping structure due to higher vibration levels, support

parts etc. Detection of these displacements and damages in

advance of catastrophic failures can help to reduce

maintenance cost and improve reliability. Also proper

detection can help to plan in advance the repairing or future

work based on severity of damage. Various monitoring and

diagnostic techniques, which can evaluate the integrity of

transformer, are essential to evolve optimum and better

reliability of the equipment. Several techniques such as

thermal monitoring, oil analysis, partial discharge

measurement, capacitance & tan delta measurements,

recovery voltage measurements etc. are applied for

transformer wherein each one is applied for a specific type

of problem and have their own merits. One of these reliable

methods to check the mechanical integrity of core and

winding is SFRA [1-3].

SFRA is an effective mechanical condition assessment

technique for power transformers. Large power

transformers represent a complex RLC network. Frequency

response of transformer winding is sensitive to physical

parameters of the transformer. Any deformation results in

relative changes to the internal inductance and capacitance

of the winding which in turn changes the resonant pole

frequencies, phase and amplitude of voltage ratios in dB

level. These significant deviations in frequency responses

are widely used as a tool to check internal mechanical

integrity. SFRA is a comparative method, based on

comparison between the measured response with the fresh

responses taken at site for detection and diagnosis of core winding deformation or displacement.

Abstract Transportation of large power transformers is

typically costly and can sometimes become a substantial

portion of the overall lead time of procuring a transformer.

Whenever the power transformer face the internal damage

due to any fault or transportation, the utilities and

manufacturers bears a high impact on reliability, cost and

delivery cycle. There are various diagnostics methods

available to assess the mechanical integrity of the transformer.

One of the key tests applied for the detection of possible core

and winding movement during construction, assembly and

transportation of the transformer is Sweep Frequency

Response Analysis (SFRA). Sweep Frequency Response

Analysis (SFRA) is one of the effective diagnostic tools for

detection of winding movement and other mechanical faults

which affects the transformer impedance. Key advantages of

SFRA compared to other diagnostic techniques are its proven

sensitivity towards variety of mechanical faults and a lesser

dependency on previous reference measurements. In this

regards, an attempt has been made in this paper to check the

SFRA analysis sensitivity towards clamping structure and

insulation related faults. Case studies are presented here with

the details of SFRA and other tests performed during

manufacturing and transportation stages. Detailed analysis

and findings are discussed in detail.

Keywords Diagnostic techniques, failures, insulation

damage, mechanical condition, SFRA sensitivity analysis,

transportation.

I. INTRODUCTION

The deregulation of the power distribution industry in

recent years has lead to new approaches for optimizations

of the power networks. The operating stress levels in the

networks are closer to the transformers withstand levels

and the amounts of spare capacity in the networks are

decreasing. This has lead to increased quality demands on

the transformer manufacturers, and an incentive for

established transformer condition assessment routines in

the power industry. The transformer is a critical component

in the power system and its failure is a costlier event.

During operation, the power transformers are subject to

damage from faults, short circuiting, ageing or during

transportation.

774

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 4, April 2013)

The internal mechanical faults can also be detectable by

electrical tests like leakage reactance, overall capacitance

and DGA results. Based on severe of damage, they show

significant variation otherwise they have very small effect

in results which can be easily overlooked and may not

indicate the fault at times. But these tests along with SFRA

analysis can help to detect the insulation and clamping

structure related faults and damage [4] [6].

An attempt has made in this paper to check the

sensitivity of SFRA analysis towards the detection of such

faults. This paper presents experimental investigations

carried out by SFRA technique for power transformers who

received several shocks while transportation. Case studies

are presented in paper demonstrates the sensitivity of

technique towards the insulation damage related faults.

SFRA measurements carried out on 120 MVA, 132 kV

Three Phase Transformer and its detailed analysis during

various stages of transportation which helped to detect such

faults are also presented.

SFRA test performed on power transformer provides

information about the impedance behavior over wide range

of frequency of 20 Hz to 2 MHz [3] [5]. Change in

impedance level and resonance shift helps to check the

internal damages. Interpretation of SFRA is based on visual

comparison of reference and fresh responses. Transformers

damage occurred during transportation can be effectively

detectable if impact recorders details along with SFRA

comparison analysis are considered.

III. EXPERIMENTAL RESULTS AND ANALYSIS

At manufacturing level, every power transformer has

designed with considered limit loads and stresses. During

transportation, transformer who experiences the heavy

shocks and vibrations can get damage as visible damage or

concealed damage based on severity. In such situations,

impact recorder details and analysis are essential to

consider. The mechanical shock is generally characterized

by maximum value of occurring acceleration or

deceleration and duration of shock. During shock,

acceleration increases, reaches to maximum value and then

slows down to specific level. If transformer hits with any

hard surface with its initial shock velocity, it will increase

the shock pulse and higher amplitude acceleration in

shorter time duration. Thus the power transformer can get

damage in the low frequency range of few hundred Hz. The

damage due to mechanical shock can be loss of clamping

pressure, visible damage to core and winding, damage to

bushings and parts etc.

Vibrations are periodical oscillatory movements caused

by various causes. During transportation, generated

vibrations consist of frequency spectrum with individual

frequency with different amplitudes. Whenever the natural

frequency of transformer parts coincides with the induced

vibration frequency with larger amplitude, it creates the

resonance vibrations or co-vibrations which can damage

internal parts. The damage due to vibrations can be

looseness of insulation blocks, structure components or

minor cracks etc. Transformer mechanical condition

assessment and reliability check is generally based on

various longitudinal, transversal and vertical impact levels

of loads using impact recorders details. Here few cases are

considered for transformer damage during transport.

During transportation, the impact recorders and electrical

tests like leakage reactance, DGA and capacitance at stages

are also considered.

II. SFRA MEASUREMENTS

The main purpose of SFRA is to detect core and winding

displacements after over-currents caused by through faults,

tap-changer faults and faulty synchronization etc. Other

applications of SFRA include mechanical condition

assessment after transportation and the detection of any

other problems which result in changes to the inductance or

capacitance distribution in transformers which usually a

means to provide the reliable information of confirming

that the core and winding have not suffered mechanical

damage despite sustaining shocks and vibrations during

transportation. As part of factory acceptance procedures

and quality control, a number of electrical tests are to be

performed on the transformer and its sub-assemblies.

Mostly SFRA is performed in three stages, factory level,

and site after dispatch and at intermediate stage during

transportation.

For SFRA measurements, a sinusoidal voltage signal at

different frequencies is applied to one end of winding,

(with and without core), and output voltage is taken at the

other end with respect to a common ground terminal using

SFRA. The voltage ratio of measured to reference voltage

signal gives a magnitude response in decibels and phase

response in degree as a function of frequency. These

responses are used for comparison with different

displacement. The phase responses are not considered, as

they do not give additional information.

775

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 4, April 2013)

Thus the variation in G level occurred due to mechanical

shocks or vibrations are considered as one of the condition

to check the internal damage. In case impact recorders

show marginal variations then SFRA detailed analysis is

carried out.

After transportation, as per routine procedure, SFRA

was conducted on transformer. SFRA responses showed

that the open circuit condition HV winding has significant

variation in low frequency range <2 kHz and the short

circuit response of the same winding with no variation. The

responses comparison clearly indicated the lower and mid

frequency variation. Also right shift of resonances are

observed which indicates the reduction of overall LC

component. This indicated the possibilities of problem with

core magnetic circuit or with core assembly. But the LV

winding short circuit responses showed significant

variation in mid frequency range around 40 kHz.

A. Case: Detection of insulation damage

SFRA measurements are carried out on 120 MVA, 132

kV/ 33 kV transformers at various stages at factory, during

dispatch and after receipt at site.

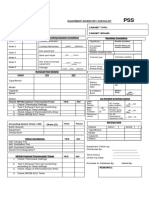

TABLE I

TRANSFORMER NAMEPLATE DETAILS

Configuration

Three Phase Transformer

KV

132 kV/ 33 kV

MVA

120

TABLE 2

IMPACT RECORDER DETAILS

R phase

Y phase

B phase

10

8.7

Fig. 2: SFRA Response of HV winding in open circuit condition after

transportation

Fig. 1: SFRA Response of HV winding in open circuit condition at

factory

Fig. 3: SFRA Response of HV winding in short circuit condition after

transportation

776

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 4, April 2013)

After suspecting the problem with SFRA responses,

electrical tests like excitation current and capacitance tests

were performed on site. As expected, excitation current

showed variation but was very small value. Capacitance

test results did not show any variation in results.

Considering the factors, high impact levels, slight variation

in capacitance measurement and SFRA deviation, internal

inspection was decided to carry out on site to check the

condition and severity of damage. Internal inspection was

carried out at site. The unit was opened up and complete

core coil assembly and clamping structures were

inspected. Internal inspection showed the slight move

along with two core supports were loosened and winding

insulation blocks were fallen outside of phase. Due to such

blocking, there was clear indication of looseness of

structure and bringing back the transformer to factory

became essential for further actions.

Future work includes the testing the SFRA sensitivity

towards detection of damage during transportation with

large number of cases and accuracy need to be established.

Following proper transportation procedures and conditions

along with SFRA test at various stages can be helpful to

improve the interpretation.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

IV. CONCLUSION

Impact recorders are helpful (in above experience) to

locate the internal insulation and clamping structure

damage during transportation. Sometimes, these recorder

events may not reveal the actual picture of internal

condition of transformer with high impact and electrical

tests may not support in minor cases. Performing SFRA at

stages like factory level, during transportation, change of

mode of transport, after dispatch etc. has become essential

to confirm the SFRA sensitivity towards insulation and

clamping structure.

[7]

777

J. Lapworth, Doble, Transformer condition assessment by SFRA

2003

CIGRE 2009, Kreatege Kruger, Viljeen Dierks, FRA sensitivity for

fault detection, 2008

CIGRE A2-209,Condition assessment of medium power

transformer using diagnostic methods, 2008

CIGRE WG A2.26 (342),Mechanical condition assessment of

transformer windings using Frequency Response Analysis, 2008

Richard Ladroga, Transformer transportation damage a case

presentation of low impact event, International Doble client

conference, 2010

Enrique Betancourt, Carlos Hernandez, Power transformer

manufacturer experience with transportation mishandling,

Weidman Diagnostic Solutions 7th Annual conference, 2008

WG report on Transportation issues Guide, IEEE (PC57.150)

technical committee.

Вам также может понравиться

- SFRAДокумент14 страницSFRARahul DasОценок пока нет

- Application of Modern Techniques For The Condition Assessment of Power TransformersДокумент12 страницApplication of Modern Techniques For The Condition Assessment of Power Transformerscarlos vidalОценок пока нет

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesОт EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesОценок пока нет

- Expert System For Sweep Frequency Response Analysis of Power TransformerДокумент7 страницExpert System For Sweep Frequency Response Analysis of Power TransformerAlexander DeckerОценок пока нет

- A Multi-Dimensional Diagnostic Fingerprint For Power TransformersДокумент4 страницыA Multi-Dimensional Diagnostic Fingerprint For Power TransformersRicardo RampersadОценок пока нет

- Using Cross-Correlation Coefficients To Analyze Transformer Sweep Frequency Response Analysis (SFRA) TracesДокумент6 страницUsing Cross-Correlation Coefficients To Analyze Transformer Sweep Frequency Response Analysis (SFRA) TracesSandeep PhagariaОценок пока нет

- Investigation and Understanding The Conditions of Power Transformer Internal Faults Using On-Line TechniqueДокумент6 страницInvestigation and Understanding The Conditions of Power Transformer Internal Faults Using On-Line TechniqueDante FilhoОценок пока нет

- Review Sfra PDFДокумент17 страницReview Sfra PDFNeha SharmaОценок пока нет

- Comprehensive Study On Transformer Fault DetectionДокумент31 страницаComprehensive Study On Transformer Fault DetectionsОценок пока нет

- Condition Monitoring and Life Extension of TransformerДокумент6 страницCondition Monitoring and Life Extension of Transformerreza515heiОценок пока нет

- SFRA Method - Frequency Analysis of TransformersДокумент4 страницыSFRA Method - Frequency Analysis of TransformersNirmal mehtaОценок пока нет

- A Novel Online Technique To Detect Power Transformer Winding FaultsДокумент9 страницA Novel Online Technique To Detect Power Transformer Winding FaultsV S B Chaitanya DuvvuryОценок пока нет

- Frequency Response Analysis of Power Transformers: TransmissionДокумент4 страницыFrequency Response Analysis of Power Transformers: Transmissionrcarrasco07Оценок пока нет

- Iv 2014Документ12 страницIv 2014Chandan YadavОценок пока нет

- Electrical Machines 2 Laboratory Paper 2Документ8 страницElectrical Machines 2 Laboratory Paper 2Kent Brian TauthoОценок пока нет

- 18 - Aizam - HV IT in TNB Substations - Paper PDFДокумент5 страниц18 - Aizam - HV IT in TNB Substations - Paper PDFbcqbaoОценок пока нет

- The Importance of Demagnetizing The Transformer Core: Why Is It Important To Demagnetize A Transformer's Core?Документ5 страницThe Importance of Demagnetizing The Transformer Core: Why Is It Important To Demagnetize A Transformer's Core?brianОценок пока нет

- 1.1. Overview: Power Quality Enhancement Using Dynamic Voltage Restorer (D.V.R)Документ47 страниц1.1. Overview: Power Quality Enhancement Using Dynamic Voltage Restorer (D.V.R)Harsh Vardhan Singh TomarОценок пока нет

- Power Quality Enhancement Using Dynamic Voltage Restorer (D.V.R)Документ39 страницPower Quality Enhancement Using Dynamic Voltage Restorer (D.V.R)Aayush guptaОценок пока нет

- Transformers Test FacilityДокумент25 страницTransformers Test FacilityHIRAK CHATTERJEEОценок пока нет

- SFRA Iee PaperДокумент6 страницSFRA Iee PaperMelkin NPОценок пока нет

- 9470 English TarjomeFaДокумент10 страниц9470 English TarjomeFatusarОценок пока нет

- Mtekpro Service ProfileДокумент13 страницMtekpro Service ProfilepriyankadasguptaОценок пока нет

- Adaptability of Distribution Automation PDFДокумент8 страницAdaptability of Distribution Automation PDFMHEP_DANIELОценок пока нет

- SFRA Test of TransformerДокумент5 страницSFRA Test of Transformerp_devanganОценок пока нет

- FRA BandДокумент8 страницFRA BandlimanОценок пока нет

- Voltage Quality Improvement DVRДокумент30 страницVoltage Quality Improvement DVRKeerthi PriyankaОценок пока нет

- Power Quality Enhancement Using Dynamic Voltage Restorer (D.V.R)Документ41 страницаPower Quality Enhancement Using Dynamic Voltage Restorer (D.V.R)Aayush guptaОценок пока нет

- Health Index Monitoring Assessment of A TransformerДокумент6 страницHealth Index Monitoring Assessment of A TransformerOmkar WaghОценок пока нет

- Smart Techniques For Fault Diagnosis in PowerДокумент10 страницSmart Techniques For Fault Diagnosis in PowerMuhammad RasyidiОценок пока нет

- M5100 Bochure W-New WordsДокумент4 страницыM5100 Bochure W-New WordsOSCAR TRUJILLOОценок пока нет

- Simulation Effect of Switching Surge On The Overhead Line (With and Without Surge Arrestor)Документ37 страницSimulation Effect of Switching Surge On The Overhead Line (With and Without Surge Arrestor)Nafisah AbdullahОценок пока нет

- Online Transformer Internal Fault Detection Based On Instantaneous Voltage and Current Measurements Considering Impact of HarmonicsДокумент12 страницOnline Transformer Internal Fault Detection Based On Instantaneous Voltage and Current Measurements Considering Impact of Harmonicsdibyaranjan barikОценок пока нет

- 29 - Luwendran MoodleyДокумент9 страниц29 - Luwendran MoodleySudheerKumarОценок пока нет

- 3.1 Syllabus: Adhiparasakthi College of EngineeringДокумент22 страницы3.1 Syllabus: Adhiparasakthi College of EngineeringSabareshwar SankaranarayananОценок пока нет

- EDOC-Transformer Diagnostics and Condition AssessmentДокумент16 страницEDOC-Transformer Diagnostics and Condition AssessmentEl Comedor BenedictОценок пока нет

- EDOC-Transformer Diagnostics and Condition AssessmentДокумент16 страницEDOC-Transformer Diagnostics and Condition AssessmentEl Comedor Benedict100% (1)

- Voltage Quality Improvement Using DVRДокумент3 страницыVoltage Quality Improvement Using DVRSeid EndrisОценок пока нет

- Cigre, 13 Years Test Experience With Short Circuit Withstand Capability of Large Power TransformersДокумент7 страницCigre, 13 Years Test Experience With Short Circuit Withstand Capability of Large Power TransformersMartin ButcherОценок пока нет

- PotM 2018 11 Reliable SFRA Measurements ENUДокумент13 страницPotM 2018 11 Reliable SFRA Measurements ENUgulatimanish1985Оценок пока нет

- Transformer Condition Monitoring Sethuraman MuthukaruppДокумент8 страницTransformer Condition Monitoring Sethuraman MuthukaruppAnantha RkОценок пока нет

- FRAX SeriesДокумент6 страницFRAX Seriespoeta_oscuroОценок пока нет

- Devlopement of The Dynamic Resistance Measurement (DRM) Method For Condition Assessment of OltcДокумент5 страницDevlopement of The Dynamic Resistance Measurement (DRM) Method For Condition Assessment of OltcesatjournalsОценок пока нет

- Frequency Response Analysis - Low Frequency Characteristics and Fault Diagnosis On Power TransformersДокумент4 страницыFrequency Response Analysis - Low Frequency Characteristics and Fault Diagnosis On Power TransformersErfan AhmedОценок пока нет

- KDL 3-4Документ30 страницKDL 3-4Kelvin ManikОценок пока нет

- Cigré2016 Experiencesandinnovationsinpowertransformershort Circuitcurrentwithstandtesting A2 304Документ11 страницCigré2016 Experiencesandinnovationsinpowertransformershort Circuitcurrentwithstandtesting A2 304cisnatelОценок пока нет

- Analysis of Failed and Working Power Transformer and Their DiagnosticsДокумент6 страницAnalysis of Failed and Working Power Transformer and Their DiagnosticsPrasanth ThomasОценок пока нет

- Cigre, 13 Years Test Experience With Short Circuit Withstand Capability of Large Power TransformersДокумент7 страницCigre, 13 Years Test Experience With Short Circuit Withstand Capability of Large Power TransformersAnonymous YBOliZYОценок пока нет

- (13358871 - Measurement Science Review) Frequency and Time Fault Diagnosis Methods of Power TransformersДокумент6 страниц(13358871 - Measurement Science Review) Frequency and Time Fault Diagnosis Methods of Power TransformersRonna SerniculaОценок пока нет

- 11 Chapter2 PDFДокумент22 страницы11 Chapter2 PDFUserОценок пока нет

- Publishedvershion AxialДокумент9 страницPublishedvershion AxialCaio FlemingОценок пока нет

- Best Practice For Sweep Frequency Response AnalysisДокумент44 страницыBest Practice For Sweep Frequency Response AnalysisRabah Amer100% (1)

- PotM 2017 05 Electrical Interferences in SFRA Measurements ENU 01Документ18 страницPotM 2017 05 Electrical Interferences in SFRA Measurements ENU 01Kukuh Widodo100% (1)

- FRAnalyzer Brochure ENUДокумент12 страницFRAnalyzer Brochure ENUJohar ShamОценок пока нет

- Roc App B Tov ReportДокумент8 страницRoc App B Tov Reporthino_kaguОценок пока нет

- Transformer Testing by Afees Ahamed Egger IndiaДокумент27 страницTransformer Testing by Afees Ahamed Egger IndialrpatraОценок пока нет

- Power Transformer MaintenanceДокумент19 страницPower Transformer Maintenanceadnan80% (5)

- LM6361Документ11 страницLM6361api-3825669Оценок пока нет

- Survey & Mitigation: Who We Are & What We DoДокумент5 страницSurvey & Mitigation: Who We Are & What We DorustyОценок пока нет

- Lumiax Smart-N5Li-series Datasheet EN JH08Документ2 страницыLumiax Smart-N5Li-series Datasheet EN JH08Cheesnap Photography100% (1)

- 2012 ELECTRICAL Connectors and Harnesses - TL PDFДокумент66 страниц2012 ELECTRICAL Connectors and Harnesses - TL PDFsoftallОценок пока нет

- Qualcomm Client Interview Question - Downlaod VLSI FOR ALLДокумент18 страницQualcomm Client Interview Question - Downlaod VLSI FOR ALLPrajwal SОценок пока нет

- Block Diagram: X555LD Repair GuideДокумент7 страницBlock Diagram: X555LD Repair GuideGustavo GarciaОценок пока нет

- Distribution Safety InstructionДокумент12 страницDistribution Safety InstructionShakeb RahmanОценок пока нет

- The Sound Project EssayДокумент2 страницыThe Sound Project EssaymrpicklesmediaОценок пока нет

- Punit Resume WorkДокумент3 страницыPunit Resume Workapi-321948941Оценок пока нет

- DSR Electrical 2012Документ60 страницDSR Electrical 2012vijay_raina31140% (1)

- 63230-500-282A1 PM8 Install GuideДокумент8 страниц63230-500-282A1 PM8 Install GuideJohan M. CcoriОценок пока нет

- Third Year 5 Semester Syllabus: (Applicable From The Academic Session 2018-2019)Документ23 страницыThird Year 5 Semester Syllabus: (Applicable From The Academic Session 2018-2019)Tignangshu ChatterjeeОценок пока нет

- RSA306B USB Real Time Spectrum Analyzer Datasheet 37W603759Документ26 страницRSA306B USB Real Time Spectrum Analyzer Datasheet 37W603759HafiziAhmadОценок пока нет

- PLDT Equipment Inventory Checklist PSSДокумент2 страницыPLDT Equipment Inventory Checklist PSSGerald CorneliaОценок пока нет

- UC Series: Fire Fighting Equipments Designed According ToДокумент12 страницUC Series: Fire Fighting Equipments Designed According ToJulio Acuña RОценок пока нет

- Opamp 24Документ111 страницOpamp 24api-3750190Оценок пока нет

- Level3 - Application Note Earth Leakage RelayДокумент4 страницыLevel3 - Application Note Earth Leakage RelayChhinPidenОценок пока нет

- Mathcad - UCC3817 Design Procedure 7 29 08Документ10 страницMathcad - UCC3817 Design Procedure 7 29 08servetОценок пока нет

- 2ee4104 Power ElectronicsДокумент2 страницы2ee4104 Power ElectronicsGangadhar AkkiОценок пока нет

- 19-9-2014Документ3 страницы19-9-2014MANSA MARKETINGОценок пока нет

- Technology: ControlsДокумент32 страницыTechnology: ControlsAli Hossain AdnanОценок пока нет

- Cedes: GLS 126 NT and GLS 151 NTДокумент2 страницыCedes: GLS 126 NT and GLS 151 NTLoloy NorybОценок пока нет

- Health Index Monitoring Assessment of A TransformerДокумент6 страницHealth Index Monitoring Assessment of A TransformerOmkar WaghОценок пока нет

- FDAS Technical Data SheetsДокумент6 страницFDAS Technical Data SheetsPhel FloresОценок пока нет

- Music Easel Operation Manual 2nd EdДокумент66 страницMusic Easel Operation Manual 2nd EdNeilОценок пока нет

- KSW-230 (Water Flow Switch)Документ2 страницыKSW-230 (Water Flow Switch)Anonymous XYAPaxjbYОценок пока нет

- Chemical Technicians 10-2021Документ30 страницChemical Technicians 10-2021PRC BaguioОценок пока нет

- XFP 10G SM 40Km TRF7052FN (Opnext)Документ29 страницXFP 10G SM 40Km TRF7052FN (Opnext)Ayan ChakrabortyОценок пока нет

- Timetableautumn2012 13Документ2 страницыTimetableautumn2012 13Savant KrishnaОценок пока нет

- A Multi-Functional In-Memory Inference Processor Using A Standard 6T SRAM ArrayДокумент14 страницA Multi-Functional In-Memory Inference Processor Using A Standard 6T SRAM ArrayNavritaBeniwalОценок пока нет