Академический Документы

Профессиональный Документы

Культура Документы

SFO - HSE Audit Report 31.08.2014

Загружено:

Sriram Baskaran0 оценок0% нашли этот документ полезным (0 голосов)

275 просмотров7 страницfgfgfg

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документfgfgfg

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

275 просмотров7 страницSFO - HSE Audit Report 31.08.2014

Загружено:

Sriram Baskaranfgfgfg

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

HSE AUDIT REPORT

‘Audit Report Ret: DPCIMSEIAnAU20tA 001

HSE AUDIT REPORT

DPC/ Tender! 2013/ 49 - Construction of 33/11 kV 2 X 20 MVA

Primary Substation designated as North Awgad II.

Ref: DPC/HSE/Audit/2014/ 001 dated 31.08.2014

Auditors: Namo janature Date: 31/08/2014

KS Balachandran

Said Ahmed Al Mashini

Distribution

Original ‘Muridharan Nair Project Manager, SFO

Copies

Eng.Alllssa Shamas - Chiat Executive Ofticer

‘Mr. Omar ALAwadi - Acting Director— Projects

‘Mr. Walid MA == HSE Manager - OPC

Me. § Sawant = Site Manager, HES

HSE AUDIT REPORT

‘ot Repet Ra: DPCIMSEIA/201 0

Executive Summary

During the aust, the compliance to HSE requirements, contractual terms and conditions and

applicable regulatory requrements was assessed. The assessment was performed through

feview and. verification of supporting evidences, records, documents, work practices and

interaction with HES, and Contractor's personnel.

Following good practices and observations fr improvement were noted during the audit

114 Good Practices

4. Generally housekeeping standard is high throughout the eit however suggest to maintain

‘tall time,

2. The site has achieved 11988 manhours with « miner incident on 08.05.2014 and

2850 Km without any trafic incidence.

3, Contract documents and approved HSE plan & Contractors HSE requirements were

‘avaiable at site office

4, Documents related to workmen compensation insurance of contractor and subcontractor

wae avaliable sn found tobe vai ti 2015,

5. Contractor displayed company HSE Policy at prominent locations.

6, HSE issues were dszussed in veokly progress review meetings and recorded,

7. Contractor conducts dally tol box taks and cords were avalable.

8, Contractor maintains he record of HSE statistic at site office and records were a

9, Contractor has an agproved CEP at site 2s an Electrical Engineer.

the activities and records avaliable,

10. Contractor has card out sk assessment for

11, Contractor has identi and maintained method statements for al high risk activites.

12, Contracor has provided workers rest room, wash room, tole at ste offie.

19, Contracor has recerds of incident and corrective measures cascaded to all employees.

+4. Contractor has ideniied emergency assembly point and emergency evacuation route for

‘te office and curing the emergeny alarm sounded, all employees assembled at

assembly point ina shor time

416, Subcontractor engaged forthe activity Is being approved by Consulta” DPC and records

were available.

4.2 Observations on documentation:

1, Approved HSE Officer has been demobilized from ste and CV of prasent HSE Advisor is

rot approved by Consultant and DPC.

2. Comprehensive aulsmobie liabiity insurance as per clause no, ® of contract is not

‘avalable and records were nat provided for evidence.

3, Training matrix provided by the contractor isnot matching with DPC taining requirements

‘and found thal HSE induction by contractor and OPC were not carted out and records

‘wore not available al site for evidence

4. Refer to appravad HSE plan serial no. 11, Site safety committee; Safty committee isnot

‘consiuied forthe project and there were no records available

'5. Responsibities mertioned for CEO of the contractor for carving out site inspections.

However no records avaiable.

brennan en Ens

HSE AUDIT REPORT

‘Audit Report Rot: OPCISEIAvsR2014/001

6. HSE Manager Roles and responsbites mentioned in the aporoved HSE plan however it

is not reflected in the approved Organogram,

7. Refer to approved HSE plan sl, No. 11; Weekly Safety walk downs ~ No records were

available a8 evdence.

8. Refer to SI no, 12 of approved HSE plan, Vehicle & Equipment inspection formats used

for eneuring safely requirements were found to be inadequate 6 per the safely

requiremens,

9. Refer to SI No, 13 of approved HSE plan, Equipments, third party inspection certificates

of all equipments were nt available and there were no records avaiable as evidence.

10. Refer to SI no, 15 of approved HSE Pian, House keeping, there were no records avaiable

for house keeping inspections by the contractor as evidence.

11. Refer to SI no, 16 of approved HSE Plan, Scaffold; Scaffld taining was not done for any

‘workers and there were no records avaiable for evidence

12. Refer to SI no, 17 ol approved HSE Plan, Electrical safety, there is trained electrician at

‘te and celficate was found tobe Invalid. ELCB's were not inspected a site office and

‘records were not avalable for evidence.

19, Refer to SI no, 19 of approved HSE Plan, Fre precautions, there are no records available

for contractor trained ther employees in fe prevention and fre watchers were not

‘denied

14, Refer to SI no. 19 of approved HSE Plan, emergency dls are to be cated cut every

‘month, however no recor were available as evidence.

16. Refer to Sino, 28 cf approved HSE Plan, HSE Ault schedule; there were no records

‘avaliable forthe quately audits as per the plan.

16, Refer to page no. 33 of approved HSE Plan; Weekly safety inspection schedule; there

wore no records avalabl for evidence,

17. Refer to page no. 39 & 40 of approved HSE Plan; Pemit system; there were no records

availabe for evidence

418. Refer to page no. 47 of approved HSE Pan; there were no records avaliable 2s an

evidence for waste management

49, Refer to OES 4 contactor has not provided wih power supply forthe electical potable

hand tg0!8 and no resrds available

20, Refer to MO 28612008 - Third party inspection certificates of all iting tool, tackles,

hydraulic operated machines and safely harnass Is not avaliable and there were no

records avaliable a evidence.

Refer to MD 28672008 - There were no records available for ensuring the legal

urement related lo accommodation of werkers and is inspections and there were no

‘record avaliable as evidence

2

2. Personnel Involved

PC Mohammed Ba Alaw

HES ‘Sawant, Sulaiman, VenuBabu, Sreejth

SFO ‘Mural Nair, Abfilash C, Shi P, Aru, Rajeev, Abhlash

HSE AUDIT REPORT

‘sit Report Rat: DPCAISEIAus2016 001

‘Audit Scope

‘The aust was caried out lo assess the implementation of the requirements in DPC Contract

document, Project HSE Plan, MD 286/2008 and DPC HSE requirements for contractors,

4. Summary of Audit Findings

During the Auct, the implementation of the HSE requirements was examined. The aut was.

performed tough review and verification of supporting evidence, records, documents, work

Dractces and interaction wit personne

‘This par is based on the samples reviewed and hence shall be considered representation only.

“This fret aud conducted by DPC isto be considered for educating the consuitant and contractor

{for improving the HSE requrements as pr th Vision and HSE strategy of DPC.

\Non conformance report (NCR) 1s not raised as the auditors noted that contactor needs to

Improve further to DPC requirements as this audits conducted onl to verify the present standard

of implementing the requirements, However Owners Engineer of the contract shall review the

progress salus of mplemertaion of HSE requirements periodically and submit report to DPC.

‘Some observations were ako made curing the audit, which are described in section 1.2 under

fexecitve summary. Detaled sta findings were also noted below as serial no. 5 ofthis report for

Immediate compliance.

ProjectSte Manager of Contractor should take action on all observations and site findings.

Fundamental cause of each observation should be analysed and actions implemented to prevent

future recurrences. This process may involve staf other than the immediate audtee(6)~ e.g. the

Senior management - and the time needed to make the analysis and implement the actions Is

likely to take fonger than the cortection ofthe immeciate observation. The Owners Engineer of

the contract should take intatveinfolowup and close out ofall the observations and site findings

for further improving the HSE requirements and update DPC Project Deparment! HSE

department,

‘Onmers Engineer (HES) sha further nfrmed to take not af the DPC HSE requirements and

‘conduct audte to all other convactorsassocatee with DPC and HES In a time fame for

Imnpresng the HSE standard and submit repr to DPC project and HSE depariment

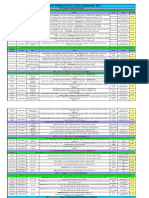

5. Detaled sito Findings

5.1, Portacabin Base Earting & Anchoring tobe done

52. Portacabin (SFO Office, Fist Ad Room & Store)

28) Spacer to be provided between Caling Light & Root

») Dis type fat fing tobe provided

€) Locking Arrangement o be provided

5.3. Drinking Water facil tobe provided in First Aid Room

154 Thi Party Inspection Centfcato tobe avalable forthe Safety BellHamess

HSE AUDIT REPORT

‘ait Report Ra: DPCIISEIANsI2014/001

5555 House Keeping tobe inproved near Rest Room,

5.8 A onaiton (A.C) o be provided for Rest Room

517 Body Earting to be povided for Rebar Cuting Machine,

58 All the Stee! Rods used for Barrcation has to be provided with End Caps

(VciWeoden)

5.9. Structural Consutant Approved Drawing not available for Bulding Roof Slab Scaffold,

‘The same tobe implented ir Future Projects

15.10 Base Plate to be provided for Scaffold.

5.11 Cable Trench to be Baricaded (Hard Baricaion required)

5. 12 Excavated Areas for Power Ty/Capactor Bank Foundation & Boundary Wall, Cable

Trenches ete

2) Enty& Escape Routes ar o be provided with clear access.

2) Wooden Ladders ae tobe replaced with Approved Aluminium Ladders

5.49 For Root Way,

4) One mere Side Reng has tobe provided.

1) Shayp Edge onthe he Right Han sdeof Ral o be protected

«) The Gap near the Root Enty tobe cased on both the ends.

5:14 Anais & deshttored Material tobe removed from the Reo! & Stacked Property,

5:15 Allthe Portable Power Tools mus be operated at 110 Vas per OFS 4

6. Conclusion

It was observed that there ie a general interest by the contactor for improving the HSE

Fequirements as per DPC HSE requirements. and the representatives from contractor were

familar wth the HSE requirements and Procedures. However, there Is scope for continual

Improvement as identified section-t.2 and 5 o his report

7. Photagranhs

el: DRS 01 Bigs

Improper way of acess (wooden adeer

to be replace with approved aluminum

ladder) try & Escape Routesare tebe

rovided with clear access.

‘Allis & shuttered Material tobe

removed from the Root & Stacked

Prope

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Sharikat Fanniya Omaniya LLC: Man-Hour For The Month of June 2020Документ2 страницыSharikat Fanniya Omaniya LLC: Man-Hour For The Month of June 2020Sriram BaskaranОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- HSPR 043 Covid - 19 Emergency Preparedness & ResponseДокумент5 страницHSPR 043 Covid - 19 Emergency Preparedness & ResponseSriram BaskaranОценок пока нет

- Electronic Form Please Do Not Fill With Hand: Dcrp-Hse Course Nomination Form and Local Purchase OrderДокумент7 страницElectronic Form Please Do Not Fill With Hand: Dcrp-Hse Course Nomination Form and Local Purchase OrderSriram BaskaranОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Sfo - Admin Forms - Index LogДокумент1 страницаSfo - Admin Forms - Index LogSriram BaskaranОценок пока нет

- HSE Monthly Report: Report For The Month of JUNE 2020Документ1 страницаHSE Monthly Report: Report For The Month of JUNE 2020Sriram Baskaran100% (1)

- 12.0 Associated Formats: HSEP 17 - Incident Investigation and Reporting Procedure, Rev 03 Page 9 of 12Документ1 страница12.0 Associated Formats: HSEP 17 - Incident Investigation and Reporting Procedure, Rev 03 Page 9 of 12Sriram BaskaranОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hse Inspection/ Audit Close Out Report: HSEF-51Документ2 страницыHse Inspection/ Audit Close Out Report: HSEF-51Sriram BaskaranОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Sharikat Fanniya Omaniya LLC: Evacuation Mock DrillДокумент4 страницыSharikat Fanniya Omaniya LLC: Evacuation Mock DrillSriram BaskaranОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Audit Point 6.2.4Документ2 страницыAudit Point 6.2.4Sriram BaskaranОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Sharikat Fanniya Omaniya LLC Sfo New Labor Camp Snag List CivilДокумент4 страницыSharikat Fanniya Omaniya LLC Sfo New Labor Camp Snag List CivilSriram BaskaranОценок пока нет

- 90deg SideMirrors (Blind Spot)Документ9 страниц90deg SideMirrors (Blind Spot)Sriram BaskaranОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Hse Inspection/ Audit Close Out Report: HSEF-51Документ2 страницыHse Inspection/ Audit Close Out Report: HSEF-51Sriram BaskaranОценок пока нет

- Application For Electrical Contractors Registration Grade-AДокумент32 страницыApplication For Electrical Contractors Registration Grade-ASriram Baskaran100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Vinoth SafetyДокумент3 страницыVinoth SafetySriram BaskaranОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Sharikat Fanniya Omaniya LLC: Evacuation Mock DrillДокумент3 страницыSharikat Fanniya Omaniya LLC: Evacuation Mock DrillSriram BaskaranОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- F49 Scaffold Errection ChecklistДокумент4 страницыF49 Scaffold Errection ChecklistSriram BaskaranОценок пока нет

- 101 - HSEF 04 - Format-4-First Aid Boxes InspectionДокумент1 страница101 - HSEF 04 - Format-4-First Aid Boxes InspectionSriram BaskaranОценок пока нет

- Chemical Storage AreaДокумент4 страницыChemical Storage AreaSriram BaskaranОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Sharikat Fanniya Omaniya LLC: Camp Requirements Toilets and BathroomsДокумент4 страницыSharikat Fanniya Omaniya LLC: Camp Requirements Toilets and BathroomsSriram BaskaranОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Planning The Work1Документ2 страницыPlanning The Work1Sriram BaskaranОценок пока нет

- Project Name: Construction of 33/11Kv, 2X20 Mva Primary Substation Desiginated As North Awquad - IiДокумент1 страницаProject Name: Construction of 33/11Kv, 2X20 Mva Primary Substation Desiginated As North Awquad - IiSriram BaskaranОценок пока нет

- Discharge Procedures RevДокумент7 страницDischarge Procedures RevSriram BaskaranОценок пока нет

- Raju Resume201Документ2 страницыRaju Resume201Sriram BaskaranОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Phy 2Документ1 страницаPhy 2Sriram BaskaranОценок пока нет

- LaptopДокумент19 страницLaptopRaj AgarwalОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)