Академический Документы

Профессиональный Документы

Культура Документы

(Practicas de Completacion Golfo de Mexico), d26

Загружено:

RAGF2014Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

(Practicas de Completacion Golfo de Mexico), d26

Загружено:

RAGF2014Авторское право:

Доступные форматы

SPE/IADC 52810

Best Completion Practices

William Q. Dyson, SPE, Schlumberger Oilfield Services; Earl Coludrovich, SPE; Rachael Creech; John C. Weldy, SPE,

Texaco Exploration and Production; Michael Fruge, SPE; Marlon Guidry, SPE, Schlumberger Oilfield Services

IADC Members

Copyright 1999, SPE/IADC Drilling Conference

This paper was prepared for presentation at the 1999 SPE/IADC Drilling Conference held in

Amsterdam, Holland, 911 March 1999.

This paper was selected for presentation by an SPE/IADC Program Committee following

review of information contained in an abstract submitted by the author(s). Contents of the

paper, as presented, have not been reviewed by the Society of Petroleum Engineers or the

International Association of Drilling Contractors and are subject to correction by the author(s).

The material, as presented, does not necessarily reflect any position of the SPE or IADC, their

officers, or members. Papers presented at the SPE/IADC meetings are subject to publication

review by Editorial Committees of the SPE and IADC. Electronic reproduction, distribution, or

storage of any part of this paper for commercial purposes without the written consent of the

Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to

an abstract of not more than 300 words; illustrations may not be copied. The abstract must

contain conspicuous acknowledgment of where and by whom the paper was presented. Write

Librarian, SPE, P.O. Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

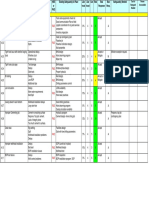

Figure 1 titled Single, Flowing Completions, depicts each of

the completion types discussed in this paper; it also contains

some completion guidelines and decision aids. An Alliance

Process Improvement Team (APIT) designed this schematic as

a reference for basic decisions concerning completions. The

APITs purpose is to implement process improvements, reduce

completion costs and increase overall efficiency by merging

the knowledge and experience of operating and service

company personnel; the completion practices outlined in this

paper are focused toward this goal.

Abstract

Over one hundred Gulf of Mexico completions have been

analyzed over a period of two years, resulting in the best

practices, as outlined in this paper. The completions have been

categorized into ten different types, and optimized methods for

implementing each type are listed. Completion engineers,

production engineers, rig foremen and many service company

personnel have contributed to Best Completion Practices. The

work, however, has mainly been driven by an Alliance Process

Improvement Team (APIT) composed of the authors, thus

shared visions and solutions are the means by which common

completion objectives have been reached.

It should be noted that all of the completion types discussed in

this paper are flowing, and have only a single tubing string.

Some completions such as cased hole horizontal, furan resin

consolidation and screenless frac packs did not exist in the set

of wells examined, so they have been omitted from discussion.

Introduction

The number of possible completion configurations for oil and

gas wells is infinite; nevertheless this paper endeavors to

classify completions into three basic categories: non-sand

control, sand control and horizontal. This classification is

based on experience from over one hundred Gulf of Mexico

wells. Several conventions are adopted in order to define these

three major completion categories: (1) a non-sand control

completion is any non-horizontal completion without a gravel

pack screen, (2) a sand control completion is any nonhorizontal completion with a gravel pack screen, and (3) a

horizontal completion is one with deviation greater than

eighty-five degrees. For example, a well with seventy-degree

deviation and no gravel pack screen would be termed non-sand

control. Within these three categories there are ten individual

completion types, which are diagrammed in Figure 1 (located

in the appendix).

A number of different completion configurations exist for

wells with multiple pay zones; sometimes only minor changes

are made for different well conditions. Once it has been

determined whether sand control and fracturing are necessary,

the process of equipment selection can begin. Pertinent

reservoir information is also necessary to determine working

pressures for equipment. The completions discussed below

can be greatly affected by the lack of a satisfactory primary

cement job across the pay intervals. Methods to handle

secondary cementing will be mentioned at the end of the

discussion on completion types.

Common Decisions

In the Gulf of Mexico it is common to encounter multiple pay

sands with commercial potential in a single well. This can

prove very helpful to the economics of a newly drilled well,

but increased planning is required to provide the operator with

an optimal completion.

Nodal analyses and economic evaluations are performed to

determine whether to complete and produce multiple zones

simultaneously or independently. Mechanically, it is less risky

to produce the lowest zone to its economic limit and then

recomplete in the upper zone. However, because it is more

economical, the upper zone is often selected as the initial

DYSON, COLUDROVICH, CREECH, FRUGE, WELDY, GUIDRY

SPE/IADC 52810

completion. In this case, a sliding sleeve, or some other type

of isolation device which can be operated with slickline or

coiled tubing, can be used. The major disadvantage in

producing the upper zone first is reliance on isolation devices

that can later fail. Sand production, corrosive well fluids, or

the inability to operate the device can lead to costly

remediation. On the other hand, this type of completion is

more economical because it affords future access to a lower

zone. 9

Type 4 Multiple Packers with Plug Back(s) This type of

completion is used when two productive zones that are

separated by a significant distance need to be completed. The

difference between Type 4 and Type 3 is that two additional

packers are required for Type 4. This configuration allows

block squeeze perforations to be isolated between the two

packers. Placing a plug in the tubing between the lowest two

packers is the easiest way to perform the plug back to the

upper zone.

Non-Sand Control Completions

Within the context of this paper a non-sand control completion

is one that has less than eighty-five degrees deviation, and

does not require sand control screens. These completions are

generally confined to land, inland waters or deep, consolidated

offshore reservoirs.

Perforating Both tubing- and wireline-conveyed perforating

methods are used in non-sand control completions, but the

wireline-conveyed option is more common and more

economical, as it does not require a rig. Shot density, entrance

hole diameter, and perforation tunnel length should be

considered in order to prevent sand production in non sand

control completions. Large diameter, deep penetrating charges

in densities greater than six shots per foot (twelve shots per

foot preferred) can prevent or defer sand production. This

technique allows the production of marginally economic zones

not suitable for sand control completions.

Type 1 Open Hole Single There are many variations of

open hole single completions, but this type is not often used in

the Gulf Coast because of poor consolidation of many of the

formations. However, open hole single completions should not

be eliminated from consideration, as they are inexpensive and

quite versatile. However for well consolidated formations,

open hole single completions should be considered because of

their low cost and versatility.

Type 2 Cased Hole Single Unlike open hole completions,

cased hole single completions guarantee hole stability.

Furthermore, a successful primary cement job will isolate the

productive interval from water zones. This type of completion

is typical of land and inland waters wells, but it is also found

offshore when sand control is not required. Cased hole single

completions are more expensive than open hole completions

due to the cost of production casing, but they are still relatively

inexpensive due to the limited hardware and number of

services required for their installation. Aside from the cost of

setting production casing, completion costs include tubing,

nipples, packer, fluids and perforating (normally done with

wireline). Shallow dry gas wells (1,400 to 3,000 feet) may

frequently be produced in this manner, whereas oil zones at

similar depths require sand control.

Type 3 Single Packer with Plug Back(s) The cost and

mechanics of this completion type are essentially the same as

the previous one. The difference between the two is that Type

3 allows for a future plug back to a secondary zone located

between the primary zone and the production packer. Multiple

wireline plug backs (WLPBs) can be performed under a

single packer as long as the zones are reasonably close

together, and meet the same conditions as the primary zone,

such as not requiring sand-control or artificial lift. In some

cases, WLPBs can be performed with a single packer even

when there are large distances between zones.

Tubing-conveyed guns may be used as zone length increases.

For long zones, which would require multiple wireline trips,

tubing conveyed perforating (TCP) is likely the best option.

Another benefit of TCP is that it allows significantly higher

underbalance pressures than the wireline method. Perforating

underbalanced is important in order to create open, undamaged

perforations so that productivity is not hampered, but it creates

the added risk of sticking the guns in the hole. Using an

exploding firing head to drop the guns upon detonation can

minimize this risk. This technique works very well when the

guns are run in the hole below the production packer.

Other factors to be considered are shot density and phasing.

Many times zero degree phasing and low shot densities are

sufficient, but when there are heterogeneities such as

anisotropy or laminations that require higher shot densities,

TCP is the method of choice. However, when fracture

stimulation is to be performed, wireline-conveyed methods are

most often used because fracturing sufficiently addresses the

heterogeneities. 1,2

Fracturing The second and third completion types described

above may be candidates for a fracture stimulation that is

pumped down the production tubing. Wells that are to be

fractured should be designed so that (1) a permanent, seal bore

type packer is used, and (2) the production seal assembly has

adequate length to accommodate shrinkage during fracturing.

One additional concern is the tubing size: 2 7/8 inch tubing is

generally the smallest size that can accommodate a fracture

treatment, but the pump rate is limited to about twenty barrels

per minute.

SPE/IADC 52810

BEST COMPLETION PRACTICES

Sand Control Completions

There are many completion types commonly considered to be

sand control completions; only those with sand control screens

are addressed here. Four major types of sand control

completions are defined below, and their relative strengths and

weaknesses are discussed. Issues such as sand control pumping

techniques and perforating techniques are discussed later in

this section. While sand control can significantly increase

completion costs, the life of the completion is also greatly

increased. Proper hardware selection insures completion

reliability. Some general rules, which contributed to the

success of the studied wells, include:

1) Maintain 0.85 inch minimum standoff from gravel pack

screen to casing inner diameter.

2) Use ninety feet of blank above gravel pack screen

whenever possible.

3) Keep draw down pressure less than 1000 psi for gravel

packs and 500 psi for non-sand control completions.

4) Restress gravel packs at pressures ranging from 1000 to

1500 psi.

5) Insure that gravel pack assembly inner diameter is at least

1.875 inches.

6) Test cement squeezes to within 80% of fracture gradient.

7) Allow no more than 10 feet between the bottom

perforation and the top of sump packer or bridge plug.

8) Always use P-110 grade pipe in order minimize the risk of

blank pipe collapse.

Type 5 Single Gravel Pack Completion The most basic

and least likely to fail sand control completion, the single

gravel pack is widely used, but is limited by the need for a rig

workover if other zones are to be produced. This completion

type may have a sump packer or a bridge plug below the

gravel pack screen. A sump packer should be used (1) if an

open sump is required in order to accommodate production

logging tools, or (2) to allow debris to fall through the

completion. Bridge plugs or cement retainers (if squeeze

cementing is necessary) are generally used in conjunction with

a bull plugged lower screen. This method saves time and

money during completion operations, but does not allow

complete evaluation of the perforated interval with production

logging tools.

Type 6 Single Selective This type of completion is gravel

packed with an internal sliding sleeve, which allows a nonsand control completion to be produced through the gravel

packed completion. However, if the sliding sleeve fails,

secondary reserves may be lost if a rig workover cannot be

justified. For this reason, the zone with larger reserves is

generally produced first. A single selective completion differs

from a single gravel pack in two ways: (1) the presence of a

productive zone below the primary completion, and (2) a

sliding sleeve that allows the production of a secondary zone

after depletion of the primary zone. A major limitation of

single selective completions is their dependence on a sliding

sleeves.

Type 7 Single Selective with Multiple Options The single

selective with multiple options is perhaps the most common

completion in the Gulf of Mexico offshore. This configuration

allows for great versatility and minimizes the need for rig

workovers, but its success depends on the reliability of more

mechanical components than the types discussed above. Great

care must be taken in the design of these completions to insure

their prolonged success.

Type 8 - Stacked Selective This is the most complex of the

single tubing completions and is often avoided for this reason.

It requires the use of no fewer than three gravel pack packers,

and usually a sump packer. These completions are quite

expensive and require several weeks to install, but these

drawbacks are offset by the ability to produce three or more

zones without a single workover. Usually these are installed in

marginally economic zones, and where future workover costs

can be prohibitively high, such as offshore. If significant

reserves exist, performing a future workover to produce uphole

zones is more attractive than the mechanical risk of a complex

completion.

Perforating High shot density guns (casing guns with twelve

shots per foot or more) using big-hole perforating charges are

commonly used to maximize completion efficiency.

Underbalanced perforating is the best technique for removing

debris from the perforation tunnels; consequently, it

contributes greatly to the productivity of the completion.6

Debris can mix with the gravel pack sand, reducing the its

permeability. However, often it is not possible to perforate at

the optimum underbalance pressure due to the following

limitations: (1) the danger of casing collapse, (2) the

production of large quantities of formation sand, (3) the

potential for sticking the pipe or guns, and (4) movement of

the perforating packer.8

TCP systems offer the benefits of longer gun length and

greater underbalance pressures, but they are prone to sticking.

Care must be taken in gun selection to insure annular clearance

(usually one-half to one inch) for two reasons. (1) The

clearance is necessary should guns become stuck and require

fishing. (2) Entrance hole diameter is highly sensitive the

annular clearance. This problem is magnified in deviated

wells where the gun system lies on the bottom of the hole

causing an absence of perforations in the upper portion of the

hole.

Another concern in deviated wells is the cleaning of the

perforation tunnels on the lower side of the hole. Gravity

prevents removal of the debris and thus the tunnels cannot be

properly gravel packed. This makes them suseptible to

collapse which drastically reduces the productivity of the

DYSON, COLUDROVICH, CREECH, FRUGE, WELDY, GUIDRY

completion. Perforation cleaning is also hampered by the

presence of the guns, so for the above reasons, perforating the

lower portion of the hole in deviated zones is often avoided.

Furthermore, the upper portion of the hole in deviated zones is

sometimes not perforated due to the difficulty of placing

gravel pack sand in the perforation tunnels in this portion of

the hole. This perforating method also minimizes the

possibility of water production through an inadequate cement

sheath on the lower side of the hole.

Single Trip Perforating and Gravel Packing The practice of

single trip perforating and gravel packing involves combining

the tools and hardware necessary for both perforating and

gravel packing, and running them into the hole simultaneously.

This method saves many hours of rig time, and prevents large

fluid losses after perforating. 7, 11 These two benefits lower

completion cost and enhance well productivity; they should be

used whenever possible. Some factors that limit the use of

single trip perforating and gravel packing systems are

inadequate sump space for perforating guns, productive zones

beneath the zone of interest, and old perforations above the

zone of interest.4 (The term single trip perforating and gravel

packing does not imply that frac packing is not an option with

these systems.)

Sand Control Pumping Techniques The sand control

completion types discussed above require pumping, normally

one the following techniques: (1) a gravel pack using a mildly

viscous carrier fluid, (2) a high rate water pack (HRWP) using

a completion brine carrier fluid, or (3) a frac pack, which uses

a highly viscous carrier fluid.

Frac packs generally provide good completion efficiency with

a slightly negative skin. They minimize the mobility of fine

grained sediments, and thus reduce the necessity for future

acid treatments.5 Drawback of frac packs are that they

sometimes require long clean up periods and they can foul the

production facilities with guar gel. These problems can be

minimized by using visco elastic surfactant (VES) fluids. The

viscosity of VES fluids is broken upon contact with

hydrocarbons, thus causing less proppant pack damage, and

providing faster well clean up.

Another common use of VES fluids is in gravel packing. They

can be used effectively to reduce pumping costs when the

alternative carrier fluid is heavy completion brine. This VES

method is the middle ground between frac packs and gravel

packs using completion brine. Since they are slightly viscous,

VES fluids allow typical proppant concentrations of three to

four PPA, and proppant placement is usually at least 150

pounds of proppant per foot of perforations. Normally, pump

rates are about 8 barrels per minute (BPM). These treatments

are pumped in the circulating position with the annulus closed.

Near the end of the treatment, 25% of the pump rate is allowed

to return through the annulus to insure a good pack. This

SPE/IADC 52810

method is also applied to gravel packs using completion

brines, commonly referred to as high rate water packs

(HRWP).

Most current sand control pumping techniques fall into one of

the above categories. Frac packs are almost always considered

to be the best method unless (1) the reserves do not justify the

expense, (2) there is excessive zone length in a highly deviated

well, or (3) there is significant risk of connecting a nearby

water sand with the frac pack.

Remedial Cementing In circumstances where the primary

cement job does not meet acceptable standards, secondary

cementing techniques are sometimes necessary. The most

common method is a block squeeze. Cement block squeezes

are performed in an effort to isolate productive zones and

prevent extraneous water production. They can also

substantially drive up the cost of the initial completion.

Determining whether a block squeeze is necessary is usually

left up to the completion engineer based on his interpretation

of the cement bond log. In the past, if there was doubt about

the interpretation, a block squeeze was usually performed. To

prevent an excessive number of block squeezes, thereby

reducing costs, the APIT recommends the following guidelines

for sufficient bond:12

1)

2)

3)

4)

5 feet of 60% bond in 5 inch casing

6 feet of 60% bond in 5 inch casing

10 feet of 60% bond in 7 inch casing

12 feet of 60% bond in 7 5/8 inch casing

These guidelines promote a lean forward approach to

reducing the number of block squeezes, resulting in three main

benefits, significantly reduced completion costs, less rig time

and elimination of complications resulting from the squeezes.

Horizontal Completions

A horizontal completion offers several advantages over a high

angle or vertical completion: (1) it can eliminate water or gas

coning problems, (2) it increases the area open to flow thus

reducing reservoir fluid velocities and fine grained sediment

mobility, and (3) it may allow for more efficient reservoir

drainage.3 These benefits make horizontal wells very

attractive, but there are also limitations, including increased

drilling and completion cost, poor completion reliability and

very limited intervention options. In order to optimize

completion design, it is necessary to compare the costs and

benefits of several viable completion options.

For discussion purposes, horizontal completions have been

divided into two main types, supported and unsupported open

hole. In supported completions, the support is in the form of a

slotted liner or a shrouded screen. A shrouded screen refers to

the open hole version of the shunt tube technology where

integral joints of perforated casing and gravel pack screen are

SPE/IADC 52810

BEST COMPLETION PRACTICES

made up and run in the hole simultaneously. It should be noted

that screen alone is not considered adequate support for the

borehole.

Type 9 - Open Hole Unsupported This type of horizontal

open hole completion may be without screen, or it may have

any type of sand control screen with or without a gravel pack.

This type of completion is divided into three sub-categories:

barefoot, screened, and gravel packed. Barefoot completions

are those without screen or gravel pack, and are the least

expensive of horizontal completions, but they are limited to

competent rock that does not produce sand. Screened and

gravel packed completions are effective in controlling sand

production, and reduce the migration of fine grained sediment

into the wellbore. It should be noted that none of the horizontal

completion types discussed above are recommended in

formations with poor hole stability. Experience has shown that

open hole, unsupported horizontal completions fail if they are

placed in formations with an unstable borehole.

Type 10 - Open Hole Supported If the competency or

stability of the hole is questionable, an alternative horizontal

completion is the open hole supported type, in which

mechanical borehole support, in the form of a slotted liner or

shrouded screen, is added. In one field where seven horizontal

wells were completed, six were Type 9 and one was Type 10.

After slightly more than one year of production, all but two of

the unsupported variety had failed. The supported well was, in

fact, the most trouble-free horizontal in the field.

Note that the supported, horizontal completion type does not

include cemented, cased hole horizontal completions. These

have been omitted from this discussion because none existed

in the wells that were studied.

Summary and Recommendations

For competent formations, non sand control completions are

best because of fewer components, little risk and low

installation cost. In poorly consolidated formations, sand

control completions are required. Since they are more prone to

failure and intervention is expensive, mechanical risk should

be minimized. Horizontal completions are the best alternative

in reservoirs where a fluid interface such as an oil-water

contact is present and the vertical and horizontal permeability

are similar.

Communication and flexibility are keys to designing and

performing the optimum completions. This communication

should begin long in advance of the drilling phase of the well.

Expected flowrates should be identified by the production

engineers and confirmed with the geologists data. Nodal

analyses should be performed over the entire range of possible

outcomes, and the most likely production tubing size should be

selected. The actual reservoir often differs from initial

expectations, so changes to the completion design are

common. It is imperative have sufficient to incorporate these

changes both from a cost and equipment standpoint. Wells

with deviations greater than sixty-five degrees may require

additional planning since equipment such as electric line

cannot be used. In these wells, the number of trips should be

minimized whenever possible to avoid increased cost and

reduce the chance sticking. Logging and slickline work should

be minimized or eliminated.

Completions with multiple pay zones require more equipment

and hardware (packers, gravel pack settings, etc.) than single

zone completions. Because of the difficulty and expense of

removing this equipment, designs should attempt to minimize

risk whenever feasible. Sliding sleeves have less chance of

failure if not relied upon to produce upper sands prior to lower

sands. Another danger lies in using unproven technology and

equipment with inadequate caution. However, the rewards of

using new systems such as single trip perforating and gravel

packing have been well worth the risk. The overall goal in

multiple zone completion design should be to achieve a

trouble-free completion that will provide a production outlet

for the life of all zones in the well.

The importance of post-completion bottom hole pressure data

can not be overemphasized. Tracking completion performance

and determining the extent of formation stimulation or damage

is essential in designing and developing new completion

procedures. However, without drawdown and buildup test

data, the validity and efficiency of these methods cannot be

accurately assessed.10

DYSON, COLUDROVICH, CREECH, FRUGE, WELDY, GUIDRY

Acknowledgements

The authors would like to thank the previous members of the

Completion APIT , especially R. J. Buddy Domangue for his

efforts in drafting the original schematic entitled Single,

Flowing Completions. This work was the basis and

inspiration for Best Completion Practices.

References

1. Behrman, L.A, Nolte, K.G. Perforating Requirements for

Fracture Stimulation SPE 39453. Presented at the SPE

International Symposium on Formation Damage Control,

Lafayette, LA; February 1998.

2.

Economides, M.J., Nolte, K.G.: Reservoir Stimulation,

Schlumberger Educational Services, Houston, TX, 1987.

3.

Milne, A.; Horizontal Well Completion and Stimulation

Technology, Dowell Schlumberger, Houston, TX, 1991.

4.

Jones, R.H., Bolin, T.D. New Single Trip Single Trip

Perforating and Gravel Pack Procedure with Advanced

Stimulation Design Reduces Formation Damage in High

Permeability Reservoirs: Case Histories. SPE 39434

Presented at the SPE International Symposium on

Formation Damage Control, Lafayette, LA; February

1998.

5.

Toffanin, E. et al: Frac Packing Using Conventional and

Alternative Path Technology: SPE 39478 Presented at the

SPE International Symposium on Formation Damage

Control, Lafayette, LA; February 1998.

6.

McLeod, H.O.: The Effect of Perforating and Perforation

Cleaning on Gravel Packed Well Performance. SPE

39456 Presented at the SPE International Symposium on

Formation Damage Control, Lafayette, LA; February

1998.

7.

Palthe, P.V.W. et al A Novel Technique for SingleSelective Sand Control Completions Cuts Completion

Costs in Half: Method Development and a Case History

from the Gulf of Mexico SPE 50650 Presented at the

EUROPEC Conference, Den Haag, The Netherlands;

October, 1998.

8.

Tariq, S.M.: New, Generated Criteria for Determining

the Level of Underbalance for Obtaining Clean

Perforations SPE 38635.

9.

Cramer, D.D.: Knowledge of State-of-Art Techniques

Important Oil and Gas Journal (Aug 22, 1988) PP 41-47.

10. McLeod, H.O., Pashen, M.A.: Well Completion Audits

to Evaluate Gravel Packing Procedures SPE 31088

11. Parlar, M. et al: Guidelines for Selection of Fluid Loss

SPE/IADC 52810

Control Methods Before and After Treatments to

Maximize Well Productivity and Cost Effectiveness SPE

39460, Presented at the SPE International Symposium on

Formation Damage Control, Lafayette, LA; February

1998.

12. Texaco-Schlumberger, New Orleans Completion APIT

Update; Third Quarter 1997.

SPE/IADC 52810

BEST COMPLETION PRACTICES

Appendix

Non Sand Control Completion

Non

Sand Control Completion

Best

Practices

Best Practices

Perforate

through tubing using wireline conveyed strip guns

Perforate

through

tubing

wireline

conveyed

strip gunstubing and packer

If TCP

techniques

are

used,using

run guns

in hole

with production

If up

TCP

aredown

used,orrun

guns in

hole

withwhenever

production

tubing and packer

Set

fortechniques

wireline plug

wireline

plug

back

possible

Set2 up

wireline

or wireline

plug backoperations

whenever possible

Use

7/8for

inch

tubingplug

as adown

minimum

when fracturing

are expected

Use 2 7/8 inch tubing as a minimum when fracturing operations are expected

Limitations

Limitations

May

produce formation sand

May produce

formation

Reserves

may not

justify asand

rig workover

Reserves may not justify a rig workover

Single,

Single,Flowing

FlowingCompletions

Completions

Bestslotted

Practices

Use

liner or shrouded screens where hole stability is a concern

Use

slotted

linertooraddress

shrouded

screens

where

holegrained

stabilitysediment

is a concern

Use

gravel

packs

stop

migration

of fine

Use

gravel

packs to address

stop

migration

fine grained

sediment

Use

these

completions

to prevent

water

or gasofconing

in suitable

Use these completions to prevent water or gas coning in suitable

reservoirs

reservoirs

Limitations

Limitations

Poor

hole stability can cause catastrophic completion failure

Poor

hole stability

cause

failure

If the

completion

fails,can

it may

becatastrophic

necessary tocompletion

sidetrack the

well

If the and

completion

fails,ofit these

may be

necessary

sidetrack

the well

Drilling

completion

wells

can be to

quite

expensive

Drilling and completion of these wells can be quite expensive

Development Plan

Development Plan

Sand Control Completion

Sand

Control Completion

Best

Practices

1 - Open Hole Single

1 - Open Hole Single

Secondary zones in well?

Secondary zones in well?

no

no

Horizontal Completion

Horizontal

Best

Practices Completion

Best Practices

Combine

pipe trips when possible: one trip perforating and gravel pack.

Combine

pipe trips

possible:

one frac

trip perforating

and

gravel

Perforate

balanced

orwhen

overbalance

when

packing (can

use

wire pack.

line).

Perforate

balanced

or overbalance

when

frac packing (can use wire line).

Perforate

TCP

under-balanced

if not frac

packing.

Perforate

under-balanced

not frac

packing.

Frac

pack toTCP

reduce

the mobility ofif fine

grained

sediment

Frac pack to reduce the mobility of fine grained sediment

Limitations

Limitations

Take

care to avoid sticking guns when perforating under-balanced.

Take carereliability

to avoid sticking

when sleeves

perforating under-balanced.

Completion

may relyguns

on sliding

Completion reliability may rely on sliding sleeves

no

Stable Bore Hole?

Stable Bore Hole?

9 - Supported Open Hole

9 - Supported Open Hole

Secondary zones in well?

Secondary zones in well?

5 - Single Gravel Pack

5 - Single Gravel Pack

- can be naked open hole

- may use a screen, slotted liner

- may be gravel packed

no

10 - Unsupported Open Hole

10 - Unsupported Open Hole

- good bore hole support

- may have screen inside liner

- may or may not be gravel

packed

yes

- no bore hole support

- may have screen in open hole

- may or may not be gravel

packed

open hole

open hole

yes

yes

2 - Cased Hole Single

2 - Cased Hole Single

Large distance between

Large and

distance

between

Primary

Secondary?

Primary and Secondary?

- may use sump packer or bridge plug

zone of

interest

no

sliding

sleeve

- can do through tubing gravel pack

no

3 - Single Packer Plug Back

3 - Single Packer Plug Back

yes

7 - Single Selective with Multiple Options

7 - Single Selective with Multiple Options

6 - Single Selective

6 - Single Selective

}

}

Producing zones from bottom to top is standard

Producing

zones from

bottom

to top

standard

practice,

but sliding

sleeves

enable

anyiszone

to be

practice,first.

but However,

sliding sleeves

enablerisk

anyshould

zone tobebe

produced

mechanical

produced

first.toHowever,

risk should

be

evaluated

prior

producingmechanical

up-hole reserves

before

evaluated

to producing

up-hole

lower

ones. Itprior

is likely

that the zone

withreserves

more before

lower ones.

It is likely

zone with

recoverable

reserves

willthat

be the

produced

first.more

recoverable reserves will be produced first.

4 - Multiple Packer Plug Back

4 - Multiple Packer Plug Back

secondary

sliding

sleeve

Considerations for Sand Control Pumping

for Sand

Control

Pumping

1) Considerations

Frac packs are preferable

to gravel

packs

except when:

1) Frac packs

preferable

to gravel packs except when:

reserves

do not are

justify

the expense

reserves

do not justify

the expense

there

is excessive

zone length

in a highly deviated well

there

is excessive

zone

length in aahighly

there

is significant

risk

of connecting

waterdeviated

sand well

therepacks

is significant

riskthe

of connecting

water

sand

2) Frac

minimize

mobility ofafine

grain

sediment

2) Frac

packs

minimize

the mobility

of fine grain sediment

and

the need

for future

acid treatments

and

the

need

for

future

acid

treatments

3) VES fracturing fluids can be used on frac packs to minimize

3) VESflow

fracturing

fluids canand

be proppant

used on frac

packs

to minimize

back problems

pack

damage

flow back

problems

and be

proppant

4) Slightly viscous

VES

Fluids can

used inpack

placedamage

of

4) Slightly

viscous

VES Fluids

be used

in place of

heavy

completion

brinescan

on gravel

packs

heavy completion brines on gravel packs

8 - Stacked Selective

8 - Stacked Selective

May or may not

need screens

primary

- can do through tubing plug back

- limited access to primary zone

Spacer assembly required

sump packer

primary

}

}

sliding

sleeve

potential non

gravel packed zone

non gravel packed

zone

Figure 1- Single, Flowing Completions

Tubingless, packerless, monobore,

Tubingless,

monobore,

dual

and coiledpackerless,

tubing completions

dual

and coiled tubing completions

not

depicted.

not depicted.

sliding

sleeve

upper zone

primary zone with

sliding sleeve

secondary

Gravel pack screen

Slotted liner or shrouded screen

sump packer

potential non

gravel-packed completion

This diagram was originally prepared by

R. This

J. Domangue

diagram was

of Texaco,

originally

and

prepared

was by

revised

R. J. by

Domangue

the Texaco-Schlumberger

of Texaco, and was

Completion

revised byAPIT

the Texaco-Schlumberger

for presentation with

Completion

APIT

for presentation

with

SPE

52810 Best

Completion

Practices.

SPE 52810 Best Completion Practices.

Вам также может понравиться

- Manual CAT938K PDFДокумент618 страницManual CAT938K PDFRAGF2014100% (1)

- Manual CAT938K PDFДокумент618 страницManual CAT938K PDFRAGF2014100% (1)

- Mack Granite MAKARIOS PDFДокумент11 страницMack Granite MAKARIOS PDFRAGF2014Оценок пока нет

- Whoc12 - 3632, D2Документ13 страницWhoc12 - 3632, D2RAGF2014Оценок пока нет

- PetroleoДокумент11 страницPetroleoRAGF2014Оценок пока нет

- IPR JB&G Gravel PackДокумент9 страницIPR JB&G Gravel PackRAGF2014Оценок пока нет

- Stereonet HelpДокумент30 страницStereonet HelpRAGF2014Оценок пока нет

- DIPS Reference ManualДокумент79 страницDIPS Reference ManualRAGF2014Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- 2 - George Asquith - SECOND EDITION BASIC WELL LOG - AAPG PDFДокумент254 страницы2 - George Asquith - SECOND EDITION BASIC WELL LOG - AAPG PDFLorenza LorenzanaОценок пока нет

- What Is RT? Logging-While-Drilling and Wireline Resistivity Measurements Spotlighted: An Offshore Case Study in AbudhabiДокумент7 страницWhat Is RT? Logging-While-Drilling and Wireline Resistivity Measurements Spotlighted: An Offshore Case Study in AbudhabiAlejandroОценок пока нет

- Grant Grindley: Operations and Wellsite GeologistДокумент8 страницGrant Grindley: Operations and Wellsite GeologistMuhammad AnwerОценок пока нет

- Poster Corrosion Well Logging 9Документ1 страницаPoster Corrosion Well Logging 9Moh Abd Ben100% (1)

- Risk Assesment 1Документ1 страницаRisk Assesment 1Leon MonsalveОценок пока нет

- SLIDE2-Basic Rock PptiesДокумент100 страницSLIDE2-Basic Rock PptiesolaseyeОценок пока нет

- Acoustic EchometerДокумент14 страницAcoustic EchometerNW ArselanОценок пока нет

- LWD For SLB PDFДокумент21 страницаLWD For SLB PDFMohamed KableОценок пока нет

- Man-10000527 7447362 02Документ77 страницMan-10000527 7447362 02Didik safdali100% (2)

- Reverse Circulating Junk BasketДокумент7 страницReverse Circulating Junk BasketLove KumarОценок пока нет

- Flow Tube and Pressure WorkДокумент3 страницыFlow Tube and Pressure WorkCARLOSELSOARESОценок пока нет

- Deliver The Well: Rodney Howard Halliburton, AberdeenДокумент100 страницDeliver The Well: Rodney Howard Halliburton, AberdeenЮрий УсковОценок пока нет

- Swarbrick Osborne 1998 AAPG MEMOIR 70Документ22 страницыSwarbrick Osborne 1998 AAPG MEMOIR 70Ehan Candra50% (4)

- Wire Line EquipmentДокумент70 страницWire Line EquipmentwelshinОценок пока нет

- Subsurface Safety Valve BasicsДокумент33 страницыSubsurface Safety Valve BasicsPun Chee100% (4)

- Well Test Design and Data AcquisitionДокумент20 страницWell Test Design and Data Acquisitionasik asikОценок пока нет

- A 97Документ1 страницаA 97AnuranjanОценок пока нет

- SPE-25499-MS Fishing With Coiled TubingДокумент16 страницSPE-25499-MS Fishing With Coiled TubingirhaniefОценок пока нет

- Safety Handbook for Addressable Release Tool and Voltage Protection ModulesДокумент38 страницSafety Handbook for Addressable Release Tool and Voltage Protection ModulesJuan Pablo Vélez Duque100% (1)

- The Downhole NMR Fluid Analyzer: Numar, HalliburtonДокумент9 страницThe Downhole NMR Fluid Analyzer: Numar, Halliburtonamramazon88Оценок пока нет

- Sterling Tender Equipment ListДокумент34 страницыSterling Tender Equipment ListRahul RajОценок пока нет

- Daily Drilling Progress ReportДокумент25 страницDaily Drilling Progress ReportHamed NazariОценок пока нет

- IOGP Well Control 628Документ60 страницIOGP Well Control 628mustafaelsaid21100% (1)

- The OZ MachineДокумент11 страницThe OZ MachineFigueiredo MarcosОценок пока нет

- SPE 142022 The Role of Geomechanics in Diagnosing Drilling Hazards and Providing Solutions To The Northern Iraq FieldsДокумент11 страницSPE 142022 The Role of Geomechanics in Diagnosing Drilling Hazards and Providing Solutions To The Northern Iraq FieldsAnkit SharmaОценок пока нет

- Formation Testing and Sampling in Low-MobilityДокумент6 страницFormation Testing and Sampling in Low-MobilityjombibiОценок пока нет

- Hydraulic in Situ Testing For MiningДокумент18 страницHydraulic in Situ Testing For MiningItalo GutierrezОценок пока нет

- CTT CatalogДокумент18 страницCTT Catalogdineshmehta2013Оценок пока нет

- Well Completion (2) Model AnswerДокумент4 страницыWell Completion (2) Model Answermissaoui0% (1)

- Raptor Cased-Hole Reservoir Evaluation Tool: Wireline ServicesДокумент3 страницыRaptor Cased-Hole Reservoir Evaluation Tool: Wireline ServicesLuis ApudОценок пока нет