Академический Документы

Профессиональный Документы

Культура Документы

Sourcing Management: Post Graduate Diploma in Supply Chain Management

Загружено:

Enamul Huque SarkerОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sourcing Management: Post Graduate Diploma in Supply Chain Management

Загружено:

Enamul Huque SarkerАвторское право:

Доступные форматы

2/8/2015

Post Graduate Diploma in

Supply Chain Management

Sourcing Management

Presented By :

Mahfuzul Haque

International Supply Chain Education Alliance

Course Objective

Course Outline

The purpose of this course is to provide students with an in-depth understanding of the

theoretical as well as practical aspects of sourcing management. This course serves the

purpose of creating a detailed understanding on the role of sourcing in a supply chain,

ways and means of effectively managing various activities of sourcing management,

different sourcing strategies, contract management and overall procurement execution.

At the completion of this course, students will acquire the necessary skills to:

Assure sourcing and on-time delivery of best priced best quality materials and services

Finding the right supplier and effectively execute supplier relationship management for win-win

partnerships

Negotiate win-win deals for the best interests of the organization

Find solutions to sourcing bottlenecks and risks to ensure on-time delivery of materials

Encourage suppliers early in new product or service development and foster innovation

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Introduction to Sourcing

Sourcing Cycle Steps in Sourcing Process

Sourcing Management Process - Policies, Procedures & Guidelines

Requirement Specification & Value Analysis

Supplier Scoring & Assessment

New Vendor Development & Enlistment

Negotiation & Supplier Selection

Contract Management & Supplier Relationship Management

Risk Management in Sourcing & Strategic Sourcing

Legal aspects of sourcing & Environmental Procurement

Global Sourcing

e-Sourcing

Execute sourcing at the global level and use sourcing as a means of competitive advantage.

2/8/2015

Introduction to Sourcing

What is Sourcing

CHAPTER OVERVIEW

Define Sourcing

Difference between Procurement and Sourcing

Objective of Sourcing

The role of sourcing in a Supply Chain

In-house or outsource

Centralized vs. De-centralized Sourcing

Trends in Sourcing

Different segments of Sourcing

What is Sourcing

The process of obtaining goods and services from

preparation and processing of a requisition through to

receipt and approval of the invoice for payment. It

commonly involves (1) purchase planning, (2) standards

determination, (3) specifications development, (4) supplier

research and selection, (5) value analysis, (6) financing, (7)

price negotiation, (8) making the purchase, (9) supply

contract administration, (10) inventory control and stores,

and (11) disposals and other related functions.

What is Sourcing?

Set of activities, functions, and processes concerned with economic procurement

and inflow of inputs into the enterprise and an efficient control over flow of funds

out of the company.

Includes Sourcing, Inbound Logistics, and Supplier Relationship Management

Does not cover procurement of Capital, personnel, data, proprietary rights such

as licenses and patents.

What is Sourcing

Sourcing or Procurement is a subset of

supply chain management. Purchasing

deals primarily with managing all aspects

related to the inputs to an organization

(i.e., purchased goods, materials, and

services), while supply chain management

deals with inputs, conversion, and outputs.

2/8/2015

Difference between Procurement and

Sourcing

Many times people are confused between the terms procurement and sourcing

thinking them to be the same and these words are used interchangeably.

Role of Sourcing

Impact on Cash-flow

Contribution to the company profitability

Business realized that efforts required to increase profits through increasing sales

were far greater than those involved in generating equivalent returns through

reduction in procurement prices.

Sourcing and Strategic Sourcing are critical steps in buying goods and services. In this stage, individuals

or groups analyze, assess, and select vendors and their goods and services based on certain

specifications and requirements. This relationship is typically documented in a contract with terms and

conditions regarding products, services, prices, and service levels.

The next steps are Purchasing and Procurement Management which are established after Sourcing and

Strategic Sourcing to execute upon the contract and to supply the enterprise with required goods and

services at the negotiated price and agreed-upon times. These actions are typically represented in

purchase orders (POs) or release orders/instructions on master POs. POs are communicated via phone,

fax, mail, EDI, etc.

Source: Copyright 2005 United Parcel Service of America, Inc. All Rights Reserved

Role of Sourcing

Objective of Sourcing

Role of Sourcing

Objective:

Analyzing spend for cost savings opportunities, negotiating, and

selecting reliable sources of supply will always be critical. These

functions fuel profit and provide competitive advantage for the

organization.

Purchasing is responsible for obtaining the materials, parts, and

supplies and services needed to produce a product or provide a

service.

Develop and implement purchasing plans for products

and services that support operations strategies

Continuity of the companys core activities

Control and Reduction of all sourcing costs

Reduction of Risk exposure in relation to Supply

markets.

- Contribution to product and process innovation

2/8/2015

Duties of Sourcing

Duties of Sourcing

Interfaces of Sourcing/Purchasing

Interfaces

Legal

Identifying sources of supply

Operations

Accounting

Negotiating contracts

Maintaining a database of suppliers

Data

processing

Purchasing

Obtaining goods and services

Managing supplies

Design

Receiving

Suppliers

Sourcing Steps

In-house or outsource

In-house vs. outsourcing

Requisition Received

Every business has to determine

whether they should perform a

service themselves in-house or

outsource that particular service to

an outside vendor.

Supplier Selection

Place Order

Delivery Monitoring

The main driver of outsourcing is the

competitiveness:

- Outsource where others can do it better

Top line View

Goods Received

- Outsource to focus on core business

- Outsource to reduce cost base

2/8/2015

In-house vs. outsourcing

In-house

Administrative

involvement

In house developed

resources

Good control

Quick decision making

Generally high cost of

ownership

Outsourcing

Economy of scale

No cost of ownership

Easy to switch/change

No cost of obsolescence

Expanded geographical

reach

Reduction in operating

cost

Spreading risk

Outsourcing

Outsourcing:

The Outsourcing Institute has defined

outsourcing as the strategic use of

outside resources

to perform

activities traditionally handled by

internal staff and resources.

So, outsourcing is essentially the

contracting out of non-core activities.

As the outsourcing decisions impact

upon the nature and scope of the

organization, they involve top

management.

Centralized vs. Decentralized Sourcing

Trends in Sourcing

Strategic importance

Centralized Procurement

Centralized procurement implies that purchasing

decisions are made either by company

headquarters or some regional or divisional level

Purchasing is handled by one special

department

Decentralized Procurement

A decentralized procurement function means that

an organization's activities are spread over a

number of plants or locations. More recently, it

also refers to purchasing delegated to actual

users.

Individual departments or separate locations

handle their own purchasing requirements

Cost

Quality

Agility

Customer service

Competitive advantage

Technology management

Benefits

Risks

Purchasing function

Increased outsourcing

Increased conversion to lean production

Just-in-time deliveries

Globalization

Source: (Lysons and Farrington, 2006).

2/8/2015

Primary and Support activities of

Sourcing

Different segments of Sourcing

- Primary Activities

- Types of Sourcing

-

Materials and Services

Direct Materials and Services

Indirect Materials and Services

Sourcing for Primary Activity

Sourcing for Support Activity

Inbound Logistics

Operations

Outbound Logistics

Marketing & Sales

Service

- Support Activities

-

Facility Management

Human Resource Management

IS/IT

Finance

21

22

Classification of Sourced Materials

Classification of procured materials:

- Raw Materials, basic input for a production process

- Supplementary Materials, used or consumed in the

operations

- Semi-manufactured products

- Components, are incorporated as a part of system

- Finished products, purchased to be sold

- Capital equipment

- Maintenance, Repair and Operating (OMR) materials

- Services

Thank You

23

Вам также может понравиться

- Strategic Analysis of Internal Environment of a Business OrganisationОт EverandStrategic Analysis of Internal Environment of a Business OrganisationОценок пока нет

- Module 1Документ20 страницModule 1Sanak Aditya MannaОценок пока нет

- Supply Chain and Procurement Quick Reference: How to navigate and be successful in structured organizationsОт EverandSupply Chain and Procurement Quick Reference: How to navigate and be successful in structured organizationsОценок пока нет

- 1.principle Unit 1Документ18 страниц1.principle Unit 1musonza murwiraОценок пока нет

- LESSON 1 - Prepare Frame Work and Objectives of Procurement Management Within The Organization PDFДокумент11 страницLESSON 1 - Prepare Frame Work and Objectives of Procurement Management Within The Organization PDFSaid Sabri KibwanaОценок пока нет

- SCM - Procurement and Supplier FocusДокумент32 страницыSCM - Procurement and Supplier FocusMissy AnoyoОценок пока нет

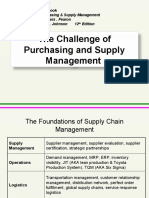

- The Challenge of Purchasing and Supply ManagementДокумент48 страницThe Challenge of Purchasing and Supply ManagementWaseem Ahmed HingorjoОценок пока нет

- Logistics Management: Definition: Logistics Is The Process of StrategicallyДокумент9 страницLogistics Management: Definition: Logistics Is The Process of StrategicallyashwinОценок пока нет

- Supply Chain Chapter 3Документ55 страницSupply Chain Chapter 3Youssef Ait zahraОценок пока нет

- Sourcing and ProcurementДокумент14 страницSourcing and Procurementgeorge aarthiОценок пока нет

- Topic 03 - Procurement, Sourcing and BuyingДокумент46 страницTopic 03 - Procurement, Sourcing and BuyingMinh TrangОценок пока нет

- SCM ch05Документ84 страницыSCM ch05Hasan RazaОценок пока нет

- SourcingДокумент18 страницSourcingsatyamchoudhary2004Оценок пока нет

- PMM711S Unit 1Документ48 страницPMM711S Unit 1Laimi MutikishaОценок пока нет

- Procurement: Total Cost of OwnershipДокумент5 страницProcurement: Total Cost of OwnershipRaheel Abdul RehmanОценок пока нет

- Supply Chain Management and Purchasing Function (Continued) : Talal AbadiДокумент44 страницыSupply Chain Management and Purchasing Function (Continued) : Talal Abadijoel collinsОценок пока нет

- Procurement and Purchasing.Документ36 страницProcurement and Purchasing.Arif Shan100% (1)

- AssignmentДокумент7 страницAssignmentlulu luvelyОценок пока нет

- Supply Chain Management A Logistics Perspective 10Th Edition Coyle Solutions Manual Full Chapter PDFДокумент36 страницSupply Chain Management A Logistics Perspective 10Th Edition Coyle Solutions Manual Full Chapter PDFsusan.ross888100% (11)

- Module 2: Procurement StrategiesДокумент41 страницаModule 2: Procurement StrategiesYemen YemenОценок пока нет

- An Introduction To Strategic SourcingДокумент29 страницAn Introduction To Strategic SourcingAdeen ShahОценок пока нет

- Chapter 5Документ7 страницChapter 5Dhimas YogaОценок пока нет

- Topic 1 Purchasing and Supplies ManagementДокумент13 страницTopic 1 Purchasing and Supplies Managementtashabriana86Оценок пока нет

- Outsourcing - Some Definitions 1/2: - Outsourcing - Outsourcing - Offshoring - MultisourcingДокумент20 страницOutsourcing - Some Definitions 1/2: - Outsourcing - Outsourcing - Offshoring - MultisourcingjuanОценок пока нет

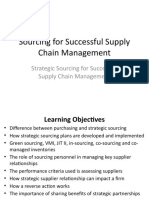

- Sourcing For Successful SCMДокумент27 страницSourcing For Successful SCMShovan ChowdhuryОценок пока нет

- Materials Management-Unit-3Документ15 страницMaterials Management-Unit-3Garima KwatraОценок пока нет

- PROCUREMENTДокумент23 страницыPROCUREMENTKlee LumineОценок пока нет

- L1 Effective ProcurementДокумент57 страницL1 Effective ProcurementDu Lich Vung TauОценок пока нет

- BBM 340 IntroductionДокумент27 страницBBM 340 Introductionbrian ochiengОценок пока нет

- AIS ch4Документ6 страницAIS ch4BappyОценок пока нет

- Evaluating A Firms Internal Environment: Session 3Документ17 страницEvaluating A Firms Internal Environment: Session 3Ni Ni BobokhidzeОценок пока нет

- CH 6 Procurement PDFДокумент24 страницыCH 6 Procurement PDFvamshiОценок пока нет

- SCM - Unit-1Документ20 страницSCM - Unit-1Aashish Singh IIОценок пока нет

- WEEK 2 Reading Materials - SMP - PDFДокумент24 страницыWEEK 2 Reading Materials - SMP - PDFMd Abdullah Al ArmanОценок пока нет

- Chapter 10 Supply Chain ManagementДокумент9 страницChapter 10 Supply Chain ManagementarantonizhaОценок пока нет

- Procurement Management 001Документ71 страницаProcurement Management 001Colin Km100% (1)

- Procurement Strategy Framework FinalДокумент42 страницыProcurement Strategy Framework FinalPartha Pratim SenguptaОценок пока нет

- Learning Block 1: Supply Management and Procurement OverviewДокумент63 страницыLearning Block 1: Supply Management and Procurement OverviewBon-Boni Arnaiz100% (1)

- Topic 1 - Fundamentals of ProcurementДокумент8 страницTopic 1 - Fundamentals of ProcurementsimushiОценок пока нет

- SCM301 MДокумент19 страницSCM301 MHà My NguyễnОценок пока нет

- Ethical and Sustainable SourcingДокумент30 страницEthical and Sustainable SourcingAshok SharmaОценок пока нет

- URLsДокумент17 страницURLsNazia EnayetОценок пока нет

- Meaning of Purchasing ManagementДокумент10 страницMeaning of Purchasing ManagementZAKAYO NJONYОценок пока нет

- What's The Difference Between PROCUREMENT and PURCHASINGДокумент6 страницWhat's The Difference Between PROCUREMENT and PURCHASINGVivian MonteiroОценок пока нет

- Introduction To Operation ManagementДокумент3 страницыIntroduction To Operation Managementhehehehehloo100% (1)

- Supply Chain Planning and ControlДокумент13 страницSupply Chain Planning and ControlRemigi CosmasОценок пока нет

- Chapter 5 Transition From Service To Strategic FunctionДокумент41 страницаChapter 5 Transition From Service To Strategic Functionmunashe sekesoОценок пока нет

- SourcingДокумент14 страницSourcingPoornima KesavanОценок пока нет

- Introduction Purchasing SourcingДокумент23 страницыIntroduction Purchasing Sourcingchirag_arora_1Оценок пока нет

- P&S Lec 1Документ18 страницP&S Lec 1nomanashrafОценок пока нет

- AssignmentДокумент5 страницAssignmentibraheemumarОценок пока нет

- 4 Operations SrtrategyДокумент37 страниц4 Operations SrtrategyRosni ShahОценок пока нет

- Procurement & Distribution: ProcuringДокумент46 страницProcurement & Distribution: ProcuringAmanuel Mulatu BocheОценок пока нет

- Procurement ManagementДокумент8 страницProcurement ManagementManoj AgarwalОценок пока нет

- DPS 304 Sourcing Strategies & PoliciesДокумент34 страницыDPS 304 Sourcing Strategies & PoliciesSehar AdilОценок пока нет

- PSCM SlideДокумент16 страницPSCM SlideShubham RawatОценок пока нет

- CIPS L4M1.3.2 Impact PoliciesДокумент15 страницCIPS L4M1.3.2 Impact Policiessami mohmed aliОценок пока нет

- Lecture 04Документ17 страницLecture 04Syed Abdul Mussaver ShahОценок пока нет

- Chap .1 PurchasingДокумент39 страницChap .1 Purchasingakshay jadhavОценок пока нет

- We Build Your Child's Foundation: Memo No. DateДокумент13 страницWe Build Your Child's Foundation: Memo No. DateEnamul Huque SarkerОценок пока нет

- Strategic Supply Chain Management - Chapter 6Документ34 страницыStrategic Supply Chain Management - Chapter 6Enamul Huque SarkerОценок пока нет

- Play - (English Medium) Morning Shift: We Build Your Child's FoundationДокумент12 страницPlay - (English Medium) Morning Shift: We Build Your Child's FoundationEnamul Huque SarkerОценок пока нет

- 2011eДокумент177 страниц2011eSamanyarak Anan0% (1)

- Material Type Material Material Description PlantДокумент2 страницыMaterial Type Material Material Description PlantEnamul Huque SarkerОценок пока нет

- A Case Study On Inventory ManagementДокумент4 страницыA Case Study On Inventory ManagementEnamul Huque SarkerОценок пока нет

- BB5: Criteria To Evaluate Offers-Cont'd: - Life Cycle Cost Cost of Acquisition + Cost of Ownership Cost of AcquisitionДокумент5 страницBB5: Criteria To Evaluate Offers-Cont'd: - Life Cycle Cost Cost of Acquisition + Cost of Ownership Cost of AcquisitionEnamul Huque SarkerОценок пока нет

- Chapter 6 Process Technology and CapacityДокумент62 страницыChapter 6 Process Technology and CapacityEnamul Huque Sarker100% (1)

- Supply Chain Management PaperДокумент26 страницSupply Chain Management PaperdeeptiannapareddyОценок пока нет

- MP06 - Purchasing: MRF Name / LogoДокумент5 страницMP06 - Purchasing: MRF Name / LogoEnamul Huque SarkerОценок пока нет

- Word Stress RulesДокумент2 страницыWord Stress RulesEnamul Huque Sarker100% (1)

- Consumer Behavior: An OverviewДокумент35 страницConsumer Behavior: An OverviewEnamul Huque SarkerОценок пока нет

- A How To Prepare Booklet For The Departmental Procurement Officer I 10948 Written ExaminationДокумент16 страницA How To Prepare Booklet For The Departmental Procurement Officer I 10948 Written ExaminationEnamul Huque SarkerОценок пока нет

- Research Proposal ExamplesДокумент2 страницыResearch Proposal ExamplesEnamul Huque SarkerОценок пока нет

- Falcon PB110 2013Документ268 страницFalcon PB110 2013Security Lock DistributorsОценок пока нет

- Advertising - Vocabulary BankДокумент6 страницAdvertising - Vocabulary BankNghia NguyenОценок пока нет

- Book SponsorshipДокумент160 страницBook SponsorshipMarcos SoarОценок пока нет

- Time Series ComponentsДокумент3 страницыTime Series Componentsitsmoulali212Оценок пока нет

- 2014 Syllabus 11 AccountancyДокумент4 страницы2014 Syllabus 11 Accountancyapi-248768984Оценок пока нет

- Philippine Business TaxesДокумент3 страницыPhilippine Business TaxesEmmanuel60% (5)

- Adi AssignmentДокумент13 страницAdi AssignmentShraddha KhuranaОценок пока нет

- Business Law - MCQ's With AnswersДокумент10 страницBusiness Law - MCQ's With Answersvhs100% (2)

- How Coca Cola Did It in IndiaДокумент2 страницыHow Coca Cola Did It in IndiaVinod JoshiОценок пока нет

- Acctg 120 CVP Bud Resp 2018 KeyДокумент11 страницAcctg 120 CVP Bud Resp 2018 KeyChristopher BioreОценок пока нет

- Tender Maintenance BRTДокумент104 страницыTender Maintenance BRTBhaskar BabiОценок пока нет

- Britannia Market AnalysisДокумент10 страницBritannia Market Analysisurmi_patel22Оценок пока нет

- (Tax) CPAR Preweek2Документ7 страниц(Tax) CPAR Preweek2Nor-janisah PundaodayaОценок пока нет

- FM Company Statement of Comprehensive Income For The Year Ended December 31, 2017 Net SalesДокумент2 страницыFM Company Statement of Comprehensive Income For The Year Ended December 31, 2017 Net SalesJelly Ann AndresОценок пока нет

- Sales Advisor Job DescriptionДокумент2 страницыSales Advisor Job DescriptionhaoОценок пока нет

- Chapter 6 StrategyДокумент47 страницChapter 6 StrategyHamis Rabiam MagundaОценок пока нет

- SCDL Business Law Paper - 4Документ6 страницSCDL Business Law Paper - 4Kattey Spares100% (2)

- Universiti Teknologi Mara Final Examination: Confidential BM/SEP 2011/MKT243/260Документ8 страницUniversiti Teknologi Mara Final Examination: Confidential BM/SEP 2011/MKT243/260Iman NabihahОценок пока нет

- Section 1 30 Minutes (20 Questions) : Gmat Math Problem SolvingДокумент23 страницыSection 1 30 Minutes (20 Questions) : Gmat Math Problem Solvingajju1378Оценок пока нет

- Cost LeadershipДокумент12 страницCost LeadershipMichelle Chong Xui IngОценок пока нет

- Scenario Work On Bata BangladeshДокумент33 страницыScenario Work On Bata BangladeshMahmudul Islam100% (5)

- Mendez Bags Trial Balance For The Year Ended December 31, 2019 Account Title Debit CreditДокумент9 страницMendez Bags Trial Balance For The Year Ended December 31, 2019 Account Title Debit CreditMecah Lou Odchigue LanzaderasОценок пока нет

- Berger PaintsДокумент52 страницыBerger Paintsaishwarya mishraОценок пока нет

- Ride Details Bill Details: Thanks For Travelling With Us, SwapnilДокумент3 страницыRide Details Bill Details: Thanks For Travelling With Us, Swapnilnavneet pathakОценок пока нет

- Spaces - LlIF0pT8AZAtn4HA X1 PDF 3716139572 PDFДокумент251 страницаSpaces - LlIF0pT8AZAtn4HA X1 PDF 3716139572 PDFDana GnОценок пока нет

- Bergerac SystemsДокумент13 страницBergerac SystemsKomal Verma100% (2)

- Tata Steel Market Strategy YashДокумент28 страницTata Steel Market Strategy YashEdu Platform100% (1)

- Macondray & Co. v. Sellner, 33 Phil. 370 - HighlightedДокумент6 страницMacondray & Co. v. Sellner, 33 Phil. 370 - HighlightedJoshua Janine LugtuОценок пока нет

- 04 2010 Gillett PDFДокумент4 страницы04 2010 Gillett PDFSheraz ShafiqueОценок пока нет

- Advanced Business Calculations Level 3/series 2 2008 (Code 3003)Документ20 страницAdvanced Business Calculations Level 3/series 2 2008 (Code 3003)Hein Linn Kyaw93% (14)