Академический Документы

Профессиональный Документы

Культура Документы

Crankshaft

Загружено:

PankajBhamareАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Crankshaft

Загружено:

PankajBhamareАвторское право:

Доступные форматы

Crankshaft

SUBMITtED TO:

RAKESH GOYAL

SUBMITtED BY:

1) vikas dogra (e084114)

2) VIKRAM KHULLAR (E084115)

3) VISHAL PRASHER (E084117)

4) avinav goel (e08)

5) sukhwinder singh (e08404)

BRANCH:MECHNICAL

M.E.-4Y

Introduction

2snd

YEAR

The crankshaft, sometimes casually abbreviated to crank, is the part

of an engine which translates reciprocating linear piston motion into

rotation. To convert the reciprocating motion into rotation, the

crankshaft has "crank throws" or "crankpins", additional bearing

surfaces whose axis is offset from that of the crank, to which the "big

ends" of the connecting rods from each cylinder attach.

It typically connects to a flywheel, to reduce the pulsation

characteristic of the four-stroke cycle, and sometimes a torsional or

vibrational damper at the opposite end, to reduce the torsion

vibrations often caused along the length of the crankshaft by the

cylinders farthest from the output end acting on the torsional elasticity

of the metal.

Design

Components of a typical, four stroke cycle, DOHC piston engine. (E) Exhaust

camshaft, (I) Intake camshaft, (S) Spark plug, (V) Valves, (P) Piston, (R)

Connecting rod, (C) Crankshaft, (W) Water jacket for coolant flow.

Large engines are usually multicylinder to reduce pulsations from

individual firing strokes, with more than one piston attached to a

complex crankshaft. Many small engines, such as those found in

mopeds or garden machinery, are single cylinder and use only a single

piston, simplifying crankshaft design. This engine can also be built

with no riveted seam.

Engine balance

For some engines it is necessary to provide counterweights for the

reciprocating mass of each piston and connecting rod to improve

engine balance. These are typically cast as part of the crankshaft but,

occasionally, are bolt-on pieces. While counter weights add a

considerable amount of weight to the crankshaft it provides a

smoother running engine and allows higher RPMs to be reached

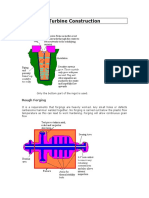

Construction

Crankshafts can be monolithic (made in a single piece)

or assembled from several pieces. Monolithic

crankshafts are most common, but some smaller and

larger engines use assembled crankshafts.

Forging and casting

Crankshafts can be forged from a steel bar usually through roll

forging or cast in ductile steel. Today more and more manufacturers

tend to favor the use of forged crankshafts due to their lighter weight,

more compact dimensions and better inherent dampening. With

forged crankshafts, vanadium microalloyed steels are mostly used as

these steels can be air cooled after reaching high strengths without

additional heat treatment, with exception to the surface hardening of

the bearing surfaces. The low alloy content also makes the material

cheaper than high alloy steels. Carbon steels are also used, but these

require additional heat treatment to reach the desired properties. Iron

crankshafts are today mostly found in cheaper production engines

(such as those found in the Ford Focus diesel engines) where the

loads are lower. Some engines also use cast iron crankshafts for low

output versions while the more expensive high output version use

forged steel.

Machining

Crankshafts can also be machined out of a billet, often using a bar of

high quality vacuum remelted steel. Even though the fiber flow (local

inhomogeneities of the material's chemical composition generated

during casting) doesnt follow the shape of the crankshaft (which is

undesirable), this is usually not a problem since higher quality steels

which normally are difficult to forge can be used. These crankshafts

tend to be very expensive due to the large amount of material removal

which needs to be done by using lathes and milling machines, the

high material cost and the additional heat treatment required.

However, since no expensive tooling is required, this production

method allows small production runs of crankshafts to be made

without high costs.

Fatigue strength

The fatigue strength of crankshafts is usually increased by using a

radius at the ends of each main and crankpin bearing. The radius itself

reduces the stress in these critical areas, but since the radii in most

cases are rolled, this also leaves some compressive residual stress in

the surface which prevents cracks from forming.

Hardening

Most production crankshafts use induction hardened bearing surfaces

since that method gives good results with low costs. It also allows the

crankshaft to be reground without having to redo the hardening. But

high performance crankshafts, billet crankshafts in particular, tend to

use nitridization instead. Nitridization is slower and thereby more

costly, and in addition it puts certain demands on the alloying metals

in the steel, in order to be able to create stable nitrides. The advantage

with nitridization is that it can be done at low temperatures, it

produces a very hard surface and the process will leave some

compressive residual stress in the surface which is good for the

fatigue properties of the crankshaft. The low temperature during

treatment is advantageous in that it doesnt have any negative effects

on the steel, such as annealing. With crankshafts that operate on roller

bearings, the use of carburization tends to be favored due to the high

Hertzian contact stresses in such an application. Like nitriding,

carburization also leaves some compressive residual stresses in the

surface.

Counterweights

Some expensive, high performance crankshafts also use heavy-metal

counterweights to make the crankshaft more compact. The heavymetal used is most often a tungsten alloy but depleted uranium has

also been used. A cheaper option is to use lead, but compared with

tungsten its density is much lower.

Stress on crankshafts

The shaft is subjected to various forces but generally needs to be

analysed in two positions. Firstly, failure may occur at the position of

maximum bending; this may be at the centre of the crank or at either

end. In such a condition the failure is due to bending and the pressure

in the cylinder is maximal. Second, the crank may fail due to twisting,

so the conrod needs to be checked for shear at the position of maximal

twisting. The pressure at this position is the maximal pressure, but

only a fraction of maximal pressure.

Crank shaft material

The crankshaft was the most highly stressed part of the

entire

Liberty engine, and, therefore, every metallurgical

precaution

was taken to guarantee the quality of this part. The

material

used

for the greater portion of the Liberty crankshafts

produced

was

nickel-chromium steel of the following chemical

composition: Carbon,0.350 to 0.450 per cent;

manganese, 0.300 to 0.600 per cent; phosphorus,0.040

maximum per cent; sulphur , 0.045 maximum per cent;

nickel,1.750 to 2.250 per cent; chromium, 0.700 to

0.900 per cent.

Heat treatment Process

The heat treatment used to produce these physical

properties consistedin normalizing the forgings at a

temperature of from 1,550 to 1,600deg.F.,followed by

quenching in water at a temperature of from 1,475 to

1,525 deg.F. and tempering at a temperature of from

1,000 to 1,100deg.F. It is absolutely necessary that the

crankshafts be removed from the quenching tank

before being allowed to cool below a temperature of

500 deg.F., and immediately placed in the tempering

furnace to eliminate the possibility of quenching cracks.

Crank shaft material properties

Each crankshaft was heat-treated to show the following

minimum

physical properties: Elastic limit, 116,000 lb. per square

inch;

elongation in 2 in., 16 per cent, reduction of area, 50

per cent,

Izod impact, 34 ft.-lb.; Brinell hardness, 266 to 321.

Вам также может понравиться

- Crankshaft ContructionДокумент2 страницыCrankshaft Contructionapi-3863246Оценок пока нет

- Forging of CrankshaftДокумент4 страницыForging of Crankshaftkhor_yin_1Оценок пока нет

- Case Study: CrankshaftsДокумент12 страницCase Study: CrankshaftsDHRUV SINGHALОценок пока нет

- CrankShaft PDFДокумент4 страницыCrankShaft PDFYASHWARDHAN SAHI0% (1)

- Introduction To Rolling Element Bearing Manufacturing ProcessДокумент18 страницIntroduction To Rolling Element Bearing Manufacturing ProcessRamakanth P JoshiОценок пока нет

- CrankshaftДокумент12 страницCrankshaftbereket tekleОценок пока нет

- Cylinder Liners & Piston RingsДокумент16 страницCylinder Liners & Piston RingsMr.Babu TОценок пока нет

- Reduce Inner Ring Fractures With NSK "TL": (Tough and Long Life) Series of Spherical Roller BearingsДокумент2 страницыReduce Inner Ring Fractures With NSK "TL": (Tough and Long Life) Series of Spherical Roller Bearingseng13Оценок пока нет

- Pistons, Rings, and Connecting RodsДокумент57 страницPistons, Rings, and Connecting Rodscrewz_19Оценок пока нет

- Crank ShaftДокумент65 страницCrank ShaftWebsoft Tech-HydОценок пока нет

- Chapter-3 Cylinder Heads, Cylinders & LinersДокумент18 страницChapter-3 Cylinder Heads, Cylinders & LinersdearsaswatОценок пока нет

- Case-Hardening Steel: Everything That Moves Needs Case-Hardened GearsДокумент5 страницCase-Hardening Steel: Everything That Moves Needs Case-Hardened GearsjeyakumarОценок пока нет

- Ceramic Ball BearingДокумент8 страницCeramic Ball BearingSachin Kadwadkar100% (1)

- Crankshaft DesignДокумент25 страницCrankshaft Designsunitmhasade89% (28)

- Understanding Tapered Roller BearingsДокумент75 страницUnderstanding Tapered Roller Bearingsamir8100Оценок пока нет

- Crankshaft Construction DesignДокумент10 страницCrankshaft Construction DesignChockalingam AthilingamОценок пока нет

- Design and Static Structural Analysis of Crank Shaft: ISSN 2319-8885 Vol.04, Issue.07, March-2015, Pages:1393-1398Документ6 страницDesign and Static Structural Analysis of Crank Shaft: ISSN 2319-8885 Vol.04, Issue.07, March-2015, Pages:1393-1398Yuliantari YuliantariОценок пока нет

- Block - ConrodДокумент22 страницыBlock - ConrodArnold ChafewaОценок пока нет

- Connecting Rod TechДокумент9 страницConnecting Rod TechadolfoclesОценок пока нет

- Bed Plate Main Engine BedplateДокумент52 страницыBed Plate Main Engine BedplateSuhas KassaОценок пока нет

- 2 ReviewДокумент17 страниц2 ReviewsathishОценок пока нет

- Crank Shaft-NitridingДокумент13 страницCrank Shaft-NitridingDhanu MalarОценок пока нет

- Design of Leaf SpringsДокумент27 страницDesign of Leaf Springsmic50% (2)

- Power Point Template 3 1Документ52 страницыPower Point Template 3 1Red ReidОценок пока нет

- Case HardeningДокумент2 страницыCase HardeningdanielsasikumarОценок пока нет

- Design Criteria For Selecting The Turbine Blade MaterialДокумент2 страницыDesign Criteria For Selecting The Turbine Blade MaterialbalachandranmenonОценок пока нет

- Turbine ConstructionДокумент7 страницTurbine ConstructionPrasannaОценок пока нет

- MDДокумент17 страницMDJay ShindeОценок пока нет

- Cold FormingДокумент6 страницCold FormingMOHAMMED AMEEN MOHAMMED QAIDОценок пока нет

- Coil Springs1Документ8 страницCoil Springs1Abhishek ShindeОценок пока нет

- Manufacturing Process of Train Wheel and Automobile Wheel RimДокумент14 страницManufacturing Process of Train Wheel and Automobile Wheel RimUsamah Abdul Latif79% (14)

- Hardening: NitridizationДокумент1 страницаHardening: Nitridization13311A0341 S SHIVA SAI KIRANОценок пока нет

- Piston: Parts, Types, Working, Piston Clearance, Shape and MoreДокумент12 страницPiston: Parts, Types, Working, Piston Clearance, Shape and MoreAndre RichardОценок пока нет

- CrankДокумент9 страницCrankKresna BayuОценок пока нет

- CRANKSHAFTДокумент26 страницCRANKSHAFTMohammed SaleemОценок пока нет

- Materials For Engine: © 2016 Scrivener Publishing LLC. Published 2016 by John Wiley & Sons, IncДокумент8 страницMaterials For Engine: © 2016 Scrivener Publishing LLC. Published 2016 by John Wiley & Sons, IncDzaky ArizsaОценок пока нет

- Crankshaft 1Документ14 страницCrankshaft 1Shweta NarayanОценок пока нет

- Ceramic BearingsДокумент9 страницCeramic Bearingssureshnfcl100% (1)

- Timken Bearings Design Manual - Chap - 1Документ24 страницыTimken Bearings Design Manual - Chap - 1aliОценок пока нет

- Understanding Valve Design and AlloysДокумент6 страницUnderstanding Valve Design and Alloysmuki10Оценок пока нет

- Machine Design Gears Part 3 MUY BUENOДокумент50 страницMachine Design Gears Part 3 MUY BUENOnapoleonmОценок пока нет

- ProjectДокумент21 страницаProjectzaheer bhОценок пока нет

- Steel Crankshaft HardeningДокумент2 страницыSteel Crankshaft Hardening13311A0341 S SHIVA SAI KIRANОценок пока нет

- Carbon Steels (1 000, 11 00, 1 200, and 1500 Series)Документ18 страницCarbon Steels (1 000, 11 00, 1 200, and 1500 Series)Kerem Cengiz KılıçОценок пока нет

- Report On Engine BlocksДокумент7 страницReport On Engine Blocksmanshulakesh59Оценок пока нет

- Bearing SteelДокумент2 страницыBearing Steelarunkumar17Оценок пока нет

- Chapter-3 Cylinder Heads, Cylinders & LinersДокумент18 страницChapter-3 Cylinder Heads, Cylinders & LinersRam KumarОценок пока нет

- Research Paper On Hybrid BearingДокумент6 страницResearch Paper On Hybrid Bearingc9rz4vrm100% (1)

- 2-Pole Turbine Generators: WEG GroupДокумент12 страниц2-Pole Turbine Generators: WEG GroupVasudev AgrawalОценок пока нет

- ENB 04 0553 Rev B Bearing Materials Technical InformationДокумент4 страницыENB 04 0553 Rev B Bearing Materials Technical Informationmanasha majhiОценок пока нет

- Development of Large-Capacity, Highly Efficient Welded Rotor For Steam TurbinesДокумент6 страницDevelopment of Large-Capacity, Highly Efficient Welded Rotor For Steam Turbinesdzikrie primaОценок пока нет

- Worm Drives PDFДокумент6 страницWorm Drives PDFdesetekОценок пока нет

- NTN Bearings MaterialsДокумент2 страницыNTN Bearings MaterialsCristina Andreea CrissyОценок пока нет

- MMEN 120 - Surface HardeningДокумент19 страницMMEN 120 - Surface HardeningnattydreadfathelahОценок пока нет

- Crank Shaft: Software Used-Catia V5R20 Submitted To Submitted byДокумент47 страницCrank Shaft: Software Used-Catia V5R20 Submitted To Submitted byYaman Saluja0% (1)

- Bearing Material LimitsДокумент3 страницыBearing Material Limitsrifal1990Оценок пока нет

- Stainlesssteelforgings 9016Документ46 страницStainlesssteelforgings 9016Julian MësäОценок пока нет

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkОт EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkОценок пока нет

- Chapter 7 Balancing of LinkagesДокумент21 страницаChapter 7 Balancing of LinkagesRajeev MisraОценок пока нет

- Failuer Analysis Crankshaft in Diesel LocomotiveДокумент74 страницыFailuer Analysis Crankshaft in Diesel LocomotivePankajBhamareОценок пока нет

- Francis - Engine Dynamics and Structural VibrationДокумент19 страницFrancis - Engine Dynamics and Structural VibrationPankajBhamareОценок пока нет

- Balancing of Rotating and Reciprocating Systems in EngineДокумент12 страницBalancing of Rotating and Reciprocating Systems in EngineNeacsu EugenОценок пока нет

- Balancing TheoryДокумент181 страницаBalancing TheoryDANE8083% (6)

- Basics of Balancing 202Документ28 страницBasics of Balancing 202PankajBhamareОценок пока нет

- Engine BalancingДокумент29 страницEngine BalancingqingcaoheОценок пока нет

- Balancing of InlineДокумент25 страницBalancing of InlinePankajBhamare50% (2)

- Paper - Latest Developments in Online Oil Condition Monitoring SensorsДокумент18 страницPaper - Latest Developments in Online Oil Condition Monitoring SensorsPankajBhamareОценок пока нет

- 1.5 Atomic Structure and PeriodicityДокумент13 страниц1.5 Atomic Structure and PeriodicitychwalidОценок пока нет

- Xfs Sub Surface Dripline Performance ChartsДокумент2 страницыXfs Sub Surface Dripline Performance ChartsYASSER SHAALANОценок пока нет

- STP 538-1973Документ239 страницSTP 538-1973Tim SchouwОценок пока нет

- 7m.span SlabДокумент15 страниц7m.span SlabEngineeri TadiyosОценок пока нет

- Ceweld Catalogue 8-4-2016 enДокумент48 страницCeweld Catalogue 8-4-2016 enAzize AmrouneОценок пока нет

- NGДокумент23 страницыNGEngr. Md. Tipu SultanОценок пока нет

- TENSILEДокумент16 страницTENSILESahithi SahiОценок пока нет

- Seminar 1 RheometerДокумент11 страницSeminar 1 RheometerSwapnil Ahire (APPL-HIN)Оценок пока нет

- Tunnelling For Randstadrail in RotterdamДокумент9 страницTunnelling For Randstadrail in RotterdamHarold TaylorОценок пока нет

- SOLAR PV TechnologiesДокумент33 страницыSOLAR PV TechnologiesMuraryspottyОценок пока нет

- 457 Plus: Physical DescriptionДокумент2 страницы457 Plus: Physical DescriptionZirve PolimerОценок пока нет

- Effectiveness of Sodium Polyacrylate (Superabsorbent Polymer) As A Growing Medium of Hydroponically Grown Ocimum Basilicum (Basil)Документ18 страницEffectiveness of Sodium Polyacrylate (Superabsorbent Polymer) As A Growing Medium of Hydroponically Grown Ocimum Basilicum (Basil)Research ParkОценок пока нет

- VMS WetarДокумент24 страницыVMS WetarErwin AnshariОценок пока нет

- Blocks & M Sand RegisterДокумент2 страницыBlocks & M Sand Registersurendra kumarОценок пока нет

- Equivis ZS: ApplicationsДокумент1 страницаEquivis ZS: ApplicationsDeka TariganОценок пока нет

- Ce133p 2 A74 HW1 DaguipaДокумент13 страницCe133p 2 A74 HW1 DaguipaColin Dwight M. DaguipaОценок пока нет

- Sigma Marine Coatings Manual - Part45Документ2 страницыSigma Marine Coatings Manual - Part45EngTamerОценок пока нет

- Determination Arsenic by AASДокумент13 страницDetermination Arsenic by AASMartuaHaojahanSaragihSidabutarОценок пока нет

- CE Board Nov 2020 - RCD - Set 3 MonoДокумент2 страницыCE Board Nov 2020 - RCD - Set 3 MonoDale MalazzabОценок пока нет

- Palm Oil Mill PipingДокумент4 страницыPalm Oil Mill PipingmshkОценок пока нет

- Ethylene Production by Naphtha Cracking TechnologyДокумент6 страницEthylene Production by Naphtha Cracking TechnologyHina IbrahimОценок пока нет

- Citgo Compressorgard Ge: Product Information SheetДокумент1 страницаCitgo Compressorgard Ge: Product Information SheetDavid ChirinosОценок пока нет

- Preformulasi RifaximinДокумент19 страницPreformulasi RifaximinVilza Dwiki YuvitaОценок пока нет

- Research Paper On PN JunctionДокумент4 страницыResearch Paper On PN Junctionogisxnbnd100% (1)

- Experiment 3: Neutralization Capacity of Commercial Antacid AcidДокумент10 страницExperiment 3: Neutralization Capacity of Commercial Antacid AcidfizaОценок пока нет

- Hilti HIT-RE 500V3 Injection Adhesive With Rebar ApplicationДокумент1 страницаHilti HIT-RE 500V3 Injection Adhesive With Rebar ApplicationnoneОценок пока нет

- Spec SCAPSA Metallic Material Selected StdsДокумент107 страницSpec SCAPSA Metallic Material Selected StdsSwath M MuraliОценок пока нет

- IBT Sample Questions: ScienceДокумент2 страницыIBT Sample Questions: Scienceshrutiverma_1Оценок пока нет

- Beam Column - IS 800Документ2 страницыBeam Column - IS 800parishith0% (1)