Академический Документы

Профессиональный Документы

Культура Документы

2001 Rev.0 - Magnetic Particle Testing Level 1 & 2 Combined - Note Book

Загружено:

Nayan VyasИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2001 Rev.0 - Magnetic Particle Testing Level 1 & 2 Combined - Note Book

Загружено:

Nayan VyasАвторское право:

Доступные форматы

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

TABLE OF CONTENTS

CHAPTER 1 QUALIFICATION, CERTIFICATION AND AUTHORISATION .............................. 2

CHAPTER 2 BASIC PRINCIPLES .......................................................................................... 5

CHAPTER 3 MAGNETIC PROPERTIES .............................................................................. 14

CHAPTER 4 CURRENT TYPES........................................................................................... 25

CHAPTER 5 MAGNETIZING METHODS............................................................................ 27

CHAPTER 6 DEMAGNETISATION .................................................................................... 46

CHAPTER 7 DETECTION MEDIUM................................................................................... 48

CHAPTER 8 VIEWING CONDITIONS ................................................................................ 56

CHAPTER 9 MAGNETIC FIELD INDICATORS .................................................................... 61

CHAPTER 10 PERFORMANCE CHECKS ............................................................................ 65

CHAPTER 11 INTERPRETATION VS. EVALUATION .......................................................... 68

PAGE 1 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

CHAPTER 1 QUALIFICATION, CERTIFICATION AND AUTHORISATION

SNT-TC-1A & ISO 9712

It is important that the technician be qualified and certified in the NDT method before the

technique is used and the test results evaluated.

The American Society for Nondestructive Testing recommends the use of their document

Recommended Practice No SNT-TC-1A.

The International Standards Organisation requires the use of their Specification, namely ISO

9712.

These documents provides the employer with the necessary guidelines to properly qualify and

certify the NDT technician in all methods.

To comply with these documents, the employer must establish a written practice which describes

in detail how the technician will be trained, examined and certified.

These documents specifies the initial number of hours of classroom instruction and months or

hours of experience necessary to be certified as an NDT testing technician. The main difference

between these documents are that:

SNT-TC-1A requires Company (Employer) Certification, and

ISO 9712 requires Certification by a Body such as PCN or CSWIP.

PAGE 2 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

LEVELS OF QUALIFICATION

Level 1

An individual certified to Level 1 has demonstrated competence to carry out NDT according to

written instructions and under the supervision of Level 2 or Level 3 personnel. Within the scope

of the competence defined on the certificate, Level 1 personnel may be authorized by the

employer to perform the following in accordance with NDT instructions:

a)

b)

c)

d)

set up NDT equipment;

perform the tests;

record and classify the results of the tests according to written criteria;

report the results.

Level 1 certified personnel shall neither be responsible for the choice of test method or

technique to be used, nor for the evaluation of test results.

Level 2

An individual certified to Level 2 has demonstrated competence to perform NDT according to

NDT procedures. Within the scope of the competence defined on the certificate, Level 2

personnel may be authorized by the employer to:

a)

b)

c)

d)

e)

f)

g)

h)

i)

select the NDT technique for the testing method to be used;

define the limitations of application of the testing method;

translate NDT codes, standards, specifications, and procedures into NDT instructions

adapted to the actual working conditions;

set up and verify equipment settings;

perform and supervise tests;

interpret and evaluate results according to applicable standards, codes, specifications or

procedures;

carry out and supervise all tasks at or below Level 2;

provide guidance for personnel at or below Level 2;

report the results of NDT.

Level 3

An individual certified to Level 3 has demonstrated competence to perform and direct NDT

operations for which he is certified. Level 3 personnel have demonstrated:

a)

b)

c)

the competence to evaluate and interpret results in terms of existing standards, codes,

and specifications;

sufficient practical knowledge of applicable materials, fabrication, process, and product

technology to select NDT methods, establish NDT techniques, and assist in establishing

acceptance criteria where none are otherwise available;

a general familiarity with other NDT methods.

PAGE 3 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Within the scope of the competence defined on the certificate, Level 3 personnel may be

authorized to:

a)

b)

assume full responsibility for a test facility or examination centre and staff;

establish, review for editorial and technical correctness, and validate NDT instructions

and procedures;

interpret standards, codes, specifications, and procedures;

designate the particular test methods, procedures, and NDT instructions to be used;

carry out and supervise all tasks at all levels;

provide guidance for NDT personnel at all levels.

c)

d)

e)

f)

EXAMINATION BREAKDOWN

The end of Course examination (SNT-TC-1A), at NASA will comprise of the following:

General examination:

Closed book.

40 Multi-choice questions.

1 Hour.

Specific examination:

20 Multi-choice questions.

5 Open Code Book Questions. (10 points)

1 Hour.

Practical examination:

Pre-Test Calibrations:

Complete a Calibration Procedure as allocated by examiner.

1 Hour.

Practical 1:

Visible, wet, continuous method with AC Yoke on welded sample.

Complete a Written Instruction.

Fill out a Test Report.

3 Hours.

Practical 2:

Fluorescent, wet, continuous method with AC Yoke on welded sample.

Complete a Technique sheet.

Fill out a Test Report.

2 Hours.

A minimum of 70% must be scored on each segment of the exam with an aggregate of 80% in

order to pass.

PAGE 4 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

CHAPTER 2 BASIC PRINCIPLES

INTRODUCTION

Magnetic Particle Testing (Inspection) (MT or MPI) is a Non-Destructive Testing method used for

defect detection. MPI is fast and relatively easy to apply, and part surface preparation is not as

critical as it is for some other NDT methods. These characteristics make MPI one of the most

widely utilized non-destructive testing methods.

MPI uses magnetic fields and small magnetic particles (i.e. iron filings) to detect flaws in

components. The only requirement from an inspectability standpoint is that the component

being inspected must be made of a ferromagnetic material such as iron, nickel, cobalt, or some of

their alloys. Ferromagnetic materials are materials that can be magnetized to a level that will

allow the inspection to be effective.

The method is used to inspect a variety of product forms including castings, forgings, and

weldments. Many different industries use magnetic particle inspection for determining a

component's fitness-for-use. Some examples of industries that use magnetic particle inspection

are the structural steel, automotive, petrochemical, power generation, and aerospace industries.

Underwater inspection is another area where magnetic particle inspection may be used to test

items such as offshore structures and underwater pipelines.

BASIC PRINCIPLES

A magnetic field is introduces into a specimen to be tested, then fine particles of ferromagnetic

powder, or ferromagnetic particles in a liquid suspension, are applied to the area being tested.

Any discontinuity in the test area which cuts across the magnetic field creates a leakage field. A

leakage field has a north and South Pole on either side of it, and therefore will attract the

ferromagnetic particles in great numbers.

There are many ways to apply a magnetic field, e.g. by the use of permanent magnets,

electromagnetic yokes, coils, prods, cables and other devices.

A basic sequence of operations for the examination of a weld using MPI with a permanent

magnet and black ink is shown below:

1.

2.

3.

4.

5.

6.

7.

8.

Clean area using a wire brush if required.

Apply a thin layer of white contrast paint.

When the paint is dry, straddle the magnet over the weld at 90 to the weld axis.

Apply the magnetic particles.

Interpret the area. Look for indications with their length lying along the same axis as the

weld. Evaluate in accordance with the relevant specification.

To look for transverse weld discontinuities, turn magnet approximately 90 and re-apply

the ink.

Interpret the area. Look for indication with their length perpendicular to the weld axis.

Evaluate in accordance with the relevant specification.

PAGE 5 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

HISTORY

Magnetism is the ability of matter to attract other matter to itself. The ancient Greeks were the

first to discover this phenomenon in a mineral they named magnetite. Later on Bergmann,

Becquerel, and Faraday discovered that all matter including liquids and gasses were affected by

magnetism, but only a few responded to a noticeable extent.

The earliest known use of magnetism to inspect an object took place as early as 1868. Cannon

barrels were checked for defects by magnetizing the barrel then sliding a magnetic compass

along the barrel's length. These early inspectors were able to locate flaws in the barrels by

monitoring the needle of the compass. This was a form of Non-Destructive Testing but the term

was not commonly used until some time after World War I.

In the early 1920s, William Hoke realized that magnetic particles (coloured metal shavings) could

be used with magnetism as a means of locating defects. Hoke discovered that a surface or

subsurface flaw in a magnetized material caused the magnetic field to distort and extend beyond

the part. This discovery was brought to his attention in the machine shop. He noticed that the

metallic grindings from hard steel parts (held by a magnetic chuck while being ground) formed

patterns on the face of the parts which corresponded to the cracks in the surface. Applying a fine

ferromagnetic powder to the parts caused a build-up of powder over flaws and formed a visible

indication. The image shows a 1928 Electro-Magnetic Steel Testing Device (MPI) made by the

Equipment and Engineering Company Ltd. (ECO) of Strand, England.

In the early 1930s, magnetic particle inspection was quickly replacing the oil-and-whiting method

(an early form of the liquid penetrant inspection) as the method of choice by the railroad industry

to inspect steam engine boilers, wheels, axles, and tracks. Today, the MT inspection method is

used extensively to check for flaws in a large variety of manufactured materials and components.

PAGE 6 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

TEST PROCEDURES

Approved procedures for magnetic particle testing are formulated from analysis of the test

specimen, review of its past history, experience and information available concerning

discontinuities in like or similar articles. It is the responsibility of personnel conducting or

checking tests to ensure that the test procedures are adequately performed, and that the test

objective is accomplished. Procedures found incorrect or inadequate must be brought to the

attention of responsible supervision for correction.

TEST OBJECTIVE

The objective of magnetic particle testing is to ensure maximum reliability by providing a means

of:

Obtaining a visual image of an indication related to a discontinuity below the surface or

at the surface of a material.

Disclosing the nature of discontinuities without impairing the material.

Separating acceptable and unacceptable material in accordance with predetermined

standards.

ADVANTAGES

The magnetic particle method has a number of outstanding advantages within its field of

usefulness that is, on ferromagnetic materials. Some of these are the following:

It is the best and most reliable method available for finding surface cracks, especially

very fine and shallow ones.

It will detect cracks filled with foreign material.

No elaborate pre-cleaning is ordinarily necessary.

It will work well through thin coatings of paint, or other nonmagnetic coverings such as

plating.

DISADVANTAGES

Although the method has many desirable and attractive advantages, it has, as does every

method, certain limitations. These, the operator must be aware of, and take into account by

observing the precautions which they dictate. Some of these are the following:

It will work only on ferromagnetic materials.

It is not in all cases reliable for locating discontinuities which lie wholly below the

surface.

Exceedingly heavy currents are sometimes required for the testing of very large castings

and forgings.

Care is required to avoid local heating and burning of highly finished parts or surfaces at

the points of electrical contact.

PAGE 7 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

TERMINOLOGY

Air Gap When a magnetic circuit contains a small gap, which the magnetic flux must cross, the

space is referred to as an air gap. Cracks produce small air gaps on the surface of an article.

Alternating Current Electric current periodically reversing in polarity or direction of flow.

Ampere The unit of electrical current. One ampere is the current that flows through a

conductor having a resistance of one ohm at a potential of one volt.

Ampere Turns The product of the number of turns in a coil and the number of amperes flowing

through it. A measure of the magnetizing or demagnetizing strength of the coil.

Bath The suspension of iron oxide particles in a liquid vehicle (light oil or water).

Black light Radiant energy in the near ultraviolet range. This light has a wavelength of 3200 to

4000 angstrom units (A), peaking at 3650 A, on the spectrum. This is between visible light and

ultraviolet light.

Black light filter A filter that transmits black light while suppressing the transmission of visible

light and harmful ultraviolet radiation.

Carbon Steel Steel which does not contain significant amounts of alloying elements other than

carbon and manganese.

Carrier Fluid The fluid in which fluorescent and non-fluorescent magnetic particles are

suspended to facilitate their application in the wet method.

Central Conductor An electrical conductor that is passed through the opening in a ring or tube,

or any hole in an article, for the purpose of creating a circular field in the ring or tube, or around

the hole.

Circular Field See Field, circular Magnetic.

Coercive Force The reverse magnetizing force necessary to remove residual magnetism in

demagnetizing an article.

Coil Shot A pulse of magnetizing current passed through a coil surrounding an article for the

purpose of longitudinal magnetization.

Contact Head The electrode, fixed to the magnetic particle testing unit, through which the

magnetizing current is drawn.

Contact Pads Replaceable metal pad, usually of copper braid, placed on contact heads to give

good electrical contact thereby preventing damage to the article under test.

Continuous Method An inspection method in which ample amounts of magnetic particles are

applied, or are present on the piece, during the time the magnetizing current is applied.

Circular Magnetization A method of inducing a magnetic field in an article so that the magnetic

lines of force take the form of concentric rings about the axis of the current. This is accomplished

by passing the current directly through the article or through a conductor which passes into or

through a hole in the article. The circular method is applicable for the detection of

discontinuities with axes approximately parallel to the axis of the current through the article.

PAGE 8 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Core That part of the magnetic circuit which is within the electrical winding.

Curie Point The temperature at which ferromagnetic materials can no longer be magnetized by

outside forces, and at which they lose their residual magnetism: approximately 1200 to 1600F

(649 to 871C) for many metals.

Current Flow Method A method of circular magnetization by passing a currant through an article

via prods or contact heads. The current may be alternating, half-wave rectified alternating, or

direct.

Current Induction Method A method of magnetization in which a circulating current is induced

in a ring-shaped component by fluctuating magnetic field.

Defect A discontinuity that interferes with the usefulness of an article or exceeds acceptability

limits established by applicable specifications. A fault in any material or part which is

detrimental to its serviceability. Note that all cracks, seams, laps, etc., are not necessarily defects

as they may not affect the serviceability of the part in which they exist.

Demagnetization The reduction in the degree of residual magnetism in ferromagnetic materials

to an acceptable level.

Diffuse Indications Indications that are not clearly defined as, for example, indications of

subsurface defects.

Direct Current An electric current which flows steadily in one direction.

Discontinuity An interruption (cracks, forging laps, seams, inclusions, porosity, etc.) in the

normal physical structure of configuration of an article. A discontinuity may or may not affect the

usefulness of the article.

Distorted Field The direction of a magnetic field in a symmetrical object will be substantially

uniform if produced by a uniformly applied magnetizing force. But if the article being magnetized

is irregular in shape, the field is distorted and does not follow a straight path or have a uniform

distribution.

Dry Method Magnetic particle inspection in which the particles employed are in the dry powder

form.

Dry Powder (Dry Method) Finely divided ferromagnetic particles suitably selected and prepared

for magnetic particle inspection by the dry method.

Electromagnet A magnet created by inserting a suitable metal core within, or near, a

magnetizing field formed by passing electric current through a coil of insulated wire.

Etching The process of exposing subsurface conditions of metal articles by removal of the

outside surface through the use of chemical agents. Due to the action of the chemicals in eating

away the surface, various surface or subsurface conditions are exposed or exaggerated and made

visible to the eye. For example forging flow lines, discontinuities, and defects.

Ferromagnetic A term applied to materials which can be magnetized and strongly attracted by a

magnetic field.

Field, Bipolar Longitudinal magnetic field within an article that creates two poles.

PAGE 9 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Fields, Circular Magnetic Generally, the magnetic field in and surrounding any electrical

conductor or article resulting from a current being passed through the conductor or article or

from prods.

Field, Magnetic Leakage The magnetic field that leaves or enters the surface of an article at a

magnetic pole.

Field, Longitudinal Magnetic A magnetic field where in the flux lines traverse the component in a

direction essentially parallel with the axis of the magnetizing coil or to a line connecting the two

poles at the magnetizing yoke.

Field, Magnetic The space within and surrounding a magnetized article, or a conductor carrying

current, in which the magnetic force is present.

Field, Residual Magnetic The field that remains in magnetizable material after the magnetizing

force has been removed.

Field Resultant Magnetic A magnetic field that is the result of two magnetic forces impressed

upon the same area of a magnetizable object at the same timesometimes called a vector

field.

Field, Vector See Field, Resultant Magnetic.

Flash Magnetization Magnetization by current flow of very brief duration.

Fluorescence The emission of visible radiation by a substance as the result of, and only during,

the absorption of black light radiation.

Fluorescent Magnetic Particle Inspection The magnetic particle inspection process employing a

finely divided fluorescent ferromagnetic Inspection medium that fluoresces when activated by

black light of 3200 to 4000 Angstroms.

Flux Density This is the flux-per-unit area through an element which cuts the unit area at right

angles to the direction of the flux. Flux density is usually designated by the letter B and its unit is

the gauss.

Flux Leakage Magnetic lines of force which leave and enter an article at poles on the surface.

Flux Lines Imaginary magnetic lines used as a means of explaining the behavior of magnetic

fields. Their conception is based on the pattern of lines produced when iron filings are sprinkled

over a piece of paper laid over a permanent magnet. Also called lines of force, the unit is a

single line of force called the Maxwell designated by the Greek letter Phi().

Flux Penetration, Magnetic The depth to which a magnetic flux is present in an article.

Furring Build-up, or bristling, of magnetic particles due to excessive magnetization of the article

under examination resulting in a furry appearance also referred to as Fur or Grass.

Gauss The unit of flux density. Numerically, one gauss is one line of flux per square centimeter

of area and is designated by the letter B.

Heads The clamping contacts on a stationary magnetizing unit.

PAGE 10 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Head Shot A short pulse of magnetizing current passed through an article or a central conductor

while clamped between the head contacts of a stationary magnetizing unit for the purpose of

circularly magnetizing the article.

Horseshoe Magnet A bar magnet, bent into the shape of a horseshoe so that the two poles are

adjacent. Usually the term applies to a permanent magnet.

Hysteresis

1) The lagging of the magnetic effect when the magnetic force acting upon a ferromagnetic

body is changed.

2) The phenomenon exhibited by a magnetic system wherein its state is influenced by its

previous magnetic history.

Hysteresis Loop A curve showing the flux density, B, plotted as a function of magnetizing force,

H. As the magnetizing force is increased to the saturation point in both the positive, negative,

and positive direction sequentially, the curve forms a characteristic S-shaped loop. Intercepts of

the loop with the B and H axes and the points of maximum and minimum magnetizing force

define important magnetic characteristics of the material.

Indication Any magnetically held magnetic particle pattern on the surface of an article being

tested.

Inductance The magnetism produced in a ferromagnetic body by some outside magnetizing

force. The magnetism is not the result of passing current through the article.

Inspection The process of examining and checking materials and articles for possible defects or

for deviation from established standards.

Interpretation The determining of the cause and significance of indications of discontinuities

from the standpoint of whether they are detrimental defects or false or non-relevant indications.

Leakage Field The magnetic field forced out into the air by the distortion of the field within an

article.

Lines of Force. See Flux Lines.

Longitudinal Field See Field, Longitudinal Magnetic.

Longitudinal Magnetization The process of inducting a magnetic field into the article such that

the magnetic lines of force extending through the article are approximately parallel to the axis of

the magnetizing coil or to a line connecting the two poles when yokes (electromagnets) are used.

Magnet, Permanent A highly retentive metal that has been strongly magnetized for example,

the alloy Alnico.

Magnetic Field See Field, magnetic.

Magnetic Field Meter An instrument designed to detect and/or measure the flux density and

polarity of magnetic fields.

Magnetic Field Strength The measured intensity of a magnetic field at a point always external to

the magnet or conductor usually expressed in Oersted.

PAGE 11 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Magnetic Material Some materials are attracted by a magnet while others are repelled. From

the definition of magnetism it follows that magnetic materials are those that are attracted by

magnetism. These materials are known as paramagnetic materials, whereas materials which

repel are known as diamagnetic materials. The subdivision of paramagnetic, called

ferromagnetic, is a main concern as only ferromagnetic materials can be strongly magnetized.

Magnetic Particle Inspection A nondestructive inspection method for locating discontinuities in

ferromagnetic materials. It utilizes flux leakage that forms magnetic poles to attract finely

divided magnetic particles which mark the discontinuity.

Magnetic Particle Inspection Indications The accumulation of ferromagnetic particles that may

be either true indications of discontinuities, or may be false or non-relevant indications.

Magnetic Writing A form of non-relevant indications caused when the surface of a magnetized

part comes in contact with ;another piece of ferromagnetic material that is magnetized to a

different value.

Magnetizing Current The flow of either alternating, rectified alternating or direct current used to

induce magnetism into the article being inspected.

Magnetizing Force This is the total force tending to set up a magnetic flux by a magnetizing

current. It is usually designated by the letter H and its unit is the Oersted.

Non-relevant Indication A magnetic particle indication due to a leakage magnetic field which is

not caused by an actual discontinuity in the magnetized material, but by some other condition

which does not affect the usefulness of the article (such as a change of section).

Oersted A unit of field strength which produces magnetic induction and is designated by the

letter H.

Paramagnetic Materials which are slightly attracted by a magnetic field. Examples are

chromium, manganese, and aluminum.

Paste (Slurry) Finely divided, ferromagnetic particles in paste form used in preparing wet

suspensions.

Permeability

1)

The ease with which a material can become magnetized.

2)

The ratio between field strength produced and the magnetizing force (B/H).

3)

The ratio of flux density produced to magnetizing force.

Pole The area on a magnetized article from which the magnetic field is leaving or returning to

the article.

Prods Hand-held electrodes attached to cables used to transmit the magnetizing current from

the source to the article under inspection.

Rectified Alternating Current Alternating current which has been converted into direct current.

Reluctance The opposition of a magnetic material to the establishment of magnetic flux. The

reluctance of the material determines the magnitude of the flux produced by a given magnetic

force. Reluctance is analogous to the resistance; in an electric circuit.

PAGE 12 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Residual Field See Field, Residual Magnetic.

Residual Magnetism The amount of magnetism that a magnetic material retains after the

magnetizing force is removed also called residual field.

Residual Method A procedure in which the indicating material is applied after the magnetizing

force has been discontinued.

Resultant Field See Field, Resultant Magnetic.

Retentivity The ability of a material to retain a portion of the magnetic force induced in it after

the magnetizing force has been removed.

Saturation The point in the magnetization of a magnetizable article at which an increase in the

magnetizing force produces no increase in the magnetic field within the article.

Sensitivity The capacity of degree of responsiveness to magnetic particle inspection.

Solenoid (Coil) An electric conductor formed into a coil; often wrapped around a central core of

highly permeable material.

Subsurface Discontinuity Any discontinuity which does not open onto the surface of the article

in which it exists.

Suspension The correct term applied to the liquid bath in which is suspended the ferromagnetic

particles used in the wet magnetic particle inspection method.

Swinging Field Magnetization Magnetic fields induced in two different directions alternately

and quickly to detect, more accurately, defects oriented in different directions in an article.

Test Piece An article containing known artificial or natural defects used for checking the

efficiency of magnetic particle flaw detection processes.

Vector Field See Field, Resultant Magnetic.

Wet Method The inspection method employing ferromagnetic particles suspended in a liquid

(oil or water) as a vehicle.

Yoke A U or C shaped piece of highly permeable magnetic material, either solid or

laminated, sometimes with adjustable pole pieces, around which is wound a coil carrying the

magnetizing current.

Yoke Magnetization A longitudinal magnetic field induced in an article, or in an area of an

article, by means of an external electromagnet shaped like a yoke.

CONVERSION TABLE

1m

1 000 mm

1 000 000 m

1 Bar

14.5 Psi

100 000 Pascal

3650

365 nm

10 W/m

1 000 w/cm

1 fc (foot-candle)

10,76 lx (lux)

1 C

(? F - 32) x 5/9

1 000 000 000 nm

PAGE 13 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

CHAPTER 3 MAGNETIC PROPERTIES

MAGNETISM

All materials consist of atoms and molecules which may or may not have a permanent magnetic

influence depending on the electron configuration within the material.

Atoms in magnetic materials group together in regions called magnetic domains; each domain

has its own north and South Pole. When these domains are randomly positioned, the material is

unmagnetized. If the domains are aligned in a common direction, then the material will be

magnetised and the material itself will have its own north and South Pole.

The domains can be aligned by bringing them within an existing magnetic field. If the domains

remain aligned when they are removed from the influence of the magnetic field, then the

material is said to be permanently magnetised.

The poles of magnetised materials have an inherent attraction/ repulsion effect. If two pieces of

magnetised material are placed with their dissimilar poles end to end there is an attraction, but if

the poles are alike then there is a repulsion, therefore: like poles repel, unlike poles attract.

When two magnetizing fields are imposed simultaneously in the same part, the object is not

magnetized in two directions at the same time. A vector field is formed which is the resultant

direction and strength of the two imposed fields. This is illustrated in below where A is the first

magnetizing force, B is the second force, and C equals the resultant magnetizing force.

PAGE 14 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

LINES OF FORCE

Faraday used the concept of lines of force to explain what happens in the space between two

magnets. He suggested properties for these lines of force, which he imagined as spreading out

from all magnetic poles into the surrounding space.

It can be seen in the magnetograph that there are poles all along the length of the magnet but

that the poles are concentrated at the ends of the magnet. The area where the exit Poles are

concentrated is called the magnet's North Pole and the area where the entrance poles are

concentrated is called the magnet's South Pole.

By assuming the lines were in tension, like pieces of stretched elastic, he could account for the

attraction of unlike poles, since the lines of force stretch from one pole to another.

But, the tension of the lines of force must increase as they shorten, since the repulsive force

between two like poles increases as the poles approach. With like poles, the lines of force also

tend to curve outwards, seeming to suggest that they repel each other. Faraday used this

hypotheses to account for the repulsion of like poles.

PAGE 15 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

The properties of magnetic lines of force are as follows:

They form closed loops between north and south poles.

They do not cross one another. (Repel each other laterally)

They seek paths of least magnetic resistance.

Their density decreases with increasing distance from the poles, i.e. the number of lines

of force in a unit area decreases.

They are considered to have direction, that is: from the north pole to South Pole

external to the magnet, and from the South Pole to the North Pole within the magnet.

They are in a constant state of tension.

PAGE 16 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

MATERIAL PROPERTIES

The degree to which materials are capable of being influenced by a magnetic field varies greatly

from material to material, however, they fall into three specific categories defined by their

behaviour in the magnetic field.

Diamagnetic materials

These are, to a very slight degree, repelled by a magnetic field and include copper, titanium and

most non-metals. ( < 1)

Paramagnetic materials

These are very weakly attracted by a magnetic field and include oxygen and most metals

including austenitic stainless steel, magnesium, molybdenum, lithium and tantalum. ( 1)

Ferromagnetic materials

These are strongly attracted by a magnetic field and include iron, cobalt, nickel and many of their

alloys. They also exhibit permanent magnetism and can themselves be magnetized. ( > 1 ; 240

or more)

PAGE 17 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

PERMEABILITY ()

For magnetic particle inspection, the only materials of interest are those which are

ferromagnetic. Within this group, some materials are more easily magnetised than others, that is

to say, more permeable.

To permeate means to spread through. In this context it refers to the ease by which the magnetic

lines of force are spread through the material. Soft iron and low carbon steel have a high

permeability, i.e. they are easy to magnetise. Hard iron and high carbon steel have a low

permeability, i.e. they are difficult to magnetise.

An alternative description favoured in the USA would be, the ability to concentrate magnetic

fields and it is shown on the 'slope' of the B/H curve which varies continuously.

Permeability () may be calculated by dividing the flux density (B) achieved by the magnetising

force applied (H).

=

The permeability of a material may be given a value based on a ratio when compared with free

space. These values vary depending on alloy composition, heat treatment and any working

applied.

RELUCTANCE (R)

Magnetic reluctance, or magnetic resistance, is a concept used in the analysis of magnetic

circuits. It is analogous to resistance in an electrical circuit, but rather than dissipating electric

energy it stores magnetic energy. In likeness to the way an electric field causes an electric current

to follow the path of least resistance, a magnetic field causes magnetic flux to follow the path of

least magnetic reluctance.

Reluctance is the reciprocal of permeability, i.e.

R=

RETENTIVITY

When a magnetising force is removed from a ferromagnetic material the amount of magnetism

remaining will vary between materials and depends upon the permeability of the material. The

remaining magnetism is termed residual magnetism and the material is said to have retentivity or

retained magnetism.

If a material has high permeability it is very difficult to magnetise, that is to say it has high

magnetic reluctance, but once magnetisation has been achieved then it does not give up the

magnetic force easily, therefore it has high retentivity.

High permeability = Low retentivity

Low permeability = High retentivity

PAGE 18 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

RESIDUAL MAGNETISM

Remanence or remanent magnetization is the magnetization left behind in a ferromagnetic

material after an external magnetic field is removed.

The equivalent term residual magnetization is generally used in engineering applications. In

transformers, electric motors and generators a large residual magnetization is not desirable as it

is an unwanted contamination, for example a magnetization remaining in an electromagnet after

the current in the coil is turned off. Where it is unwanted, it can be removed by demagnetisation.

COERCIVE FORCE

Coerce means to forcibly control; in this context it relates to the reversed magnetising force

which is necessary to remove remnant or residual magnetism for demagnetisation of a part.

To summarise:

PERMEABILITY

RELUCTANCE

RESIDUAL MAGNETISM

RETENTIVITY

COERCIVE FORCE

This refers to the ease with which a magnetic flux is established in

the article being inspected.

This is the opposition of a magnetic material to the establishment of

a magnetic flux. A material with a high permeability will have a low

reluctance.

This refers to the amount of magnetism retained after the

magnetizing force is removed.

Refers to the ability of the material to retain a certain amount of

residual magnetism.

Refers to the reverse magnetizing force necessary to remove the

residual magnetism from the part.

MAGNETIC FLUX () AND MAGNETIC FLUX DENSITY (B)

When a specimen is magnetised, lines of force or flux exist within the specimen the stronger the

magnetising force applied, the greater the amount of flux produced. The magnetising force may

be applied by using a permanent magnet or electrically operated magnetic flow apparatus, or by

passing an electric current through the specimen.

Magnetic flux is measured in Webers (Wb).

1 Wb = 108 lines of force

The number of lines of force (or flux) passing transversely through a given cross-sectional area is

known as the flux density (B)

Flux density (B) =

Where: = flux

A = Area

PAGE 19 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Flux density is measured in Tesla (T)

1 Wb/m2 = 1 Tesla (T).

The old (cgs) unit for flux density which is still widely encountered is the Gauss:

1 Gauss = 1 line of force/cm2.

10,000 (104) Gauss = 1 Tesla

1 Gauss = 0.1 mT

MAGNETIC FIELD STRENGTH (H)

The magnetic field strength or magnetising force is that which is needed to induce a flux in a

magnetic circuit and is measured in amperes per metre (A/m), or in old (cgs) units, the Oersted.

1 Oersted =79.58 Amperes per metre.

MAGNETIC HYSTERESIS

A great deal of information can be learned about the magnetic properties of a material by

studying its hysteresis loop. A hysteresis loop shows the relationship between the induced

magnetic flux density (B) and the magnetizing force (H). It is often referred to as the B-H loop. An

example hysteresis loop is shown below.

The loop is generated by measuring the magnetic flux of a ferromagnetic material while the

magnetizing force is changed. A ferromagnetic material that has never been previously

magnetized or has been thoroughly demagnetized will follow the dashed line as H is increased. As

the line demonstrates, the greater the amount of current applied (H+), the stronger the magnetic

field in the component (B+). At point "a" almost all of the magnetic domains are aligned and an

PAGE 20 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

additional increase in the magnetizing force will produce very little increase in magnetic flux. The

material has reached the point of magnetic saturation. When H is reduced to zero, the curve will

move from point "a" to point "b." At this point, it can be seen that some magnetic flux remains in

the material even though the magnetizing force is zero. This is referred to as the point of

retentivity on the graph and indicates the Remanence or level of residual magnetism in the

material. (Some of the magnetic domains remain aligned but some have lost their alignment.)

As the magnetizing force is reversed, the curve moves to point "c", where the flux has been

reduced to zero. This is called the point of coercivity on the curve. (The reversed magnetizing

force has flipped enough of the domains so that the net flux within the material is zero.) The

force required to remove the residual magnetism from the material is called the coercive force or

coercivity of the material.

As the magnetizing force is increased in the negative direction, the material will again become

magnetically saturated but in the opposite direction (point "d"). Reducing H to zero brings the

curve to point "e." It will have a level of residual magnetism equal to that achieved in the other

direction. Increasing H back in the positive direction will return B to zero. Notice that the curve

did not return to the origin of the graph because some force is required to remove the residual

magnetism. The curve will take a different path from point "f" back to the saturation point where

it with complete the loop.

When AC is used for magnetising a specimen, a complete hysteresis loop is produced with each

cycle of current; in the U.K. this is 50 times per second.*

A material which exhibits a hysteresis loop with a wide appearance will have high retentivity and

therefore may be useful for making permanent magnets. A material which exhibits a hysteresis

loop with a narrow appearance will have low retentivity and therefore may be useful for making

magnetic particles.

The gradient of the loop also gives information regarding the usefulness of materials for use in

magnetising apparatus, for making magnetic particles or for magnetising purposes. For example,

a material which exhibits a steep gradient will attain a high flux density when using a low

magnetising force.

PAGE 21 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

FLUX LEAKAGE

When a magnetic field is created within a ferromagnetic within a ferromagnetic specimen, lines

of magnetic flux are developed and flow through and around the material completing a circuit.

Magnetic particle inspection relies on a leakage of flux occurring within this circuit, this may be

caused by a break or discontinuity in the material.

Because it is a change in magnetic permeability that causes a leakage field, flux leakages may also

be caused by changes in metallurgy.

Opposite poles attract, therefore any break or discontinuity causing a flux leakage will, because

of the magnetic poles, attract a ferromagnetic material such as iron powder. This would

accumulate at the area of the leakage field and give an indication of the defect's existence.

Where the flux leaves the circuit a North Pole is created.

Where the flux re-enters the circuit a South Pole is created.

For a discontinuity to be detected by MPI it must interrupt the lines of force. Any linear

discontinuities running parallel with the flux or small non-linear discontinuities, i.e. equiaxed

defects do not break the lines of force, they bend around these defects taking the path of least

resistance; these discontinuities therefore remain undetected.

MPI is most effective in detecting discontinuities with their major axis at 90 to the lines of force,

but will usually remain effective down to about 45 of this axis (BS EN ISO 17638: 2009 and BS EN

ISO 9934: 2001 quotes 60). Below that it is unlikely that the discontinuity will be found,

therefore in order to examine a specimen completely, the lines of force must be applied in

different directions.

Magnetic particle inspection used for the detection of surface breaking discontinuities and only in

ferromagnetic materials. This is because the magnetic fields induced are concentrated at the

surface of the components. However, sub-surface discontinuities may be detected if using

permanent magnets or electrical systems using direct or rectified current, because the magnetic

field penetrants much further into the test specimen in comparison with MPI test methods which

use alternating current. It is unlikely that any form of MPI would be used to detect discontinuities

deeper than 2 mm or 3 mm below the surface.

MPI test equipment using alternating current as an output produces a high density magnetic flux

at the surface of the test component. This phenomenon, known as the skin effect, produces a far

stronger flux leakage field on the surface breaking, or near surface discontinuities, compared to

permanent magnets or direct current test equipment.

PAGE 22 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

The depth of flux penetration is governed by the wave frequency of the alternating current, the

conductivity of the test material and its permeability. If any of these variables increase, the depth

of penetration will decrease.

It is difficult to try and interpret very weak and diffused MPI indications which could be from

sources other than defects, e.g. caused by rough/ uneven surfaces or changes in permeability.

Because of this problem, sub-surface, or body defects, would normally be located by other

methods of NDT, assuming the detection of sub-surface defects is a requirement.

ELECTROMAGNETISM

There is a fundamental relationship between electricity and magnetism; the movement of an

electric charge will create a magnetic force field around it, in a plane perpendicular to the

direction of travel of the electric charge.

PAGE 23 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Electrons that are moving in a current carrying conductor set up a magnetic field, the direction

and orientation of which are given by the right hand rule if we assume the current flow, by

convention, is opposite to electron flow; or the left hand rule if we assume the direction of

electron flow.

Current Flow Theory = Right Hand Rule =

+ to

Electron Flow Theory = Left Hand Rule =

to +

When a current carrying conductor is formed into a loop or several loops to form a coil, a

magnetic field develops that flows through the center of the loop or coil along its longitudinal

axis and circles back around the outside of the loop or coil. The magnetic field circling each loop

of wire combines with the fields from the other loops to produce a concentrated field down the

center of the coil. A loosely wound coil is illustrated below to show the interaction of the

magnetic field. The magnetic field is essentially uniform down the length of the coil when it is

wound tighter.

The strength of a coil's magnetic field increases not only with increasing current but also with

each loop that is added to the coil. A long, straight coil of wire is called a solenoid and can be

used to generate a nearly uniform magnetic field similar to that of a bar magnet. The

concentrated magnetic field inside a coil is very useful in magnetizing ferromagnetic materials for

inspection using the magnetic particle testing method. Please be aware that the field outside the

coil is weak and is not suitable for magnetizing ferromagnetic materials.

PAGE 24 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

CHAPTER 4 CURRENT TYPES

As seen in the previous pages, electric current is often used to establish the magnetic field in

components during magnetic particle inspection. Alternating current and direct current are the

two basic types of current commonly used. Current from single phase 110 volts, to three phase

440 volts, are used when generating an electric field in a component. Current flow is often

modified to provide the appropriate field within the part. The type of current used can have an

effect on the inspection results, so the types of currents commonly used will be briefly reviewed.

Direct Current

Direct current (DC) flows continuously in one direction at a constant voltage. A battery is the

most common source of direct current. As previously mentioned, current is said to flow from the

positive to the negative terminal. In actuality, the electrons flow in the opposite direction. DC is

very desirable when inspecting for subsurface defects because DC generates a magnetic field that

penetrates deeper into the material. In ferromagnetic materials, the magnetic field produced by

DC generally penetrates the entire cross-section of the component. Conversely, the field

produced using alternating current is concentrated in a thin layer at the surface of the

component.

Alternating Current

Alternating current (AC) reverses in direction at a rate of 50 or 60 cycles per second. In the United

States, 60 cycle current is the commercial norm but 50 cycle current is common in many

countries. Since AC is readily available in most facilities, it is convenient to make use of it for

magnetic particle inspection. However, when AC is used to induce a magnetic field in

ferromagnetic materials, the magnetic field will be limited to narrow region at the surface of the

component. This phenomenon is known as the "skin effect" and occurs because the changing

magnetic field generates eddy currents in the test object. The eddy currents produce a magnetic

field that opposes the primary field, thus reducing the net magnetic flux below the surface.

Therefore, it is recommended that AC be used only when the inspection is limited to surface

defects.

Rectified Alternating Current

Clearly, the skin effect limits the use of AC since many inspection applications call for the

detection of subsurface defects. However, the convenient access to AC, drives its use beyond

surface flaw inspections. Luckily, AC can be converted to current that is very much like DC

through the process of rectification. With the use of rectifiers, the reversing AC can be converted

to a one directional current. The three commonly used types of rectified current are described

below.

PAGE 25 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Half Wave Rectified Alternating Current (HWAC)

When single phase alternating current is passed through a rectifier, current is allowed to flow in

only one direction. The reverse half of each cycle is blocked out so that a one directional,

pulsating current is produced. The current rises from zero to a maximum and then returns to

zero. No current flows during the time when the reverse cycle is blocked out. The HWAC repeats

at same rate as the unrectified current (60 hertz typical). Since half of the current is blocked out,

the amperage is half of the unaltered AC.

This type of current is often referred to as half wave DC or pulsating DC. The pulsation of the

HWAC helps magnetic particle indications form by vibrating the particles and giving them added

mobility. This added mobility is especially important when using dry particles. The pulsation is

reported to significantly improve inspection sensitivity. HWAC is most often used to power

electromagnetic yokes.

Full Wave Rectified Alternating Current (FWAC) (Single Phase)

Full wave rectification inverts the negative current to positive current rather than blocking it out.

This produces a pulsating DC with no interval between the pulses. Filtering is usually performed

to soften the sharp polarity switching in the rectified current. While particle mobility is not as

good as half-wave AC due to the reduction in pulsation, the depth of the subsurface magnetic

field is improved.

Three Phase Full Wave Rectified Alternating Current

Three phase current is often used to power industrial equipment because it has more favorable

power transmission and line loading characteristics. This type of electrical current is also highly

desirable for magnetic particle testing because when it is rectified and filtered, the resulting

current very closely resembles direct current. Stationary magnetic particle equipment wired with

three phase AC will usually have the ability to magnetize with AC or DC (three phase full wave

rectified), providing the inspector with the advantages of each current form.

PAGE 26 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

CHAPTER 5 MAGNETIZING METHODS

CONTINUOUS MAGNETISATION METHOD

The continuous method is a testing method by which the magnetic ink or powder is applied to

prior to and during energisation and the test area is viewed whilst the magnetising force is

applied. This is always considered to be the most sensitive method, whatever apparatus is used

to magnetise, due to the fact that the induced magnetic field is always the strongest whilst the

magnetising force is being applied.

RESIDUAL MAGNETISATION METHOD

The residual method is a testing method where the magnetic ink or powder is applied and the

test area is viewed after the magnetising force has been removed. The test is performed using

the residual magnetism left in the sample. This method is generally only used on materials with a

high retentivity. When multiple items are being tested by the residual method, care must be

taken to ensure that the components do not come into contact with each other before the

detecting media is applied otherwise a phenomena know as magnetic writing will occur.

LONGITUDINAL MAGNETISATION

When the length of a component is several times larger than its diameter, a longitudinal

magnetic field can be established in the component. The component is often placed

longitudinally in the concentrated magnetic field that fills the center of a coil or solenoid. This

magnetization technique is often referred to as a "coil shot." It can be accomplished by placing a

part in a fixed coil or wrapping the part with flexible cable.

Another method of longitudinally magnetising a part or rather a section of the part is by using

Permanent magnets or Electromagnetic Yokes. These methods is by far the most widely used

today, especially for site inspections.

PAGE 27 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

PERMANENT MAGNETS

Permanent magnets are so called because they are able to maintain a magnetic field in the

surrounding space. The field strength can vary considerably, depending on the flux density in the

magnet and its shape.

The simplest form of penetrant magnet is a bar magnet, which is basically a piece of

ferromagnetic material with a magnetic pole at each end.

If the bar was formed into a closed loop, then the magnetic field would be fully contained within

a closed circuit and no external field would exist. If a defect was present in the loop, a flux

leakage would still occur.

Neither bar magnets or ring (looped) magnets have any use in MPI. But, if a bar magnet is simply

formed into a U shape, the magnetic lines of force will be concentrated in the gap between the

magnetic poles; this provides an ideal configuration for magnetic particle inspection.

Permanent magnets provide magnetic flow only in the specimen and produce a longitudinal

magnetic field between the poles.

The degree of magnetisation in permanent magnets is determined by the amount of pull

required to lift the magnet clear of the work piece, or by its lifting power.

The pull off force is the force that has to be applied to one pole to break its attraction to the

surface, whilst leaving the other pole attracted.

The lifting power is the ability of the magnet to lift a piece of ferromagnetic material by attraction

alone.

Certain specifications will state the minimum requirements for the strengths of permanent

magnets. When not in use a permanent magnet should have a keeper placed across the poles to

prevent loss of magnetism.

Some permanent magnets may have adjustable arms, others may have rollers attached to the

poles; the rollers are set to keep the magnet just clear of the surface and enable it to be moved

over the work piece with relative ease.

PAGE 28 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Advantages of permanent magnets include:

No power supply required.

Inexpensive.

No damage to the test piece from arcing.

Relatively lightweight (easily portable).

They cling to vertical and overhead surfaces.

Both hands free after the magnet is placed onto the surface.

Disadvantages include:

Deterioration with wear/ abuse.

Have to be pulled from the test surface.

Magnetic particles attracted to poles.

Limited application on awkward shapes.

No control over field strength (unless adjustable arms are used).

Only small areas examined in each position.

Keeper required when not in use.

Not recommended to be used in conjunction with flux indicators.

Toxic material when machined.

Very hard.

Low flux density unless rare earth magnets used.

ELECTROMAGNETIC YOKES

Electromagnetic yokes or electromagnets require a source of electrical energy which may be AC

or DC. The test method used is sometimes referred to as the magnetic flow or magnetic flux path

method, producing a longitudinal magnetic field.

The yoke is made from highly permeable, low retentive steel, which is laminated to reduce

induction caused by eddy current flow (associated only with alternating current) this also helps to

prevent the yoke becoming permanently magnetized.

Magnetism is induced into the yoke by encircling it with a coil through which a current is passed,

the strength of the field produced can be varied in one of two ways:

1.

2.

By adjusting the current (amperage) flowing through the yoke - only certain

electromagnets allow for this.

By varying the distance between the poles - most electromagnets allow for this but not

at all.

PAGE 29 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Certain specifications will state the minimum requirements for the lifting power of Yokes.

Electromagnets may operate direct from the mains supply of 240V but are available at 110V

(battery packs are now available at 12/ 24/ 36V for more flexibility) when required for site use.

The field produced from an electromagnetic yoke is longitudinal, travelling from pole to pole as

with permanent magnets, however the depth of the field within the test piece will depend upon

the type of current used to induce magnetism.

Surface discontinuities will be more readily found using AC, sub-surface defects will be more

easily located using DC, but Yokes is usually accepted as a surface technique only. The magnet

will have a much greater pull on DC but the flux will be less at the surface of the component

being tested.

The area of inspection for electromagnets is a rectangular area between the poles of the

magnet(s).

Advantages of electromagnetic yokes include:

AC or rectified DC operation.

Controllable field strength (not in all cases).

Can be switched on/off as required.

No damage done to test piece.

Relatively lightweight.

AC yokes can be used to demagnetise.

Disadvantages include:

Power supply required.

Only small areas can be examined at each magnet location.

Leaves only one hand free.

DC yokes are not recommended to be used in conjunction with flux indicators.

PAGE 30 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

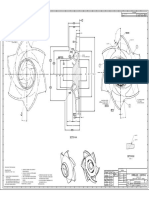

Typical Permanent Magnet and Yoke placement when testing welds.

PAGE 31 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

COIL TECHNIQUE

RIGID (FIXED) COIL

This technique consists of placing the specimen inside a coil of tubular or solid construction,

through which a low voltage, high amperage current is passed. The magnetic field passing

through the centre if the coil - typically three or five turns - creates longitudinal magnetization

and is therefore used to detect discontinuities which lie transverse to the components major axis,

e.g. good for detecting circumferential discontinuities in shafts or the bores of tubes.

For practical purposes only defects which lie within the confines of the coil should be interpreted

although the field will extend for 100 to 225 mm beyond either end.

If the specimen being tested has a small diameter in relation to the inside diameter if the coil, it

should ideally be positioned close to one side of the coil and rotated to obtain the best results.

NB. The strongest magnetic field is on the inside edge of the coil.

When using any of the current flow or threaded bar methods, the fields strength is largely

determined by the current (amperes) flowing in the circuit. When using any form of coil the field

strength is determined by the current flowing in the circuit and by the number of turns in that

coil, thereby obtaining ampere/ turns. These requirements will be specified by the Procedure

Code used.

PAGE 32 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

FLEXIBLE CABLES

When a single conductor is used, the magnetic field reduces rapidly at increasing distance from

the conductor; this restricts the production of an adequate test area with a sufficient constant

magnetic field. If the current is made to flow in the same direction through conductors spaced

some distance apart, a relatively constant field is produced.

Flexible cable techniques can be used on a considerable variety of component shapes.

Configurations used are normally obtained with a heavy insulated flexible cable which is placed

through, on, or around the specimen. A current passed through the cable will then induce a

magnetic field into the test piece.

Defects lying parallel to the cable will be the most readily detected. On complex shapes the

position and method in which the cable is wound may have to be found by experimentation to

ensure an adequate field in all areas.

Current values to be used shall be specified by the Procedure Code. Values shall be calculated

considering the Length/Diameter Ratio of the part and the number of turns in the coil.

Advantages of using a Coil:

Slightly Subsurface discontinuities may be found when using DC, HWDC or FWDC.

AC energised equipment may be used for demagnetisation operations.

Large areas inspected with each set-up.

No poles to attract magnetic particles.

Field strength can be altered.

Predictable field strengths.

Disadvantages include:

Cumbersome long heavy cables required.

Longer setting up times.

Heavy transformers required for large amperages.

Expensive equipment.

PAGE 33 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

CIRCULAR MAGNETISATION

As discussed previously, when current is passed through a solid conductor, a magnetic field forms

in and around the conductor. The following statements can be made about the distribution and

intensity of the magnetic field.

The field strength varies from zero at the center of the component to a maximum at the

surface.

The field strength at the surface of the conductor decreases as the radius of the conductor

increases when the current strength is held constant. (However, a larger conductor is

capable of carrying more current.)

The field strength outside the conductor is directly proportional to the current strength.

Inside the conductor, the field strength is dependent on the current strength, magnetic

permeability of the material, and if magnetic, the location on the B-H curve.

The field strength outside the conductor decreases with distance from the conductor.

In the images below, the magnetic field strength is graphed versus distance from the center of

the conductor. It can be seen that in a nonmagnetic conductor carrying DC, the internal field

strength rises from zero at the center to a maximum value at the surface of the conductor. The

external field strength decrease with distance from the surface of the conductor.

When the conductor is a magnetic material, the field strength within the conductor is much

greater than it is in the nonmagnetic conductor. This is due to the permeability of the magnetic

material. The external field is exactly the same for the two materials provided the current level

and conductor radius are the same.

PAGE 34 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

When the conductor is carrying alternating current, the internal magnetic field strength rises

from zero at the center to a maximum at the surface. However, the field is concentrated in a thin

layer near the surface of the conductor. This is known as the "skin effect." The skin effect is

evident in the field strength versus distance graph for a magnetic conductor shown to the right.

The external field decreases with increasing distance from the surface as it does with DC. It

should be remembered that with AC the field is constantly varying in strength and direction.

In a hollow circular conductor there is no magnetic field in the void area. The magnetic field is

zero at the inside wall surface and rises until it reaches a maximum at the outside wall surface. As

with a solid conductor, when the conductor is a magnetic material, the field strength within the

conductor is much greater than it was in the nonmagnetic conductor due to the permeability of

the magnetic material. The external field strength decreases with distance from the surface of

the conductor. The external field is exactly the same for the two materials provided the current

level and conductor radius are the same.

PAGE 35 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

When AC is passed through a hollow circular conductor, the skin effect concentrates the

magnetic field at the outside diameter of the component.

As can be learned from these three field distribution images, the field strength at the inside

surface of hollow conductor is very low when a circular magnetic field was established by direct

magnetization. Therefore, the direct method of magnetization is not recommended when

inspecting the inside diameter wall of a hollow component for shallow defects. The field strength

increases rapidly as one moves out (into the material) from the ID, so if the defect has significant

depth, it may be detectable.

However, a much better method of magnetizing hollow components for inspection of the ID and

OD surfaces is with the use of a central conductor. As can be seen in the field distribution image

to the right, when current is passed through a nonmagnetic central conductor (copper bar), the

magnetic field produced on the inside diameter surface of a magnetic tube is much greater and

the field is still strong enough for defect detection on the OD surface.

PAGE 36 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

PROD TECHNIQUE

With this technique the current is introduced into the item under test by using electrical contacts

known as prods. Prods induce a circular magnetic field within the specimen using current values

typically in the region of 1000 amps; at this current level arcing can occur between the electrodes

and the test surface causing damage. To prevent this possible damage, the prod contact tips and

the test surface must be kept clear of any contamination and the current must not be switched

on until firm contact has been established, likewise, the current should be switched off before

lifting the prods.

Precautions when using current flow in respect to prods/clamps shall be taken to prevent

excessive heating, burning or arcing. Certain metals including copper and zinc (including

galvanised prod tips) may, if used as prod material, contaminate and cause metallurgical damage

to the component if arcing occurs. For this reason and the fact that perfect contact is difficult to

achieve with prods, ideally they shall be made of steel or aluminium. Zinc shall not be used and

copper or copper-tipped prods shall be used only in applications where complete assurance can

be given that metallurgical damage will not occur. The cleanliness of both prod contact faces and

the component shall be such to ensure good electrical contact. Prods shall have a minimum

dimension of 10 mm and shall have as large a contact area as possible. Arcing or excessive

heating shall be regarded as a defect requiring a verdict of acceptability. If further testing is

required on such affected areas, it shall be carried out using a different technique.

Note: Lead contact pads may be used, but only in well ventilated conditions, because they may

generate harmful vapour which may cause headaches and/or dizziness.

Since the lines of force radiate from prods, correct positioning is essential to ensure that all

possible defects are located. Ideally the prods should be in a line parallel to, and on the same

axis, as the defects being sought.

Current requirements shall be specified by the Procedure Code and is based on the thickness of

the part and the distance between the prods.

PAGE 37 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Advantages of the prod technique include:

AC, DC, HWDC, and FWDC equipment available.

AC energised equipment may be used for demagnetisation operations.

Low voltage output.

No poles to attract magnetic particles.

Variable field strength, on/off control.

Can be used in confined spaces.

Relatively fast coverage of area under test.

Disadvantage include:

Risk of creating arc strikes (forming localised hard spots which may contain cracking).

Heavy transformer required.

Classed as a two person operation.

Contacts and small test items can overheat.

Careful positioning and spacing of prods required.

Possible to switch on without creating a field.

May leave residual field which interfere with next prod positions.

Expensive equipment.

PAGE 38 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

CURRENT FLOW TECHNIQUE (DIRECT MAGNETISATION) (HEAD SHOT OR CLAMPS)

Current flow techniques produce a circular magnetic field by passing a current through the test

piece, i.e. concentric rings of magnetic lines of force radiate at 90 (perpendicular) to the current

flow.

The current flow is normally obtained from a transformer DC, HWDC, FWDC or 3 PHASE FWDC.

The output voltage of current flow equipment is so low that there is no risk of electrical shock to

the operator from the equipment's specimen contact points or test specimen.

The choice of power supply depends on the test requirements, i.e. using AC will reveal only

surface discontinuities, thus not recommended, using DC or rectified DC will reveal

discontinuities typically up to 2 mm to 3 mm below the surface.

An ammeter is usually incorporated in the equipment to indicate the amount if current flowing

through the work piece.

In fixed installations, i.e. bench equipment, the component is firmly clamped between contact

heads. With portable equipment, electrical contact is made by the use of prods and/or clamps.

Current flow can also be achieved in regularly shaped items, e.g. bar or tube, by applying contacts

to the ends of a test piece and passing a high amperage, low voltage current through it. This sets

up a circular field in the ferromagnetic material in a direction at 90 to the current flow, therefore

the technique is used for detecting defects parallel to, and up to 45, of current flow, e.g.

longitudinal defects in bar. Copper gauze is usually placed between the contracts and the test

piece to increase the contract area and reduce the possibility of burning.

Irregular shaped items may also be tested by contact heads, although, depending on the

component's shape and dimensions, it may be preferable to use an alternative method.

Because the current values are dependant only on the test piece perimeter, the length of the test

piece is of no importance, i.e. on a test piece of 25 mm diameter, the same current value would

be used whether it was 10 cm long or 1 m long, therefore, if two test pieces of differing

diameters using the same current, the magnetic field would be stronger in the smaller diameter

test piece. Specifications usually stipulates the current requirements.

PAGE 39 OF 70

MAGNETIC PARTICLE TESTING LEVEL 1 & 2 COMBINED NOTE BOOK

NASA-MT-2001 REV.0

Advantages of the Head Shot technique include:

AC, DC, HWDC, and FWDC equipment available.

AC energised equipment may be used for demagnetisation operations.

Low voltage output.

No poles to attract magnetic particles.

Variable field strength, on/off control.

Relatively fast coverage of area under test.

Disadvantage include:

Risk of creating arc strikes (forming localised hard spots which may contain cracking).

Heavy transformer required.

Contacts and small test items can overheat.

Possible to switch on without creating a field.

May leave residual fields.

Expensive equipment.

PAGE 40 OF 70