Академический Документы

Профессиональный Документы

Культура Документы

D6N WH

Загружено:

Fabio JuniorАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

D6N WH

Загружено:

Fabio JuniorАвторское право:

Доступные форматы

D6N WH Waste Handler

Waste Handling Guarding

Extensive Guarding helps protect critical

machine components, body panels and the

cooling system from being damaged by debris

under harsh waste handling environments.

Debris Resistant Features

A debris resistant cooling system helps reduce

plugging, extend service life, and enhance productivity.

Recommended Options

Several recommended options complement the

Waste Handling Arrangement to ensure peak

performance. These range from landfill blades

and front striker bars to specially designed track

shoes and hydraulic rippers. Consult your dealer

for further recommendations.

Undercarriage

Elevated sprocket design isolates the final drives from

ground induced impacts for excellent component life.

The XL or the LGP configurations allow you to

match the machine to your specific application.

Differential Steering System

Differential Steering maintains power to both tracks

while turning. Operator controls machine speed,

direction and steering with the tiller bar controller,

while maximizing production.

Serviceability

The time between PM service intervals has increased

allowing more up-time. All major components,

filters, and lube points are easily accessible and

modular in design. The EMS III machine monitoring

system adds increased diagnostic capabilities.

Operator Station

State-of-the-art operator station has reduced sound

levels, lower cab vibrations and excellent visibility.

The (optional) Caterpillar comfort series air suspension

seat helps reduce operator fatigue. Cab and air

conditioning are standard.

Complete Customer Support

Your Cat dealers investment in service begins with

the fastest and most complete parts availability in the

industry. The full range of exchange components and

Caterpillar Remanufactured parts is aimed at saving

you time and money, while carrying new-parts warranty.

D6N WH Waste Handler

7

9

4

1

3

5

2

8

1) Heavy-Duty Hinged Radiator Grille

Angled plate type grille, hinged for easier access.

A lockable, hand-operated latch. The 45 angle of

the bars diverts airflow up and away from the back

of the dozer blade. The angling helps keep debris

from damaging the radiator.

2) Heavy-Duty Bottom Guards

The Heavy-Duty Guards are a heavier construction

for stronger protection. They prevent debris from

damaging power train components and help keep

debris out.

3) Lift Cylinder Lines Guards

Help protect the hydraulic tubes on the lift cylinders

from damage.

4) Heavy-Duty Engine Enclosures

Perforations sized to enhance airflow while limiting

debris entry. Front hinged for easy access.

Note: If Sound Suppression arrangement is ordered,

the perforated doors are replaced with solid doors.

5) Debris Guards

Several debris guards are added to prevent damage to

sheet metal panels from debris carried by the track.

6) Perforated Hood

Perforations sized to enhance airflow while limiting

debris entry.

7) Heavy-Duty Hydraulic Tank Guard

A hinged cover to protect the filter housing and

fill spout.

8) Trash Rack

(optional LGP version shown)

Increase dozing capacity in trash applications.

Helps prevent trash from spilling over the blade.

Open design maximizes visibility.

(viewing area to the front)

9) Heavy-Duty Battery Box and Sheet Metal

Thicker steel for more structural strength.

Trash Resistant Cooling System

(required not shown)

Wider 6 fins/inch spacing.

Allows longer run time between cleanouts.

Easier to keep clean.

D6N WH Waste Handler

11

12

16

10

14

13

15

17

10) Heavy-Duty Fenders

Twice as thick as standard fenders.

Includes edge protection for sheet metal panels.

Maintains serviceability.

11) Heavy-Duty Latches

On sheet metal access panels and engine enclosures.

12) Heavy-Duty Fuel Tank Guard

10 mm (0.375 in) thick steel for maximum strength.

Includes fuel fill cap protection.

Adds additional stiffness to structures.

13) Final Drive Seal Guards

Tightly fitted overlapping steel rings, pressed and

welded to final drive hub and spindle.

Helps keep damaging wire out of the final drive

seal area.

14) Idler Seal Guards

Machined parts added to help prevent wrapping

materials from damaging the idler seals.

15) Rear Striker Bar (optional)

Rear striker bars incorporate a rigid drawbar

and housing with large access doors for storage

on machines not equipped with winch or ripper.

Helps keep damaging debris from being carried

by track to fender area.

16) Tilt Lines Guards (optional)

Additional guards added for bulldozer tilt lines.

17) Trapezoidal Hole Track Shoes (optional)

The trapezoidal hole track shoes reduce refuse

packing within the track and chain.

18) Heavy-Duty Rear Guard

(optional not shown)

10 mm (0.375 in) thick steel for maximum protection.

Lockable for vandalism protection

Вам также может понравиться

- D7R IiДокумент24 страницыD7R IiVictor M. Mejia DiazОценок пока нет

- Surface Belt Structure: Cema C & D SeriesДокумент8 страницSurface Belt Structure: Cema C & D SeriesSari Ully SibaraniОценок пока нет

- Waste HandlerДокумент8 страницWaste HandlerDharmesh patelОценок пока нет

- 330CL Series Spec Sheet ExcavatorДокумент24 страницы330CL Series Spec Sheet ExcavatorMohamed Abbas100% (2)

- D7GIIДокумент16 страницD7GIIlulu3232Оценок пока нет

- Cargador Frontal 15yd3 PDFДокумент24 страницыCargador Frontal 15yd3 PDFOscar TrigoОценок пока нет

- DX480LC-EN 03-10 LRДокумент20 страницDX480LC-EN 03-10 LREngineermoaz MoazОценок пока нет

- D Guillotine BrochureДокумент4 страницыD Guillotine Brochurexaaabbb_550464353100% (1)

- Cat D6GДокумент16 страницCat D6GShailesh Khodke75% (4)

- MD5150 Track Drill AEHQ6857 00Документ28 страницMD5150 Track Drill AEHQ6857 00Francisco SalazarОценок пока нет

- 322CL PDFДокумент24 страницы322CL PDFLuis Fernando Vasquez RamosОценок пока нет

- Slayer Series Product BookletДокумент16 страницSlayer Series Product BookletLorcán McGrathОценок пока нет

- HT AgitatorsДокумент12 страницHT AgitatorsSantoshkota123Оценок пока нет

- D8T, D9T, D10T: Waste HandlerДокумент16 страницD8T, D9T, D10T: Waste HandlerJuan Alfredo ValdésОценок пока нет

- Hydraulic Track Drill AEXQ0599 01Документ8 страницHydraulic Track Drill AEXQ0599 01DrianquisОценок пока нет

- Roll Crusher BrochureДокумент4 страницыRoll Crusher BrochureWaris La Joi Wakatobi100% (1)

- Cool Machines CV Series Insulation Removal VacuumДокумент3 страницыCool Machines CV Series Insulation Removal Vacuumbrooklynarmstrong487Оценок пока нет

- Track Drill: General DataДокумент20 страницTrack Drill: General Datadeath666darkОценок пока нет

- 01 Chemical ProcessДокумент333 страницы01 Chemical ProcessDavid ValladaresОценок пока нет

- 21 H135-155FT-BTG PDFДокумент20 страниц21 H135-155FT-BTG PDFAndrés Felipe Gutiérrez RodríguezОценок пока нет

- Belt Filter PressKompress SpreadДокумент5 страницBelt Filter PressKompress SpreadDinesh ChhabraОценок пока нет

- Cat 320d LRRДокумент28 страницCat 320d LRRt1meОценок пока нет

- Caterpillar 816FДокумент20 страницCaterpillar 816FForomaquinas100% (1)

- WIL Cement Separators Brochure PDFДокумент12 страницWIL Cement Separators Brochure PDFPaulo Vidas100% (3)

- CVBHW FlexsteelДокумент10 страницCVBHW FlexsteelfranciscocvОценок пока нет

- Track-Type Tractor: XL & LGPДокумент20 страницTrack-Type Tractor: XL & LGPRoussel Florez Zuloaga100% (3)

- Manual Book Cat 320D-320D LДокумент28 страницManual Book Cat 320D-320D Ljono timur90% (29)

- Affordable Reservoir and Port Dredging with the IMS DM-60Документ2 страницыAffordable Reservoir and Port Dredging with the IMS DM-60Mohamed ZaghloulОценок пока нет

- CVBHW FlexsteelДокумент10 страницCVBHW FlexsteelSrini KumarОценок пока нет

- Hydro-Turbine Bearings: Zero Pollution - High Performance - Bearing & Seal SystemsДокумент12 страницHydro-Turbine Bearings: Zero Pollution - High Performance - Bearing & Seal SystemsardossantosОценок пока нет

- Pipelayer: Engine Engine (Continued)Документ20 страницPipelayer: Engine Engine (Continued)Daniel Marx ChillitupaОценок пока нет

- Bettis HD-Series ActuatorsДокумент6 страницBettis HD-Series Actuatorstxlucky80Оценок пока нет

- Conveyor ComponentsДокумент26 страницConveyor Componentswmacadd100% (6)

- 320D GC Series 2: Hydraulic ExcavatorДокумент28 страниц320D GC Series 2: Hydraulic ExcavatorPurwoko100% (1)

- Hydraulic Track Drills: & Associated Rock Drill ProductsДокумент8 страницHydraulic Track Drills: & Associated Rock Drill ProductsJean-Jacques OuandaogoОценок пока нет

- High Performance Composite V-BeltsДокумент20 страницHigh Performance Composite V-Beltschidambaram kasiОценок пока нет

- NOV Prochem Bulletin 720 - v02Документ10 страницNOV Prochem Bulletin 720 - v02saulomonОценок пока нет

- Blasthole Drills Power and PerformanceДокумент6 страницBlasthole Drills Power and PerformanceJose Maluenda100% (1)

- Unax InternalsДокумент4 страницыUnax InternalsMohamed ShehataОценок пока нет

- Underground Mining LoaderДокумент20 страницUnderground Mining LoaderPedro Pablo Fernández FernándezОценок пока нет

- 313FLДокумент36 страниц313FLAndrew GoadОценок пока нет

- Underground Mining LoaderДокумент20 страницUnderground Mining LoaderPedro Pablo Fernández Fernández100% (1)

- Don GTS BrochureДокумент8 страницDon GTS BrochuresanigzlОценок пока нет

- 16H Motor Grader: Global VersionДокумент30 страниц16H Motor Grader: Global VersionsuryarisОценок пока нет

- E 314C SpecalogДокумент16 страницE 314C SpecalogArmando Muñoz100% (1)

- DuctIsolationSystems DiverterDampersДокумент12 страницDuctIsolationSystems DiverterDampersefte_14100% (1)

- PumpsДокумент19 страницPumpsIon_Riswan100% (1)

- Omega 2pg 1384.021v3-10Документ2 страницыOmega 2pg 1384.021v3-10Hesham AmerОценок пока нет

- 311D LRR SRR EccvatiorДокумент24 страницы311D LRR SRR EccvatiorVinod YbОценок пока нет

- MD5150 Track DrillДокумент28 страницMD5150 Track DrillDavid Santo100% (2)

- Cs - Cp-533e Specalog (Qehq9995)Документ16 страницCs - Cp-533e Specalog (Qehq9995)Sanggalangi LatinroОценок пока нет

- GE Large Induction MotorsДокумент8 страницGE Large Induction MotorsidontlikeebooksОценок пока нет

- D9T Eng 15Документ28 страницD9T Eng 15Israel Méndez EstradaОценок пока нет

- D9T PDFДокумент28 страницD9T PDFGisseRamirezОценок пока нет

- Brochure Track Drills BucyrusДокумент12 страницBrochure Track Drills BucyrusWashington Huallpa100% (1)

- Cat SealsДокумент44 страницыCat SealsAki ToyОценок пока нет

- Caterpillar Filter ไส้กรอง กรองลม กรองน้ำมันДокумент19 страницCaterpillar Filter ไส้กรอง กรองลม กรองน้ำมันParinpa KetarОценок пока нет

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!От EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Рейтинг: 5 из 5 звезд5/5 (2)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallОт EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallРейтинг: 4 из 5 звезд4/5 (8)

- The Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignОт EverandThe Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Cicuit Temp Air y OleoДокумент12 страницCicuit Temp Air y OleoFabio JuniorОценок пока нет

- K-Suite 1.89Документ3 страницыK-Suite 1.89Fabio JuniorОценок пока нет

- InteliGen 6.0 PDFДокумент19 страницInteliGen 6.0 PDFFabio JuniorОценок пока нет

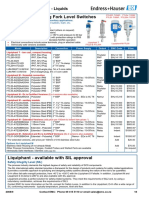

- Liquid Level Float Switch: Description AccessoriesДокумент1 страницаLiquid Level Float Switch: Description AccessoriesFabio JuniorОценок пока нет

- NVS Needle ValveДокумент1 страницаNVS Needle ValveFabio JuniorОценок пока нет

- InteliGen 6.0 PDFДокумент19 страницInteliGen 6.0 PDFFabio JuniorОценок пока нет

- ELC Data SheetДокумент2 страницыELC Data SheetFabio Junior100% (1)

- Emerson Thermowell Pressure RatingДокумент1 страницаEmerson Thermowell Pressure RatingFabio JuniorОценок пока нет

- LINC L471manualДокумент20 страницLINC L471manualFabio JuniorОценок пока нет

- 1117 RTDДокумент5 страниц1117 RTDNa Rukok Sibak JoeОценок пока нет

- Drawings PO80335843Документ8 страницDrawings PO80335843Fabio JuniorОценок пока нет

- F63 Series Liquid Level Float SwitchДокумент8 страницF63 Series Liquid Level Float SwitchFabio JuniorОценок пока нет

- LFR-D enДокумент16 страницLFR-D enFabio JuniorОценок пока нет

- Asco - Iom 327 SeriesДокумент4 страницыAsco - Iom 327 SeriesFabio JuniorОценок пока нет

- F63 SeriesДокумент3 страницыF63 SeriesFabio JuniorОценок пока нет

- MC68 Adm PDFДокумент128 страницMC68 Adm PDFFabio JuniorОценок пока нет

- Anzex 07 3081 VM WSVMДокумент14 страницAnzex 07 3081 VM WSVMFabio Junior0% (1)

- L471 VerДокумент18 страницL471 VerFabio JuniorОценок пока нет

- C-11, C-13, C-15 TS Manual 2006 PDFДокумент420 страницC-11, C-13, C-15 TS Manual 2006 PDFFabio Junior83% (6)

- Liquiphant Vibrating Fork Level SwitchesДокумент1 страницаLiquiphant Vibrating Fork Level SwitchesFabio JuniorОценок пока нет

- Mcm3320 Servico 2012 InglesДокумент312 страницMcm3320 Servico 2012 InglesFabio Junior100% (2)

- Farris 3800 ManualДокумент12 страницFarris 3800 ManualNelson AlvarezОценок пока нет

- Cat Electronic Tech Nician 2014A v1.0Документ27 страницCat Electronic Tech Nician 2014A v1.0Fabio JuniorОценок пока нет

- An951 PDFДокумент14 страницAn951 PDFFabio JuniorОценок пока нет

- In Pulse™ II: ApplicationsДокумент4 страницыIn Pulse™ II: ApplicationsFabio JuniorОценок пока нет

- XC9572 In-System Programmable CPLD: Features DescriptionДокумент9 страницXC9572 In-System Programmable CPLD: Features DescriptionManish PushkarОценок пока нет

- Data Sheet PDFДокумент13 страницData Sheet PDFFabio JuniorОценок пока нет

- XC9572 In-System Programmable CPLD: Figure 1: Typical I vs. Frequency For XC9572Документ8 страницXC9572 In-System Programmable CPLD: Figure 1: Typical I vs. Frequency For XC9572Siddhi Nitin MahajanОценок пока нет

- Tle 6220 PDFДокумент17 страницTle 6220 PDFFabio JuniorОценок пока нет

- Tle 6220 PDFДокумент17 страницTle 6220 PDFFabio JuniorОценок пока нет

- Ryerson EthicsДокумент20 страницRyerson EthicssinghbabaОценок пока нет

- Oblicon SampleДокумент1 страницаOblicon SamplelazylawatudentОценок пока нет

- Antiquity: Middle AgesДокумент6 страницAntiquity: Middle AgesPABLO DIAZОценок пока нет

- Mechanics of Deformable BodiesДокумент21 страницаMechanics of Deformable BodiesVarun. hrОценок пока нет

- Colour Ring Labels for Wireless BTS IdentificationДокумент3 страницыColour Ring Labels for Wireless BTS Identificationehab-engОценок пока нет

- Weir Stability Analysis Report PDFДокумент47 страницWeir Stability Analysis Report PDFSubodh PoudelОценок пока нет

- NameДокумент5 страницNameMaine DagoyОценок пока нет

- Practice Like-Love - Hate and PronounsДокумент3 страницыPractice Like-Love - Hate and PronounsangelinarojascnОценок пока нет

- Roadmap For Digitalization in The MMO Industry - For SHARINGДокумент77 страницRoadmap For Digitalization in The MMO Industry - For SHARINGBjarte Haugland100% (1)

- B. Ing Kls 6Документ5 страницB. Ing Kls 6siskaОценок пока нет

- Basic Five Creative ArtsДокумент4 страницыBasic Five Creative Artsprincedonkor177Оценок пока нет

- Variable Speed Pump Efficiency Calculation For Fluid Flow Systems With and Without Static HeadДокумент10 страницVariable Speed Pump Efficiency Calculation For Fluid Flow Systems With and Without Static HeadVũ Tuệ MinhОценок пока нет

- The Teacher and The Community School Culture and Organizational LeadershipДокумент10 страницThe Teacher and The Community School Culture and Organizational LeadershipChefandrew FranciaОценок пока нет

- Cold Forging Process TutorialДокумент28 страницCold Forging Process TutorialpanyamnrОценок пока нет

- Installation Instruction XALM IndoorДокумент37 страницInstallation Instruction XALM IndoorVanek505Оценок пока нет

- GIS Arrester PDFДокумент0 страницGIS Arrester PDFMrC03Оценок пока нет

- ME6404 Thermal EngineeringДокумент18 страницME6404 Thermal EngineeringAnonymous mRBbdopMKfОценок пока нет

- Control SystemsДокумент269 страницControl SystemsAntonis SiderisОценок пока нет

- Philips DVD Player SpecificationsДокумент2 страницыPhilips DVD Player Specificationsbhau_20Оценок пока нет

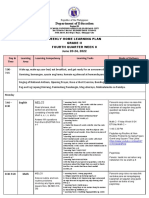

- Department of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Документ8 страницDepartment of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Evelyn DEL ROSARIOОценок пока нет

- Biomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCДокумент125 страницBiomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCAlpesh Jadhav100% (1)

- PharmacologyAnesthesiology RevalidaДокумент166 страницPharmacologyAnesthesiology RevalidaKENT DANIEL SEGUBIENSE100% (1)

- Benjie Reyes SbarДокумент6 страницBenjie Reyes Sbarnoronisa talusobОценок пока нет

- Optimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyДокумент7 страницOptimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDr-Paras PorwalОценок пока нет

- Suband Coding in MatlabДокумент5 страницSuband Coding in MatlabZoro Roronoa0% (1)

- Elmeasure Solenoid Ates CatalogДокумент12 страницElmeasure Solenoid Ates CatalogSEO BDMОценок пока нет

- Lesson 2 Mathematics Curriculum in The Intermediate GradesДокумент15 страницLesson 2 Mathematics Curriculum in The Intermediate GradesRose Angel Manaog100% (1)

- Ca. Rajani Mathur: 09718286332, EmailДокумент2 страницыCa. Rajani Mathur: 09718286332, EmailSanket KohliОценок пока нет

- SD-SCD-QF75 - Factory Audit Checklist - Rev.1 - 16 Sept.2019Документ6 страницSD-SCD-QF75 - Factory Audit Checklist - Rev.1 - 16 Sept.2019Lawrence PeОценок пока нет

- Master of Commerce: 1 YearДокумент8 страницMaster of Commerce: 1 YearAston Rahul PintoОценок пока нет