Академический Документы

Профессиональный Документы

Культура Документы

Quenched and Tempered Alloyed Engineering Steel DIN

Загружено:

kazdoelahИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Quenched and Tempered Alloyed Engineering Steel DIN

Загружено:

kazdoelahАвторское право:

Доступные форматы

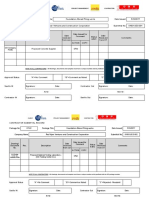

Quenched and Tempered Alloyed Engineering Steel

6582 DIN 34 CrNiMo 6

Standards Europe : DIN EN 10083-1 / DIN EN 10250-3 / DIN EN 10263-4

C Si Mn P S Cr Mo Ni

Chemical 0.30 - 0.38 0.15 - 0.40 0.50 - 0.80 < 0.035 < 0.035 1.30 - 1.70 0.15-0.30 1.30 - 1.70

Composition in %

Narrower or other tolerance ranges in chemical composition have to be agreed before order is placed.

Material A quenched and tempered alloy engineering steel with a high hardenability. Suitable for large sections with high

Characteristics tensile strength properties and impact toughness.

On hardening in oil a bar diameter of 25 mm and on hardening in water a bar diameter of 35 mm will have a

Transformation martenistic microstructure in the one of the bar dimensions. A martensitic / bainitic microstructure will be obatined

Characteristics in the core of the bar diameters up to 200 mm on hardening in oil and up to 260 mm on hardening in water

o o o

Transformation temperature : Acl ~ 715 C; Ac3 : ~ 765 C; Ms: ~325 C

For mechanical components subjected to high stresses. Shafts, crankshafts and propeller shafts of large

Applications

dimensions, Large gears and transmission components.

Hot rolled bars in Quenched and Tempered condition (DIN EN Hot forged bars in Quenched and Tempered

Delivery Condition

10083-1) condition (DIN EN 10250-3)

Hardening Tempering Annealing Jominy Test

0

830-860 C / oil or water 540 - 680 0C 650 - 700 0C 845 - 855 0C

Heat Treatment

Normalizing Hot Forming

0

850 - 880 C 850 - 1050 oC

1.5 mm 3 mm 5 mm 7 mm 9 mm 11 mm 13 mm 15 mm 20 mm

50 - 58 50 - 58 50 - 58 50 - 58 49 - 57 48 - 57 48 - 57 48 - 57 48 - 57

Jominy 25 mm 30 mm 35 mm 40 mm 45 mm 50 mm

hardenability in

47 - 57 47 - 57 47 - 57 46 - 57 45 - 57 44 - 57

HRc

If required, more limited hardenbility values on the lower range (HL) or higher range (HH) can be supplied. These

narrower limits have to be specifically ordered.

Quenched & Tempered

Hardness (HB) < 16 mm 16-40 mm 40-100 mm 100-160 mm 160-320 mm 330-500 mm

min. 350 min. 320 min. 285 min. 260 min. 215 min. 200

Physical Properties Density at 20o C is 7.92 kg / dm3

Mechanical Bar Reduction Impact Toughness

0.2% Proof Stress Tensile Strength Elongation

Properties in diameter in of Area (Z) (Av) in Joules (ISO-

(Rp.0.2) in MPa (Rm) in Mpa (A5) in%

Quenched and mm in % V-Notch)

Tempered

condition ≤ 16 > 980 1180 - 1380 >9 > 40 > 35

corresponding to > 16-40 > 885 1080 - 1280 > 10 > 45 > 45

DIN EN 10083-1

(Longitudinal > 40-100 > 785 980 - 1180 > 11 > 50 > 45

samples)

>100-160 > 685 880 - 1080 > 12 > 55 > 45

Mechanical Bar Impact Toughness

0.2% Proof Stress Tensile Strength

Properties in diameter in Elongation (A5) in % (Av) in Joules (ISO-

(Rp.0.2) in MPa (Rm) in Mpa

Quenched and mm V-Notch)

Tempered

condition ≥ 14 (longitudinal) ≥ 45 (longitudinal)

160 - 330 ≥ 540 ≥ 750

corresponding to ≥ 10 (transverse) ≥ 22 (transverse)

DIN EN 10250-3

(Longitudinal ≥ 15 (longitudinal) ≥ 40 (longitudinal)

330 - 500 ≥ 490 ≥ 700

samples) ≥ 11 (transverse) ≥ 20 (transverse)

Spherodized annealed + drawn

Properties Wire rods and bars spherodized Spherodized annealed + peeled

(wire rods < 28 mm or bars ≤ 40

corresponding to annealed (dimensions up to 40 mm) (bars : 20 - 40 mm)

mm )

DIN EN 10263-4

(longitudinal Tensile strength (Rm) ≤ 700 Mpa Tensile strength (Rm) ≤ 800 Mpa Tensile strength (Rm) ≤ 720 Mpa

samples)

Reduction of Area (Z) > 60% Reduction of Area (Z) > 55% Reduction of Area (Z) > 58%

Temper-Hardness Diagram of Steel 1.6582

(15 mm Bar Diameter)

600

500

Hardness in HV

400

300

200

100

0

200 300 400 500 600 700

Te m pe ring Te m pe ra ture in °C

ISAN METALL

A Division of Otto Wolff Handelsgesellschaft mbH

ThyssenKrupp Services AG

Our official trading arm in Indonesia :

Jl. P. Jayakarta 24/10, Jakarta 10730 Tel .(021) 639-3933 Fax. (021) 639-8906

Website: www.krupindo.com E-mail : info@krupindo.com

Вам также может понравиться

- Outstanding As On 9/jun/18 Vs Outstanding As On Today - PWHTДокумент4 страницыOutstanding As On 9/jun/18 Vs Outstanding As On Today - PWHTvenkyОценок пока нет

- UTMOSHE P0820 Emergency Preparedness and Response 15.9.2022Документ11 страницUTMOSHE P0820 Emergency Preparedness and Response 15.9.2022Mohamed Nazri Mohd MokhtarОценок пока нет

- QAP1005AДокумент13 страницQAP1005Avinay8464Оценок пока нет

- Location Site Name Site Features/Access Location Site Name Site Features/AccessДокумент1 страницаLocation Site Name Site Features/Access Location Site Name Site Features/AccessAlicia GiménezОценок пока нет

- IC Simple Gantt Chart 10941 PowerPointДокумент3 страницыIC Simple Gantt Chart 10941 PowerPointchristian mchОценок пока нет

- Welders Performance NDT Rates Summary: Project Name HPCL-VMRP Project (Epcc-7) PipingДокумент2 страницыWelders Performance NDT Rates Summary: Project Name HPCL-VMRP Project (Epcc-7) PipingvenkyОценок пока нет

- Asirusa WPS-P-002 1FДокумент5 страницAsirusa WPS-P-002 1FWalter RuedaОценок пока нет

- Contractor Submittal RecordДокумент172 страницыContractor Submittal RecordErwin ObenzaОценок пока нет

- 1B Approval FormДокумент1 страница1B Approval FormAgnes G. Arguilles Taladtad100% (1)

- Islamic Republic of Iran Ministry of Petroleum Vendor Evaluation Questionnaire ١-Company InformationДокумент5 страницIslamic Republic of Iran Ministry of Petroleum Vendor Evaluation Questionnaire ١-Company InformationmagnusgrenzelОценок пока нет

- MC-01 Audit PlanДокумент1 страницаMC-01 Audit PlanMo ZeroОценок пока нет

- Toolbox Talk - Ladders: Planning and Assessment of RisksДокумент3 страницыToolbox Talk - Ladders: Planning and Assessment of RisksRedouan Lerhrissi100% (1)

- Itp GRPДокумент4 страницыItp GRPJo FrancescОценок пока нет

- Project Cost and Schedule Control (20-00108PR)Документ32 страницыProject Cost and Schedule Control (20-00108PR)Mohammad Rony AbjantoОценок пока нет

- QUALITY CONTROL PROCEDURE FOR Access Control System InstallationДокумент8 страницQUALITY CONTROL PROCEDURE FOR Access Control System InstallationAbdul JabbarОценок пока нет

- PUR-F-SPR - Supplier Performance RatingДокумент4 страницыPUR-F-SPR - Supplier Performance RatingRajkumar PrajapatiОценок пока нет

- Uv Resistance GRP Test ReportДокумент2 страницыUv Resistance GRP Test ReportA.Subin DasОценок пока нет

- ALDAR Projects Health and Safety Alert Electrical SafetyДокумент1 страницаALDAR Projects Health and Safety Alert Electrical SafetyerwinОценок пока нет

- OCP - 26-HO Travelling To SiteДокумент2 страницыOCP - 26-HO Travelling To SiteNagendra Kumar SinghОценок пока нет

- Emergency Preparedness and Proper Response PlanДокумент3 страницыEmergency Preparedness and Proper Response PlanCarmela Goc-ongОценок пока нет

- SEVEN Materials (MIR) Work (WIR) Inspection Requests Procedure 0DMQL00-DLVR-00-SEV-QM-PRO-00005Документ11 страницSEVEN Materials (MIR) Work (WIR) Inspection Requests Procedure 0DMQL00-DLVR-00-SEV-QM-PRO-00005Meshaal ALBalharithОценок пока нет

- Define of WPS & PQRДокумент16 страницDefine of WPS & PQRThanh Hua100% (1)

- Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionДокумент2 страницыWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionTrudie0% (1)

- Mc-ph01-p04-06a03-Vme-sor-ele-000001 Site Observation Site Temporary Electrical Layout 24 Aug 2021Документ2 страницыMc-ph01-p04-06a03-Vme-sor-ele-000001 Site Observation Site Temporary Electrical Layout 24 Aug 2021ehteshamОценок пока нет

- ASMI-OSHMS-PR-14 - Control of Documents and Record Retention ProcedureДокумент10 страницASMI-OSHMS-PR-14 - Control of Documents and Record Retention ProcedureJHUPEL ABARIALОценок пока нет

- General Inspection ReportДокумент1 страницаGeneral Inspection ReportBilly KurniawanОценок пока нет

- Test Results Tracker TemplateДокумент11 страницTest Results Tracker TemplatekdhingraОценок пока нет

- Work Site Inspection Checklist 1Документ13 страницWork Site Inspection Checklist 1syed hassanОценок пока нет

- Engineering ManagementДокумент1 страницаEngineering ManagementJsmn OsianОценок пока нет

- SEVEN Quality Inspection and Test Plans (ITP) Procedure 0DMQL00-DLVR-00-SEV-QM-PRO-00004Документ10 страницSEVEN Quality Inspection and Test Plans (ITP) Procedure 0DMQL00-DLVR-00-SEV-QM-PRO-00004Meshaal ALBalharithОценок пока нет

- Sanjay Pandit Best Safety Employee Award Certificate For Month July 2017Документ1 страницаSanjay Pandit Best Safety Employee Award Certificate For Month July 2017api-349606419Оценок пока нет

- Heat Input CalculatorДокумент2 страницыHeat Input CalculatorKiukStaksОценок пока нет

- Manufacturing Standard FOR Handling and Manufacturing of Grade 91 MaterialДокумент9 страницManufacturing Standard FOR Handling and Manufacturing of Grade 91 Materialramaus100% (1)

- Week 34-Cell Phone PolicyДокумент1 страницаWeek 34-Cell Phone Policypl_rajaОценок пока нет

- Cahier de Soudage G 11950 - Ver B - WPS 14 PDFДокумент1 страницаCahier de Soudage G 11950 - Ver B - WPS 14 PDFYassineElabdОценок пока нет

- Distortion in Aluminum Welded StructuresДокумент3 страницыDistortion in Aluminum Welded StructuresRaron1Оценок пока нет

- CQP - Comments Response SheetДокумент7 страницCQP - Comments Response SheetCharles JacobОценок пока нет

- LaborДокумент50 страницLaborReda EmamОценок пока нет

- Test Results & Reports SubmittalДокумент1 страницаTest Results & Reports SubmittalromahiОценок пока нет

- 05 - RFI - Request For Inspection FORM - 2017Документ1 страница05 - RFI - Request For Inspection FORM - 2017Rahul KalathingalОценок пока нет

- Height Work Guidelines: Thermax Engineering Construction Co. LTD Operational Control ProcedureДокумент2 страницыHeight Work Guidelines: Thermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghОценок пока нет

- Monthly Package I November 2016Документ87 страницMonthly Package I November 2016Suad BushiОценок пока нет

- Iso 1005Документ21 страницаIso 1005JOKOMAFE2012100% (1)

- Civil Works Quality Control & Testing TrackerДокумент18 страницCivil Works Quality Control & Testing TrackerMitendra Kumar ChauhanОценок пока нет

- ASMI-OSHMS-PR-02 - Targets and Objectives ProcedureДокумент9 страницASMI-OSHMS-PR-02 - Targets and Objectives ProcedureJHUPEL ABARIALОценок пока нет

- Checklist Fire PDFДокумент1 страницаChecklist Fire PDFMadan TiwariОценок пока нет

- Hse Moment - Compliance Dept 2023Документ7 страницHse Moment - Compliance Dept 2023SamsonОценок пока нет

- Guidelines For HO Staff Traveling To Site: Thermax Engineering Construction Co. LTD Operational Control ProcedureДокумент2 страницыGuidelines For HO Staff Traveling To Site: Thermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghОценок пока нет

- Beyond Challenges - : Locks, Maasbracht, The NetherlandsДокумент20 страницBeyond Challenges - : Locks, Maasbracht, The NetherlandsShreepad BandagiОценок пока нет

- Procedure: Qatar Steel Company Q.S.CДокумент30 страницProcedure: Qatar Steel Company Q.S.CyogakharismaОценок пока нет

- Asme 1325-18 (2007)Документ1 страницаAsme 1325-18 (2007)Matthew TaylorОценок пока нет

- Inspection and Test Plan (ITP) - Civil WorksДокумент1 страницаInspection and Test Plan (ITP) - Civil WorksNaveen GladsonОценок пока нет

- 2.2.16 - QPR-RHE-002 RLC Waste Management 2 (220205)Документ30 страниц2.2.16 - QPR-RHE-002 RLC Waste Management 2 (220205)Lyle KorytarОценок пока нет

- PLN-1400-0000-013 Community Health and Safety Plan 4 October PDFДокумент13 страницPLN-1400-0000-013 Community Health and Safety Plan 4 October PDFrodman823Оценок пока нет

- Crisis Management - Bomb ThreatДокумент6 страницCrisis Management - Bomb Threatmonica dwimandhaniОценок пока нет

- 4.2.1 HVA Adhesive Anchor: Anchoring SystemsДокумент15 страниц4.2.1 HVA Adhesive Anchor: Anchoring SystemsechavarriОценок пока нет

- Quenched and Tempered Alloyed Engineering Steel DINДокумент2 страницыQuenched and Tempered Alloyed Engineering Steel DINkazdoelahОценок пока нет

- Annealed Engineering Steel C45E / 1042 (ASTMДокумент2 страницыAnnealed Engineering Steel C45E / 1042 (ASTMkazdoelahОценок пока нет

- Steel Grade: Material Data SheetДокумент5 страницSteel Grade: Material Data Sheetdan howsОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Quenched and Tempered Alloyed Engineering Steel DINДокумент2 страницыQuenched and Tempered Alloyed Engineering Steel DINkazdoelahОценок пока нет

- Cold Work Tool Steel DIN 100 MNCRWДокумент2 страницыCold Work Tool Steel DIN 100 MNCRWkazdoelahОценок пока нет

- Standards Chemical Composition in % C 0.45Документ2 страницыStandards Chemical Composition in % C 0.45kazdoelah100% (1)

- Standards Chemical Composition in % C 0.35Документ2 страницыStandards Chemical Composition in % C 0.35kazdoelahОценок пока нет

- Standards Chemical Composition in %Документ2 страницыStandards Chemical Composition in %kazdoelahОценок пока нет

- Standards Chemical Composition in % C 0.35Документ2 страницыStandards Chemical Composition in % C 0.35kazdoelahОценок пока нет

- Annealed Engineering Steel C45E / 1042 (ASTMДокумент2 страницыAnnealed Engineering Steel C45E / 1042 (ASTMkazdoelahОценок пока нет

- Manganese Steel 3401Документ1 страницаManganese Steel 3401kazdoelahОценок пока нет

- Steel Comp A Ration TableДокумент1 страницаSteel Comp A Ration TablekazdoelahОценок пока нет

- 52 CentFans PDFДокумент70 страниц52 CentFans PDFmuhdjusriОценок пока нет

- Power Source CharacteristicsДокумент22 страницыPower Source CharacteristicsKyОценок пока нет

- Catalog For TransformersДокумент20 страницCatalog For TransformersParthibanMKrishnanОценок пока нет

- U-2 Sheet Metal OperationsДокумент72 страницыU-2 Sheet Metal Operationsapi-271354682Оценок пока нет

- Pre-Columbian Surface MetallurgyДокумент8 страницPre-Columbian Surface MetallurgyAantchuОценок пока нет

- Stainless Steel Size 1 Enclosure Type: Increased Safety EexeДокумент1 страницаStainless Steel Size 1 Enclosure Type: Increased Safety Eexewe202Оценок пока нет

- CTS-Clean-out Block-16 PDFДокумент2 страницыCTS-Clean-out Block-16 PDFsoarec2Оценок пока нет

- Cathodic Protection PresentationДокумент56 страницCathodic Protection Presentationsameer_rect2429100% (13)

- p18 - p19 Compounds Ionic-AnswersДокумент8 страницp18 - p19 Compounds Ionic-Answersapi-423980580Оценок пока нет

- ArcelorMittal SPEC GUIDE 20070801Документ78 страницArcelorMittal SPEC GUIDE 20070801SH1961Оценок пока нет

- Development and Intersection: Learning CompetenciesДокумент31 страницаDevelopment and Intersection: Learning CompetenciesezedinОценок пока нет

- ASTM A36 Steel Plate - Completely SpecificationsДокумент3 страницыASTM A36 Steel Plate - Completely SpecificationsTaimur WaleedОценок пока нет

- EC 1350-O Product Specification Rev.0Документ3 страницыEC 1350-O Product Specification Rev.0serkan temelОценок пока нет

- Facts About Magnetism-Part1Документ7 страницFacts About Magnetism-Part1Muhammad MosaОценок пока нет

- 9 Strip Casting Technology PYMenetДокумент5 страниц9 Strip Casting Technology PYMenetNikolas Kolasni Lakenir Ckerde DockosОценок пока нет

- TSL 2009 349Документ7 страницTSL 2009 349Soo Sang ParkОценок пока нет

- TS MaterialGuide en 2015.04Документ52 страницыTS MaterialGuide en 2015.04Stefano MartelliОценок пока нет

- Speed Rail CatalogДокумент60 страницSpeed Rail CatalogmtОценок пока нет

- Free Standing Walls and Cladding Design GuideДокумент33 страницыFree Standing Walls and Cladding Design GuideNatalia SnegurОценок пока нет

- Continuous Hot-Dip Galvanized Steel Bars For Concrete ReinforcementДокумент5 страницContinuous Hot-Dip Galvanized Steel Bars For Concrete Reinforcementmohammed karasnehОценок пока нет

- Materials Characterisation ExercisesДокумент4 страницыMaterials Characterisation Exercisesyaswanth1992Оценок пока нет

- TMC Cable CatalogДокумент71 страницаTMC Cable Cataloglam266Оценок пока нет

- EVMSU3Документ5 страницEVMSU3Marcos Ulises Luis MonzonОценок пока нет

- 27 Riveted Joints Types and UsesДокумент11 страниц27 Riveted Joints Types and UsesPRASAD326100% (1)

- Japanese Iron and Steel Certified Reference Materials: I. Crms For Chemical Analysis I-1. Pure Iron SeriesДокумент10 страницJapanese Iron and Steel Certified Reference Materials: I. Crms For Chemical Analysis I-1. Pure Iron SeriesrizaedlysamОценок пока нет

- SAIC-L-2014 Rev. 5Документ10 страницSAIC-L-2014 Rev. 5Jagadeesh PuppalaОценок пока нет

- ERW Hook CrackДокумент9 страницERW Hook CrackElias KapaОценок пока нет

- Lighting For Roadways and Bridges PDFДокумент45 страницLighting For Roadways and Bridges PDFwafikmh4Оценок пока нет

- 17-7 PH Data BulletinДокумент16 страниц17-7 PH Data Bulletinmeckup123Оценок пока нет

- Civil Affairs Handbook Belgium Section 8Документ124 страницыCivil Affairs Handbook Belgium Section 8Robert ValeОценок пока нет