Академический Документы

Профессиональный Документы

Культура Документы

Rotating Itp 1

Загружено:

abdul azizАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Rotating Itp 1

Загружено:

abdul azizАвторское право:

Доступные форматы

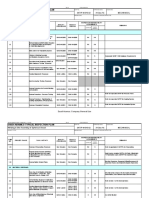

DOC No:- PLL/ROTATING/ITP/ 07

INSPECTION AND TEST PLAN FOR MECHANICAL

WORKS(ROTATING)

REV 0

PROJECT:PROJECT: ERECTION OF CRACKING FURNACES DUAL FEED

CRACKER UNITProject :

WNER: M/sONGC Petro Additions Ltd.SEZ, Dahej, Gujarat, India

PMC:

M/s. ENGINEERS INDIA LTD

Sub.Contractor : M/s. PUNJ LLOYD LTD

Sl.

No.

Activity Description

PLL

LINDE/SECL

EIL

Documents

a) Contractor' s supply meterial check / testing

HP

IMIR

b) Material traceability

RW

IMIR

c) Storage and handling

RW

IMIR

d)Damage

HP

IMIR

RW

RW

Testing Lab report

a) Working Radius

RW

b)Swing obstruction

RW

c) Load chart Etc.

RW

d) Availability of Tools and tackles

RW

e) Ensure any temporary platform or scaffolding

requirement.

RW

f) Placement of main and Trailing crane as per approved

rigging procedure.

RW

PRIOR TO ERECTION (ROTATING EQUIPMENTS)

1 Incoming Project material

2 Calibration of testing / Checking equipments

3 Erection scheme verification (in case of heavy lift)

4 Pre Installation check

APPROVED SAFETY / REGGING PROCEDRE

PLL/ROTATING/F-02

a) As Built condition of foundation (Foundation Acceptance

Report)

HP

PLL/ROTATING/F-02

b)Identification marking, Dimensional and visual check

centre line and marking

PLL/ROTATING/F-02

c) Pad plate elevation and livel check

PLL/ROTATING/F-02

d)Check Dimension of Anchor bolt

PLL/ROTATING/F-02

e)Check pad plate for damage

PLL/ROTATING/F-02

f)Positioning of Equipment for Erection

PLL/ROTATING/F-02

g)Chipping and roughening of Pocket / top of foundation

I ) Normal

Equipment

II) Critical Equipment

HP

h) Placement of Shims (as required)

PLL/ROTATING/F-02

i) Level / elevation of base frame

PLL/ROTATING/F-03

j) Distance between coupling

PLL/ROTATING/F-06

k) Availibility of Vendor Person at site ( for Critical

Equipment )

HP

REPORT TO BE PROVIDED BY VENDER

REPRESENTATIVE

SIGN.

NAME

DATE

PLL/ROTATING/F-02

Prepared & Checked by (PLL)

Approved By (LINDE/SCEL)

Page 1 of 2

Reviewed & Approved by ( EIL)

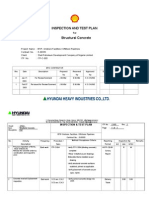

DOC No:- PLL/ROTATING/ITP/ 07

INSPECTION AND TEST PLAN FOR MECHANICAL WORKS(ROTATING)

REV 0

PROJECT:PROJECT: ERECTION OF CRACKING FURNACES DUAL FEED

CRACKER UNITProject :

WNER: M/sONGC Petro Additions Ltd.SEZ, Dahej, Gujarat, India

PMC:

M/s. ENGINEERS INDIA LTD

Sub.Contractor : M/s. PUNJ LLOYD LTD

Sl.

No.

Activity Description

PLL

LINDE/SECL

EIL

Documents

a) Coupling Hubs installation

PLL/ROTATING/F-06

b) Soft foot

PLL/ROTATING/F-06

c) Coupling alignment

PLL/ROTATING/F-06

d) Release for grouting (critical equipment )

HP

HP

PLL/ROTATING/F-04

a) Grouting material

HP

PLL/ROTATING/F-05

b) Grouting Clearance

PLL/ROTATING/F-05

c) Curing of Grout.

PLL/ROTATING/F-05

d) Temperature check during grouting

PLL/ROTATING/F-05

e) Lab testing (if any )

PLL/ROTATING/F-05

a) Parallelism / Squareness

PLL/ROTATING/F-06

b) Clearance

PLL/ROTATING/F-06

c) Concentricity

PLL/ROTATING/F-06

a) Soft foot

PLL/ROTATING/F-06

b) Check Distence Between Shaft Ends (DBSE)

PLL/ROTATING/F-06

c) Coupling alignment (without piping )

PLL/ROTATING/F-06

d ) Coupling alignment (with piping )

HP

PLL/ROTATING/F-06

e) Al protection and sefety guard installation.

PLL/ROTATING/F-06

f) Bolt Tightening Equipment and connected piping.

PLL/ROTATING/F-06

g)Boxing - Up

HP

HP

PLL/ROTATING/F-07

h) No load Run of Motors

HP

ELECTRICAL ITP FORMET WILL APPLY

i) Re-Coupling of motors & Reconfirmation f Alignment

HP

PLL/ROTATING/F-06

ALIGNMENT

1 Priliminary Alignment (before grouting)

2 Grouting works

3 Flange alignment

4 Flange alignment (after piping , hydro test,& solo run test)

LEGEND-

W : Witness point

RW : Random Witness

HP : HOLD POINT

S : Surviellance

: 100% Examination by Contractor

SIGN.

NAME

DATE

Prepared & Checked by (PLL)

Approved By (LINDE/SCEL)

Reviewed & Approved by ( EIL)

Page 2 of 2

Вам также может понравиться

- A Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsДокумент4 страницыA Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsGaapchu100% (2)

- Welder Test Param19!03!201211Документ151 страницаWelder Test Param19!03!201211VapaVapaОценок пока нет

- 003 ITP UG PipingДокумент4 страницы003 ITP UG Pipingrvsingh70100% (1)

- Al-Uqlah Central Processing Facility Water Level & Settlement TableДокумент12 страницAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaОценок пока нет

- WPS - Smaw - 2Документ6 страницWPS - Smaw - 2Harkesh RajputОценок пока нет

- Itp For InsulationДокумент14 страницItp For InsulationHytham El-NoubyОценок пока нет

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDДокумент10 страницFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- ITP Heat ExchangerДокумент1 страницаITP Heat Exchangersarmad009Оценок пока нет

- Steel TankДокумент4 страницыSteel TankRanu JanuarОценок пока нет

- Site Inspection Test PlanДокумент24 страницыSite Inspection Test Planprabu palaniswamyОценок пока нет

- Inspection and Test Plan Piping Works Main Deck, Service Platform, Module, EtcДокумент3 страницыInspection and Test Plan Piping Works Main Deck, Service Platform, Module, Etcaditya kokoОценок пока нет

- Itp PipingДокумент4 страницыItp PipingkennethОценок пока нет

- Hindustan Petroleum Standard Piping Inspection Test PlanДокумент6 страницHindustan Petroleum Standard Piping Inspection Test Planمحمد أزها نو الدينОценок пока нет

- ITP For CW and ACW Piping WorkДокумент8 страницITP For CW and ACW Piping WorkPhong DoОценок пока нет

- QC FORMДокумент3 страницыQC FORMRicardo LourençoОценок пока нет

- Fit Up & Weld VisualДокумент2 страницыFit Up & Weld VisualBhanu Pratap ChoudhuryОценок пока нет

- ITP For Steel Structure1Документ3 страницыITP For Steel Structure1吴兴泊Оценок пока нет

- Inspection & Test Plan for Chilled Water Expansion TanksДокумент1 страницаInspection & Test Plan for Chilled Water Expansion TanksvictorОценок пока нет

- Material Inspection Report: Project Name Date InspДокумент22 страницыMaterial Inspection Report: Project Name Date InspRafiqKuОценок пока нет

- Itp - Tanks - 01Документ10 страницItp - Tanks - 01ravigurajapuОценок пока нет

- ARCC Hydrotest Packages Summary ReportДокумент4 страницыARCC Hydrotest Packages Summary ReportSiddiqui Abdul KhaliqОценок пока нет

- FInal QAP HDPE WeldingДокумент2 страницыFInal QAP HDPE Weldingkannagi198Оценок пока нет

- Elding Rocedure Pecification: 7200-HDPE Butt WeldДокумент2 страницыElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifОценок пока нет

- Inspection Test Plan (Itp) at Shop: Remark No DescriptionДокумент2 страницыInspection Test Plan (Itp) at Shop: Remark No Descriptionanang_pri100% (1)

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalДокумент5 страницSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinОценок пока нет

- Tins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)Документ4 страницыTins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)achusanachuОценок пока нет

- J910-DH02-P10ZEN-040007 - (AHF) Field ITP For Bund Wall Work For Ash Handling Facilities - Rev.AДокумент18 страницJ910-DH02-P10ZEN-040007 - (AHF) Field ITP For Bund Wall Work For Ash Handling Facilities - Rev.Arudi sarifudinОценок пока нет

- Piping Inspection and Test PlanДокумент22 страницыPiping Inspection and Test PlanHaythem Ben Zid100% (1)

- Sample # 1Документ3 страницыSample # 1Clarence Ferro100% (1)

- ITP C 005 (Structural Concrete)Документ4 страницыITP C 005 (Structural Concrete)segun ajibolaОценок пока нет

- Procedure For DYE PENETRANT TestingДокумент10 страницProcedure For DYE PENETRANT TestingKarrar Talib100% (1)

- 62-P-90Rev A Method Statement For Oxygen Line FabricationДокумент13 страниц62-P-90Rev A Method Statement For Oxygen Line FabricationAsadAliAliОценок пока нет

- Cable Tray InstallationДокумент1 страницаCable Tray InstallationNaeemОценок пока нет

- Precision Storage Vessels PVT LTD: Pressure Test ReportДокумент2 страницыPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- Pt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and ErectionДокумент5 страницPt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and Erectioneldobie3100% (1)

- Larsen & Toubro underground piping inspection planДокумент4 страницыLarsen & Toubro underground piping inspection planBhavani PrasadОценок пока нет

- ITP-SV-M-FAN-CENTRIFUGAL&AXIALДокумент7 страницITP-SV-M-FAN-CENTRIFUGAL&AXIALgauravamberkarОценок пока нет

- Inspection Test Plan (Itp) : Mobile Fire ExtinguisherДокумент4 страницыInspection Test Plan (Itp) : Mobile Fire Extinguisher87482127Оценок пока нет

- Checklist For Fabrication & Erection of Structural Steel WorkДокумент1 страницаChecklist For Fabrication & Erection of Structural Steel Workbetelehem hailuОценок пока нет

- ITP - (Pressure Testing Piping) PDFДокумент3 страницыITP - (Pressure Testing Piping) PDFSUNNY BOSS100% (1)

- Qality Assurance Inspection and Test Plan: Piping Fabrication & InstallationДокумент16 страницQality Assurance Inspection and Test Plan: Piping Fabrication & Installationmanoj thakkarОценок пока нет

- Ug PipingДокумент1 страницаUg PipingVinoth KumarОценок пока нет

- FM-16 Material Verification RecordДокумент1 страницаFM-16 Material Verification RecordBleep NewsОценок пока нет

- Natural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at ShopДокумент3 страницыNatural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at Shopanang_priОценок пока нет

- ITP - OF - Structural Work FOR PARADEEPДокумент4 страницыITP - OF - Structural Work FOR PARADEEPRajeev KumarОценок пока нет

- JK Pipeline Welding & Installation Traceability Procedure CoДокумент1 страницаJK Pipeline Welding & Installation Traceability Procedure Cogst ajahОценок пока нет

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionДокумент1 страницаPunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoОценок пока нет

- Storage Tank Foundation Settlement Quality Control and Inspection Report FormДокумент1 страницаStorage Tank Foundation Settlement Quality Control and Inspection Report FormKhepa BabaОценок пока нет

- ITP For Pipeline (Sampel)Документ5 страницITP For Pipeline (Sampel)Reza RkndОценок пока нет

- Dayang Enterprise Sdn. BHD.: Inspection and Test Plan (Instrument)Документ2 страницыDayang Enterprise Sdn. BHD.: Inspection and Test Plan (Instrument)AmyОценок пока нет

- Inspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksДокумент9 страницInspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksDelta akathehuskyОценок пока нет

- WP 11 Corrosion Protection Tape CoatingДокумент3 страницыWP 11 Corrosion Protection Tape CoatingKarthikОценок пока нет

- ITP SampleДокумент2 страницыITP Sampleeiman_zerep50% (2)

- Bolt Tightening ReportДокумент2 страницыBolt Tightening Reportmujahed_muhammedОценок пока нет

- Itp For Storage TanksДокумент7 страницItp For Storage TanksHamid MansouriОценок пока нет

- Bus Duct Inspection Test PlanДокумент2 страницыBus Duct Inspection Test PlankamlОценок пока нет

- HDPE Butt Fusion Weld Inspection and Imaging PDFДокумент19 страницHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdОценок пока нет

- 02 MechanicalДокумент44 страницы02 MechanicalSigit Bintan100% (1)

- Installation of Cranes in PS-17Документ18 страницInstallation of Cranes in PS-17Ijaz Mh100% (7)

- Carbon Monoxide Co Gas Detectors GcoДокумент7 страницCarbon Monoxide Co Gas Detectors Gcoabdul azizОценок пока нет

- Check List ElectricalДокумент40 страницCheck List Electricalabdul azizОценок пока нет

- Oman Electric RulesДокумент83 страницыOman Electric RulesAyoo PcpОценок пока нет

- Autocad ShortcutsДокумент13 страницAutocad ShortcutsKriscel CaraanОценок пока нет

- LANDYS-GYR Catalog Sheet T550 UH50 enДокумент21 страницаLANDYS-GYR Catalog Sheet T550 UH50 enabdul azizОценок пока нет

- Heat LoadДокумент53 страницыHeat Loadabdul azizОценок пока нет

- Substation 3Документ1 страницаSubstation 3abdul azizОценок пока нет

- Material Index - LGДокумент37 страницMaterial Index - LGabdul azizОценок пока нет

- CHW Method Statement of FlushingДокумент5 страницCHW Method Statement of FlushingNaiyer Karimi100% (1)

- QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.Документ6 страницQCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.abdul aziz100% (1)

- R22 Wall Split Unit 1.5 TR Nominal Model MS GF 18 VC + MU GF 18 VCДокумент2 страницыR22 Wall Split Unit 1.5 TR Nominal Model MS GF 18 VC + MU GF 18 VCabdul azizОценок пока нет

- Heat Exchanger InspectionДокумент43 страницыHeat Exchanger Inspectionabdul aziz100% (6)

- Heat Exchanger InspectionДокумент43 страницыHeat Exchanger Inspectionabdul aziz100% (6)

- RT Procedure 200-004 Rev. 07Документ33 страницыRT Procedure 200-004 Rev. 07abdul aziz67% (6)

- Candidate Nebosh PaperreportДокумент14 страницCandidate Nebosh Paperreportabdul azizОценок пока нет

- Inspection & Test Plans 1 of 50Документ49 страницInspection & Test Plans 1 of 50abdul azizОценок пока нет

- Compressor Train PDFДокумент1 страницаCompressor Train PDFabdul azizОценок пока нет

- Ganga Pollution CasesДокумент3 страницыGanga Pollution CasesRuchita KaundalОценок пока нет

- Theoretical Framework for Measuring Job Satisfaction (SampleДокумент4 страницыTheoretical Framework for Measuring Job Satisfaction (SampleJoseEdgarNolascoLucesОценок пока нет

- Chemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsДокумент5 страницChemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsShalini KumariОценок пока нет

- Three Little PigsДокумент9 страницThree Little PigsrОценок пока нет

- Moot CourtДокумент7 страницMoot CourtsushmaОценок пока нет

- Adrv9008 1Документ68 страницAdrv9008 1doubleОценок пока нет

- Fuel System D28Документ4 страницыFuel System D28Ian MuhammadОценок пока нет

- 1 6Документ58 страниц1 6Emiliano.Armando Aguilera.Vázquez100% (1)

- Supplementary Feeding ProgramДокумент2 страницыSupplementary Feeding ProgramVictor Anthony CuaresmaОценок пока нет

- Two-day workshop budgetДокумент2 страницыTwo-day workshop budgetVishwanath BaliОценок пока нет

- 2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryДокумент5 страниц2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryJulio Cesar Velasco CastroОценок пока нет

- Single Inlet Centrifugal FanДокумент43 страницыSingle Inlet Centrifugal Fan4uengineerОценок пока нет

- Nabertherm RHTH Tube Furnace SOPДокумент4 страницыNabertherm RHTH Tube Furnace SOPIyere PatrickОценок пока нет

- Project Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.Документ6 страницProject Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.EIRI Board of Consultants and Publishers0% (1)

- Dialectical Behavior Therapy With Adolescents - Settings, Treatments, and DiagnosesДокумент254 страницыDialectical Behavior Therapy With Adolescents - Settings, Treatments, and DiagnosesAlguém100% (2)

- Materi Bahasa Inggris Kelas 9 - LabelsДокумент12 страницMateri Bahasa Inggris Kelas 9 - LabelsEnglish Is fun67% (3)

- Brian Cody Mcgonegal ResumeДокумент2 страницыBrian Cody Mcgonegal Resumeapi-348833348Оценок пока нет

- Narrative Poetry 6305Документ14 страницNarrative Poetry 6305Siti AisyahОценок пока нет

- Effects of Sucrose Concentration On Cell Respiration in YeastДокумент7 страницEffects of Sucrose Concentration On Cell Respiration in YeastRachel Utomo83% (23)

- Microeconomics 5th Edition Hubbard Solutions Manual 1Документ23 страницыMicroeconomics 5th Edition Hubbard Solutions Manual 1christina100% (48)

- P1007 PPPS For Raw Milk 1AR SD3 Cheese Risk AssessmentДокумент304 страницыP1007 PPPS For Raw Milk 1AR SD3 Cheese Risk AssessmentNicholasОценок пока нет

- Human Resource Management: Submitted By: Group # 6 Submitted To: Sir Usama NajamДокумент23 страницыHuman Resource Management: Submitted By: Group # 6 Submitted To: Sir Usama NajamkamranОценок пока нет

- Asian Organized CrimeДокумент17 страницAsian Organized CrimeMagr EscaОценок пока нет

- What is Intermodulation InterferenceДокумент3 страницыWhat is Intermodulation InterferencedekcarcОценок пока нет

- Ethics and Disasters: Patricia Reynolds Director, Bishopric Medical Library Sarasota Memorial Hospital Sarasota, FLДокумент61 страницаEthics and Disasters: Patricia Reynolds Director, Bishopric Medical Library Sarasota Memorial Hospital Sarasota, FLChandra Prakash JainОценок пока нет

- EMAAR HOUSING HVAC SYSTEM SPECIFICATIONSДокумент91 страницаEMAAR HOUSING HVAC SYSTEM SPECIFICATIONSBhuvan BajajОценок пока нет

- Technical Information Bulletins Ajax # 010717Документ28 страницTechnical Information Bulletins Ajax # 010717harley florezОценок пока нет

- PRC 2017 Annual Report ENДокумент88 страницPRC 2017 Annual Report ENmuhammad suryadiОценок пока нет

- DaloДокумент2 страницыDalojosua tuisawauОценок пока нет

- Personal Development: Quarter 1 - Module 5: Developmental Tasks and Challenges of AdolescenceДокумент16 страницPersonal Development: Quarter 1 - Module 5: Developmental Tasks and Challenges of AdolescenceMary Joy CejalboОценок пока нет