Академический Документы

Профессиональный Документы

Культура Документы

Shaft Calculation

Загружено:

Waris La Joi WakatobiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Shaft Calculation

Загружено:

Waris La Joi WakatobiАвторское право:

Доступные форматы

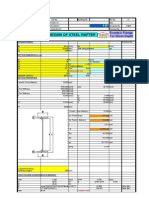

Shaft calculation

Shaft design and calculation

i

ii

Clear table of results

Check lines:7.4;7.5;

Informace

Project information

o projektu

Author

Date

Project No.

PT. Bangun Arta Hutama

26/05/2015

111-111

File name

shaft_01.xls

Project Name

Head Shaft Calculation Chain Feeder

Basic Info

Shaft: L = 2300 , Dmax. = 130 , Mat: (Rm/Su) = 1100 [MPa]

Project Notes

Comments

?

1.0

Input sectinon

Preliminary shaft diameter design

SI Units (N, mm, kW)

1.1 Calculation units

1.2 Transmitted power

1.4 Torsion moment

56,4

[/min]

18625,89

[Nm]

128,69

[mm]

1.5 Preliminary min. diameter

2.0

[kW]

110,00

1.3 Shaft speed

1.6 Type of shaft load

BStatic torsion + bending

1.7 Material of the shaft

C...High-strength structural steel (1200)

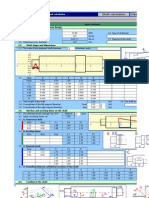

Shaft shape and dimensions

2.1 The scale of the displayed shaft diameter.

SI Units (N, mm, kW)

Calculation units

800

600

400

200

0

-500

-200 0

500

1000

1500

2000

2500

-400

-600

-800

2.2

Table

10

Origin

0,00

450,00

621,00

1459,00

1630,00

2300,00

2300,00

2300,00

2300,00

2300,00

450,000

171,000

838,000

171,000

670,000

Da

100,000

100,000

130,000

130,000

100,000

Db

100,000

130,000

130,000

100,000

100,000

da

0,000

0,000

0,000

0,000

0,000

db

0,000

0,000

0,000

0,000

0,000

0,000

0,000

0,000

0,000

2.3 Total length of the shaft

2.4 X-coordinate of the left support (bearing)

[mm]

Fixed

140,00

[mm]

Free

1940,00

[mm]

2.5 X-coordinate of the right support (bearing)

3.0

0,000

2300,00

2.6 The shaft surface (Roughness Ra)

CGround (0,8)

Notches and necking-down on the shaft

3.1 The ultimate tensile strength (Su, Rm)

3.2 Notch sensitivity factor (q)

1100,0

[MPa]

0,8

3.3 A. Transverse hole

X[mm]

d[mm]

bc

bb

bt

1,00

1,00

1,00

1,00

1,00

1,00

-500

3.4 B. Necking-down

X[mm]

d[mm]

r[mm]

bc

bb

bt

1,00

1,00

1,00

1,00

1,00

1,00

1,00

1,00

1,00

3.5 C. General notch

X[mm]

b[mm]

bc

bb

bt

330,00

120,00

1,86

1,86

2,32

Keyway (slotting cutter)

1630,00

120,00

1,86

1,86

2,32

Keyway (slotting cutter)

2110,00

180,00

2,38

2,38

2,32

Keyway (end mill)

500

1000

1500

2000

2500

1,00

1,00

1,00

User values

1,00

1,00

1,00

User values

3.6 D. Rounding between cylindrical sections of the shaft

1

bc

1,00

1,00

1,00

1,00

1,00

1,00

1,00

1,00

1,00

bb

1,00

1,00

1,00

1,00

1,00

1,00

1,00

1,00

1,00

bt

1,00

1,00

1,00

1,00

1,00

1,00

1,00

1,00

1,00

4.0

Loading of the shaft

-500

500

4.1 Loading

1000

Fx

[mm]

[N]

1500

alfa

2000

Mt

Mb

[]

390,00

1963,0

52508,5

1690,00

1963,0

52508,5

2300,00

0,0

0,0

[Nm]

9312,95

13392,00

9312,95

13392,00

-18625,89

0,00

2500

alfa

alfa

[]

[N/mm]

[mm]

[]

4

5

6

7

8

9

10

5.0

Rotating masses

5.1 Additional rotating masses (resonance speed)

Yes

5.2 Use loading from the weight of disks in the calculation?

5.3

[mm]

Ro

[kg/m^3]

[kg]

M1

100,00

200,00

100,00

80,00

7800,0

14,70

M2

1800,00

200,00

100,00

80,00

7800,0

14,70

M3

0,00

0,00

0,00

0,00

7800,0

0,00

M4

0,00

0,00

0,00

0,00

7800,0

0,00

M5

0,00

0,00

0,00

0,00

7800,0

0,00

6.0

Material and the type of loading

6.1 Shaft material (Ultimate tensile strength min-max)

CCase-hardened steel (700 - 1200)

1100

6.17 Dead load

No

10

1100

[MPa]

[MPa]

6.18 Max. displayed coefficient of safety

6.19 Stress ratio factor

a0

6.3 Yield strength in tension

Su/Rm

SY/Re

800

[MPa]

6.20 Coefficient of maximum loading

6.4 Yield strength in bending

SYb/Reb

858

[MPa]

6.21 Bending

1,50

6.5 Yield strength in shear

SYs/Res

400

[MPa]

6.22 Radial load

1,50

6.23 Torsion

1,50

1,50

6.2 Ultimate tensile strength

6.6 For reversed loading

6.7 Fatigue limit - tension-pressure

6.8 Fatigue limit - bending

6.9 Fatigue limit - torsion

sC

seC

462

506

[MPa]

[MPa]

6.24 Tension/Compression

6.25 Loading conditions

tC

330

[MPa]

6.26 Loading from bending moment

AStatic

6.27 Loading from radial force

AStatic

6.10 For cyclic loading

6.11 Fatigue limit - tension-pressure

6.12 Fatigue limit - bending

6.13 Fatigue limit - torsion

10

1,15

shC

sehC

thC

693

[MPa]

6.28 Load from torsional moment

BRepeated

759

429

[MPa]

[MPa]

6.29 Loading from tension/pressure force

6.30 Dynamic strength check

AStatic

Ro

7850,0

[kg/m^3]

6.31 Impact from shaft surface

Yes

6.15 Modulus of elasticity in tension

210000

[MPa]

6.32 Impact from shaft size

Yes

6.16 Modulus of elasticity in shear

80000

[MPa]

Yes

6.33 Impact from stress concentration (notch)

6.14 Specific mass

Results section

7.0

Results - summary

x

S y+z

7.17 Graph

7.1 Reaction in the support R1

-3926

-8,967E-08 -67236,462 67236,4624 [N]

15Angular deflection - Sum []

7.2 Reaction in the support R2

-8,046E-08 -37492,072 37492,0716 [N]

16Deflection - Sum [mm]

7.3 Total shaft weight

184,70

[kg]

7.4 Maximum deflection

2,3641

[mm]

7.5 Maximum angular deflection

1,2768

[]

7.6 Angular deflection in R1

0,2917

[]

7.7 Angular deflection in R2

0,3599

[]

7.8 Max. bending stress

se

ts

tt

sg

sr

252,0

[MPa]

0,25

8,8

[MPa]

0,2

99,9

[MPa]

0,5

[MPa]

272,6

[MPa]

7.13 Min. static safety

SFSt

2,07

7.14 Min. dynamic safety

SFD

7.9 Max. stress in shear

7.10 Max. stress in torsion

7.11 Max. stress in tension/pressure

7.12 Max. equivalent stress

0,3

1,5

0,15

0,1

0,5

0,05

2,26

7.15 Critical speed (A)

nc

9767,4

[/min]

Critical speed (B)

nc

4836,4

[/min]

Critical speed (C)

nc

4304,1

[/min]

7.16 Results for X co-ordinate

2,5

0,4

0,35

0

0

500

1000

1500

2000

2500

Shaft freely rotating in bearings, rotating disc between the bearings (K=1)

174,63

1371,60

16Deflection - Sum [mm]

0,15339421

2,27311

15Angular deflection - Sum []

0,28945581 0,05986012 0,06804186 0,35988841 0,35988841 0,35988841 0,35988841 0,35988841

17Bending stress - Sum [MPa]

20,7279763 83,6375459 85,2234356

18Stress in shear - Sum [MPa]

8,57713611 1,12046552 1,12046552

26Stress in torsion [MPa]

8.0

1397,00

2095,50

2127,25

2127,25

2127,25

2127,25

2,24777097 0,96109766 1,16336789 1,16336789 1,16336789 1,16336789

21,5887298 21,5887298 94,8608788 99,8535567 99,8535567 99,8535567 99,8535567

Graph - Deflection, Bending angle

8.1 Curves in graph

XZ Plane

XY Plane

Sum

Deflection [mm]

3

2

200

0,4

180

0,3

160

140

120

0

100

0

500

1000

1500

2000

-1

250080

60

40

-2

20

-3

9.0

Angle

Bending angle []

200

180

160

0,2

140

0,1

120

-0,1

100

0

500

1000

1500

2000

250080

60

-0,2

40

-0,3

20

-0,4

Graph - Bending moment, Bending stress

9.1 Curves in graph

XZ Plane

XY Plane

Sum

Bending moment [Nm]

Angle

Bending stress [MPa]

30000

400

350

20000

300

400

350

200

300

10000

250

200

0

500

1000

1500

-10000

2000

2500

150

300

100

50

-30000

10.0

Graph - Radial force, Stress in shear

200

0

-100

100

-20000

250

0

500

1000

1500

2000

2500

150

100

-200

-300

50

0

10.1 Curves in graph

XZ Plane

XY Plane

Sum

Radial force [N]

80000

400

60000

350

40000

300

20000

250

0

-20000

200

500

1000

1500

2000

2500

150

-40000

100

-60000

50

-80000

11.0

Angle

Stress in shear [MPa]

10

400

350

300

250

2

0

200

-2 0

500

1000

1500

2000

2500

-4

100

-6

50

-8

-10

Graph - Axial force, Torsional moment

Tensile-Compressive stress [MPa]

Axial force [N]

0,6

4500

4000

0,5

3500

0,4

3000

2500

0,3

2000

0,2

1500

1000

0,1

500

0

0

12.0

500

1000

1500

2000

Stress in torsion [MPa]

Torsional moment [Nm]

120

20000

18000

100

16000

14000

80

12000

60

10000

8000

40

6000

4000

20

2000

0

2500

0

0

500

1000

1500

2000

2500

Graph - Torsional angle, Reduced stress, Safety coeficient

Reduced stress [MPa]

Torsional angle []

300

1,4

250

1,2

Dynamic safety

Static safety

12

12

10

10

0,6

0,4

200

0,8

150

100

50

0,2

2

0

13.0

150

500

1000

1500

Graphical output, CAD systems

2000

2500

500

1000

1500

2000

2500

0

Вам также может понравиться

- Design and Calculation ShaftДокумент115 страницDesign and Calculation ShaftDavid Lambert100% (3)

- Shaft Design - Overheads PDFДокумент20 страницShaft Design - Overheads PDFRyan BaleОценок пока нет

- M 452 ContentДокумент63 страницыM 452 ContentprasannaОценок пока нет

- Technical Data: Bearing Load CalculationДокумент8 страницTechnical Data: Bearing Load Calculationmac_devОценок пока нет

- Shaft CalculationsДокумент11 страницShaft Calculationscena3135Оценок пока нет

- Lecture 8 Shaft DesignДокумент65 страницLecture 8 Shaft DesignYasir A. Al-ShataifОценок пока нет

- IS 9178 - Part 3 PDFДокумент75 страницIS 9178 - Part 3 PDFSOURAVОценок пока нет

- Belt Conveyor CalculationДокумент8 страницBelt Conveyor CalculationFarrahxviiiОценок пока нет

- Planetary Gearbox CalculationsДокумент3 страницыPlanetary Gearbox CalculationsChinnuClansОценок пока нет

- Rexnord Power Transmission FormulasДокумент1 страницаRexnord Power Transmission FormulasDeividi CardosoОценок пока нет

- Machine Design Project ReportДокумент11 страницMachine Design Project ReportMuhammad Abdullah100% (1)

- Screw Jack CalculationsДокумент6 страницScrew Jack CalculationsDaniel SherwinОценок пока нет

- Hoist - Lifting Screw JackДокумент10 страницHoist - Lifting Screw JackAh Leng LauОценок пока нет

- Estimate weight and compressive force calculationsДокумент2 страницыEstimate weight and compressive force calculationsAmi PutraОценок пока нет

- ME307-11 Tutorial 9Документ9 страницME307-11 Tutorial 9Mohammed A IsaОценок пока нет

- Reference Notation Description: 1.bottom Plate ThicknessДокумент6 страницReference Notation Description: 1.bottom Plate ThicknessSakib RafeeОценок пока нет

- Shaft Torsion 1Документ2 страницыShaft Torsion 1neelОценок пока нет

- Conveyor Design Summary: Coal Bituminous 50 Mesh 870 800 45 30Документ47 страницConveyor Design Summary: Coal Bituminous 50 Mesh 870 800 45 30Boy AlfredoОценок пока нет

- Shaft Component Generator Results SEOДокумент7 страницShaft Component Generator Results SEOWaris La Joi WakatobiОценок пока нет

- Shaft CalculationДокумент4 страницыShaft Calculationksangeeth2000Оценок пока нет

- Synechron: Customer Name Date Created byДокумент1 страницаSynechron: Customer Name Date Created byneelОценок пока нет

- Calculate motor power for 35t LRF transfer carДокумент2 страницыCalculate motor power for 35t LRF transfer carmech_abhiОценок пока нет

- Process of Selection and Example of SelectionДокумент8 страницProcess of Selection and Example of Selectionarvi_vinОценок пока нет

- M 275 ContentДокумент40 страницM 275 ContentAnonymous DQ4wYUmОценок пока нет

- Calculation - Bolt SizeДокумент1 страницаCalculation - Bolt Sizemimi_chan_17100% (1)

- Conveyor CalculationДокумент48 страницConveyor CalculationearthplightОценок пока нет

- Annexure - Bolt Torque CalculationДокумент4 страницыAnnexure - Bolt Torque CalculationDarshan Panchal100% (1)

- Power ScrewДокумент21 страницаPower Screwstruc-engОценок пока нет

- Design and Fabrication of Pneumatic Crane StartДокумент6 страницDesign and Fabrication of Pneumatic Crane StartHimani MahetaОценок пока нет

- Spur Gear DesignДокумент3 страницыSpur Gear DesignThirumalaimuthukumaranMohan100% (1)

- RP11LДокумент18 страницRP11Lمحمد جوادОценок пока нет

- Gantry Crane Load r2Документ12 страницGantry Crane Load r2Bang OchimОценок пока нет

- Agitator Guide for Mixing and Stirring Tank ProductsДокумент10 страницAgitator Guide for Mixing and Stirring Tank Productsagrocel_bhv5591Оценок пока нет

- Design Calculations for Worm & Worm Gear Endurance StrengthДокумент9 страницDesign Calculations for Worm & Worm Gear Endurance StrengthVenkateswaran venkateswaranОценок пока нет

- Spreaer Beam&Lifting Line Beam p5Документ2 страницыSpreaer Beam&Lifting Line Beam p5Sabrang LorОценок пока нет

- Shaft Stress CalculationsДокумент2 страницыShaft Stress CalculationsVivek PrajapatiОценок пока нет

- Chain Drive: NO. of Teeths On Driving Sprocket No. of Teeths On Driven Sprocket Engine Power Service FactorДокумент3 страницыChain Drive: NO. of Teeths On Driving Sprocket No. of Teeths On Driven Sprocket Engine Power Service FactorSUMEET SINGHОценок пока нет

- Machine Foundation-Irrigation Pump 17.6.2001Документ1 страницаMachine Foundation-Irrigation Pump 17.6.2001Prantik Adhar SamantaОценок пока нет

- Screw Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoДокумент2 страницыScrew Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoTheodoros AtheridisОценок пока нет

- Bearing CalculationДокумент4 страницыBearing CalculationAnonymous lTQDM21Оценок пока нет

- Integral Analysis of Conveyor Pulley Using ®nite Element MethodДокумент30 страницIntegral Analysis of Conveyor Pulley Using ®nite Element MethodEsteban CorderoОценок пока нет

- Apron Feeder PDFДокумент3 страницыApron Feeder PDFabdulloh_99Оценок пока нет

- Stress Analysis of Drive ShaftДокумент7 страницStress Analysis of Drive ShaftnachigansОценок пока нет

- Mechanical MaintenanceДокумент12 страницMechanical MaintenanceJoniОценок пока нет

- Belt Conveyor # 1Документ14 страницBelt Conveyor # 1hinojosa074068Оценок пока нет

- Design of Steel Rafter: Econmic Flange For Given DepthДокумент31 страницаDesign of Steel Rafter: Econmic Flange For Given DepthYusuf KardelenОценок пока нет

- Gear4 02Документ101 страницаGear4 02pratapslairОценок пока нет

- Konveyör Hesabı 7.24Документ9 страницKonveyör Hesabı 7.24Salih HasОценок пока нет

- LiftingLugStress Rev 1.5Документ20 страницLiftingLugStress Rev 1.5ilijarskОценок пока нет

- DRIVE POWER CALCULATION OF BELT CONVEYOR - GLOBAL COAL - Part 1CДокумент2 страницыDRIVE POWER CALCULATION OF BELT CONVEYOR - GLOBAL COAL - Part 1CBimal DeyОценок пока нет

- Helix Chute Design Sample Report 2Документ26 страницHelix Chute Design Sample Report 2Sergio Diaz DuarteОценок пока нет

- Spur Gear DesignДокумент2 страницыSpur Gear DesignRamji RaoОценок пока нет

- Shaft StabilityДокумент2 страницыShaft Stabilitythulasi_krishnaОценок пока нет

- Rack and PinionДокумент16 страницRack and PinionjeronimoisraelОценок пока нет

- Teague's ShaftДокумент145 страницTeague's ShaftBUDAPESОценок пока нет

- Exp. 5. Application of Information Technology in Calculating The Machine ElementsДокумент25 страницExp. 5. Application of Information Technology in Calculating The Machine ElementsBah NahОценок пока нет

- Machine-Design - Gear Shaft ProblemДокумент51 страницаMachine-Design - Gear Shaft ProblemkidseismicОценок пока нет

- BS-5950-90 Example 001Документ7 страницBS-5950-90 Example 001Win ThanОценок пока нет

- IJATES Journal PaperДокумент9 страницIJATES Journal PaperAJIT SHINDEОценок пока нет

- Machine Elements I - AMEM 316 Assignment 1: Shaft DesignДокумент67 страницMachine Elements I - AMEM 316 Assignment 1: Shaft DesignFarid Nasri100% (1)

- Technical Data Hino 700 ProfiaДокумент5 страницTechnical Data Hino 700 ProfiaWaris La Joi WakatobiОценок пока нет

- RENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSДокумент1 страницаRENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSWaris La Joi Wakatobi0% (1)

- Calc - Vibrating Screen Single Deck NPK1Документ5 страницCalc - Vibrating Screen Single Deck NPK1Waris La Joi WakatobiОценок пока нет

- Operating Instructions: BA G298 EN 08.98Документ39 страницOperating Instructions: BA G298 EN 08.98Waris La Joi WakatobiОценок пока нет

- Flexible N-EUPEXДокумент22 страницыFlexible N-EUPEXWaris La Joi WakatobiОценок пока нет

- Recommended Lubricants for Gear UnitsДокумент9 страницRecommended Lubricants for Gear UnitsWaris La Joi WakatobiОценок пока нет

- RUPEX Coupling RWNДокумент26 страницRUPEX Coupling RWNWaris La Joi WakatobiОценок пока нет

- Pulley Weight Calc PDFДокумент9 страницPulley Weight Calc PDFWaris La Joi WakatobiОценок пока нет

- Operating Instructions: BA K295 EN 06.97Документ45 страницOperating Instructions: BA K295 EN 06.97Waris La Joi WakatobiОценок пока нет

- 8702en PDFДокумент32 страницы8702en PDFWaris La Joi WakatobiОценок пока нет

- ELPEX Flexible CouplingДокумент24 страницыELPEX Flexible CouplingWaris La Joi WakatobiОценок пока нет

- N-EUPEX CouplingДокумент24 страницыN-EUPEX CouplingWaris La Joi WakatobiОценок пока нет

- Flender GearboxДокумент47 страницFlender GearboxWaris La Joi Wakatobi100% (2)

- ZAPEX CouplingДокумент22 страницыZAPEX CouplingWaris La Joi WakatobiОценок пока нет

- Recommended Lubricants for Gear UnitsДокумент9 страницRecommended Lubricants for Gear UnitsWaris La Joi WakatobiОценок пока нет

- Arpex CouplingДокумент38 страницArpex CouplingWaris La Joi WakatobiОценок пока нет

- Measuring Bulk Coal Friction on Wear PlatesДокумент8 страницMeasuring Bulk Coal Friction on Wear PlatesWaris La Joi WakatobiОценок пока нет

- Gear CouplingДокумент36 страницGear CouplingWaris La Joi WakatobiОценок пока нет

- 8703en PDFДокумент35 страниц8703en PDFWaris La Joi WakatobiОценок пока нет

- Survey of Cargo Handling ResearchДокумент95 страницSurvey of Cargo Handling ResearchWaris La Joi WakatobiОценок пока нет

- UNCTAD Review of Maritime Transport 2017 2017 10Документ130 страницUNCTAD Review of Maritime Transport 2017 2017 10Mehmet AliОценок пока нет

- SdeДокумент10 страницSderefiiiОценок пока нет

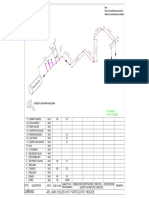

- Analisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIДокумент10 страницAnalisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIWaris La Joi WakatobiОценок пока нет

- Power LV CopperДокумент52 страницыPower LV CopperBeny Indrawan SОценок пока нет

- PARAMAX NEW Copy Rev2Документ281 страницаPARAMAX NEW Copy Rev2Waris La Joi WakatobiОценок пока нет

- Editor User's ManualДокумент60 страницEditor User's ManualWaris La Joi WakatobiОценок пока нет

- Lsis Is7 Simple Usermanual PDFДокумент255 страницLsis Is7 Simple Usermanual PDFMichael DavenportОценок пока нет

- Editor User's ManualДокумент60 страницEditor User's ManualWaris La Joi WakatobiОценок пока нет

- DPO 6 0 Enterprise ManualДокумент63 страницыDPO 6 0 Enterprise ManualWaris La Joi WakatobiОценок пока нет

- AlldocumentsДокумент8 страницAlldocumentsWaris La Joi WakatobiОценок пока нет

- Nearpeer MDCAT Physics by Prof Zia PDFДокумент309 страницNearpeer MDCAT Physics by Prof Zia PDFShoaib Yaseen80% (10)

- LIVRO An Introduction To Inverse Problems With ApplicationsДокумент255 страницLIVRO An Introduction To Inverse Problems With ApplicationsIanka Cristine100% (2)

- An Atlas of Glass-Ionomer Cements - A Clinician's Guide, 3rd EditionДокумент214 страницAn Atlas of Glass-Ionomer Cements - A Clinician's Guide, 3rd EditionCasandra Costin100% (4)

- Krytox GPL 226Документ1 страницаKrytox GPL 226Blanca MedinaОценок пока нет

- The Formula of Formulas by Periander A. EsplanaДокумент5 страницThe Formula of Formulas by Periander A. Esplanaperixmind100% (2)

- A Cheat Sheet of MathsДокумент1 страницаA Cheat Sheet of MathsaadoyeОценок пока нет

- CASE STUDY: Advanced Analysis of Reciprocating Engines, Compressors and Gas PipelinesДокумент4 страницыCASE STUDY: Advanced Analysis of Reciprocating Engines, Compressors and Gas PipelinesabdulbasitbОценок пока нет

- Power Estimation Methods For Sequential Logic Circuits: Pedram, M. DespainДокумент13 страницPower Estimation Methods For Sequential Logic Circuits: Pedram, M. DespainHeejung SoОценок пока нет

- Reliable Hot Water Piping SystemДокумент6 страницReliable Hot Water Piping SystemAzher AОценок пока нет

- For The Classes of Crystal: For Searching Project ReportsДокумент15 страницFor The Classes of Crystal: For Searching Project ReportsDhanapal PalОценок пока нет

- Atomic Spectrometer Lab Experiment AnalysisДокумент18 страницAtomic Spectrometer Lab Experiment AnalysisVickyОценок пока нет

- Framing Channels - Heavy Duty Framing System: Halfen Industrial TechnologyДокумент2 страницыFraming Channels - Heavy Duty Framing System: Halfen Industrial TechnologyJake GoodmanОценок пока нет

- Graflex xl Cameras Lenses Accessories GuideДокумент12 страницGraflex xl Cameras Lenses Accessories GuideDocОценок пока нет

- Patterned Sapphire SubstratesДокумент4 страницыPatterned Sapphire SubstratesSabri TraderОценок пока нет

- Lab 2: Estimating Avogadro's NumberДокумент4 страницыLab 2: Estimating Avogadro's NumbersabrinaОценок пока нет

- SMB101 PDFДокумент4 страницыSMB101 PDFJeya RamanОценок пока нет

- Building CollapseДокумент22 страницыBuilding CollapseManishSharmaОценок пока нет

- Chapter 1 PDFДокумент43 страницыChapter 1 PDFAbdoОценок пока нет

- Influence of The Clinker SO3 On The Cement CharacteristicsДокумент1 страницаInfluence of The Clinker SO3 On The Cement Characteristicsroshan_geo078896Оценок пока нет

- 采矿专业英语大全Документ50 страниц采矿专业英语大全Dino ChengОценок пока нет

- Ieee STD c37.06.1 - Guide For High-Voltage Circuit BreakersДокумент12 страницIeee STD c37.06.1 - Guide For High-Voltage Circuit Breakerstatacps100% (2)

- Ballistic Particle Manufacturing (BPM)Документ15 страницBallistic Particle Manufacturing (BPM)Senaka BandaraОценок пока нет

- Delhi Public School, Gandhinagar SYLLABUS - 2019-20 Class - IxДокумент12 страницDelhi Public School, Gandhinagar SYLLABUS - 2019-20 Class - IxAman MultaniОценок пока нет

- ECBC Compliance MethodsДокумент21 страницаECBC Compliance MethodsKakoli100% (2)

- ABB Cabinet B HP Auxiliary-T ProtectionДокумент91 страницаABB Cabinet B HP Auxiliary-T ProtectionJonasОценок пока нет

- Kinetic Energy Flywheel Energy StorageДокумент13 страницKinetic Energy Flywheel Energy StorageSarfarazHasanОценок пока нет

- 11 Foldable Bridge 2017 PrintДокумент48 страниц11 Foldable Bridge 2017 PrintChockalingam AthilingamОценок пока нет

- Stepper Catalog PDFДокумент36 страницStepper Catalog PDFCano VoyОценок пока нет

- 02 Clicker QuestionsДокумент41 страница02 Clicker QuestionsBouzoubaa OmarОценок пока нет

- Crane - Flow of Fluids Through Valves, Fittings and Pipe (1986) by CraneДокумент131 страницаCrane - Flow of Fluids Through Valves, Fittings and Pipe (1986) by CranesnamprogОценок пока нет