Академический Документы

Профессиональный Документы

Культура Документы

1 Input Data: Profis Anchor 2.4.6

Загружено:

Naresh KumarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1 Input Data: Profis Anchor 2.4.6

Загружено:

Naresh KumarАвторское право:

Доступные форматы

Profis Anchor 2.4.

www.hilti.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

CANAP ENGINEERING PVT LTD

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

DIESEL STORAGE

4/11/2015

Specifier's comments:

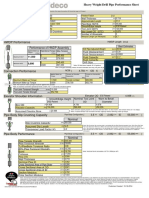

1 Input data

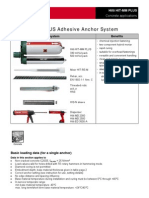

Anchor type and diameter:

HIT-HY 200 + HIT-V-F (8.8) M30

Effective embedment depth:

hef,act = 120 mm (hef,limit = - mm)

Material:

8.8

Evaluation Service Report:

ETA 11/0493

Issued I Valid:

8/8/2012 | 12/23/2016

Proof:

design method ETAG BOND (EOTA TR 029)

Stand-off installation:

without clamping (anchor); restraint level (anchor plate): 1.00; eb = 25 mm; t = 20 mm

Hilti Grout: , multipurpose, fc,Grout = 30.00 N/mm2

Anchor plate:

lx x ly x t = 270 mm x 270 mm x 20 mm; (Recommended plate thickness: not calculated)

Profile:

IPB/HEB; (L x W x T x FT) = 100 mm x 100 mm x 10 mm x 10 mm

Base material:

uncracked concrete, C40/50, fcc = 50.00 N/mm2; h = 250 mm, Temp. short/long: 40/24 C

Installation:

hammer drilled hole, installation condition: dry

Reinforcement:

no reinforcement or reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

with longitudinal edge reinforcement d >= 12

Reinforcement to control splitting according to EOTA TR 029, 5.2.2.6 present.

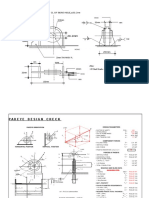

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.6

www.hilti.com

2

DIESEL STORAGE

Page:

Project:

Sub-Project I Pos. No.:

Date:

CANAP ENGINEERING PVT LTD

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

4/11/2015

2 Load case/Resulting anchor forces

Load case: Design loads

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Anchor

Tension force

Shear force

Shear force x

1

0.000

12.125

11.526

2

20.011

12.021

11.526

3

4.646

12.457

11.874

4

33.539

12.356

11.874

max. concrete compressive strain:

0.23 []

max. concrete compressive stress:

6.76 [N/mm2]

resulting tension force in (x/y)=(77/25):

58.196 [kN]

resulting compression force in (x/y)=(-100/-60): 47.066 [kN]

Shear force y

3.764

3.416

3.764

3.416

Tension

x

Compression

3 Tension load (EOTA TR 029, Section 5.2.2)

Load [kN]

33.539

Capacity [kN]

299.333

Utilization bN [%]

12

Status

OK

Combined pullout-concrete cone failure**

58.196

143.941

41

OK

Concrete Breakout Strength**

58.196

79.656

74

OK

58.196

104.814

56

OK

Steel Strength*

Splitting failure**

* anchor having the highest loading

**anchor group (anchors in tension)

3.1 Steel Strength

NRk,s [kN]

449.000

gM,s

1.500

NRd,s [kN]

299.333

NSd [kN]

33.539

3.2 Combined pullout-concrete cone failure

Ap,N [mm2]

244800

A0p,N [mm2]

129600

2

tRk,ucr,25 [N/mm ]

15.00

scr,Np [mm]

360

ccr,Np [mm]

180

yc

1.000

2

tRk,ucr [N/mm ]

15.00

k

3.200

yg,Np

1.000

yg,Np

1.000

ec1,N [mm]

41

yec1,Np

0.816

ec2,N [mm]

2

yec2,Np

0.991

ys,Np

1.000

N0Rk,p [kN]

169.646

NRk,p [kN]

259.093

gM,p

1.800

NRd,p [kN]

143.941

NSd [kN]

58.196

cmin [mm]

yre,Np

1.000

3.3 Concrete Breakout Strength

Ac,N [mm2]

244800

A0c,N [mm2]

129600

ccr,N [mm]

180

scr,N [mm]

360

ec1,N [mm]

41

yec1,N

0.816

ec2,N [mm]

2

yec2,N

0.991

N0Rk,c [kN]

93.881

gM,c

1.800

NRd,c [kN]

79.656

NSd [kN]

58.196

Ac,N [mm2]

134400

A0c,N [mm2]

57600

ccr,sp [mm]

120

scr,sp [mm]

240

yh,sp

1.169

ec1,N [mm]

41

yec1,N

0.747

ec2,N [mm]

2

yec2,N

0.986

ys,N

1.000

N0Rk,c [kN]

93.881

gM,sp

1.800

NRd,sp [kN]

104.814

NSd [kN]

58.196

ys,N

1.000

yre,N

1.000

k1

10.100

yre,N

1.000

k1

10.100

3.4 Splitting failure

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.6

www.hilti.com

Page:

Project:

Sub-Project I Pos. No.:

Date:

CANAP ENGINEERING PVT LTD

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

3

DIESEL STORAGE

4/11/2015

4 Shear load (EOTA TR 029, Section 5.2.3)

Load [kN]

N/A

Steel Strength (without lever arm)*

Capacity [kN]

N/A

Utilization bV [%]

N/A

Status

N/A

OK

Steel failure (with lever arm)*

12.356

25.559

49

Pryout Strength**

48.954

257.088

20

OK

N/A

N/A

N/A

N/A

Concrete edge failure in direction **

* anchor having the highest loading

**anchor group (relevant anchors)

4.1 Steel failure (with lever arm)

l [mm]

50

aM

1.00

NSd / NRd,s

0.112

1 - NSd / NRd,s

0.888

M0Rk [kNm]

1.799

VM

Rk,s = aM * MRk,s / l [kN]

31.949

MRk,s = M0Rk,s (1 - NSd/NRd,s) [kNm]

1.597

gMs,b,V

1.250

VM

Rd,s [kN]

25.559

VSd [kN]

12.356

4.2 Pryout Strength (Concrete Breakout Strength controls)

Ac,N [mm2]

270400

A0c,N [mm2]

129600

ccr,N [mm]

180

scr,N [mm]

360

k-factor

2.000

k1

10.100

ec1,V [mm]

1

yec1,N

0.996

ec2,V [mm]

2

yec2,N

0.988

ys,N

1.000

yre,N

1.000

gM,c,p

1.500

VRd,c1 [kN]

257.088

VSd [kN]

48.954

N0Rk,c [kN]

93.881

5 Combined tension and shear loads (EOTA TR 029, Section 5.2.4)

bN

0.731

a

bV

0.483

a

1.500

Utilization bN,V [%]

97

Status

OK

bN + bV <= 1

6 Displacements (highest loaded anchor)

Short term loading:

NSk

24.844 [kN]

dN

0.176 [mm]

VSk

9.152 [kN]

dV

0.275 [mm]

dNV

0.326 [mm]

Long term loading:

NSk

24.844 [kN]

dN

0.351 [mm]

VSk

9.152 [kN]

dV

0.458 [mm]

dNV

0.577 [mm]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements

are valid without friction between the concrete and the anchor plate! The gap due to the drilled hole and clearance hole tolerances are not

included in this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.6

www.hilti.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

CANAP ENGINEERING PVT LTD

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

4

DIESEL STORAGE

4/11/2015

7 Warnings

To avoid failure of the anchor plate the required thickness can be calculated in PROFIS Anchor. Load re-distributions on the anchors due to

elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be sufficiently stiff, in order not to be deformed

when subjected to the loading!

Checking the transfer of loads into the base material is required in accordance with EOTA TR 029, Section 7!

The design is only valid if the clearance hole in the fixture is not larger than the value given in Table 4.1 of EOTA TR029! For larger

diameters of the clearance hole see Chapter 1.1. of EOTA TR029!

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to

be followed to ensure a proper installation.

Bore hole cleaning must be performed according to instructions for use (blow twice with oil-free compressed air (min. 6 bar), brush twice,

blow twice with oil-free compressed air (min. 6 bar)).

Characteristic bond resistances depend on short- and long-term temperatures.

Please contact Hilti to check feasibility of HIT-V rod supply.

Edge reinforcement is not required to avoid splitting failure

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.6

www.hilti.com

Page:

Project:

Sub-Project I Pos. No.:

Date:

CANAP ENGINEERING PVT LTD

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

5

DIESEL STORAGE

4/11/2015

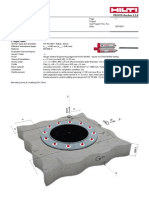

8 Installation data

Anchor plate, steel: Profile: IPB/HEB; 100 x 100 x 10 x 10 mm

Hole diameter in the fixture: df = 33 mm

Plate thickness (input): 20 mm

Recommended plate thickness: not calculated

Cleaning: Premium cleaning of the drilled hole is required

Anchor type and diameter: HIT-HY 200 + HIT-V-F (8.8), M30

Installation torque: 0.300 kNm

Hole diameter in the base material: 35 mm

Hole depth in the base material: 120 mm

Minimum thickness of the base material: 190 mm

8.1 Required accessories

Cleaning

Compressed air with required

accessories to blow from the bottom of

the hole

Proper diameter wire brush

y

Drilling

Suitable Rotary Hammer

Properly sized drill bit

135

55

135

Setting

Dispenser including cassette and mixer

Torque wrench

160

135

135

55

65

160

Coordinates Anchor [mm]

Anchor

1

2

3

4

x

-70

90

-70

90

y

-80

-80

80

80

c-x

-

c+x

-

c-y

-

c+y

-

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

45

Profis Anchor 2.4.6

www.hilti.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

CANAP ENGINEERING PVT LTD

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

6

DIESEL STORAGE

4/11/2015

9 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Вам также может понравиться

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- M2-CV-RC-D-005 (R1)Документ22 страницыM2-CV-RC-D-005 (R1)ksshashidharОценок пока нет

- Session 2 - 01 (Energy Efficiency Potential Assessment of Chandrapura TPS, DVC)Документ52 страницыSession 2 - 01 (Energy Efficiency Potential Assessment of Chandrapura TPS, DVC)pkumarОценок пока нет

- Redken Shades EQ Color Chart 02 PDFДокумент28 страницRedken Shades EQ Color Chart 02 PDFHailey MarieОценок пока нет

- Body Flange FEAДокумент19 страницBody Flange FEANaresh KumarОценок пока нет

- Padeye - SkidДокумент16 страницPadeye - SkidNaresh Kumar100% (1)

- HeavyWeight 3.5 25.58lbs NC-38Документ3 страницыHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаОценок пока нет

- PE D Vi10 422.023 ME CAL 001 01 E - Calculation Sheet Acc. en 14015 - VAR - 3Документ33 страницыPE D Vi10 422.023 ME CAL 001 01 E - Calculation Sheet Acc. en 14015 - VAR - 3Virginia Elena Iordache67% (3)

- 1 Input Data: Profis Anchor 2.2.4Документ6 страниц1 Input Data: Profis Anchor 2.2.4Safiueddin A. SafiueddinОценок пока нет

- Offcon DNV Zorro SkidДокумент7 страницOffcon DNV Zorro SkidRAMSINGH CHAUHANОценок пока нет

- 1 Input Data: WWW - HiltiДокумент5 страниц1 Input Data: WWW - HiltiCibotaru MihaiОценок пока нет

- Beam Splice Connection Calculation - (Bolted)Документ9 страницBeam Splice Connection Calculation - (Bolted)Naresh KumarОценок пока нет

- Hilti - Profis Anchor Design Report 594Документ5 страницHilti - Profis Anchor Design Report 594Madhu GuptaОценок пока нет

- PROFIS Anchor 2.2.0: WWW - Hilti.deДокумент6 страницPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguОценок пока нет

- FMT 09 - Management Review (IS 17025-2017) VITДокумент2 страницыFMT 09 - Management Review (IS 17025-2017) VITSrirevathi Balapattabi100% (1)

- Equipo Sony Mod - Mhc-ex660+Mhc-ex880+Mhc-ex990 Ver1.0 - BRДокумент87 страницEquipo Sony Mod - Mhc-ex660+Mhc-ex880+Mhc-ex990 Ver1.0 - BRManuel100% (3)

- Scheme of Work: Cambridge IGCSE / Cambridge IGCSE (9-1) Computer Science 0478 / 0984Документ39 страницScheme of Work: Cambridge IGCSE / Cambridge IGCSE (9-1) Computer Science 0478 / 0984Syed Ashar80% (10)

- 26071-100-GPP-GPX-00008-001 Packing & Shipping Instruction and Marking SpecificationДокумент57 страниц26071-100-GPP-GPX-00008-001 Packing & Shipping Instruction and Marking SpecificationNaresh Kumar100% (2)

- Specialist Services: Force Resolution CalculationДокумент5 страницSpecialist Services: Force Resolution CalculationNaresh KumarОценок пока нет

- Hilti Bolt DesignДокумент7 страницHilti Bolt Designcheligp1981Оценок пока нет

- 1 Input Data: WWW - Hilti.inДокумент5 страниц1 Input Data: WWW - Hilti.inpudumaiОценок пока нет

- Specialist Services: Heavy Oil Production Facility at Umm Niqa (15049) CONTRACT NO. 15052398Документ1 страницаSpecialist Services: Heavy Oil Production Facility at Umm Niqa (15049) CONTRACT NO. 15052398Naresh KumarОценок пока нет

- A345Документ4 страницыA345nvh202148Оценок пока нет

- HALFEN ConectoriДокумент12 страницHALFEN ConectoriSárközi Pál-ZoltánОценок пока нет

- 1 Input Data: WWW - Hilti.co - UkДокумент6 страниц1 Input Data: WWW - Hilti.co - UkihpeterОценок пока нет

- Pipe Rack Hilti Bolt CalculationsДокумент6 страницPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVОценок пока нет

- Beam End Connection ReportДокумент6 страницBeam End Connection ReportHibri HalimОценок пока нет

- Canopy M16 HIT-RE500Документ5 страницCanopy M16 HIT-RE500marchus09Оценок пока нет

- Base CHS X 10tДокумент7 страницBase CHS X 10tCollin NguОценок пока нет

- PROFIS Anchor 2.1.4: WWW - Hilti.atДокумент5 страницPROFIS Anchor 2.1.4: WWW - Hilti.atfrog15Оценок пока нет

- Hilti AnchorДокумент5 страницHilti AnchorGopi KrishnanОценок пока нет

- 250x16 Shs Column Base - Pa2123Документ5 страниц250x16 Shs Column Base - Pa2123ihpeterОценок пока нет

- PROFIS Anchor 2.4.6: WWW - Hilti.luДокумент6 страницPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliОценок пока нет

- 1 Input Data: Profis Anchor 2.6.6Документ6 страниц1 Input Data: Profis Anchor 2.6.6Collin NguОценок пока нет

- H 200mm Thick Slab - Pa2Документ6 страницH 200mm Thick Slab - Pa2ihpeterОценок пока нет

- PROFIS Anchor 2.0.7Документ4 страницыPROFIS Anchor 2.0.7Miky CastenОценок пока нет

- 290mm Thick Slab and 540mm EcenДокумент6 страниц290mm Thick Slab and 540mm EcenihpeterОценок пока нет

- Hilti AnchorДокумент6 страницHilti AnchorantonioОценок пока нет

- PROFIS Anchor 2.4.6: WWW - Hilti.luДокумент6 страницPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliОценок пока нет

- Connection d01 1Документ6 страницConnection d01 1Win ThanОценок пока нет

- PROFIS Anchor 2.2.6: WWW - Hilti.inДокумент6 страницPROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007Оценок пока нет

- PROFIS Anchor 2.0.7: WWW - Hilti.usДокумент5 страницPROFIS Anchor 2.0.7: WWW - Hilti.usadelhelmiОценок пока нет

- PROFIS Anchor 2.4.6: WWW - Hilti.luДокумент6 страницPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliОценок пока нет

- Rowad Debugging MachineДокумент6 страницRowad Debugging MachineRonnie De Joya AguirreОценок пока нет

- PES Hilti M10 HSA ReportДокумент4 страницыPES Hilti M10 HSA ReportCollin NguОценок пока нет

- 44 - HVZ Adhesive AnchorДокумент14 страниц44 - HVZ Adhesive AnchorHuan VoОценок пока нет

- PES Hilti M10 HSA Report RunnerДокумент4 страницыPES Hilti M10 HSA Report RunnerCollin NguОценок пока нет

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Документ12 страницHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuОценок пока нет

- Profis Rebar ReportДокумент5 страницProfis Rebar ReportSowmya MajumderОценок пока нет

- Anchor Design - Hilti (HP)Документ6 страницAnchor Design - Hilti (HP)Harikrishnan PОценок пока нет

- Hilti HVZ 1Документ13 страницHilti HVZ 1Mihnea-Bogdan NicolaescuОценок пока нет

- Machine RoomДокумент6 страницMachine RoomRonnie De Joya AguirreОценок пока нет

- SAMPLE HILTI SolutionДокумент6 страницSAMPLE HILTI SolutionJester AbucayОценок пока нет

- Hilti HIT HY 150 MAX With RebarДокумент14 страницHilti HIT HY 150 MAX With RebarNelly BuquironОценок пока нет

- 1 Input Data: Profis Anchor 2.5.2Документ5 страниц1 Input Data: Profis Anchor 2.5.2jasekan.dcОценок пока нет

- Kempinski Hilti Rc-OДокумент6 страницKempinski Hilti Rc-OsobhiОценок пока нет

- WIT-PE 500 Design Manual RBДокумент24 страницыWIT-PE 500 Design Manual RBMadusha TisseraОценок пока нет

- Shaft B, Hb1 Kempinski 11-1-17.pa2Документ7 страницShaft B, Hb1 Kempinski 11-1-17.pa2sobhiОценок пока нет

- Hilti Hit Hy 150 Max Con Barra CorrugadaДокумент20 страницHilti Hit Hy 150 Max Con Barra Corrugadalandsv01Оценок пока нет

- Hilti HST 1Документ11 страницHilti HST 1Mihnea-Bogdan NicolaescuОценок пока нет

- Hilti Connection ReportДокумент7 страницHilti Connection ReportFrancisco BonillaОценок пока нет

- Hilti HIT-HY 150 With Rebar PDFДокумент16 страницHilti HIT-HY 150 With Rebar PDFMuzammil HawaОценок пока нет

- X BT Brochure en W3987Документ68 страницX BT Brochure en W3987Paul RobbinsОценок пока нет

- Anclaje Quimico HILTIДокумент84 страницыAnclaje Quimico HILTIWuceirОценок пока нет

- Chumbador HiltДокумент14 страницChumbador HiltSamanta FigueredoОценок пока нет

- Hilti HIT MM Plus 1Документ14 страницHilti HIT MM Plus 1Mihnea-Bogdan NicolaescuОценок пока нет

- Technische Dokumentation Technical Documentation: Fully Lined Flanged Filters & Strainers (DIN Version), Type Y101, PN 16Документ5 страницTechnische Dokumentation Technical Documentation: Fully Lined Flanged Filters & Strainers (DIN Version), Type Y101, PN 16peroooОценок пока нет

- 2014 HKD Push-In Anchor - Single Anchor ApplicationДокумент3 страницы2014 HKD Push-In Anchor - Single Anchor ApplicationDifa LiuОценок пока нет

- Hilti Hit Hy 200 With Hit VДокумент18 страницHilti Hit Hy 200 With Hit VRobinReyndersОценок пока нет

- UB254X146X31 Base Connection IДокумент6 страницUB254X146X31 Base Connection IANTONYSAMY SANTHANAMОценок пока нет

- Job Specific Data Tag No-PRJ0010315-1, 2, 3 & 4 Quantity - 4 NosДокумент6 страницJob Specific Data Tag No-PRJ0010315-1, 2, 3 & 4 Quantity - 4 NosNaresh KumarОценок пока нет

- Job Specific Data Tag No-PRJ0010315-5, 6,7 & 8 Quantity - 4 NosДокумент6 страницJob Specific Data Tag No-PRJ0010315-5, 6,7 & 8 Quantity - 4 NosNaresh KumarОценок пока нет

- Load Calcs - Rev1Документ11 страницLoad Calcs - Rev1Naresh KumarОценок пока нет

- Tsa ZaДокумент2 страницыTsa ZaNaresh KumarОценок пока нет

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKДокумент1 страницаAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarОценок пока нет

- Bolt Item CodesДокумент1 страницаBolt Item CodesNaresh KumarОценок пока нет

- 2014 Ford Fusion - 2.5L PDFДокумент1 страница2014 Ford Fusion - 2.5L PDFNaresh KumarОценок пока нет

- Tsa YzДокумент2 страницыTsa YzNaresh KumarОценок пока нет

- WES 1003 HC 0016 - r3Документ17 страницWES 1003 HC 0016 - r3Naresh KumarОценок пока нет

- CSC PlatesДокумент1 страницаCSC PlatesNaresh KumarОценок пока нет

- Multiport Distribution Skid Civil Load Data - Rev-BДокумент2 страницыMultiport Distribution Skid Civil Load Data - Rev-BNaresh KumarОценок пока нет

- Civil GetДокумент5 страницCivil GetNaresh KumarОценок пока нет

- Specialist Services: 1440PSI Knock Out PotДокумент1 страницаSpecialist Services: 1440PSI Knock Out PotNaresh KumarОценок пока нет

- Circular Plate Stress CheckДокумент2 страницыCircular Plate Stress CheckNaresh KumarОценок пока нет

- S. No Item Description Wt/m/m2 Length/ Area No's WEIGHT (KG) RemarksДокумент1 страницаS. No Item Description Wt/m/m2 Length/ Area No's WEIGHT (KG) RemarksNaresh KumarОценок пока нет

- R R R R: Em's SubmittalsДокумент4 страницыR R R R: Em's SubmittalsNaresh KumarОценок пока нет

- DM Adm OkДокумент32 страницыDM Adm Okp17421183048 ANA MAWARNI MUSTIKAWATIОценок пока нет

- Juniper Netscreen ISG Series DatasheetДокумент12 страницJuniper Netscreen ISG Series Datasheetbh.youssefОценок пока нет

- Strategic Mine Planning-1Документ7 страницStrategic Mine Planning-1Harristio AdamОценок пока нет

- 04 15 2021 Basics of Automotive Ethernet Rev1.1Документ71 страница04 15 2021 Basics of Automotive Ethernet Rev1.1RakshithОценок пока нет

- Long-Stay Visa Application Form: French RepublicДокумент3 страницыLong-Stay Visa Application Form: French Republicsunny singhОценок пока нет

- Blended Learning Lesson PlanДокумент5 страницBlended Learning Lesson Planapi-710577606Оценок пока нет

- Deloitte Rethink Your Learning ApproachДокумент28 страницDeloitte Rethink Your Learning ApproachTram AnhhОценок пока нет

- Quentic Whitepaper ISO 14001Документ23 страницыQuentic Whitepaper ISO 14001Magdalena MichulecОценок пока нет

- Usbee Suite ManualДокумент152 страницыUsbee Suite ManualJortonОценок пока нет

- Vat Relief Bir Transmittal Form Annex A 1 PDFДокумент1 страницаVat Relief Bir Transmittal Form Annex A 1 PDFJoselito Pastrana100% (1)

- Introduction To HazidДокумент29 страницIntroduction To Hazidafan nur arifОценок пока нет

- Teks Pembaca Nominasi Akademik Dan Non AkademikДокумент2 страницыTeks Pembaca Nominasi Akademik Dan Non AkademikReyhan Dwi SaputraОценок пока нет

- RapidWright Tutorials (3) .OdtДокумент17 страницRapidWright Tutorials (3) .OdtSrijeet GuhaОценок пока нет

- Criteria Exam Vocabulary Builder Meriam-Webster DictionaryДокумент2 страницыCriteria Exam Vocabulary Builder Meriam-Webster Dictionaryjoyrena ochondraОценок пока нет

- TS 52PRO: Test SetДокумент28 страницTS 52PRO: Test SetOscar ChavesОценок пока нет

- BAR EXAMINATIONS APPLICATION PROCESS Supreme Court of The PhilippinesДокумент1 страницаBAR EXAMINATIONS APPLICATION PROCESS Supreme Court of The PhilippinesPrettyОценок пока нет

- Contrast-Associated Acute Kidney Injury NEJMДокумент4 страницыContrast-Associated Acute Kidney Injury NEJMJorge BalbinОценок пока нет

- Variable Voltaje AlternadorДокумент37 страницVariable Voltaje AlternadorFrank Araya DiazОценок пока нет

- Write An Essay (At Least 300 Words) About Your Experiences and Learnings in Math 100Документ2 страницыWrite An Essay (At Least 300 Words) About Your Experiences and Learnings in Math 100Christian Shane BejeranoОценок пока нет

- SCRBD 4Документ27 страницSCRBD 4neichusОценок пока нет

- 1.0 ESC 21 - ENGG MGT PRESENTATION-What Is Eng. Mgt. - Rev 0 Aug 12 2021Документ14 страниц1.0 ESC 21 - ENGG MGT PRESENTATION-What Is Eng. Mgt. - Rev 0 Aug 12 2021Feolo Riel TarayОценок пока нет

- Why Leakage Reactance in Transformer Is Important For Design ConsiderationДокумент3 страницыWhy Leakage Reactance in Transformer Is Important For Design ConsiderationaocalayОценок пока нет

- Website AgreementДокумент4 страницыWebsite AgreementDarko MilosevicОценок пока нет