Академический Документы

Профессиональный Документы

Культура Документы

Global Transmission Sleeve: Product Data Sheet

Загружено:

goumrisalimaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Global Transmission Sleeve: Product Data Sheet

Загружено:

goumrisalimaАвторское право:

Доступные форматы

GTS-80

Global Transmission Sleeve

The GTS-80 system provides superior corrosion protection and

excellent bonding on pipelines operating up to 80C. GTS-80 has

been designed with a unique adhesive technology that remains

open longer than traditional adhesives. Also, special surface

active agents allow bonding to lower surface energy coatings

(such as polypropylene). As a result, lower preheat temperatures

are required to attain true adhesive wet-out and superior bonding

to PE and FBE surfaces is achieved.

Superior Force Cured Epoxy

Proven method of force curing the liquid epoxy to the steel allows

the installer to pre-inspect the joint prior to sleeve application

Force cured epoxy cannot be displaced during the aligning and

shrinking stages of the sleeve installation

Applications

Oil & Gas

Unique Adhesive Technology

Allows for lower installation pre-heat temperatures and superior

bonding to PE and FBE coatings

Adhesive has been formulated to bond directly to the main line

coating; epoxy is applied to the steel only

Offshore Pipelines

Onshore Pipelines

Flexible Installation

For added flexibility, the sleeve can be supplied as bulk rolls or precut to the required pipe size

Long Term Corrosion Protection

Provides a protective coating with the structural

integrity of a seamless tube, providing excellent

resistance to cathodic disbondment and excellent

durability against abrasion and chemical attack

Saves Time & Money

Lower pre-heat means less time heating

PRODUCT DATA SHEET

canusacps.com

The product information

shown here is intended as a

guide for standard products.

GTS-80

Consult your Canusa

representative for specific

projects or unique applications.

Global Transmission Sleeve

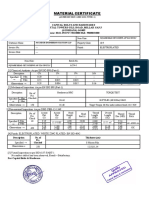

Sleeve Operating Characteristics

Test Method

Typical Values

Pipeline Operating Temp.

Up to 80C (175F)*

Minimum Installation Temp.

110C (230F)

Main Line Coating Compatibility

PE, HPPC, FBE, PP

Adhesive Properties

Softening Point

ASTM E28

124C

ISO 21809-3

365 N/cm2

Tensile Strength

ASTM D638

22 MPa

Elongation

ASTM D638

600%

Hardness

ASTM D2240

55 Shore D

ASTM D257

1017 ohm-cm

Lap Shear

Backing Properties

Volume Resistivity

Canusa-CPS

A division of ShawCor Ltd.

Adhesion Strength @ 23C

ISO 21809-3

>50 N/cm

Impact Resistance

ISO 21809-3

>15 J

Indentation Resistance

ISO 21809-3

1.0** mm (pass)

Cathodic Disbondment @ 23C, 28 days

ISO 21809-3

< 3 mm rad

ASTM D2671-C

>-26C

Thickness

25 Bethridge Rd.

Toronto, ON M9W 1M7 Canada

Tel: +1 416 743 7111

Fax: +1 416 743 5927

Sleeve Properties

Low Temp. Flexibility

Head Office

Backing (nominal thickness as supplied)

0.6 mm

(0.025)

0.9 mm

(0.035)

1.1 mm

(0.045)

Adhesive (nominal thickness as supplied)

1.0 mm

(0.040)

1.3 mm

(0.050)

1.5 mm

(0.060)

* Actual temperature rating is dependant on specific project requirements and conditions. Please consult your local Canusa representative.

** mm remaining

Epoxy usage can be referenced on the Liquid Epoxy Product Data Sheet.

Canada

Suite 3200, 450 - 1st Street S.W.

Calgary, AB T2P 5H1 Canada

Tel: +1 403 218 8207

Fax: +1 403 264 3649

Americas

2408 Timberloch Place, Building C-8

The Woodlands, TX 77380 USA

Tel: +1 281 367 8866

Fax: +1 281 367 4304

Europe, Middle East, Africa & Russia

Unit 3, Sterling Park,

Gatwick Road, Crawley, West Sussex

RH10 9QT United Kingdom

Tel: +44 1293 541254

Fax: +44 1293 541777

Asia-Pacific

101 Thomson Road,

#11-03 United Square

307591 Singapore

Tel: +65 6749 8918

Fax: +65 6749 8919

Canusa-CPS is registered

to ISO 9001:2008

Since 1967, Canusa-CPS has been a leading developer and manufacturer of specialty pipeline coatings

for the sealing and corrosion protection of pipeline joints and other substrates. Canusa-CPS high

performance products are manufactured to the highest quality standards and are available in a number

of configurations to accommodate many specific project applications.

Canusa warrants that the product conforms to

its chemical and physical description and is

appropriate for the use stated on the

product data sheet when used in compliance

with Canusas written instructions. Since many

installation factors are beyond our control,

the user shall determine the suitability of the

products for the intended use and assume all

risks and liabilities in connection therewith.

Canusas liability is stated in the standard

terms and conditions of sale. Canusa makes

no other warranty either expressed or implied.

All information contained in this data sheet is

to be used as a guide and is subject to change

without notice. This data sheet supersedes all

previous data sheets on this product. E&OE

PDS_GTS80_rev017

Вам также может понравиться

- Wrapid BondДокумент2 страницыWrapid BondgrtunaОценок пока нет

- PDS Na GTS80 PDFДокумент2 страницыPDS Na GTS80 PDFAnant RubadeОценок пока нет

- GTS-PP-120: 3 LayerДокумент2 страницыGTS-PP-120: 3 Layershoaib1985100% (1)

- Pds Na Gts65hpДокумент2 страницыPds Na Gts65hpRahadianLabigaAmidarmoОценок пока нет

- PDS A4 DDXДокумент2 страницыPDS A4 DDXRahadianLabigaAmidarmo100% (1)

- Wrapid Sleeve PDSДокумент2 страницыWrapid Sleeve PDSjayhuacat7743Оценок пока нет

- Ds Dirax PP Rev8 0309 1Документ2 страницыDs Dirax PP Rev8 0309 1Elias KapaОценок пока нет

- PE Yellow Gas - WebДокумент16 страницPE Yellow Gas - WebGavin KwanОценок пока нет

- Accesorios de Fibra de Vidrio (Conley)Документ43 страницыAccesorios de Fibra de Vidrio (Conley)Juan Carlos Vazquez RosasОценок пока нет

- HTLP Heat Shrinkable SleeveДокумент2 страницыHTLP Heat Shrinkable SleeveGanesh EshwarОценок пока нет

- Brederoshaw Pds 3lpeДокумент2 страницыBrederoshaw Pds 3lpejleonosОценок пока нет

- Canusa Wrap Benzi Termocontractibile Izolatii Conducte OtelДокумент2 страницыCanusa Wrap Benzi Termocontractibile Izolatii Conducte Oteleugen_alexutzОценок пока нет

- AB-3P 2010 EnglishДокумент12 страницAB-3P 2010 EnglishJoseph ChongОценок пока нет

- DSI Threadbar PT System Uk PDFДокумент4 страницыDSI Threadbar PT System Uk PDFkajewooОценок пока нет

- BR Polyken Rev11 Sep10Документ8 страницBR Polyken Rev11 Sep10diaccessltd_17172961Оценок пока нет

- GPT 1-3 PGE Tech SpecificationsДокумент4 страницыGPT 1-3 PGE Tech SpecificationsEhtisham AndrAbiОценок пока нет

- DENSO 50 Heat Shrink Sleeve (DENSO 50HSS)Документ3 страницыDENSO 50 Heat Shrink Sleeve (DENSO 50HSS)jay2kay5793Оценок пока нет

- Ameron Bondstrand 5000 Pipe and Fitting SpecificationДокумент2 страницыAmeron Bondstrand 5000 Pipe and Fitting SpecificationDGWОценок пока нет

- FGS 2006Документ409 страницFGS 20067radu7Оценок пока нет

- Brederoshaw Pds 3lpeДокумент2 страницыBrederoshaw Pds 3lpeadvis79Оценок пока нет

- MasterFlow880 TDSДокумент2 страницыMasterFlow880 TDSNdoro BeiОценок пока нет

- Tds r4d EcthtДокумент2 страницыTds r4d EcthtRavie OuditОценок пока нет

- JPCL Transpipe EbookДокумент82 страницыJPCL Transpipe Ebookvincent.w.stone6724Оценок пока нет

- Pipe AssureДокумент2 страницыPipe AssureUmmi HaniОценок пока нет

- Cable Tray 27Документ37 страницCable Tray 27Sri Ravindra Yadav PattapogulaОценок пока нет

- Rock Plast Pipe BrochureДокумент28 страницRock Plast Pipe BrochureHusna Mega JayaОценок пока нет

- Duratec Airline Overview BrochureДокумент8 страницDuratec Airline Overview BrochureAshutosh SaxenaОценок пока нет

- Heatshrinkable Sheets: Manufacturer Statement & Product Data SheetsДокумент15 страницHeatshrinkable Sheets: Manufacturer Statement & Product Data SheetsariyamanjulaОценок пока нет

- 1a Aquaflow HDPE Pipe CatalogueДокумент12 страниц1a Aquaflow HDPE Pipe CatalogueNick BesterОценок пока нет

- Duratec Compressed Air & Gas BrochureДокумент8 страницDuratec Compressed Air & Gas BrochureSharon LambertОценок пока нет

- Master Flow 648Документ4 страницыMaster Flow 648gazwang478Оценок пока нет

- Viega Profipress ManualДокумент16 страницViega Profipress Manualhasmit1Оценок пока нет

- Jining QiangkeДокумент35 страницJining QiangkeCobu LamОценок пока нет

- Catálogo HP Hoses - enДокумент28 страницCatálogo HP Hoses - enJavier Alfonso FernandezОценок пока нет

- SBN Corp Profile - 2 PDFДокумент33 страницыSBN Corp Profile - 2 PDFSyafiq KamaluddinОценок пока нет

- Drawing 80H30Документ3 страницыDrawing 80H30kpranjal15Оценок пока нет

- 10-D1-VHightech (Very High Density Foam)Документ1 страница10-D1-VHightech (Very High Density Foam)GPОценок пока нет

- Pastite For Pipe Connection System Bul 4300 PTPДокумент6 страницPastite For Pipe Connection System Bul 4300 PTPanoop9079Оценок пока нет

- TDS - Masterflow 648CPДокумент3 страницыTDS - Masterflow 648CPVenkata RaoОценок пока нет

- ABS Pipe Design ManualДокумент76 страницABS Pipe Design ManualAlex Chin100% (1)

- Waterproofing, Lining, Tunnel, Geomembrane Manual: Carlisle'SДокумент91 страницаWaterproofing, Lining, Tunnel, Geomembrane Manual: Carlisle'SGirdan BogdanОценок пока нет

- Klamflexproduct BrochureДокумент24 страницыKlamflexproduct BrochureblindjaxxОценок пока нет

- Gall5231328512232fip PDFДокумент15 страницGall5231328512232fip PDFAndres CortezОценок пока нет

- PolykenДокумент8 страницPolykenVictor Hugo Bustos BeltranОценок пока нет

- Breeze CatalogДокумент4 страницыBreeze CatalogJulio Isla JiménezОценок пока нет

- Novomesh 850 PDFДокумент2 страницыNovomesh 850 PDFSyawatulshuhada SyawalОценок пока нет

- Rainwater DesignДокумент64 страницыRainwater DesignarifzakirОценок пока нет

- Keystone Prefabricated CableДокумент23 страницыKeystone Prefabricated CableAntonius AjalahОценок пока нет

- GS-Retain Ring Flange SystemДокумент4 страницыGS-Retain Ring Flange SystemEduardo CramerОценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesОт EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyОт EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinОценок пока нет

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerОт EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerРейтинг: 5 из 5 звезд5/5 (1)

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresОт EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresРейтинг: 5 из 5 звезд5/5 (1)

- Use of Gold As A Routine and Long Term Preservative For Mercury in Potable Water, As Determined by ICP-MSДокумент4 страницыUse of Gold As A Routine and Long Term Preservative For Mercury in Potable Water, As Determined by ICP-MServan fuji maulanaОценок пока нет

- Air Jet Mill MicronizerДокумент6 страницAir Jet Mill MicronizerMenoddin shaikh100% (1)

- Mechanical Properties of Heat Affected ZoneДокумент9 страницMechanical Properties of Heat Affected ZoneLeandro VaccariОценок пока нет

- TDS STEELGRID HR SYSTEM - Rev 08 - Jun 2014Документ2 страницыTDS STEELGRID HR SYSTEM - Rev 08 - Jun 2014mandeep571Оценок пока нет

- CBH-22-166 Square Head Bolt 3-8 X 1 WZP 10.9Документ1 страницаCBH-22-166 Square Head Bolt 3-8 X 1 WZP 10.9qualityОценок пока нет

- Bedauli Boq PDFДокумент15 страницBedauli Boq PDFAlaguОценок пока нет

- O Ring BroДокумент256 страницO Ring BrohildanОценок пока нет

- TG1 - 2019 The Use of Modified Bituminous Binders in Road Construction 2019Документ106 страницTG1 - 2019 The Use of Modified Bituminous Binders in Road Construction 2019Roy GuoОценок пока нет

- SA Ch01Документ9 страницSA Ch01Mohd AsmawiОценок пока нет

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Документ2 страницыForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiОценок пока нет

- Project Proposal: To Study Expansive Behavior of D. I. Khan Soil and Its TreatmentДокумент8 страницProject Proposal: To Study Expansive Behavior of D. I. Khan Soil and Its TreatmentNoman KhanОценок пока нет

- REGO - Pressure Builder - Economizer CBH CBCДокумент1 страницаREGO - Pressure Builder - Economizer CBH CBCcriuvosОценок пока нет

- Is549 Evaluation of Alkali Silica Reactivity (Asr) Mortar Bar Testing (Astm c1260 and c1567) at 14 Days and 28 DaysДокумент4 страницыIs549 Evaluation of Alkali Silica Reactivity (Asr) Mortar Bar Testing (Astm c1260 and c1567) at 14 Days and 28 DaysSandro MendesОценок пока нет

- Performance Based Design For Fire SafetyДокумент23 страницыPerformance Based Design For Fire SafetyTharanga Pradeep100% (1)

- Chemistry Question Based On Transformation of SubstanceДокумент2 страницыChemistry Question Based On Transformation of SubstanceproodootОценок пока нет

- Basf Masteremaco t288 TdsДокумент2 страницыBasf Masteremaco t288 TdsharsoОценок пока нет

- Table 9.6 Pressure Vessel Codes: Defect Acceptance Criteria (Quick Reference)Документ1 страницаTable 9.6 Pressure Vessel Codes: Defect Acceptance Criteria (Quick Reference)Anonymous GE8mQqxОценок пока нет

- Proses Pembuatan KertasДокумент124 страницыProses Pembuatan Kertasgarispante07100% (7)

- Determination of Alcohol Content in Alcoholic BeveragesДокумент7 страницDetermination of Alcohol Content in Alcoholic BeveragesKaye Danielle HilomenОценок пока нет

- Lead, Zinc and Strontium Distribution in The Oxidation ZoneДокумент11 страницLead, Zinc and Strontium Distribution in The Oxidation ZoneAnonymous Lrw61wОценок пока нет

- All Metal Hose, Medium Pressure, FJ Sereis (MS-02-322-E) R2Документ6 страницAll Metal Hose, Medium Pressure, FJ Sereis (MS-02-322-E) R2herysyam1980Оценок пока нет

- 12ME102 - Workshop Practice LAB MANUALДокумент16 страниц12ME102 - Workshop Practice LAB MANUALBenuel SathishОценок пока нет

- Program Outcomes (Pos) Addressed by The Activity: Activity No. 3: Building Envelope Systems and Assemblies 1.1Документ13 страницProgram Outcomes (Pos) Addressed by The Activity: Activity No. 3: Building Envelope Systems and Assemblies 1.1Jazcel GalsimОценок пока нет

- GMW14668 - Minimum Performance Requirements For Decorative Chromium Plated PlasticsДокумент20 страницGMW14668 - Minimum Performance Requirements For Decorative Chromium Plated Plastics廖健翔Оценок пока нет

- SWMAPДокумент4 страницыSWMAPCherry Mae AnghagОценок пока нет

- Astm B 330-2007Документ5 страницAstm B 330-2007Ramsi Ankzi100% (1)

- Awareness Poster of Pesticides Waste Management (AlZaShaNi)Документ1 страницаAwareness Poster of Pesticides Waste Management (AlZaShaNi)Mohammad Bin OthmanОценок пока нет

- Part - A: by Density Bottle MethodДокумент7 страницPart - A: by Density Bottle MethodGorantla Ravi TejaОценок пока нет

- GoldyДокумент1 страницаGoldyAniket DubeОценок пока нет

- Product & Service Datasheet: Medium Voltage (6kV To 36kV) Subsea Power Cable Repair JointДокумент2 страницыProduct & Service Datasheet: Medium Voltage (6kV To 36kV) Subsea Power Cable Repair Jointnader mahfoudhiОценок пока нет