Академический Документы

Профессиональный Документы

Культура Документы

Quick Calculations: For and

Загружено:

Ahmed AzadОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Quick Calculations: For and

Загружено:

Ahmed AzadАвторское право:

Доступные форматы

HRPQC-03 (7/03)

APPLICATIONS NOTE

Quick Calculations Tables give typical and heavy load estimates

based on the conditions in each room temperature table. Conditions include construction, loading, and room surroundings.

If your conditions are very different from the typical or heavy

conditions, then figure a load estimate specifically for your job.

Here are three suggestions to help you get an accurate load

estimate for your application:

QUICK CALCULATIONS

for

WALK-IN COOLERS

and

FREEZERS

BTUH LOADS for:

6 x 6 to 40 x 40 Rooms

with 8 Ceilings

at -20F. to +35F.

Based on

95F. Ambient

2003, Heatcraft Refrigeration Products LLC

a. You can use the paper and pencil calculation in

Heatcraft Refrigeration Products Engineering Manual

(H-ENG-1)

b. You can use the box load software, in the Calculation Toolbox

of the Cold Solutions Program provided by a Sales Rep

c. Or you can call your Sales Representative for assistance

Before you do a, b, or c, get this information about your job:

1. Room information:

Length, width, and height of the box in feet

Temperature of the refrigerated room (F)

Relative humidity in the refrigerated room (if specified)

Summertime design ambient temperature (F). This is

usually the temperature expected at the location of an air

cooled condensing unit which cools the room

2. Insulation information:

Type of insulation, insulation thickness (inches), and external

temperatures on walls, ceiling, floor

3. Infiltration load information:

The temperature (F) of the entering air and the relative

humidity of the entering air. Also, an estimate of the door

usage - average, heavy, etc.

Does the box have glass doors? Dock doors? How many?

4. Product load information:

What is the product or product mix?

How many pounds of product entering at what temperature?

How long (hours) does it take to load the product into room?

How quickly (hours) should the room pull the product down

to what temperature?

How many pounds of fruit and vegetables are in the room?

(respiration load)

5. Miscellaneous loads information:

How many people work in the room?

What is the lighting (watts)?

How many motors (HP) do work in the room?

DIMENSIONS

(FEET)

ROOM ROOM BTUH BTUH

AREA VOLUME TYPICAL HEAVY

SQ. FT.

CU. FT

LOAD

LOAD

6

6

6

8

8

8

8

8

8

8

8

8

8

8

8

8

10

10

10

10

10

10

10

10

12

12

12

12

12

12

14

14

14

14

16

16

16

18

18

18

20

20

20

20

20

20

40

40

40

40

40

6

8

10

8

10

12

14

16

18

20

22

24

26

28

30

32

10

12

14

16

18

20

24

28

12

14

16

18

20

22

14

16

20

24

16

20

24

18

20

24

20

24

28

32

36

40

24

28

32

36

40

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

36

48

60

64

80

96

112

128

144

160

176

192

208

224

240

256

100

120

140

160

180

200

240

280

144

168

192

216

240

264

196

224

280

336

256

320

384

324

360

432

400

480

560

640

720

800

960

1120

1280

1440

1600

288

384

480

512

640

768

896

1024

1152

1280

1408

1536

1664

1792

1920

2048

800

960

1120

1280

1440

1600

1920

2240

1152

1344

1536

1728

1920

2112

1568

1792

2240

2688

2048

2560

3072

2592

2880

3456

3200

3840

4480

5120

5760

6400

7680

8960

10240

11520

12800

4522

5296

6020

6193

7032

7830

8597

9341

10065

11402

12097

12779

13451

14115

14770

15417

7980

8883

9752

11224

12045

12849

14413

15931

9887

11483

12423

13338

14235

15115

12547

13580

14587

15574

14704

17318

19416

17429

18592

20863

19842

22911

25289

28058

30347

33231

37745

42361

46722

51218

55479

6570

7390

8170

8360

9270

10140

10980

11790

12580

13800

14570

15320

16060

16800

17520

18240

10310

11300

12250

13630

14530

15430

17170

18860

12410

13920

14970

15990

16990

17970

15110

16260

17520

18750

17530

20420

22800

20550

21870

24460

23300

26530

29260

32380

35020

38070

43290

48420

53490

58500

63460

0F. ROOM

(add 15% to loads for 10' height)

Typical Load Conditions:

The Cold Solutions Program

automatically figures typical loads.

Here are the typical conditions:

Product - In at +10

a) Specific heat of product is 0.45

BTU per pound

b) Product loaded in a 24 hour period

c) Freezing point of product is 27

d) Reduce product to 0 in 24 hours

e) Pounds of +10 product EQUALS

room volume (cu. ft.)

External Temperatures

a) 95 on all four walls

b) 115 on the ceiling (solar effect)

c) 55 on the floor

Insulation - 4" Urethane

4" urethane on the walls, ceiling,

and floor with R = 25 and k = 0.16

Infiltration - 2 times Average

a) 95 air enters room through the

door at 50% relative humidity

b) The door openings cause TWICE

the number of air changes listed in

AVERAGE AIR CHANGES FOR

STORAGE ROOMS table

Miscellaneous

a) Lighting - One watt per square

foot of floor area

b) People Load - charged at 1person

per 25000 cu. ft. of room volume

c) Motors - charged at 1 HP per

12500 cu. ft. of room volume

Heavy Load Conditions:

Same as Typical except:

a) Pounds of product is 3 times cu. ft.

b) People load is 1 person

Safety Factor - 10%

10% safety factor is added to the

product, transmission, infiltration,

and miscellaneous loads described

above.

Run time - 18 hrs, electric defrost

18 hour condensing unit run time.

The BTU load for 24 hours is

divided by 18 to yield the hourly

heat load reported in this table.

DIMENSIONS

(FEET)

ROOM ROOM BTUH BTUH

AREA VOLUME TYPICAL HEAVY

SQ. FT.

CU. FT

LOAD

LOAD

6

6

6

8

8

8

8

8

8

8

8

8

8

8

8

8

10

10

10

10

10

10

10

10

12

12

12

12

12

12

14

14

14

14

16

16

16

18

18

18

20

20

20

20

20

20

40

40

40

40

40

6

8

10

8

10

12

14

16

18

20

22

24

26

28

30

32

10

12

14

16

18

20

24

28

12

14

16

18

20

22

14

16

20

24

16

20

24

18

20

24

20

24

28

32

36

40

24

28

32

36

40

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

36

48

60

64

80

96

112

128

144

160

176

192

208

224

240

256

100

120

140

160

180

200

240

280

144

168

192

216

240

264

196

224

280

336

256

320

384

324

360

432

400

480

560

640

720

800

960

1120

1280

1440

1600

288

384

480

512

640

768

896

1024

1152

1280

1408

1536

1664

1792

1920

2048

800

960

1120

1280

1440

1600

1920

2240

1152

1344

1536

1728

1920

2112

1568

1792

2240

2688

2048

2560

3072

2592

2880

3456

3200

3840

4480

5120

5760

6400

7680

8960

10240

11520

12800

4859

5692

8573

6654

7555

8413

9239

10039

10818

12225

12973

13708

14432

15146

15851

16549

8573

9543

10477

12028

12911

13775

15457

17090

10621

12305

13314

14297

15260

16206

13446

14554

16696

19202

15761

18533

20786

18652

19900

22336

21240

24503

27054

29993

32449

35515

40316

45232

49870

54656

59186

7070

7960

10890

8990

9960

10890

11790

12660

13510

14780

15600

16400

17200

17980

18760

19520

11070

12130

13150

14580

15550

16500

18360

20170

13310

14890

16010

17100

18160

19220

16160

17390

19780

22530

18740

21790

24320

21930

23330

26090

24850

28260

31160

34450

37260

40470

45980

51390

56730

62020

67250

-10F. ROOM

(add 15% to loads for 10' height)

Typical Load Conditions:

The Cold Solutions Program

automatically figures typical loads.

Here are the typical conditions:

Product - In at 0

a) Specific heat of product is 0.45

BTU per pound

b) Product loaded in a 24 hour period

c) Freezing point of product is 27

d) Reduce product to -10 in 24 hours

e) Pounds of 0 product EQUALS

room volume (cu. ft.)

External Temperatures

a) 95 on all four walls

b) 115 on the ceiling (solar effect)

c) 55 on the floor

Insulation - 4" Urethane

4" urethane on the walls, ceiling,

and floor with R = 25 and k = 0.16

Infiltration - 2 times Average

a) 95 air enters room through the

door at 50% relative humidity

b) The door openings cause TWICE

the number of air changes listed in

AVERAGE AIR CHANGES FOR

STORAGE ROOMS table

Miscellaneous

a) Lighting - One watt per square

foot of floor area

b) People Load - charged at 1person

per 25000 cu. ft. of room volume

c) Motors - charged at 1 HP per

12500 cu. ft. of room volume

Heavy Load Conditions:

Same as Typical except:

a) Pounds of product is 3 times cu. ft.

b) People load is 1 person

Safety Factor - 10%

10% safety factor is added to the

product, transmission, infiltration,

and miscellaneous loads described

above.

Run time - 18 hrs, electric defrost

18 hour condensing unit run time.

The BTU load for 24 hours is

divided by 18 to yield the hourly

heat load reported in this table.

DIMENSIONS

(FEET)

ROOM ROOM BTUH BTUH

AREA VOLUME TYPICAL HEAVY

SQ. FT.

CU. FT

LOAD

LOAD

6

6

6

8

8

8

8

8

8

8

8

8

8

8

8

8

10

10

10

10

10

10

10

10

12

12

12

12

12

12

14

14

14

14

16

16

16

18

18

18

20

20

20

20

20

20

40

40

40

40

40

6

8

10

8

10

12

14

16

18

20

22

24

26

28

30

32

10

12

14

16

18

20

24

28

12

14

16

18

20

22

14

16

20

24

16

20

24

18

20

24

20

24

28

32

36

40

24

28

32

36

40

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

36

48

60

64

80

96

112

128

144

160

176

192

208

224

240

256

100

120

140

160

180

200

240

280

144

168

192

216

240

264

196

224

280

336

256

320

384

324

360

432

400

480

560

640

720

800

960

1120

1280

1440

1600

288

384

480

512

640

768

896

1024

1152

1280

1408

1536

1664

1792

1920

2048

800

960

1120

1280

1440

1600

1920

2240

1152

1344

1536

1728

1920

2112

1568

1792

2240

2688

2048

2560

3072

2592

2880

3456

3200

3840

4480

5120

5760

6400

7680

8960

10240

11520

12800

5187

6076

6908

7104

8066

8982

9865

10720

11553

13031

13830

14617

15392

16156

16912

17659

9152

10187

11185

12815

13758

14682

16480

18227

11338

13108

14185

15236

16246

17274

14326

15509

17795

20441

16795

29124

22129

19850

21182

23781

22611

26066

28788

31894

34516

37762

42487

48059

52973

58047

62848

7570

8510

9390

9610

10640

11620

12580

13500

14410

15730

16600

17460

18310

19140

19970

20780

11810

12940

14020

15520

16550

17560

19530

21460

14190

15850

17030

18180

19300

20430

17190

18490

21030

23920

19920

32530

25820

23270

24760

27680

26370

29950

33030

36490

39460

42840

48270

54320

59940

65490

71000

-20F. ROOM

(add 15% to loads for 10' height)

Typical Load Conditions:

The Cold Solutions Program

automatically figures typical loads.

Here are the typical conditions:

Product - In at -10

a) Specific heat of product is 0.45

BTU per pound

b) Product loaded in a 24 hour period

c) Freezing point of product is 27

d) Reduce product to -20 in 24 hours

e) Pounds of -10 product EQUALS

room volume (cu. ft.)

External Temperatures

a) 95 on all four walls

b) 115 on the ceiling (solar effect)

c) 55 on the floor

Insulation - 4" Urethane

4" urethane on the walls, ceiling,

and floor with R = 25 and k = 0.16

Infiltration - 2 times Average

a) 95 air enters room through the

door at 50% relative humidity

b) The door openings cause TWICE

the number of air changes listed in

AVERAGE AIR CHANGES FOR

STORAGE ROOMS table

Miscellaneous

a) Lighting - One watt per square

foot of floor area

b) People Load - charged at 1person

per 25000 cu. ft. of room volume

c) Motors - charged at 1 HP per

12500 cu. ft. of room volume

Heavy Load Conditions:

Same as Typical except:

a) Pounds of product is 3 times cu. ft.

b) People load is 1 person

Safety Factor - 10%

10% safety factor is added to the

product, transmission, infiltration,

and miscellaneous loads described

above.

Run time - 18 hrs, electric defrost

18 hour condensing unit run time.

The BTU load for 24 hours is

divided by 18 to yield the hourly

heat load reported in this table.

QUICK CALCULATIONS for

QUICK CALCULATIONS for

QUICK CALCULATIONS for

FREEZERS

FREEZERS

FREEZERS

-10F. to 0F. Reach-Ins

Room Volume

Cubic Feet

Approximate

BTUH

35F. to 40F. Reach-Ins

Room Volume

Cubic Feet

Approximate

BTUH

4 - 10

11 - 18

19 - 35

1000

1350

1900

4 - 10

11 - 18

19 - 28

950 - 1150

1100 - 1300

2100

36 - 55

56 - 75

76 - 100

2900

4200

5500

29 - 38

39 - 68

69 - 100

2600

3500

5700

Based on a minimum 1-1/2 inch

urethane foam insulated fixture,

18 hours per day compressor

run time.

Based on a minimum 1 inch

urethane foam insulated fixture,

16 hours per day compressor

run time.

HEAT EQUIVALENT

in BTUH per HP of Electric

Motors Openings & Infiltration

Motor

HP

1/8 to 1/2

1/2 to 3

3 to 20

Inside

Outside

Refrigeration Refrigeration

Space

Space

4250

3700

2950

AVERAGE AIR CHANGES

for Storage Rooms due to

Door Openings & Infiltration

Room

Temperature

Heat Equivalent

per person

BTU / 24 Hours

Room

Volume

Cu. Ft.

50F.

40F.

30F.

20F.

10F.

0F.

-10F.

17280

20160

22800

25200

28800

31200

33600

200

250

300

400

500

600

800

1000

1500

2000

3000

4000

5000

6000

8000

10000

15000

2545

2545

2545

Use motor outside when the

work done by the motor is

inside the refrigerated room,

but the motor is outside of the

refrigerated room.

If occupancy is unknown

allow one person per 24

hours for each 25,000 cubic

feet of space.

Room

Room

Temp.

Temp.

Above 32F. Below 32F.

44.0

38.0

34.5

29.5

26.0

23.0

20.0

17.5

14.0

12.0

9.5

8.2

7.2

6.5

5.5

4.9

3.9

33.5

29.0

26.2

22.5

20.0

18.0

15.3

13.5

11.0

9.3

7.4

6.3

5.6

5.0

4.3

3.8

3.0

EQUATION

for

Heat Conduction

Q Total = U x A x (F. out - F. in)

Legend:

Q Total is total heat transfer in BTU

per hour (BTUH)

U is coefficient of heat transfer in

BTU / (hour x sq. ft. x F.)

x is the symbol for multiply

A is area in square feet

(F. out - F. in) is the temperature on

the outside less the temperature

on the inside of the insulation

U = 1 divided by R

U = k x (insulation thickness)

k = (insulation thickness) / R

Insulation thickness is inches.

REACH-IN GLASS DOOR LOADS

LIGHTS

(Heaters, Resistive Loads)

Watts = Amps times Volts [P = I x E]

Amps = Watts divided by Volts [I = P / E]

Volts = Amps divided by Watts [E = P / I]

of Occupancy

Use motor inside when BOTH

the motor and the work done

by the motor are inside the

refrigerated room.

Electrical Formulas

Single Phase Loads:

HEAT EQUIVALENT

Typically 1 to 1-1/2 watts per square foot. Cutting or storage rooms

can be double the storage figure.

Each watt is multiplied by 3.42 BTU per watt to get BTUH and then

multiplied by 24 to get the daily load.

Room

Temperature

BTUH

per Door

35F.

30F.

0F.

-10F.

-20F.

1060

960

1730

1730

1730

Glass door loads have been

adjusted for run time load.

Multiply number of doors by

the door load listed and add to

hourly heat load in the tables.

Three Phase Loads: (where the loads on each phase are equal)

Watts = 1.732 times Amps times Volts [P = 1.732 x I x E]

Amps = Watts divided by Volts [I = P / (1.732 x E)]

Volts = Amps divided by Watts (E = P / (1.732 x I)]

Heatcraft Refrigeration Products LLC

2175 West Park Place Boulevard Stone Mountain, GA 30087 USA

770-465-5600 Fax: 770-465-5990

www.heatcraftrpd.com

HEAT GAIN

for battery operated

lift trucks

(typically 4 - 5 equivalent HP)

Battery

operated

load

capacity,

POUNDS

Heat gain

per hour

of lift truck

operation,

BTUH

Approx.

total

weight

of lift truck,

POUNDS

2000

4000

6000

8000

14000

21000

23000

26000

6000

8000

12000

14000

For the heat gain from lift trucks

with internal combustion engines,

derive the equivalent HP by

multiplying engine HP by daily

hours of operation and dividing by

24 (typically 4 - 5 equivalent HP).

Multiply the equiv. HP by 75000

for the additional BTU/day.

If motor or loading conditions are

not known then calculate one

motor HP for each 16000 cu. ft. in

a storage cooler and 12500 cu. ft.

in a storage freezer. Loading

docks and high distribution

warehouses are heavier.

MEAT CUTTING / PREP ROOM

Floor

Square

Feet

100

200

300

400

500

600

700

800

900

1000

1200

BTUH

per Square Feet of Floor

55F.

50F.

93

88

85

81

78

75

72

69

67

65

62

105

99

95

90

87

85

81

78

75

73

69

Meat/Prep. Room loads based on

continuous operation and include

allowances for average number of

personnel, processing equipment,

etc., with glass panel in one wall

and walls and ceilings insulated

with 3 inches of styrene with box

located in air conditioned area.

Evaporator should be low outlet

velocity type to avoid drafts and

should be selected for continuous

operation and not less than 30F.

evaporator temperature.

DIMENSIONS

(FEET)

ROOM ROOM BTUH BTUH

AREA VOLUME TYPICAL HEAVY

SQ. FT.

CU. FT

LOAD

LOAD

6

6

6

8

8

8

8

8

8

8

8

8

8

8

8

8

10

10

10

10

10

10

10

10

12

12

12

12

12

12

14

14

14

14

16

16

16

18

18

18

20

20

20

20

20

20

40

40

40

40

40

6

8

10

8

10

12

14

16

18

20

22

24

26

28

30

32

10

12

14

16

18

20

24

28

12

14

16

18

20

22

14

16

20

24

16

20

24

18

20

24

20

24

28

32

36

40

24

28

32

36

40

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

36

48

60

64

80

96

112

128

144

160

176

192

208

224

240

256

100

120

140

160

180

200

240

280

144

168

192

216

240

264

196

224

280

336

256

320

384

324

360

432

400

480

560

640

720

800

960

1120

1280

1440

1600

288

384

480

512

640

768

896

1024

1152

1280

1408

1536

1664

1792

1920

2048

800

960

1120

1280

1440

1600

1920

2240

1152

1344

1536

1728

1920

2112

1568

1792

2240

2688

2048

2560

3072

2592

2880

3456

3200

3840

4480

5120

5760

6400

7680

8960

10240

11520

12800

3483

4095

4668

4812

5485

6126

6744

7343

7927

9078

9639

10192

10736

11273

11804

12330

6252

6984

7691

8956

9626

10282

11560

12804

7805

9177

9948

10700

11438

12164

10054

10907

12560

14597

11842

14093

15846

14189

15164

17071

16216

18854

22108

23277

25219

27714

31681

35721

39570

43516

47289

5190

5910

6590

6760

7580

8360

9120

9860

10580

11740

12440

13130

13820

14490

15170

15830

8520

9430

10310

11610

12460

13290

14920

16520

10460

11910

12890

13850

14800

15740

13030

14130

16270

18800

15340

18160

20480

18290

19580

22120

20990

24190

28150

30020

32670

35730

41100

46410

51670

56880

62060

30F. ROOM

(add 15% to loads for 10' height)

Typical Load Conditions:

The Cold Solutions Program

automatically figures typical loads.

Here are the typical conditions:

Product - In at +10

a) Specific heat of product is 0.90

BTU per pound

b) Product loaded in a 24 hour period

c) Freezing point of product is 27

d) Reduce product to 30 in 24 hours

e) Pounds of +40 product EQUALS

room volume (cu. ft.)

External Temperatures

a) 95 on all four walls

b) 115 on the ceiling (solar effect)

c) 55 on the floor

Insulation - 4" Urethane

4" urethane on the walls, ceiling,

and floor with R = 25 and k = 0.16

Infiltration - 2 times Average

a) 95 air enters room through the

door at 50% relative humidity

b) The door openings cause TWICE

the number of air changes listed in

AVERAGE AIR CHANGES FOR

STORAGE ROOMS table

Miscellaneous

a) Lighting - One watt per square

foot of floor area

b) People Load - charged at 1person

per 25000 cu. ft. of room volume

c) Motors - charged at 1 HP per

12500 cu. ft. of room volume

Heavy Load Conditions:

Same as Typical except:

a) Pounds of product is 3 times cu. ft.

b) People load is 1 person

Safety Factor - 10%

10% safety factor is added to the

product, transmission, infiltration,

and miscellaneous loads described

above.

Run time - 18 hrs, electric defrost

18 hour condensing unit run time.

The BTU load for 24 hours is

divided by 18 to yield the hourly

heat load reported in this table.

DIMENSIONS

(FEET)

ROOM ROOM BTUH BTUH

AREA VOLUME TYPICAL HEAVY

SQ. FT.

CU. FT.

LOAD

LOAD

6

6

6

8

8

8

8

8

8

8

8

8

8

8

8

8

10

10

10

10

10

10

10

10

12

12

12

12

12

12

14

14

14

14

16

16

16

18

18

18

20

20

20

20

20

20

40

40

40

40

40

6

8

10

8

10

12

14

16

18

20

22

24

26

28

30

32

10

12

14

16

18

20

24

28

12

14

16

18

20

22

14

16

20

24

16

20

24

18

20

24

20

24

28

32

36

40

24

28

32

36

40

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

36

48

60

64

80

96

112

128

144

160

176

192

208

224

240

256

100

120

140

160

180

200

240

280

144

168

192

216

240

264

196

224

280

336

256

320

384

324

360

432

400

480

560

640

720

800

960

1120

1280

1440

1600

288

384

480

512

640

768

896

1024

1152

1280

1408

1536

1664

1792

1920

2048

800

960

1120

1280

1440

1600

1920

2240

1152

1344

1536

1728

1920

2112

1568

1792

2240

2688

2048

2560

3072

2592

2880

3456

3200

3840

4480

5120

5760

6400

7680

8960

10240

11520

12800

4986

5884

6729

6939

7934

8887

9808

10626

11581

12588

13434

14267

15585

16398

17203

18001

9072

10164

11221

12398

13406

14890

16823

18709

11391

12728

13887

15518

16633

17732

14046

15828

18329

20756

17240

19987

22656

20132

21615

25018

23713

27005

30084

33608

36595

40190

45633

51628

57408

63278

68954

6540

7470

8350

8570

9600

10590

11550

12410

13410

14310

15190

16060

17420

18270

19120

19960

10790

11930

13040

14120

15170

16710

18740

20720

13220

14470

15680

17370

18550

19710

15850

17700

20340

22910

19200

22100

24930

22260

23830

27410

26030

29370

32650

36370

39550

43200

49040

55280

61460

67580

73650

35F. ROOM

(add 15% to loads for 10' height)

Typical Load Conditions:

The Cold Solutions Program

automatically figures typical loads.

Here are the typical conditions:

Product - In at 40

a) Specific heat of product is 0.90

BTU per pound

b) Product loaded in a 24 hour period

c) Freezing point of product is 27

d) Reduce product to 35 in 24 hours.

e) Pounds of 40 product entering the

room is two times room cu. ft.

External Temperatures

a) 95 on all four walls,

b) 115 on the ceiling (solar effect)

c) 55 on the floor

Insulation - 4" Styrofoam

a) 4" Styrofoam on the wall & ceiling,

with R = 16.7 and k = 0.24

b) 6 concrete on the floor,

with R = 4.8 and k = 1.25

Infiltration - 2 times Average

a) 95 air enters room through the

door at 50% relative humidity

b) The door openings cause TWICE

the number of air changes listed in

AVERAGE AIR CHANGES FOR

STORAGE ROOMS table.

Miscellaneous

a) Lighting - One watt per square

foot of floor area

b) People Load - charged at 1 person

per 25000 cu. ft. of room volume

c) Motors - charged at 1 HP per

16000 cu. ft. of room volume

Heavy Load Conditions:

Same as Typical except:

a) Pounds of product is 3 times cu. ft.

b) People load is 1 person

Safety Factor - 10%

10% safety factor is added to the

product, transmission, infiltration,

and miscellaneous loads described

above.

Run time - 16 hrs., air defrost

16 hour condensing unit run time.

The BTU load for 24 hours is

divided by 16 to yield the hourly

heat load reported in this table.

QUICK CALCULATIONS for

QUICK CALCULATIONS for

COOLERS

COOLERS

Вам также может понравиться

- Je Professional InstituteДокумент126 страницJe Professional InstituterihanОценок пока нет

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- Design of HVAC SystemsДокумент32 страницыDesign of HVAC Systemspriyanthabandara100% (1)

- Welcome To The PMG Educational Program: Sponsored byДокумент51 страницаWelcome To The PMG Educational Program: Sponsored byRAMESHОценок пока нет

- 4 Load EstimationДокумент175 страниц4 Load Estimationhasan bishОценок пока нет

- The Basics of Heating, Ventilation and Air ConditioningДокумент96 страницThe Basics of Heating, Ventilation and Air Conditioningsakshi1405Оценок пока нет

- Cooling Load Calculation: (Aircon Lab)Документ24 страницыCooling Load Calculation: (Aircon Lab)matthew ocampoОценок пока нет

- The Residential HVAC Design ProcessДокумент131 страницаThe Residential HVAC Design Processmarjan 01100% (3)

- HVAC Thermal Load EstimatingДокумент28 страницHVAC Thermal Load EstimatingIntisar Ali SajjadОценок пока нет

- HVACДокумент27 страницHVACajuhaseenОценок пока нет

- Career as an Air Conditioning TechnicanОт EverandCareer as an Air Conditioning TechnicanРейтинг: 5 из 5 звезд5/5 (2)

- 346N No06 HVAC Cooling LoadДокумент33 страницы346N No06 HVAC Cooling LoadmartinqОценок пока нет

- Potato Cold Storage Load CalculationsДокумент3 страницыPotato Cold Storage Load CalculationsSamiYousif100% (1)

- Efficient Display Case Refrigeration: Practical GuideДокумент7 страницEfficient Display Case Refrigeration: Practical GuideCyduck GuevarraОценок пока нет

- Air-Conditioning Load EstimationДокумент23 страницыAir-Conditioning Load Estimationtkm2004Оценок пока нет

- Coaling Load HVAC PDFДокумент10 страницCoaling Load HVAC PDFIntan Luruh LarasatiОценок пока нет

- Marine Hvac SystemДокумент58 страницMarine Hvac SystemSiti Aishah Hussien100% (3)

- Design of Raft FoundationДокумент9 страницDesign of Raft FoundationAnonymous ciKyr0tОценок пока нет

- Refrigeration and Air ConditioningДокумент1 страницаRefrigeration and Air Conditioningnavalzero910Оценок пока нет

- Flammable Refrigerants SafetyДокумент75 страницFlammable Refrigerants SafetyAhmed AzadОценок пока нет

- Sadhu Singh Theory of Machines Kinematics and Dynamics 2011 PDFДокумент1 393 страницыSadhu Singh Theory of Machines Kinematics and Dynamics 2011 PDFsajad33% (3)

- Air Cond Load EstДокумент28 страницAir Cond Load Estari_aristaОценок пока нет

- Midea SERVICE MANUAL PDFДокумент44 страницыMidea SERVICE MANUAL PDFAhmed Azad67% (3)

- Hvac Load CalculationДокумент20 страницHvac Load CalculationLalit Sisodia75% (4)

- Split Air Conditioner TrainerДокумент2 страницыSplit Air Conditioner TrainerAhmed AzadОценок пока нет

- Cooling Load CalculationДокумент14 страницCooling Load CalculationVũ Hằng PhươngОценок пока нет

- HVAC Basics - AДокумент39 страницHVAC Basics - AAbhik Bhattacharjee100% (1)

- Civflum Quiz 1Документ4 страницыCivflum Quiz 1Jhun CastroОценок пока нет

- 6B Circular Motion & Gravitation 2020-2021Документ46 страниц6B Circular Motion & Gravitation 2020-2021RandominicОценок пока нет

- Long-Wavelength Infrared Semiconductor Lasers PDFДокумент406 страницLong-Wavelength Infrared Semiconductor Lasers PDFKunchur Narayan100% (1)

- Practice PE Exam: HVAC Breadth and DepthДокумент3 страницыPractice PE Exam: HVAC Breadth and DepthAhmed EbrahimОценок пока нет

- DR ApichitДокумент139 страницDR ApichitMuh. Yousuf KhanОценок пока нет

- Heat Gain Due To InfiltrationДокумент18 страницHeat Gain Due To InfiltrationNg Swee Loong Steven100% (2)

- The Home Owner's Guide to HVAC: The Envelope and Green TechnologiesОт EverandThe Home Owner's Guide to HVAC: The Envelope and Green TechnologiesОценок пока нет

- Kitchen Ventilation (DW172)Документ6 страницKitchen Ventilation (DW172)Vishal Mohite100% (2)

- Aluminium and Its Alloys Used in Electrical EngineeringДокумент7 страницAluminium and Its Alloys Used in Electrical EngineeringTigrilloОценок пока нет

- Refrigeration Heat Load EstimatingДокумент17 страницRefrigeration Heat Load EstimatingAnonymous 1gbsuaafddОценок пока нет

- Square Foot "Rule of Thumb":: How To Estimate A Cooling Load (And Maybe Heating Load)Документ7 страницSquare Foot "Rule of Thumb":: How To Estimate A Cooling Load (And Maybe Heating Load)Arturo Del-RioОценок пока нет

- Transformer Testing: Type Test of TransformerДокумент9 страницTransformer Testing: Type Test of TransformerSanjeev DhariwalОценок пока нет

- Cooling Load and Heating Load PrincipleДокумент18 страницCooling Load and Heating Load PrincipleSaif AliОценок пока нет

- Revised Heat Gain Rates From Typical Commercial Cooking Appliances From RPДокумент36 страницRevised Heat Gain Rates From Typical Commercial Cooking Appliances From RPReza KhajeОценок пока нет

- Cooling Load Estimation For Hibir BoatДокумент10 страницCooling Load Estimation For Hibir BoatAdi WahyudiОценок пока нет

- Carrier Cold Room Calculaton PDFДокумент28 страницCarrier Cold Room Calculaton PDFMohammad Amer93% (60)

- 3 Thermal LoadsДокумент19 страниц3 Thermal LoadsJaime Fernando Leon TerrazosОценок пока нет

- Presentation 1Документ51 страницаPresentation 1Cedrick S TanОценок пока нет

- Agitator Power Requirement and Mixing Intensity CalculationДокумент28 страницAgitator Power Requirement and Mixing Intensity Calculationcandra100% (3)

- Searle Engineers HandbookДокумент31 страницаSearle Engineers HandbookDavidB1206Оценок пока нет

- Marine AC CalculationДокумент10 страницMarine AC CalculationPratikno SajaОценок пока нет

- MEM554 - Thermalfluids Lab Computer Linked RefrigerationДокумент25 страницMEM554 - Thermalfluids Lab Computer Linked Refrigerationsayabudakcomey75% (12)

- Helix StairsДокумент7 страницHelix Stairselidstone@hotmail.comОценок пока нет

- Thermal Design of Heat ExchangerДокумент9 страницThermal Design of Heat ExchangerNaqqash SajidОценок пока нет

- Glass Unit V Air-Conditioning Load CalculationДокумент26 страницGlass Unit V Air-Conditioning Load CalculationASWIN KUMAR N SОценок пока нет

- Fcsi Quiz - Halton Hood LoadДокумент19 страницFcsi Quiz - Halton Hood LoadblindjaxxОценок пока нет

- 3 Thermal LoadsДокумент19 страниц3 Thermal LoadsLaUpa Ricra PaUlОценок пока нет

- SCE Research Paper PDFДокумент12 страницSCE Research Paper PDFmuoi2002Оценок пока нет

- Lecture 6 - Air Conditioning Princples & SyatemsДокумент12 страницLecture 6 - Air Conditioning Princples & SyatemsMuhammad Faiz bin Ahmad ShafiОценок пока нет

- Cooling Load Calculation FormulaДокумент2 страницыCooling Load Calculation FormulaYamte VawaОценок пока нет

- A Simple Technique For Refrigerant Mass MeasurementДокумент11 страницA Simple Technique For Refrigerant Mass MeasurementDaniel WeeksОценок пока нет

- Low Cost Temperature & Humidity Chamber: Open Access Case StudyДокумент9 страницLow Cost Temperature & Humidity Chamber: Open Access Case StudyAlejandro Renato Rengifo LedesmaОценок пока нет

- MethodologyДокумент3 страницыMethodology무제untitledОценок пока нет

- Chapter One 1.0 Introdiction History of Air Conditioning SystemДокумент79 страницChapter One 1.0 Introdiction History of Air Conditioning Systemikperha jomafuvweОценок пока нет

- Hvacr 222 AbbieДокумент39 страницHvacr 222 AbbieApril FenolanОценок пока нет

- Basics of Air ConditioningДокумент28 страницBasics of Air ConditioningdavinderОценок пока нет

- Air Change LoadДокумент4 страницыAir Change LoadagazamiОценок пока нет

- Phuong Phap Tinh Tai Theo Phan Mem MistralДокумент8 страницPhuong Phap Tinh Tai Theo Phan Mem Mistralntt_121987Оценок пока нет

- Air Conditioner BasicsДокумент18 страницAir Conditioner BasicsBenjamin YusuphОценок пока нет

- 06 Benjamin-StulzДокумент62 страницы06 Benjamin-StulzdexterОценок пока нет

- Refrigeration Comp. LinkedДокумент6 страницRefrigeration Comp. LinkedDin TescoОценок пока нет

- R&T 2001 - Cold Storage Warehouse Dock Study - JekelДокумент12 страницR&T 2001 - Cold Storage Warehouse Dock Study - JekelPRKrauseОценок пока нет

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManОт EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManОценок пока нет

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"От EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Оценок пока нет

- Chapter 7 Cycle Diagrams and The Simple Saturated Cycle - Page117Документ18 страницChapter 7 Cycle Diagrams and The Simple Saturated Cycle - Page117Ahmed AzadОценок пока нет

- Priceguide Section 7 2015Документ18 страницPriceguide Section 7 2015Ahmed AzadОценок пока нет

- 121 DC Circuits E104A Course Outline V2Документ8 страниц121 DC Circuits E104A Course Outline V2Ahmed AzadОценок пока нет

- IPM TroubleshootingДокумент1 страницаIPM TroubleshootingAhmed AzadОценок пока нет

- Mode NG I 111116Документ68 страницMode NG I 111116Ahmed AzadОценок пока нет

- Guide To Good Commercial Refrigeration Practice: Safety & Environmental Considerations & StandardsДокумент20 страницGuide To Good Commercial Refrigeration Practice: Safety & Environmental Considerations & StandardsAhmed AzadОценок пока нет

- Correction of Service Manual Si-18 M-11011Документ18 страницCorrection of Service Manual Si-18 M-11011Ahmed AzadОценок пока нет

- Commercial Dehumidifier ManualДокумент10 страницCommercial Dehumidifier ManualAhmed AzadОценок пока нет

- 00Документ60 страниц00Ahmed AzadОценок пока нет

- Sound Insulation EngДокумент8 страницSound Insulation EngAhmed AzadОценок пока нет

- Chart Metric Imp ConvДокумент1 страницаChart Metric Imp ConvAhmed AzadОценок пока нет

- Johnson-Controls Informatiebrochure p216 enДокумент8 страницJohnson-Controls Informatiebrochure p216 enAhmed AzadОценок пока нет

- Ben 3proj3 RevДокумент6 страницBen 3proj3 RevAhmed AzadОценок пока нет

- Unit 10Документ14 страницUnit 10Ahmed AzadОценок пока нет

- Lens Pow Formula RLДокумент1 страницаLens Pow Formula RLHimanshu SethiОценок пока нет

- Design of Fluid Thermal Systems SI Edition 4th Edition by Janna ISBN Solution ManualДокумент43 страницыDesign of Fluid Thermal Systems SI Edition 4th Edition by Janna ISBN Solution Manualtimothy100% (17)

- Newton's Law of CoolingДокумент5 страницNewton's Law of Coolingjim1234uОценок пока нет

- A Low Order System Frequency Response ModelДокумент10 страницA Low Order System Frequency Response ModelNadil AminОценок пока нет

- Trigonometric Sum, Difference, Product Identities & EquationsДокумент2 страницыTrigonometric Sum, Difference, Product Identities & EquationsAnderson AlfredОценок пока нет

- Isobaric Vapor Liquid Equilibrium For Binary Systems of Cyclohexanone + Benzene, Cyclohexanone + Toluene, and Cyclohexanone + P Xylene at 101.3 KpaДокумент7 страницIsobaric Vapor Liquid Equilibrium For Binary Systems of Cyclohexanone + Benzene, Cyclohexanone + Toluene, and Cyclohexanone + P Xylene at 101.3 KpaAyush DeoreОценок пока нет

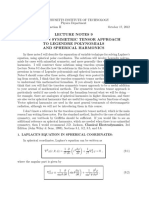

- Lecture Notes 9 Traceless Symmetric Tensor Approach To Legendre Polynomials and Spherical HarmonicsДокумент17 страницLecture Notes 9 Traceless Symmetric Tensor Approach To Legendre Polynomials and Spherical HarmonicsJefersonОценок пока нет

- RelativityДокумент49 страницRelativityKaren Jane B. LemosneroОценок пока нет

- Transhorizon Radiowave PropagationДокумент12 страницTranshorizon Radiowave PropagationoldjanusОценок пока нет

- 24.06 Magnetic Properties of Coordination Compounds and Crystal Field Theory PDFДокумент3 страницы24.06 Magnetic Properties of Coordination Compounds and Crystal Field Theory PDFSaurav PaulОценок пока нет

- Solutions Manual - Chapter 3 - RespostasДокумент8 страницSolutions Manual - Chapter 3 - RespostasJPVSSОценок пока нет

- DPP No. Standard 11Документ1 страницаDPP No. Standard 11Jyöt SîlvērОценок пока нет

- All B.Tech Courses Full SallybusДокумент21 страницаAll B.Tech Courses Full SallybusAnchitya KumarОценок пока нет

- Radar Engineering ConceptsДокумент5 страницRadar Engineering ConceptsAravind Kumar CS100% (1)

- Deep Learning in Science Theory, Algorithms, and ApplicationsДокумент8 страницDeep Learning in Science Theory, Algorithms, and ApplicationsUsman AliОценок пока нет

- 0625 w08 QP 1Документ20 страниц0625 w08 QP 1Hubbak Khan100% (1)

- Air Entrainment in Vertical DropshaftsДокумент199 страницAir Entrainment in Vertical DropshaftsZeroRecoОценок пока нет

- Sinyal Dan Sistem Latihan Soal Dan SolusiДокумент12 страницSinyal Dan Sistem Latihan Soal Dan SolusiMuh Indjra DijeОценок пока нет

- 1 Drag of A Cylinder Using Pendulum MethodДокумент9 страниц1 Drag of A Cylinder Using Pendulum MethodHarsh MehtaОценок пока нет

- Triaxial Strength of Rocks: Prepared For: Akshay Chowdu & Shane LeeДокумент16 страницTriaxial Strength of Rocks: Prepared For: Akshay Chowdu & Shane LeeAbhishek RayОценок пока нет