Академический Документы

Профессиональный Документы

Культура Документы

New Technoly of Fermernting

Загружено:

Vohinh NgoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

New Technoly of Fermernting

Загружено:

Vohinh NgoАвторское право:

Доступные форматы

J. Insi. Brew., January-February 1998, Vol. 104, pp.

19-31

FUNDAMENTALS OF IMMOBILISED YEAST CELLS FOR CONTINUOUS

BEER FERMENTATION: A REVIEW

By P. H. Pilkington1-2, A. Margaritis1*, N. A. Mensour1-2, and I. Russell2

(lDepartment of Chemical & Biochemical Engineering, University of Western Ontario, London, Ontario, Canada N6A5B9,

^Technology Development Department, Labatt Brewing Company Limited, London, Ontario, Canada N6A 4M3)

Received 9 July 1997

Recent fundamental research conducted on immobilised cells with a focus on continuous primary beer

fermentation is presented in this review. The knowledge of whole-cell immobilisation, continuous

fermentation, yeast biochemistry associated with beer flavour production, and bioreactor engineering

design is required to apply immobilised yeast cells for industrial scale beer production. Understanding

how immobilisation and continuous bioreactor operation affect yeast cell metabolism and viability will

provide the groundwork for optimising beer quality. The latest studies on immobilised cell carriers,

viability, vitality, mass transfer characteristics and bioreactor design indicate that an industrial scale

immobilised cell system for primary beer fermentation may soon be a reality in the modern brewery.

Key Words: Immobilised cell carriers, beer production,

continuous fermentation, viability, mass transfer, bioreactor

design, flavour production.

5.

for the production of consistent quality beer using im

mobilised yeast cells.

Introduction

Traditional beer fermentation technology uses freely suspended

yeast cells in batch bioreactors to ferment wort using a variety

of yeast strains to make different beer products. The sugars and

other nutrients present in the liquid phase must diffuse into the

yeast cell to be metabolised by different enzymes into cthanol

and other flavour compounds which must diffuse out of the

yeast cell into the liquid phase. The functional integrity of the

cell membrane plays a key role in determining the viability

characteristics of the yeast cells and their metabolic activity.

Over the last IS years or so, a new development in ferment

ation technology, using immobilised yeast cells for the

continuous production of beer, has gradually emerged world

wide. Earlier research by Margaritis et al.75-16'17--19 an(j otner

researchers8-25-3*65-911 iwa.i3i.i35.i38 has established the superior

characteristics and advantages of using immobilised yeast cells

to continuously produce ethanol in fixed bed and fluidised

bioreactor systems. The large number of publications on yeast

cell immobilisation highlights the importance and interest in

this new technology as we enter the twenty-first century.

Continuous beer fermentation using immobilised cells will out

perform existing mainstream brewing technology by reducing

the time to produce a finished beer, reducing inventory,

reducing floor space, and reducing product variation.

A systematic critical review of the literature on beer pro

duction using immobilised yeast cells revealed the following

problems that need to be solved through more research:

1.

2.

3.

4.

matrix and the flavour and aroma compounds that diffuse

out; and

an integrated approach is needed to incorporate all of the

above information to develop bioreactor control strategies

there is no reliable collection of data on the mixing and

mass transfer of real three-phase fluidised bioreactors;

there is a need to develop an accurate non-invasive method

to measure immobilised cell viability;

much work remains to be done on the effects of dissolved

oxygen concentration and free amino acid concentration on

immobilised yeast cell metabolism and the production of

aroma and flavour compounds which significantly influence

the quality and consumer acceptance of the beer product.

For example, one of the main problems reported is the high

diacetyl concentration in beer produced by immobilised

cells which is detrimental to the beer taste;

more research is needed to measure the diffusivitics of

nutrient compounds that diffuse into the immobilisation

Corresponding author: Dr. A. Margaritis.

In this review, the fundamental aspects of immobilised yeast cell

research needed to expedite the commercialisation of this emerging

technology for continuous beer production are summarised.

Practical importance of cell immobilisation

Producing an alcoholic beverage such as beer using a

continuous fermentation system offers several important

advantages over the commonly used batch systems:

a more uniform product

less process supervision

very high bioreactor volumetric productivity (product

weight/unit time/unit bioreactor volume).

Immobilisation may be used as a tool to confine intact cells

to an inert carrier within a bioreactor. This "tool" will further

increase the efficiency of a continuous fermentation system by

providing5-55-90:

high cell densities per unit bioreactor volume which result

in very high fermentation rates

the reuse of the same biocatalysts (yeast cells) for extended

periods of time due to constant cell regeneration

a continuous process which may be operated beyond the

nominal washout rate

a discrete phase in which cells may be manipulated

easy separation of biocatalyst from the liquid phase where

the desired products are present thus minimising separation

costs

higher cell densities combined with operation at high

dilution rates, decreasing the risk of reactor shutdown due

to contamination

improved tolerance or protection of cells from product

inhibition

smaller bioreactor volumes which may lower capital costs.

Continuous fermentation using immobilised cells also allows

for efficient plant utilisation during peak sales periods. Con

tinuous smaller-scale high rate fermentation systems can be

stepped up to meet peak output when required. This is an

improvement over the current technology utilising large batch

fermenters which are useful during peak production times but

are under-utilised during off-times83. It was also observed that

immobilised cells are less susceptible than free cells to the

This document is provided compliments of the Institute of Brewing and Distilling

www.ibd.org.uk

Copyright - Journal of the Institute of Brewing

20

FUNDAMENTALS OF IMMOBILISED YEAST CELLS FOR BEER CONTINUOUS FERMENTATION

(J. Inst. Brew.

Continuous

fermentation using

immobilized

yeast cells

Changes in

cellular

activity

---

-^

Changes due to

Changes due to a

continuous mode

combination of

of reactor operation

yeast cell

immobilization and

immobilization

Changes due to

continuous mode of

reactor operation

111,

Optimization

of reactor

Optimization

of immobilization

design

Optimization

of fermentation

method

conditions

Selection

of appropriate

biocatalvst support

J

Beer of

acceptable flavour

tr

and

quality produced

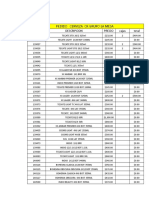

Fie. I. Considerations for the implementation of a continuous fermentation system using immobilised yeast cells.

effects of certain inhibitory compounds, pH variations, and

nutrient depletion18-77101.

The process advantages offered by continuous fermentation

will have a pronounced impact on the brewing industry. The

traditional beer production process is operated in batch mode

using free cells and generally takes 5-7 days to complete

primary fermentation. Initial studies show that a continuous

immobilised cell system can reduce the time required for

primary fermentation to as little as one day89. Maturation using

immobilised cells coupled with a heat treatment process is

shortened from 5-21 days to 2 hours27.

Many obstacles must be overcome to bring this continuous

process to industrial fruition. Currently, the flavour of beer

produced using immobilised yeast cell technology does not

match that of beer produced using batch systems. Flavourmatching may not be critical for commercial success, but there

may be need for improvement in the flavour of beer produced

using immobilised yeast before this technology becomes viable

on an industrial scale51-96. Two important factors affecting the

formation of these flavour compounds are further described

below.

The first factor involves reactor design. Beer fermentation using

free cells is normally carried out using a batch reactor, in which the

wort is added at the beginning of the fermentation67. Immobilised

cell reactors are operated continuously with fresh wort added to

metabolised wort. This implies that the fermentation process will

need to shift from a constantly changing batch to a steady state

continuous operation. For example, during batch free cell

fermentation, the bioreactor is operated aerobically for the first

segment to allow yeast to utilise the oxygen for cell growth.

Dissolved oxygen levels are subsequently depleted and the reactor

operates anaerobically for the remainder of the fermentation. In a

continuous system, dissolved oxygen will reach a constant, steadystate concentration.

How, then, can the conditions found within the batch reactor

be mimicked in a continuous immobilised cell reactor for the

production of a well-balanced beer? A thorough understanding

of yeast batch growth kinetics is required. It is postulated that

by controlling dissolved oxygen and other substrate levels, the

same relative amount of yeast growth per unit of wort processed

can be obtained in both the batch and continuous systems

The second factor involves the effect of immobilisation on

mass transfer and yeast metabolism. Internal mass transfer

involves the transfer of substrates and products within the

carrier to the yeast cell, whereas external mass transfer refers to

the transfer of nutrients from the bulk medium to the carrier

surface. Alteration of internal and external mass transfer due to

immobilisation may affect the concentration of metabolites in

the immediate vicinity of the immobilised cells and may thus

change the yeast cell's metabolic state and ultimately the flavour

of the beer produced.

The implementation of a continuous fermentation system on

an industrial scale using immobilised yeast will require a team

of applied researchers with expertise in biochemical engineer

ing, microbiology, chemistry, and biochemistry. Project

considerations are outlined in Figure I.

Properties of immobilised cell systems

Whole-cell immobilisation is defined as the localisation of

intact cells to a defined region of space with the preservation of

This document is provided compliments of the Institute of Brewing and Distilling

www.ibd.org.uk

Copyright - Journal of the Institute of Brewing

Vol. 104, 1998]

21

FUNDAMENTALS OF IMMOBILISED YEAST CELLS FOR BEER CONTINUOUS FERMENTATION

(b) Attachment or adsorption

(a) Entrapment within a matrix

to a preformed carrier

(d) Cells contained behind

(c) Self aggregation of

a barrier

cells (flocculation)

o

oo

o

o

o

oo

0

oo

oo

o

00

oo

o

Fig. 2. Basic methods of cell immobilisation.

catalytic activity55. An immobilised cell system is described by

Abbott1 to be any system in which microbial cells are confined

within a bioreactor, thus permitting their reuse. Methods of

immobilisation include physical entrapment within a porous

matrix, attachment or adsorption to a pre-formed carrier, self

aggregation by flocculation or crosslinking agents, and cells

contained behind a barrier. All of these methods have a similar

purpose: to retain high cell concentrations within the bioreactor, leading to increased volumetric productivity of the

system and lowered fermentation costs. Figure 2 illustrates

basic immobilisation techniques.

An immobilised cell system should have the following

properties for large scale industrial application90:

the carrier material must be nontoxic, readily available and

affordable;

the system should be efficient, easy to operate and give good

yields;

the carrier material should allow for high cell loading and

physical strength;

the cells should have a prolonged viability in the support.

bilising yeast cells using entrapment is a relatively simple

method and a high biomass concentration is facilitated84.

Table I lists some characteristics of alginate117 and carrageenan

gels'".

Some brewers have moved away from entrapment matrices

and are currently focusing on adsorption techniques for several

reasons. At present, gel entrapment matrices are not produced

economically on an industrial scale. Diffusion limitations due

to the gel matrix and high biomass loadings cause metabolite

concentration gradients within the polymer beads. This is a

TABLE I.

has been studied extensively. Polymeric beads are usually

spherical with diameters ranging from 0.3 to 3.0 mm. Immo

Aa/)/o-Carrjgecnan

Calcium Alginate

polymer from seaweeds

from the Phaeophycetie class

of algae

polymers from red seaweeds

such as Chondrus crispus

and Eucheuma cottonii

moderate concentrations

thermorcversible gel where

gelling temperature depends

on potassium ion

concentration

method for pilot scale

production of carrageenan

of calcium dictating agents

such as phosphates. 12DTA.

Physical entrapment within a porous matrix

The entrapment of immobilised cells within a porous

polymeric matrix such as calcium alginate1 >.".s5.97.<mu<m.i u.i im3o

or fcap/ra-carrageenan89-90101'27, along with some others44103,

Characteristics of calcium alginate and

kappa-carragtenixn gels

Mg:\ and K* ions will

disrupt alginatc gels

lack of methods for industrial

scale production of alginate

beads

This document is provided compliments of the Institute of Brewing and Distilling

www.ibd.org.uk

Copyright - Journal of the Institute of Brewing

beads is currently available8'

22

EUNDAMENTALS Ol IMMOBILISED YEAST CELLS K)R BEER CONTINUOUS FERMENTATION

concern because the flavour components in beer are affected

when mass transfer limitations alter substrate availability or

create a buildup of inhibitory products such as ethanol and

carbon dioxide in the immobilisation microenvironment. How

ever, understanding mass transfer phenomena within entrap

ment matrices may allow one to simultaneously provide

differing conditions at the gel surface and in the bead centre.

One therefore could potentially mimic the aerobic and

anaerobic stages of yeast metabolism during a batch fer

mentation using this entrapped cell system in continuous

fermentation.

This concept of utilising the different microenvironments

within a gel entrapment matrix is being studied for wastewater

treatment systems31 by Dos Santos and colleagues who refer to

the "magic bead concept" in which the nitrifying bacterium

Nitrosomonas europaea and the denitrifier Paracocctis denitri-

ficans are co-immobilised in double-layer gel beads. It was

found that oxygen264761132, due to limitation of its uptake and

diffusion, rarely penetrates greater than a few hundred micro

meters into the gel bead when it is the limiting substrate. Thus,

in a single-stage continuous air lift reactor, the aerobic nitri

fication step was carried out in the outer layer while the

anaerobic denitrification took place in the bead core31. This

result may prove to be useful for achieving aerobic and

anaerobic stages during beer fermentation.

Another limitation of gel entrapment includes the loss of gel

mechanical integrity, by dissolution or by breakdown due to

abrasion, compression, or internal gas accumulation44-84.

Researchers have treated alginate gel beads with stabilising

agents such as sodium meta-periodate and glutaraldehyde13 or

Al'* "2 to improve gel mechanical strength.

Attachment or adsorption to a preformed carrier

Adsorption involves the reversible attachment of biomass to

a solid support mainly by electrostatic, ionic and hydrogen

bonding interactions. Because it is known that yeast cells have

a net negative surface charge, a positively charged support will

be most appropriate for immobilization12. There are actually

two types of whole-cell adsorptive immobilisation carriers: (a)

carriers that allow adsorption only onto external surfaces,

because pore sizes are too small to allow microorganisms to

penetrate inside, and (b) carriers with large enough pores to

allow adsorption onto internal surfaces102. Table II lists some

examples of preformed carrier materials that have been

suggested for immobilisation of yeast.

Biomass loading is generally lower in adsorbed cell systems

than those obtainable in gel entrapment matrices, but mass

transfer may be less limiting. Adsorptive matrices do not have

the additional gel diffusion barrier between the cells and the

bulk fermentation medium. Another advantage to using

adsorption matrices is the regenerability of the support.

The strength of cell attachment to an adsorption carrier

depends on both cell and matrix type. Since there is no barrier

between cells and the surrounding medium, these immo

bilisation matrices may have significant cell leakage. This is not

appropriate for processes requiring a cell-free effluent39.

Changes in environmental ionic strength, pH, temperature,

along with physical stresses such as agitation and abrasion can

induce cell desorption. Another limitation of adsorption celt

TABLE II.

Some carrier types used recently for immobilisation by

attachment or adsorption

Carrier Material

Reference

DEAE cellulose

porous glass

silicon carbide

volcanic rock

59,107

14.59.136.137

sponge

diatomaceous earth

wood blocks

gluten pellets

86.122.123

4,53

115

99

46

10

[J. Inst. Brew.

carriers is the possibility of nonspecific binding of charged

materials within the fermentation medium12.

The thickness of the biofilm attached to the surface of these

carriers ranges from a monolayer of cells to a layer of cells one

millimetre thick55. Flow rate of feed has the biggest effect on

the depth of the biofilm because it affects the turbulence of the

liquid flowing past the adsorbed biolayer. The kinetics of

biofilm formation are complex68 and therefore difficult to

control.

DEAE-cellulose (diethylaminoethyl) support uses ionic

attraction to immobilise yeast cells. It is an inert, nondissolving

cellulose matrix which has a nonuniform granular shape that

provides a large binding area for cell colonisation. Sinebrychoff

Brewery and Cultor Ltd. have worked with DEAE-cellulose to

immobilise yeast cells for use in continuous maturation or

secondary fermentation processes. They found that the

cellulose did not bind most common yeast contaminants and is

washable, reusable and regenerable with a long service life74.

Linko and Kronlof71 conducted a study in which they

compared Spezyme*, a DEAE-cellulose carrier obtained from

Cultor Oy, Finland, with two types of commercially available

porous silica beads used as immobilised cell carriers for the

continuous primary fermentation of beer. Tubular 1.6 L or

conical 5 L packed bed columns were used for the fer

mentations in this study. The silica beads compared were

Bioceramics" from Kirin Brewery in Japan, and Siran8

developed by Schott GmBH, Germany. The researchers

observed that when DEAE-cellulose particles were used, yeast

attached to the surface of the particles only, whereas glass

beads showed yeast growth partially on the surface and

partially inside the pores. The lowest amount of yeast growth

was observed using the glass Siran8 carriers. A beer flavour

profile most similar to traditionally brewed beers was obtained

using these immobilised yeast for primary fermentation. The

only difference found from traditionally brewed beer was

slightly elevated ester and diacetyl levels. To overcome these

limitations, genetically modified yeast with the gene encoding

ct-acetolactate decarboxylase could be used to reduce diacetyl

levels, while ester levels could be controlled by optimising

oxygen levels in the immobilised cell reactor. Of the two glass

carriers, Siran* was found to be superior over Bioceramics1

because of higher mechanical strength and density.

Cashin16 recently compared five different porous carriers in

terms of minimum fiuidisation velocity, biomass loading, and

durability. The carriers compared were the DEAE-cellulose

carrier Spezyme8, three sizes of Siran81 sintered glass beads, and

Hypermics8, a porous ceramic carrier from Kirin Breweries in

Japan. Hypermics8 was found to give the highest biomass

loading, but tended to float and was mechanically weak. The

DEAE-cellulose carrier, Spezyme, had the lowest minimum

fluidisation velocity, but it had to be chemically sterilised which

was more time consuming than the steam sterilisation that was

used for the silica-based carriers. This study found Siran8 to be

the preferred carrier for a fluidised bed system because it gave

the second lowest minimum fluidisation velocity and the second

highest biomass loading, while exhibiting none of the practical

limitations found with the other carriers16.

Meura-Delta, a Belgium-based brewery equipment supply

company, in collaboration with a research team at CERIA, a

Belgian university, integrated a novel immobilisation approach

for the continuous production of beer. They designed a twostage configuration for continuous primary fermentation using

an immobilised cell reactor in the first stage followed by a free

cell system. In the first reactor, multichannel porous silicon

carbide immobilisation rods were arranged in a loop con

figuration123. Open pores in the sintered silicon carbide rods

range in size from 40-60 um, which allow for rapid yeast

colonisation. Silicon carbide is inert, durable, re-usable, steam

sterilisable, and is suitable for CIP cleaning86. Rods with inter

nal channels rather than beads were used for immobilisation in

order to maximise mass transfer between the yeast cells and the

liquid wort flowing through the channels.

This document is provided compliments of the Institute of Brewing and Distilling

www.ibd.org.uk

Copyright - Journal of the Institute of Brewing

Vol. 104, 1998]

FUNDAMENTALS OF IMMOBILISED YEAST CELLS FOR BEER CONTINUOUS FERMENTATION

Diatomaceous earth, trade named Celite", is traditionally

used in the brewing industry as a filter aid but it also possesses

desirable qualities for use as an immobilised cell carrier. Celite8

has a uniform composition, high mechanical and chemical

stability, and does not swell during fermentation33. However,

both yeast cells and Celite have negatively charged surfaces

under typical fermentation conditions, causing a relatively

weak interaction between biomass and immobilisation

support. Anderson el al.3 reported that a reduction of

cell leakage rate from Celite is needed for long-term,

large scale fermentations. One group successfully decreased

cell leakage by encasing the Celite8 in a layer of calcium

alginate33.

Zeta potential plays an important role in determining the

extent of cell adhesion to a carrier such as Celite8. When

brought into contact with a polar medium (e.g. fermentation

broth), most substances acquire a surface electric charge63. Ions

of opposing charge will migrate to this surface. The zeta

potential2 is defined as the electrical potential required to shear

off this opposingly charged liquid layer in contact with the

charged solid surface. Factors such as wort composition, yeast

strain, fermentation stage, fermentation conditions, and

medium pH will affect the zeta potential of the Celite8 and the

yeast cells. For example, one would want to select a pH that

would minimise the forces of repulsion between the carrier and

the cells to maximise biomass loading. However, pH also

affects yeast viability, so a compromise between maintaining

yeast viability and productivity while maximising cell loading is

required.

23

with very high flocculation activity may result in low concen

trations of active yeast cells due to diffusion limitation of

substrate to the cells inside the floes60.

Dominion Breweries Limited in New Zealand"-32 has been

successfully using a flocculent lager yeast strain for the con

tinuous fermentation of beer for almost 40 years. This brewery

uses a hold-up vessel followed by two stirred tank fermenters

for the continuous primary fermentation. After primary fer

mentation, the flocculent yeast are separated from the green

beer by gravity in a conical settler. Yeast is then recycled from

the first stirred tank fermenter and the conical settler back into

the hold-up vessel to achieve more precise control of the rate of

fermentation. Labatt Brewing Company Limited in Canada

was also active in earlier work on continuous primary

fermentation of beer37.

Researchers at VTT Biotechnology and Food Research in

Finland13 compared the behaviour of strongly and weakly

flocculent yeast cells immobilised on two different carriers,

Siran (sintered glass) and Spezyme8 (DEAE cellulose) for the

primary fermentation of beer. They found that the strongly

flocculent yeast cells accumulated on the immobilisation

carriers faster and consequently the desired wort attenuation

was reached more quickly than the weakly flocculent yeast

strain. In addition, they noted that a genetically modified

superflocculent yeast strain that was disregarded because it

flocculated too early for use in conventional batch ferment

ations, may prove to be very useful in continuous

fermentations.

Mulchandani el al.93 studied the effect of zeta potential on

the adsorption efficiency of cells onto solid supports including

Celite8. They showed that when the yeast-like fungus Aureo-

basidium pullulans was grown in different pH conditions,

differences in the charge distribution on the cell walls were

found. A. pullulans cells exhibited a net negative charge in

solutions above pH 2.S-3.0. This was thought to be due to

differences in cell wall composition caused by the differing

media conditions. They also found that Celite8 had a negative

zeta potential with maximum negativity at pH 6 and minimum

at pH 2. Since A. pullulans did not synthesise pullulan at pH 2,

they cultured the cells in contact with Celite8 at pH 2 for 72

hours to maximise cell loading and minimise electrostatic

repulsion, and then transferred the immobilised cells to pH 5.5

production medium for optimal fermentation conditions.

Nguyen and Shieh" used Celite8 to immobilise yeast for the

continuous production of ethanol in a fluidised bed reactor.

They obtained only 71% of the theoretical ethanol yield and

this was thought to be due to extended mean cell residence time,

inhibitory effect of high dissolved carbon dioxide concen

trations, and intermittent pH variations in the reactor.

Cells contained behind a barrier

In this type of immobilisation, cells may be retained by the

membrane in soluble form or the cells may be attached to the

surface and/or entrapped within the membrane matrix38. A

barrier formed by the liquid-liquid interface between two

immiscible fluids can also be used for immobilization55. Cell

retention behind a membrane barrier has not been widely used

to immobilise yeast cells for the continuous production of beer,

but there are several groups who have investigated their use for

continuous ethanol production50628081*4. Kyung and

Gerhardt62 investigated continuous ethanol production using

Saccharomyces cerevisiae immobilised in a membranecontained fermenter. Microporous dialysis membranes

provided a barrier which retained the yeast cells in the

fermenter and simultaneously allowed inhibitory fermentation

products such as ethanol to be continuously removed in order

to boost reactor productivity. The problem of membrane

plugging must be overcome for this immobilisation mode to

become a practical industrial-scale method for continuous

ethanol production in the future.

Self aggregation of cells

The formation of cell aggregates by flocculation, shown in

Figure 2(c), is the most simple and least expensive immo

bilisation method, but the least predictable. Stewart118 defines

flocculation as "the formation of an open agglomeration that

relies upon molecules acting as bridges between separate

particles". The natural flocculating ability of yeast cells may be

exploited106 or crosslinkers may be added to bolster the process

of aggregation for cells that do not do so naturally. The control

of cell aggregation is important to maximise bioreactor effi

ciency. Factors which influence the natural flocculation

characteristics of brewer's yeast strains include the genetic

make-up of the strain, the cell wall structure and surface

charge, the growth phase, incubation temperature, medium pH,

cation composition of the medium, and other wort com

ponents"8.

Weak flocculation activity will result in slow cell sediment

ation rates which may cause cells to be "washed out" of the

bioreactor with the fermentation medium. Consequently, a low

cell concentration is maintained in the reactor resulting in

insufficient fermentation rates. On the other hand, larger floes

Immobilised Cell Viability and Vitality

Yeast viability is defined as the percentage of live cells in a

sample, and yeast vitality is a measure of yeast activity or

fermentation performance7-66121. Lentini66, in his compre

hensive 1993 review, specifically describes yeast vitality as "a

function of the total cell viability and the physiological state of

the viable cell population". In order to efficiently and con

sistently produce quality beer using an immobilised cell system,

one must understand the impact of such a system on yeast

physiology and growth.

Many criteria are used to assess yeast cell viability and

vitality. Consequently, the perceived viability of a yeast sample

may vary depending on the criteria selected. It is often

beneficial to monitor a combination of parameters to gain a

more complete understanding of a yeast's physiological state. In

the section below a number of methods of studying yeast cell

viability and vitality are summarised while in later sections

methods for examining the patterns of yeast cell growth within

immobilisation matrices are described.

This document is provided compliments of the Institute of Brewing and Distilling

www.ibd.org.uk

Copyright - Journal of the Institute of Brewing

24

FUNDAMENTALS Ol: IMMOBILISED YEAST CELLS FOR BEER CONTINUOUS FERMENTATION

Methods for measurement of immobilised cell viability and vitality

Use ofspecific dyesfor assessing cell viability and vitality

Methylene blue is the dye most commonly used for yeast cell

viability staining. Viable cells are able to reduce this stain

making it colourless, whereas non-viable cells are unable to

reduce the stain rendering them a deep blue-purple shade66. A

viable yeast cell count may be completed using a hemocytometer and a light microscope in less than ten minutes.

When buffered and supplemented adequately, methylene blue

has no effect on yeast cell viability64. Methylene blue staining is

considered to be an accurate method only when yeast cell

viability is greater than 90%88. Some examples of methylene

blue solutions include Fink-Kuhles buffered methylene blue

(ASBC international method)120, methylene blue aqueous

solution120, and standard methylene blue solution64. Methylene

blue staining is a good method for assessing the viability of

highly concentrated yeast such as that found in immobilisation

matrices64. Other brightneld stains which have been used to

monitor yeast cell viability include Aniline Blue88 and Crystal

Violet35.

There are also many fluorescent stains designed to assess

yeast cell viability and vitality. When fluorescent stains are used

in conjunction with confocal microscopy9"110 or flow cytometry28.2.4o.48.73 valuable information may be obtained on yeast

cell growth and metabolic state. Kasten56 gives a comprehensive

review of stains available and fluorescence microscopy

techniques.

Capacitance

The principle of this method is that the application of a radio

frequency to a viable cell results in a charge buildup within the

membrane, and a capacitance is generated66. Nonviable cells

are unable to generate this capacitance. A linear correlation has

been demonstrated between capacitance and viable yeast

biomass6.

Kronlof58 recently showed that capacitance probes are

suitable for monitoring viable yeast biomass in both freely

suspended and immobilised cell systems. Yeast cells were

immobilised on porous glass carriers (SiranB) and DEAE-

cellulose (Spezyme8). Kronlof pointed out that although this

method correlates well with methods such as staining for the

detection of viable cells, it does not provide any additional

information about the yeast cell's metabolic state. Therefore

this method is best used in conjunction with other methods for

measuring yeast vitality such as nicotinamide adenine

dinucleotide (NADH) or adenosine triphosphate (ATP).

The power of reproduction as a viability indicator

Standard plate count measures the ability of yeast cells to

proliferate and form colonies on nutrient agar. It generally

takes three days for visible colonies to form and viability is

assessed by counting the number of colony forming units

(CFU). Care must be taken when using this method on very

flocculent yeast66.

Yeast viability by slide culture is also based on the ability of

yeast cells to proliferate. A drop of yeast culture is placed on a

film of nutrient agar and after approximately 18 hours of

incubation the formation of microcolonies is observed under

the microscope. Cells which have given rise to microcolonies are

considered viable whereas single cells that have not formed

microcolonies are considered non-viable120. It is relatively less

time-consuming than standard plate counts but still much

slower than the staining techniques. An advantage of the slide

culture method is that it is accurate at relatively low yeast cell

viabilities.

Viability and vitality methods based on cell metabolic state

Adenosine Triphosphate (ATP)

ATP (adenosine 5' triphosphate) is a good indicator of cell

viability since it is present in all living cells and is degraded

when cells die. ATP allows for the detection of viable cells in a

(J. Inst. Brew.

short amount of time (1015 minutes) when compared with

traditional plating techniques. Since the quantity of ATP per

cell does not vary significantly for a given strain (but varies

between strains), it can be inferred that the amount of ATP

present in a biomass sample is proportional to the number of

viable cells present of that cell type. Another advantage of using

ATP as a viability indicator is that the amount of ATP present

in a cell is roughly independent of the growth rate. Therefore a

correlation between ATP concentration and the amount of

viable cell mass can be made41.

The "firefly assay" is used to determine the quantity of ATP

present in a biomass sample. This invasive method involves

extracting the ATP from the cells and reacting it with firefly

luciferin in a two-step reaction which is catalysed by the enzyme

firefly luciferase. Light is one of the products of this reaction

and a stoichiometric relationship exists between the amount of

light produced and the quantity of ATP in the biomass sample.

Extractants used to release intracellular ATP include boiling in

buffers such as tris-EDTA, cationic detergents, acids, and

organic compounds such as acetone and ethanol. The reactions

taking place are summarised below:

Luciferin+Luciferase+ATP+Mg2* -> (Luciferin-LuciferaseAMP) + Pyrophosphate

(Luciferin-Luciferase-AMP)+O: -Oxyluciferin+Luciferase

+CO2+AMP+Light

ATP concentrations as low as 10"12 g in 100 u.1 volume may be

detected using the firefly method41.

Gikas and Livingston41 used ATP ioluminescence to charac

terise biomass viability in freely suspended and immobilised

cell bioreactors. They concluded that the kinetic data obtained

for freely suspended cells could not adequately describe

immobilised biomass kinetics because immobilised cells may be

in significantly different metabolic states than freely suspended

cells. They questioned whether differences in ATP levels

between freely suspended and immobilised cells reflect differ

ences in the biomass viable fraction or differences in metabolic

state.

NADH Fluorosensor

NADH has successfully been used as a noninvasive, on-line

method of monitoring freely suspended and immobilised yeast

cell metabolism30-69.Viable cells contain nicotinamide adenine

dinucleotide (NAD) coenzyme whereas non-viable cells or

spores normally lose their NAD17. The oxidised form, NAD*

is used by dehydrogenases to accept electrons from their

substrates. For example, in the enzymatic conversion of malate

to oxaioacetate in the presence of oxygen, malate dehydrogenase (MDE) first binds to NAD+ to form a complex of

MDE-NAD*. This complex then combines with malate to

form a ternary complex MDE-NAD+-malate. From here,

NADH, H+ ion, and oxaioacetate are released:

malate+NAD* <- oxaloacetate+NADH+H+

(oxidised)

(reduced)

The reduced form, NADH, fluoresces while the oxidised

form, NAD*, does not. NADH is strongly fluorescent with an

emission maximum at 460 nm wavelength. The total NAD is

the sum of NADH and NAD*. The reducing state is denned as

the ratio of the reduced form to the total amount of NAD:

R=[NADH] / ([NAD*]+[NADH])

Cell metabolic state determines the reducing state which will

remain constant unless there is a shift in metabolism. Thus, the

influence of substrates such as oxygen on the reducing state

may be predicted. When oxygen is in excess, the reducing state

approaches zero because NADH is easily oxidised to form

NAD* and H;O, and when there is a lack of oxygen available

to the cells, R approaches one. The concentration of [NADH]

as well as the intensity of the fluorescent signal are influenced

by the number of viable cells, the reducing state of the cells and

environmental effects. Measuring NADH has an advantage

This document is provided compliments of the Institute of Brewing and Distilling

www.ibd.org.uk

Copyright - Journal of the Institute of Brewing

Vol. 104, 1998]

FUNDAMENTALS OF IMMOBILISED YEAST CELLS FOR BEER CONTINUOUS FERMENTATION

over monitoring dissolved oxygen or pH because it directly

measures, in real time, events occurring within the cell rather

than changes outside the cell environment.

Specific Oxygen Uptake Rate (BRF Yeast Vitality Test)

Researchers at Brewing Research International (BRI)

developed a method to determine the vitality of pitching yeast

by measuring its specific oxygen uptake rate24. Various

groups24-54-82 have shown a correlation between oxygen uptake

rate of yeast and fermentation performance if yeast viability is

less than 90%. The method involves the pitching of yeast into

aerated media and the measurement of the oxygen uptake rate

for one hour M.

A reduced oxygen uptake rate parallels other yeast changes

such as the reduction in yeast lipids, glycogen, acidification

power test value, and yeast viability49. Under these conditions,

oxygen uptake rate correlates well with yeast fermentation

performance. However, Wheatcroft et a/.129 found that oxygen

uptake rate did not correlate well with fermentation per

formance when yeast had been previously acid-washed. Even

though acid-washed yeast showed decreased specific oxygen

uptake rates, they actually showed better fermentation per

formance than non-acid-washed yeast.

The biocatalytic activity of the nitrogen-fixing bacterium,

Vibrio natriegens (Baneckea natriegens), immobilised on

Celite8, was studied by Gikas and Livingston42 using specific

oxygen uptake rate [mg (O2) g~' (dry biomass) h"1]. Specific

oxygen uptake rates for immobilised and free cells in a three

phase air lift reactor were compared and it was found that the

uptake rates were significantly lower for the immobilised cells,

implying a lower biomass activity in the immobilised cell

system.

Acidification Power

The acidification power test developed by Opekarova and

Siglcr104 measures the drop in extracellular pH of a suspension

of yeast cells after the addition of glucose. This method is useful

for detecting large differences in yeast metabolic activity. The

yeast acidification power test requires extensive yeast washing

and multiple sample points which makes it impossible to use

this test on immobilised cells in situ.

Intracellular pH (ICP) Method

The ICP method uses a pH-sensitive fluorescent reagent to

measure the intracellular pH of individual cells and cell mass.

It was found that the intracellular pH of more active yeast cells

does not decrease, even if the extracellular pH is low, whereas

the intracellular pH of less active cells actually decreases under

low extracellular pH conditions49. This test may be able to

detect more subtle changes in yeast cell vitality than acidi

fication power test49.

Measurement of Yeast Vitality by Stress Response

As stated earlier, vitality may be considered a measure of

yeast activity or fermentation performance. It has also been

defined as the ability of cells to endure or overcome stress7.

Therefore one could relate vitality to the response of yeast cells

to stresses such as ethanol, heat shock, and high salt concen

trations. Methylene blue, fluorescent dyes7, and standard plate

counts101 may be used to assess the ability of cells to remain

viable after being subjected to a given stress.

Norton et al.im assessed the ethanol and heat tolerance of

brewers' yeast entrapped in K<arrageenan gel. Free and immo

bilised Saccharomyces cerevisiae cells were exposed to ethanol

concentrations of 0, 18%, and 19.4% (v/v) for a given length of

time and viability was then measured using standard plate

counts. Heat tolerance was measured by incubating yeast cells

at 48C for various lengths of time with periodic shaking. Cell

viablity following heat shock was also measured using standard

plate counts. It was found that there was a significant increase

in yeast survival against ethanol for immobilised cells as com

pared to free cells, but no distinct difference in heat resistance

25

was noted. The study concluded that the carrageenan gel matrix

provided protection to the entrapped yeast cells against ethanol.

When entrapped cells were released from the carrageenan

matrix, their ethanol tolerance returned to that of free cells.

Magnesium Release Test (MRT)

The Magnesium Release Test92 is based on the observation

that low molecular weight species such as magnesium, potas

sium, and phosphate ions are released by yeast immediately

following inoculation into glucose containing medium. Trials

performed on Saccharomyces cerevisiae showed that cells which

released greater quantities of magnesium immediately after

inoculation into high gravity (16P) wort had higher vitality and

fermentation performance than yeast which released lower

amounts of magnesium. Subsequent fermentations performed

using the more vital yeast had shorter lag phases, higher cell

counts, higher end ethanol concentrations, and lower diacetyl

levels. The magnesium release test (MRT) takes less than fifteen

minutes to perform and it uses a commercially available

magnesium test kit (Sigma) which allows the quantitative

colourimetric measurement of magnesium in wort before and

immediately after yeast inoculation.

Methods for determining cell distribution and growth patterns

within immobilised cell matrices

Method ofsuccessive dissolution of layers from gel beads

When calcium alginate is used to entrap yeast cells, calcium

chelators such as phosphates and citrates may be used to

dissolve "shells" of alginate and biomass from the beads18-43"3.

By measuring the concentration and viability of cells inside

each shell, information may be obtained about the spatial

distribution of viable cells within the entrapment matrix.

Usually shells obtained using this method have a thickness

greater than SO um. When biomass profiles are steep within the

beads, greater resolution is required to obtain an accurate

picture of yeast cell distribution. Released biomass from each

shell may be assessed for viability by using methylene blue

staining, fluorescent dyes or by plating. Problems with this

method include uniformity of dissolution of matrix, finding a

suitable nontoxic solution for dissolving the entrapment

matrix, and overall accuracy limitations.

Recently, Parascandola and Alteriis"0 studied the spatial

growth patterns of Saccharomyces cerevisiae cells entrapped in

starch-hardened gelatin discs. They used a multi-step digestion

method to collect cells belonging to five different layers of the

discs. Diluted trypsin was used to release the cells from the

gelatin and yeast viability from each of the layers was then

measured by staining the cells with fluorescent stain

Rhodamine 123 and examining them under a confocal

microscope.

Physical sectioning of immobilised cell matrix

A biomass distribution may be obtained by slicing matrices

containing yeast cells. To avoid matrix compression and to

obtain an accurate distribution, the sample is often dried and

embedded into a resin, or frozen. Shrinkage has been observed

during this preparation134. Beads may then be sliced using a

microtome or razor blade and cell concentration within each

section is obtained using image analysis and the appropriate

viability or vitality stains. However, this invasive slicing method

may cause alterations in cell distribution and other aber

rations9.

NMR imaging

Nuclear magnetic resonance imaging (NMRI) is a noninvasive technique to study spatially chemical and physical

properties of small samples68. Lewandowski et a/.68 used

NMRI to better understand the dynamics of biofilm growth

and external liquid film flow velocity distribution. These studies

are of importance since the extent of biofilm growth is in

fluenced by the local chemical environment and fluid flow

This document is provided compliments of the Institute of Brewing and Distilling

www.ibd.org.uk

Copyright - Journal of the Institute of Brewing

26

FUNDAMENTALS OF IMMOBILISED YEAST CELLS FOR BEER CONTINUOUS FERMENTATION

[J. Inst. Brew.

conditions. Substrates must also be transferred through the

biofilm-bulk medium interface to reach the cells. In addition,

researchers were able to gather information on velocity distri

bution using NMRI near microbially colonised surfaces with

an imaging time of 8-16 minutes.

The use ofconfocal microscopyfor the determination of viable

cell distribution within porous microcarriers

Confocal microscopy is a valuable tool for studying viability

of immobilised cells because of its unique ability to take optical

sections of three dimensional objects in a noninvasive manner.

This depth discrimination property allows only the region of

the object that lies close to the focal plane to be imaged

efficiently87. Using confocal microscopy, one could potentially

DULKUGUtO

PHASE

obtain three-dimensional images of yeast cell growth and

viability distribution within porous microcarriers without

actually disrupting the carrier matrix.

In an elegant study by Lim et al.10, the spatial distribution of

mammalian cells grown on modified macroporous gelatin

microcarriers was studied using confocal microscopy. Optical

sectioning employing confocal microscopy and ethidium

bromide for cell staining allowed the researchers to visualise the

distribution of cells at different stages of growth within the

Fig. 3. Schematic of the transfer of substrate from the bulk medium to

an entrapped yeast cell.

macroporous microcarriers. They found that cells initially only

attach to the external surface or within the external cavities of

the macroporous microcarriers. Subsequently, there was a slow

migration of cells toward the interior of the beads. Confocal

microscopy revealed that penetration and growth of cells to

within the outer half of the radius of the microcarriers

accounted for 87% of surface utilisation efficiency whereas the

central core, comprising the inner half radius of the spherical

particles, contributed only 13% of the total available void

fraction.

Bancel and Hu9 used confocal laser scanning microscopy to

examine the distribution of viable hybridoma cells within

macroporous microcarriers. Confocal microscopy was used to

avoid the potential artifacts that may be generated using

physical sectioning. A cationic fluorescent vital stain (dialkyl

indocarbocyanine) was used for the hybridoma cells and a

second stain (fluorescein isothiocyanate) with a different

emission wavelength was used to render the microcarriers

uniformly fluorescent. The confocal microscope allowed the

researchers to take serial optical sections of the immobilised

cells and the carrier in a noninvasive manner with the

maintenance of cell viability. Their results showed that the

initial spatial distribution of cells within the carrier affects the

kinetics of cell growth and the maximum biomass loading

possible. These factors will have a significant effect on

immobilised cell bioreactor performance.

Mass Transfer Characteristics of Immobilised Cells

Changes in the kinetic behaviour of yeast cells upon

immobilisation may be attributed to either alteration of

physiological/metabolic properties of the cells, or alteration of

the local microenvironment in the immediate vicinity of the

immobilised cells. In the second case, the microenvironment

may be described in terms of solute partitioning effects between

the bulk liquid phase and the solid immobilisation matrix,

external film mass transfer resistance and internal mass transfer

resistance91. These terms may be quantified by the solute parti

tioning coefficient (Kp), the liquid film mass transfer coefficient

(Kl), and the effective solute diffusivity within the immobilisa

tion matrix (De) respectively. The above parameters need to be

quantified in order to determine overall effectiveness factors.

Figure 3 is a schematic of the transfer of substrate from the

bulk medium to an entrapped yeast cell. Substrate must travel

through the bulk medium by diffusion and convection, through

the external liquid film surrounding the bead containing

immobilised cells, through the liquid-solid interface, through

the liquid within the solid gel phase by diffusion, through

resistance caused by microcolony formation, and finally into

the yeast cell where the reactions take place. Mass transfer

occurs by diffusion only within and close to the solid matrix

phase whereas, in the bulk liquid phase, transfer occurs by both

diffusion and convection, leading to concentration gradients

between the two phases.

"Effectiveness factor" is defined as the ratio between the

observed reaction rate and the rate of reaction in the absence of

mass transfer resistance. If the effectiveness factor is less than

one, substrate concentration on the gel surface or within the

matrix is lower than the concentration in the bulk phase. The

Thiele Modulus may be defined as the ratio between the

reaction rate and the internal diffusion rate or, the rate that

substrate is consumed relative to the rate at which it is supplied

by the diffusion process. In other words, a high Thiele Modulus

indicates that the system is mass transfer limited whereas a

lower number indicates that the system is kinetically controlled.

A Thiele Modulus of less than ten is desirable to minimise

substrate concentration gradients. For more detailed dis

cussions of mass transfer in immobilised cell systems, com

prehensive reviews are presented by Karel et al.i$, and more

recently by Westrin and Axelsson128.

The study of the transfer of oxygen in beer fermentation

using immobilised yeast cells is especially important, since a

lack of oxygen due to mass transfer limitations may force yeast

cells to switch from aerobic to anaerobic metabolism, signi

ficantly altering the production of beer flavour compounds.

Internal mass transfer characteristics

Internal mass transfer involves the transfer of substrates and

products within the carrier or solid phase100, which is especially

relevant for entrapped cell systems. The effective solute

diffusivity, Dc, is used to quantify internal mass transfer rates.

Researchers have found that the cell mass is mainly confined

to a biolayer at the periphery of entrapment matrices due to a

lack of substrate at the centre of the beads. This occurs because

substrate concentration gradients are formed, where each point

of a concentration profile reflects a local equilibrium between

supply and consumption68. Internal mass transfer can be

optimised by adjusting the immobilisation matrix size, texture

and porosity. Decreasing bead diameter is a good way to

maximise internal mass transfer. A balance must be made so

that beads are large enough for easy separation from the bulk

phase and small enough to maximise mass transfer. Oxygen is

an essential substrate for yeast cell growth, yet it is only

required in relatively small quantities in brewery fermentations.

Therefore oxygen availability is often limited by mass transfer

restrictions caused not only by the matrix itself, but also by

yeast cells themselves in highly colonised beads.

This document is provided compliments of the Institute of Brewing and Distilling

www.ibd.org.uk

Copyright - Journal of the Institute of Brewing

Vol. 104, 1998]

FUNDAMENTALS OF IMMOBILISED YEAST CELLS FOR BEER CONTINUOUS FERMENTATION

27

Unsteady State Technique for Measuring

Solute Diffusivities

= f(r,t)

CL = f(t)

Merchant et a/.91 developed an unsteady state technique for

measuring effective solute diffusivities within an entrapment

matrix used for whole-cell immobilisation. This method has

advantages over other methods in that it does not rely on the

mechanical stability or the geometry of the entrapment matrix,

and it may be carried out relatively quickly91.

The following assumptions were made in order to derive the

equations needed to determine solute diffusivities:

dr

(1) diffusion of solute occurs radially outward and there is no

concentration variation with angular position;

(2) the physical properties of the sphere are constant;

(3) there is negligible external film mass transfer resistance;

BULK

LIQUID

PHASE

and

(4) at time, t=0, the solute is uniformly distributed throughout

the sphere.

Using the spherical coordinate system shown in Figure 4, a

mass balance for unsteady-state diffusion of solute is described

by the following equation:

Fig. 4. Spherical coordinate system Tor diffusion and reaction of a

solute for a sphere immersed in a finite liquid volume.

A spherical coordinate system used to describe diffusion and

reaction in a spherical shell of thickness "dr" for a single

spherical carrier particle is depicted in Figure 4. Effective

diffusivity, Dc, is defined by Fick's law:

J=-DcaCs/dr

where J is the flux per unit of matrix area, Cs is the amount of

solute per unit liquid volume in the gel phase, and r is the radial

coordinate in the sphere105.

Methods for detection of internal mass transfer characteristics

Use of Microelectrodes

Microelectrodes allow for the measurement of concen

aCs / dt=De [(a2Cs / dr2)+(23Cs / rar)]

To solve this equation, initial and boundary conditions are

needed. Therefore, for a sphere containing solute immersed in

a finite liquid volume initially free of solute, initial and

boundary conditions are listed below.

t=0,

t=o,

t>0,

t>0,

0<r<R,

r>R,

r=0,

r=R,

Cs=constant

CL=0

dCs / (r=0

vL(acL/at)=

KPAsDe(aCs/ar)|r=R

I.C.I

I.C. 2

B.C. 1

B.C. 2

By monitoring the change in concentration of solute in the

liquid phase as solute diffuses out of the sphere, and by solving

the above equation using the aforementioned conditions, one

may evaluate D. Radiotracer techniques may be used to follow

the change in solute concentration since the method requires

very small liquid volumes.

Other researchers34 have measured effective solute diffusi

trations directly inside biofilms. Being able to do this is

important because diffusion gradients within biofilms will

influence their internal structure. For yeast cells entrapped

within calcium alginate or carrageenan gels, the measurement

of substrate concentration profiles using microelectrodes

provides a direct method for characterising the microenvironment of the cells inside the matrix. Microelectrodes have

been developed for pH, oxygen, capacitance, ammonia, and

vities using a similar method except that gel beads are placed in

a buffered aqueous solution in a well-stirred tank. The

diffusion of a given solute into or out of the gel beads is

measured by monitoring the concentration of the bulk liquid

phase. High levels of agititation are required to avoid external

mass transfer resistance at the bead surface. This method is a

relatively simple way to gather data for the calculation of

effective solute diffusivities in immobilised cell systems.

of diffusion properties of components within immobilisation

matrices, the microelectrode tip should be less than 10 urn in

diameter so that it penetrates the biocatalyst without physically

late effective diffusivities of selected simple sugars and organic

acids in calcium alginate gels with and without entrapped

Lactobacillus helveticus bacteria. The mathematical model used

allowed for the calculation of effective diffusivities and

accounted for solution sampling and external film resistance.

Their experiments showed that lower pH (4.5 vs. 5.5 and 6.5),

higher alginate concentration, and lower temperatures each

resulted in lower diffusion rates for both lactose and lactic acid.

Some difficulties are encountered when using micro

electrodes since measurements may be influenced by calibration

conditions, other metabolites, mechanical resistance and

properties of the matrix, and puncture technique. The latter

point refers to the method of insertion of the microelectrode

into the biocatalyst bead. Signal artifacts may occur due to the

sudden breakthrough of the electrode through compressed

material such as the immobilisation matrix95. Flow conditions

in the reactor and in the flow chamber where measurements are

performed must be kept the same for accurate readings. It is

also difficult to determine the exact position of the microelectrode visually and thus spatial resolution is insufficient,

especially since immobilised cell matrices tend to have large

substrate concentration gradients95.

Thin Disk Method for Determining Effective

Solute Diffusivities

This method utilises a two compartment

glucose among others21-45-58-95121125. To be useful for the study

changing its configuration68. Response time of the electrode is

also important, especially in dynamic processes using im

mobilised or flocculating cells. A response time of 0.1 seconds

is desirable for these types of systems but an electrode of this

type is extremely fragile and has a short useful life and therefore

is not suitable for routine use15.

Oyaas et al.m also used the multiple bead method to calcu

diaphragm

diffusion cell, where each equal-volume chamber contains a

well-stirred solution placed in contact with either surface of a

thin gel. Diffusion occurs from higher to lower concentration

or from "source" to "sink"52. Concentration-time measure

ments are used to determine the effective diffusivity.

Korgel et a!.51 measured effective diffusivities of galactose in

calcium alginate gel occupied by living Zymomonas mobilis

bacterial cells using this method. The unmetabolizable

galactose was chosen because it allowed for effective diffusivity

measurements independent of consumption in a gel system

containing immobilised living bacterial cells. A thin disc of

This document is provided compliments of the Institute of Brewing and Distilling

www.ibd.org.uk

Copyright - Journal of the Institute of Brewing

28

FUNDAMENTALS OF IMMOBILISED YEAST CELLS I OR BEER CONTINUOUS FERMENTATION

TABLK III.

[J. Inst. Brew.

Some advantages and disadvantages of reactors commonly used with immobilised cell systems

Reactor Type

Packed bed reactors

Fluidised bed reactors

Advantages

Disadvantages

simple design

low energy requirements

poor liquid mixing

accumulation of gas pockets

difficulty with scale up

plugging

larger bead sizes needed to maintain

pressure drop

compaction of carrier material limits

reactor height

low shear

foaming

more complex scale up than packed bed

industrial scale systems

arc currently available

benefits from economies

of scale

optimal liquid mixing

heat and mass transfer

easy separation of products

Gas lift draft tube

reactors

lower shear than fluidised beds

benefits from economies

of scale

foaming

more complex scale up than packed bed

industrial scale systems are

currently available

optimal liquid mixing,

heat and mass transfer

reduced pumping costs

compared with fluidised

bed reactor

Loop reactors

easy separation of products

large surface area/volume

easy scale up due to

modular design

industrial scale systems in

developmental stage

fabric-supported calcium alginate gel was placed in a diffusion

cell to measure the rate of diffusion of galactose from source to

sink. Z. mobilis cell concentrations ranged from 0 to ISO g dry

wt/L of gel. Effective diffusivities were found to decline with

increasing entrapped biomass concentration. They also con

cluded that the random pore model of Wakao and Smith126 is

a good predictor of sugar effective diffusivities in gel

entrapment systems.

Cylinder Method of Determining Effective

Solute Diffusivities

The cylindrical-shaped gel is initially free of solute, and the

concentrations of source and sink are maintained at C\ and C:

respectively. In this method, the gel is much thicker than the gel

used in the thin disk diffusion-cell. The solute diffuses through

the gel from source to sink in a given time, t. The gel is then

immediately sliced into thin disk-shaped slices. The solute

concentration in each slice is measured, giving concentrationdistance data to be collected within the gel cylinder. Effective

diffusivity, Dc, may then be calculated using these data30.

Colony-expansion Model

When the dynamics of the growth of immobilised cells were

initially studied qualitatively, growth of biomass was described

as expanding at similar rates throughout the beads following

start-up. With time, biomass eventually becomes confined

mainly to areas near the gel surface due to diffusion limitations.

Using a conventional pseudo-homogeneous growth model to

predict cell growth within gel entrapment matrices led to an

over-estimation of macroscopic substrate consumption rates.

This is because diffusion limitations occurring over larger

micro-colonies are not accounted for in this model.

Wijffels el a/.13' theorise that in order to incorporate

diffusion limitation across micro-colonies in a dynamic growth

model, it is necessary to consider biomass growth as expanding

complex design

plugging

lacks economies of scale

micro-colonies, rather than as a homogeneous increase of

biomass in spherical "shells" within the gel beads.When

diffusion limitation over micro-colonies is incorporated into

the dynamics of the immobilised cell system, the colonyexpansion model predicts that inoculum size will affect

substrate consumption rates. At high initial biomass concen

trations, numerous small micro-colonies appear, causing minor

diffusion limitations. However, at low initial biomass concen

trations, fewer but bigger colonies form due to significant

diffusion limitations. This resulted in increased macroscopic

substrate consumption rates in the system containing beads

with smaller microcolonies. These results were confirmed

experimentally in a continuous air lift loop reactor"1.

External mass transfer characteristics

External mass transfer refers to the transfer of nutrients from

the bulk medium to the immobilised yeast cell carrier and is

quantified using the liquid film mass transfer coefficient, KL.

Reactor design factors such as reactor type, size and operating

conditions will influence external mass transfer in immobilised

cell systems. Surface contact between the biocatalyst (immo

bilised yeast cell) and the growth medium (wort) should be

maximised by optimising liquid mixing. Sufficient agitation is

needed so that the thickness of the liquid film surrounding each

carrier particle and consequently external mass transfer resist

ance is minimised, thus facilitating the transfer of species from

the bulk medium to the carrier. The rate of shear on the

particles in a reactor will increase as agitation is increased.

However, for a given agitation rate, different reactor designs

may differ in rate of shear. If shear rates are too high, biomass

may be lost from adsorption matrices, immobilised cell

particles may break, and cell aggregates may be disrupted. It

therefore becomes important to design a reactor which provides

an adequate amount of agitation at a reasonable shear rate.

This document is provided compliments of the Institute of Brewing and Distilling

www.ibd.org.uk

Copyright - Journal of the Institute of Brewing

Vol. 104, 1998]

FUNDAMENTALS Op IMMOBILISED YEAST CELLS FOR BEER CONTINUOUS FERMENTATION

The reactors most commonly used for the continuous

production of beer with immobilised cells include packed bed,

fluidised bed, gas lift draft tube, and loop reactors. Packed bed

reactors are the simplest type of stationary reactor. The fer

mentation medium is passed either upward or downward

through the reactor which is packed with immobilised yeast.

When designing and operating a packed bed reactor, one must

ensure that there is no channelling of flow and no reactor

plugging. Even if these pitfalls are successfully avoided, it is

difficult to ensure that nutrients are distributed evenly to all

immobilised cells in the bed due to the lack of mixing and mass

transfer limitations inherent to this type of design109.

In fluidised bed reactors, beads with immobilised cells are

suspended in the upward flow of liquid medium or the

combined liquid and air flow. Good mixing and mass transfer

properties are attractive features of fluidised bed systems.

However, it is important to consider the density of immobilised

cell beads when designing a fluidised bed system because even

if pumping costs are relatively low, a low density difference

between the solid beads and the liquid medium will not result

in high mass transfer rates23.

Gas lift draft tube systems use gas to circulate fermenter

contents internally using a draft tube concentrically located

inside a columnar reactor. These reactors provide good mixing

and aeration, low power consumption, and are of simple con

struction. This makes gas lift systems very attractive for large

scale industrial operations.

The loop bioreactor design123 refers specifically to the

immobilised cell system used for the primary fermentation of

beer developed by Meura-Delta86. Yeast cells are immobilised

on porous rod matrices containing numerous internal channels.

In this design, the fermentation medium flows in a loop from the

bottom of the fermenter, through both the internal channels and

around the matrices for contact with the immobilised yeast, to

the top of the reactor with external recycle. Particle abrasion is

minimised and scale up is simple with this type of design. Table

III summarises some of the advantages and disadvantages of

packed bed, fluidised bed, gas lift draft tube, and loop reactors.

The superior mixing and surface exposure for mass transfer

found in fluidised bed and gas lift draft tube systems make these

types of reactors the most promising for use with industrial

scale immobilised yeast cell fermentation systems55-84.

Conclusions

Immobilised yeast cell technology is an innovation that may

revolutionise the way breweries operate. Using this technology

beer is produced continuously, leading to significant reductions

in production time, inventory, floor space, and product

variation. Over the last ten years or so, publications on this

topic have been on the rise, indicating that immobilised cell

technology is an area of great interest and potential. This flurry

of research activity helps bring together the different

knowledge bases that must converge to develop immobilised

cell technology for industrial primary beer fermentation. There

are already maturation27109 and low-alcohol124 immobilised

29

References

1. Abbott, B.J.. in Annual Reports on Fermentation Processes. (D.

Perlman. ed.) New York: Academic Press. 1978. 91.

2. Amory, D.E., Rouxhet, P.G. & Dufour, F.P., Journal of the

Institute of Brewing. 1988. 94, 79.

3. Anderson, W.A., Bay, P., Legge, R.L. & Moo-Young, M., Journal

of Chemical Technology ami Biotechnology. 1990,47, 93.

4. Argiriou, T.. Kancllaki. M.. Voliotis, S. & Kouinas, A.A.. Journal

of Agriculture and Food Chemistry. 1996, 44,4028.

5. Atkinson. B., in Process Engineering Aspects of Immobilized Cell

Systems. (C. Webb, G.M. Black & B. Atkinson, eds.) Manchester:

Institute of Chemical Engineers, 1986, 3.

6. Austin, G.D.. Watson. R.W.J.. Nordstrom, P.A. & D'Amorc, T.,

Master Brewers Association of the Americas Technical Quarterly.

1994, 31, 85.

7. Axcell, B.C. & O'Connor-Cox, E.S.C., Proceedings of the

Institiute of Brewing Convention, Singapore, 1996, 64.

8. Bajpai, P.K. & Margaritis. A., Biotechnology and Bioengineering.

1986. 28, 824.

9. Bancel. S. & Hu, W. Biotechnology Progress. 1996, 12, 398.

10. Bardi. E.P., Bakoyianis. V., Koutinas. A.A. & Kanellaki, M.,

Process Biochemistry. 1996,31, 425.

11. Bcjar. P.. Casas, C. Godia. F. & Sola. C, Applied Biochemistry

and Biotechnology. 1992,34.467.

12. BickerstaiT. G.F.. Immobilization of Enzymes and Cells. New

Jersey: Huniana Press, Inc.. 1997, 1.

13. Birnbaum, S.. Pcndleton. R., Larson, P. & Mosbach, K., Biotechnology Letters. 1981.3. 393.

14. Breitcnbucher, K. & Mistier, M., Mededelingen. Faculteil Landbouwwetenschappen Rijksunirersiteit. Gent. 1994,59, 2289.

15. Bungay. H.R.. Biotechnology and Bioengineering. 1984,14. 611.

16. Cashin, M.-M., Journal of the Institute of Brewing. 1996, 102. 5.

17. Chahal, P.S., Fluorosensor Controlled Fed-Batch Production of

Cychsporin-A from Beameria nivea. Ph.D. Thesis, University of

Western Ontario. 1992.

18. Cho. G.H.. Choi. C.Y.. Choi. YD. & Han. M.H.. Journal of

Chemical Technology and Biotechnology. 1982, 32, 959.

19. Coults, M. W. British Patent # 872.391, 1956.

20. Crank, J., Mathematics of Diffusion. Oxford: Clarendon, 1970.

21. Cronenberg. C.C.H. & van den Hcuvel. J.C., Biosensors and

Bioeleclronics. 1991.6.255.

22. Curin, J., Pardonova, B., Polednikova. M., Sedova, H. & Kahler,

M.. Proceedings of the European Brewerv Convention Congress,

Madrid. 1987,433.

23. da Fonseca. M.M., Black, G.M. & Webb, C, in Process

Engineering Aspects of Immobilised Cell Systems. (C. Webb. G.M.

Black & B. Atkinson, eds.) Manchester: Institute of Chemical

Engineers. 1986. 63.

24. Daoud, I.S. & Searle, B.A.. European Brewery Convention Sym

posium: Brewers' Yeast, Helsinki. Finland, 1986, 108.

25. Dautzenberg, H. & Poncelet. D., Proceedings of the Bioencapsulation Research Group V. Potsdam. Germany, 1996.

26. de Beer, D.. Van den Heuvel. J.C. & Ottengraaf. S.P.P., Applied

Environmental Microbiology. 1993, 59. 573.

27.

DillenhofTer, W. & Ronn. D., Beverage World International. 1996,

28.

14. 34.

Doran, P.M. & Bailey, J.E., Biotechnology and Bioengineering.

29.

30.

cell systems in commercial use. Continuous primary ferment

ation systems are not yet fully developed, but there are several

groups on the verge of introducing this technology for

industrial usage.

31.