Академический Документы

Профессиональный Документы

Культура Документы

JJ513-Course Outline

Загружено:

Awan TornadoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

JJ513-Course Outline

Загружено:

Awan TornadoАвторское право:

Доступные форматы

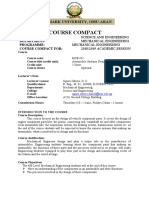

MECHANICAL ENGINEERING DEPARTMENT

POLYTHECNIC OF SULTAN ABDUL HALIM

MUADZAM SHAH

COURSE OUTLINE

SESSION 2014/15 SEMESTER DISEMBER

DEPARTMENT:

MECHANICAL ENGINEERING

COURSES / CODE:

ENGINEERING DESIGN /JJ513

INSTRUCTIONAL DURATION: 15 WEEKS

CREDIT(S):

PREREQUISITE(s):

LECTURER:

3

NONE

NORMAH CHE MAN

SYNOPSIS:

ENGINEERING DESIGN provides knowledge on basic engineering design. It

emphasizes mathematical analysis for simple component design in engineering

such as key, pin joint, bolt, nut and welding. It also provides knowledge on gear

design and selection of bearing.

LEARNING OUTCOMES: By the end of the course, students should be able to:

No

.

Course Learning

Outcome

(CLO)

Programme

Learning

Outcome(s)

Learning

Domains

Explain the basic concept

of design process of

engineering product or

component.

PLO1

LD1-C2

PLO4

LD4-C5

PLO3

&

PLO4

LD3-A4

&

LD4-A4

Design the simple

engineering components

using mathematical

analysis method

according to safe load

limitation.

Relate the basic concept

and principle to solve the

problems in of

engineering design.

Learning and Teaching Activity

Face to

Non Face

Face

to Face

Lecture

Assessm

ent

Coursework

Assessment

Preparation and

Review

STUDENT LEARNING TIME:

Face to Face

Non-Face to Face

Teaching and Learning

Activities

Lecture

Lecture-hour-assessment :

Test

Quiz

Discussion

Coursework Assessment:

Mini Project

Preparation and Review:

Lecture

Practical

Assessment

Total

Student Learning

Time(Hours)

45

15

45

15

5

125

WEEKLY SCHEDULE:

WEEK

WEEK 2

WEEK 3

WEEK 4

WEEK 5

WEEK 6

WEEK 7

WEEK 8

WEEK 9

WEEK 10

WEEK 11

WEEK 12

CONTENT

1.0 INTRODUCTION TO ENGINEERING

DESIGN

1.1Understand the engineering design.

1.2Understand the designing process.

1.3Explain the design consideration.

1.4Explain the ergonomic factors inside

design.

1.5Write the specification in design.

1.6Explain the importance of material

selection in design.

2.0 STRESS ANALYSIS

2.1 Describe the direct stresses.

2.2 Explain the deformation under direct

axial loading.

2.3 Describe the shear stress.

2.3 Describe the shear stress.

3.0 DESIGN OF MECHANICAL JOINT

3.1 Understand the Key Design.

3.2 Understand the design of pin joint, bolt

and nut

joint.

3.2 Understand the design of pin joint, bolt

and nut

joint.

3.3 Understand the welded joints design.

4.0 GEAR

4.1 Explain the kinematics of gears.

ASSESSMENT

Discussion Report 1

Quiz 1

Mini Project/Case study

Test 1

Quiz 2

WEEK 13

4.2 Understand the design of spur gear.

4.2 Understand the design of spur gear.

5.0 BEARING

5.1 Explain the rolling contact bearings.

5.2 Explain the design life bearing.

WEEK 14

WEEK 15

WEEK 16

Mini Project/Case Study

Submission &

Presentation

5.3 Explain the procedure of bearing

selection.

EVALUATION:

No.

1

2

3

4

Discussion Report 2

Assessment

Test

Quiz

Discussion Report

Case Study

Number

2

2

2

1

TOTAL

Test 2

Total

(%)

30

20

20

30

100

REFERENCES:

Autodesk(2007), Autodesk Inventor Professional 2008, USA.

B.Hawkes, R.Abinett.(1984). The Engineering Design Process.England: Longman.

Cheng, Ron K.C. (2010), Using Autodesk Inventor 6, Thompson Delmar Learning

Mohamad Kassim Abdul Jalil. (2000). Proses dan Kaedah Rekabentuk. Penerbit

Universiti Teknologi Malaysia

Randy H. Shih (2010), An Introduction to Autodesk Inventor 2011 and Auto CAD

2011. SDC Publications

Robert L.Mott. (2006). Machine Element in Mechanical Design (4th Edition).

Singapore: Pearson Prentice Hall.

Shigley, J.E & Mischke, C.R. (2003). Mechanical Engineering Design (6th Metric

Edition). New York: McGraw-Hill

Ullman, D.G. (2003). The Mechanical Design Process (3rd Ed). New York: McGrawHill.

Yousef Haik. (2003). Engineering Design Process. USA: Prentice Hall.

Prepared by:

J/K OBE JJ513

Certified by:

Signature

Signature

Date:

Date:

Вам также может понравиться

- Jj513 Engineering DesignДокумент9 страницJj513 Engineering DesignDustin AndersonОценок пока нет

- 6th Sem - 7 - Mechanical Engineering - 2 PDFДокумент39 страниц6th Sem - 7 - Mechanical Engineering - 2 PDFfotickОценок пока нет

- MD and CAD II - Outline - 2019Документ2 страницыMD and CAD II - Outline - 2019Asad KhanОценок пока нет

- Course Outline Djj1043Документ4 страницыCourse Outline Djj1043mohdazizeeОценок пока нет

- Structural Analysis and Design Tcm4-118204Документ140 страницStructural Analysis and Design Tcm4-118204Evodius RweyemamuОценок пока нет

- MEC 2017 CAMD Lab Course HandoutДокумент8 страницMEC 2017 CAMD Lab Course HandoutDr Praveen KumarОценок пока нет

- Unit 0Документ13 страницUnit 0MIe SkyОценок пока нет

- DME Lesson Plan As Per NBAДокумент3 страницыDME Lesson Plan As Per NBASabareesan Subramanian0% (1)

- Course Syllubus Design 2Документ5 страницCourse Syllubus Design 2melihОценок пока нет

- 6th Sem - 7 - Mechanical Engineering PDFДокумент37 страниц6th Sem - 7 - Mechanical Engineering PDFप्रबुद्ध खिलाड़ीОценок пока нет

- MEMB113 Engineering GraphicsДокумент6 страницMEMB113 Engineering GraphicsPoovindra PathyОценок пока нет

- Machine DesignДокумент34 страницыMachine DesignMohammed Yunus33% (3)

- Design, Modeling and Analysis of Landing Gear of An AircraftДокумент26 страницDesign, Modeling and Analysis of Landing Gear of An AircraftJoel MathewОценок пока нет

- MODULE J3103: Malaysia PolytechnicsДокумент17 страницMODULE J3103: Malaysia PolytechnicsPok KuОценок пока нет

- Karthik BN Technical Seminar PresentationДокумент18 страницKarthik BN Technical Seminar PresentationKIRAN TG 1SI19CS063Оценок пока нет

- Md2 Syl PDFДокумент3 страницыMd2 Syl PDFHimanshu JangidОценок пока нет

- Mechanical CurriculumДокумент103 страницыMechanical CurriculumPremsai Tadisetti100% (1)

- DEE6113 Course Outline Jun2016Документ4 страницыDEE6113 Course Outline Jun2016FonzBahariОценок пока нет

- BGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomesДокумент23 страницыBGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomeshemarajuОценок пока нет

- Mechanical Engineering SyllabusДокумент3 страницыMechanical Engineering SyllabusVikram BorkhediyaОценок пока нет

- 4 CivsyllДокумент62 страницы4 CivsyllCIVIL ENGINEERINGОценок пока нет

- LP Iii I Mech 55019 (2012-2013)Документ22 страницыLP Iii I Mech 55019 (2012-2013)Rahul Kumar KОценок пока нет

- New - MEMB322 (Mechanical Design Process) COURSE OUTLINE-WK-WAДокумент9 страницNew - MEMB322 (Mechanical Design Process) COURSE OUTLINE-WK-WAAnonymous 5zvxY7rsQОценок пока нет

- Course Syllabus: Fall 2012Документ8 страницCourse Syllabus: Fall 2012Alvaro MejiaОценок пока нет

- CECE 2240 Lab ManualДокумент33 страницыCECE 2240 Lab ManualAnonymous 71L8o1100% (2)

- MCE 417 Course CompactДокумент7 страницMCE 417 Course CompactKEHINDE BABALOLAОценок пока нет

- Code Semester/Year Pre-Requisite (S) Course Name Instructional Duration CreditДокумент2 страницыCode Semester/Year Pre-Requisite (S) Course Name Instructional Duration CreditThaneswaran BaluОценок пока нет

- Civil Engineering: Structural Analysis and DesignДокумент138 страницCivil Engineering: Structural Analysis and DesignjerryОценок пока нет

- BS Civil EngineeringДокумент138 страницBS Civil EngineeringBolarinwaОценок пока нет

- Lec#01Документ13 страницLec#01Tausif ArshadОценок пока нет

- MEC531 Course Outline 2015 - BibiДокумент7 страницMEC531 Course Outline 2015 - BibiXerofearОценок пока нет

- 4.32 & 4.33 TE & BE - Mech EnggДокумент13 страниц4.32 & 4.33 TE & BE - Mech EnggganeshОценок пока нет

- Mce 451 Course CompactДокумент6 страницMce 451 Course CompactKEHINDE BABALOLAОценок пока нет

- Lesson Plan DOMEДокумент3 страницыLesson Plan DOMEMamoon SarfrazОценок пока нет

- DMM I Course FileДокумент27 страницDMM I Course FileGanesh YadavОценок пока нет

- BtechaДокумент104 страницыBtechamathewsivin5266Оценок пока нет

- Reinforced Concrete - An International ManualДокумент425 страницReinforced Concrete - An International ManualPanuwat JoykladОценок пока нет

- Cad Cam Lab Manual r16Документ123 страницыCad Cam Lab Manual r16Praveen YadavОценок пока нет

- Machine Drawing PDFДокумент182 страницыMachine Drawing PDFPrasanth Kumar100% (2)

- RC-II OutlineДокумент2 страницыRC-II OutlinenebilОценок пока нет

- ECADДокумент3 страницыECADFaiz AhmadОценок пока нет

- MACHINEDESIGNДокумент35 страницMACHINEDESIGNBrandon AllenОценок пока нет

- BEMEM103Документ4 страницыBEMEM103Keerti HulakantanavarОценок пока нет

- 7022 Eng Advanced Steel Structures GriffithДокумент4 страницы7022 Eng Advanced Steel Structures GriffithApril IngramОценок пока нет

- Laboratory Manual: Department of Mechanical EngineeringДокумент9 страницLaboratory Manual: Department of Mechanical Engineeringrajamanickam sОценок пока нет

- Machine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurДокумент16 страницMachine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurDeekshaomarОценок пока нет

- Tutorials /assignments: Aditya Silver Oak Institute of TechnologyДокумент9 страницTutorials /assignments: Aditya Silver Oak Institute of TechnologyDipika GuptaОценок пока нет

- Highway Materials Engineering Participant WorkbookДокумент600 страницHighway Materials Engineering Participant WorkbookBerenisce RamosОценок пока нет

- University of Wah Wah Engineering CollegeДокумент2 страницыUniversity of Wah Wah Engineering Collegehira AliОценок пока нет

- Name of Course Aircraft Structures Course Code: Rationale For Inclusion of The Course in The ProgramДокумент3 страницыName of Course Aircraft Structures Course Code: Rationale For Inclusion of The Course in The Programmamaadam02Оценок пока нет

- Kamarul Ariffin Bin Mohd Mahpal COMPARISON OF SLAB DESIGN BETWEEN BS 8110 AND EUROCODE 2 BY USING MICROSOFT EXCELДокумент24 страницыKamarul Ariffin Bin Mohd Mahpal COMPARISON OF SLAB DESIGN BETWEEN BS 8110 AND EUROCODE 2 BY USING MICROSOFT EXCELDzulkarnain B AhmadОценок пока нет

- Mechanical Tech Pneumatic Hydraulic Systems2Документ106 страницMechanical Tech Pneumatic Hydraulic Systems2Mohan Shanmugam100% (1)

- Workshop Practice One Side Print 28janДокумент9 страницWorkshop Practice One Side Print 28janDr. A. Praveen KumarОценок пока нет

- Bmee301l Design-Of-Machine-Elements TH 1.0 67 Bmee301lДокумент3 страницыBmee301l Design-Of-Machine-Elements TH 1.0 67 Bmee301lKrijayОценок пока нет

- 22ESC144Документ4 страницы22ESC144Naveen S BasandiОценок пока нет

- BTech Mech Curriculum & Syllabi (2008-09 Onwards)Документ105 страницBTech Mech Curriculum & Syllabi (2008-09 Onwards)Raghav SarinОценок пока нет

- MC512 Mechanical Drawing IIДокумент2 страницыMC512 Mechanical Drawing IIEduardo RОценок пока нет

- Ptam CP 25.7.22Документ8 страницPtam CP 25.7.22SAMUEL SANJAY RAJA R MECHОценок пока нет

- Lean Six CreativityДокумент10 страницLean Six CreativityDanielОценок пока нет

- Develop An Extended Model of CNN Algorithm in Deep Learning For Bone Tumor Detection and Its ApplicationДокумент8 страницDevelop An Extended Model of CNN Algorithm in Deep Learning For Bone Tumor Detection and Its ApplicationInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Investigating The Impact of Agriculture and Industrial Sector On Economic Growth of IndiaДокумент13 страницInvestigating The Impact of Agriculture and Industrial Sector On Economic Growth of IndiaAadhityaОценок пока нет

- The Investigation of Simple PendulumДокумент6 страницThe Investigation of Simple PendulumUgne KupryteОценок пока нет

- House HandbookДокумент19 страницHouse HandbooksebascianОценок пока нет

- Research Chapter 1 Group 1Документ12 страницResearch Chapter 1 Group 1Florence May VillarbaОценок пока нет

- Standards and Audit For Quality Assurance NURSING ADMINIДокумент20 страницStandards and Audit For Quality Assurance NURSING ADMINILIDIYA MOL P V100% (1)

- CON107 AS3 BriefДокумент11 страницCON107 AS3 Briefjohn fordОценок пока нет

- Ziman - Real ScienceДокумент17 страницZiman - Real ScienceatilabayatОценок пока нет

- Agustin, FS-2-LE-4-act1Документ8 страницAgustin, FS-2-LE-4-act1Melissa AgustinОценок пока нет

- A Guide To Social Return On InvestmentДокумент110 страницA Guide To Social Return On InvestmentSEP INALUMОценок пока нет

- Perceptual MapДокумент17 страницPerceptual Mapthu_bui_18100% (1)

- AIDI 1010 WEEK1 v1.6Документ14 страницAIDI 1010 WEEK1 v1.6Shafat KhanОценок пока нет

- Fidp FabmДокумент5 страницFidp FabmEve Intapaya100% (1)

- Performance Based Design of Structures (PBDS-2019) : ParticipationДокумент2 страницыPerformance Based Design of Structures (PBDS-2019) : ParticipationSagar GowdaОценок пока нет

- (Cambridge Studies in Indian History and Society 23) Daniel Marston - The Indian Army and The End of The Raj-Cambridge University Press (2014)Документ398 страниц(Cambridge Studies in Indian History and Society 23) Daniel Marston - The Indian Army and The End of The Raj-Cambridge University Press (2014)mandeep5Оценок пока нет

- Dependent and Independent VariableДокумент5 страницDependent and Independent Variablenicss bonaobraОценок пока нет

- Week 15-20 (Writing Report Survey Etc.)Документ49 страницWeek 15-20 (Writing Report Survey Etc.)JAMES HENSONОценок пока нет

- 2022-10 8MA0-21 (Statistics) QPДокумент12 страниц2022-10 8MA0-21 (Statistics) QPYun-lung Wallace NGОценок пока нет

- Jurnal Cindy BДокумент6 страницJurnal Cindy Bmegawati manengkeyОценок пока нет

- AH - PK-2537-BSBTWK503 - Assessment Task 1Документ13 страницAH - PK-2537-BSBTWK503 - Assessment Task 1daniyal khan50% (2)

- 1-Operations-Management 5c2f2886781ccДокумент19 страниц1-Operations-Management 5c2f2886781ccpasiniОценок пока нет

- Internship ProjectДокумент63 страницыInternship ProjectSiddharth DhareОценок пока нет

- Nursing Students Perceptions of Nursing MetaparadДокумент9 страницNursing Students Perceptions of Nursing MetaparadJustine Mae JayonaОценок пока нет

- Module 1.2 Engineering Data AnalysisДокумент8 страницModule 1.2 Engineering Data AnalysisDirect XОценок пока нет

- Quality Gurus - AmericanДокумент6 страницQuality Gurus - AmericanMeghan PivaneОценок пока нет

- Dawkins - A Case Study in The Roots of MoralityДокумент2 страницыDawkins - A Case Study in The Roots of MoralityMichael SmithОценок пока нет

- Paper GravityДокумент8 страницPaper GravityFraztya HebbyОценок пока нет

- Philippine Normal University - NLДокумент13 страницPhilippine Normal University - NLRaymund P. CruzОценок пока нет

- Midterm Study Guide & History of Rhetoric QuestionsДокумент2 страницыMidterm Study Guide & History of Rhetoric Questionsapi-262025468Оценок пока нет