Академический Документы

Профессиональный Документы

Культура Документы

Mil-Hdbk-2155 - Failure Reporting Analysis

Загружено:

B Srinivasa RaoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mil-Hdbk-2155 - Failure Reporting Analysis

Загружено:

B Srinivasa RaoАвторское право:

Доступные форматы

Downloaded from http://www.everyspec.

com

MIL-HDBK-2 155

11 December 1995

NOTE:

Mil-SId-2 155(AS) bm been redesignated

m n

Handbook, nnd is to be used for guidance purposes only.

For administrative

expediency, the only physicnl change from

Mil-Std-2 155(AS) is this cover page. However, this document

IS no longer to be cited m n requirement.

[1 cited us n requirement,

Contractors

Interpret

mny disregnrd

its contents

tbe requirement

of this document

tmd

only M guidance.

DEPARTMENT

OF DEFENSE

HANDBOOK

FAILURE REPORTING,

ANALYSIS AND

CORRECTIVE

ACTION TAKEN

AMSC

FSC RELI

NIA

DISTRIBUTION

unlimited.

STATEMENT

A. Approved

for public

release;

distribution

is

Downloaded from http://www.everyspec.com

+41L-STD~2155(AS)

DEPARTMENT OF DEFENSE

14ashlngton,

D. C.

20301

Failure

Reporting.

Analysis,

and Corrective

Action

System

MI L-STD-2155(AS)

1.

Th{s Mf 1 f tary

Standard

is approved

for use by the

(lxmnand, Department

of the Navy, and IS aval I able

ments and Agencies

of the Department

of Defense.

2.

Benef Iclal

comments (recomnendatlons,

pertinent

data which may be of use

addressed

to:

Gmnanding

Officer,

dards Department

(Code 93),

Naval

08733,

by using the self-addressed

Proposal

(OD Form 1426) appearing

Naval Al r Systems

for use by aI 1 Depart-

addi t!ons,

deletlons)

and any

in tmproving

this document should be

Engineering

Speciflcatlons

and StanAlr Engineering

Center,

Lakehurst,

NJ

Standardization

Document Improvement

at the end of this document or by letter.

il

Downloaded from http://www.everyspec.com

MiL-STO-2

155(AS)

FOREHORD

A disciplined

and aggressive

closed

loop Failure

Rep&t!ng,

Analysis,

and

Corrective

Action

System (FRACAS) is considered

an essential

element

in the

early

and sustained

achievement

of the reliability

and maintainability

equipment,

and associated

software.

potential

Inherent

in ml lltary

systems,

The essence of a closed

loop FRACAS is that failures

and faults

of both hardware and software

are formal Iy reported,

analysls

IS performed

to the extent

that the fal lure cause is understood,

and positive

corrective

actions

are

identified,

implemented,

and verlf!ed

to prevent

further

recurrence

of the

failure.

Corrective

action

options

and flexlbi

1lty are greatest

during

design

evolution

when even major design

changes can be considered

to el Imlnate

or significantly

reduce

susceptibi

lity

to known fal lure causes.

These options

and f)extbility

become more 1 imi ted and expensive

to Implement

as a design

becomes firm.

The

earlier

a failure

cause IS Identified

and posltlve

corrective

action

implemented,

the scarer

both the producer

and user real ize the benef Its of reduced

fai lure occurrences

in the factory

and in the field.

Early

implementation

of

corrective

action

also has the advantage

of provldlng

visibility

of the

Early

adequacy of the corrective

action

in the event more effort

is required.

and detai led attention

to each failure

or fault

as it occurs

should

limit

the

s{tuation

in which prioritization

of open investigations

causes a backlog

which results

in a number of correctable

deficiencies

being left

to field

service

to resolve

over the years.

It IS recognized

that there are pragmatic

1 Imits

to the resources

In time,

money, and engineering

manpower to expend on an anal Ysis Of a Particularly

complex fal lure occurrence

or the implementation

of preferred

corrective

These 1Iml ts are determined

by item priority,

program urgency,

actions.

available

technology,

and engineering

Ingenuity.

These 1 Imits

Wi 11 vary from

program to program.

The acquiring

activity

has the responsibj

lity

of determining

these limits

in Iight

of accepted

norms established

in successful

programs or even h! gher standards

of performance

as warranted

by a particular

program.

iil

Downloaded from http://www.everyspec.com

MI L-STD-2155(AS)

CONTENTS

Paragraph

1.

1.1

1.2

1 .2.1

1 .2.2

SCOPE.

. . . .

Purpose.

. .

Application.

.

Relationship

to

Integration

with

. .

. . .

. .

other

other

2.

2.1

REFERENCED EKKWENTS

Issues ofdocuments~

3.

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

DEFINITIONS

Terms.

.

. .

.

. . .

Acquiringactlvity

. . . .

Closed

IWP faflure

reporting

Contractor

. .

. . .

Corrective

action

effectivity

Failure.

. . .

. . . . .

Fallu~eanalysis

.

. .

Failure

cause.

.

. . .

Failure

Review Board....

Fa{lure

symptom.

.

. . .

Fault

.. . .

.

. .

Laboratory

analysis

. . . .

. . . .

. . .

system

.

. .

. . .

. . . .

. . . .

. . .

. . .

. .

. .

. . . .

. . .

.

. .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

.

.

.

.

.

.

.

.

.

.

.

.

. . . .

.

. .

. . . .

. . . .

. .

. . . .

.

. .

.

. .

. . . .

.

.

. . . .

. . . .

4.

4.1

4.2

4.3

4.4

GENERAL REQUIREMENTS

Contractor

responsibility

FRAC.4S planning

. . .

Failure

Review 60ard

Failure

documentation

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

iv

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

requirements

. . .

activities

. . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

I

1

1

1

. . . . . .

I Ill

. . .

.

. . .

. . .

. . .

:::::......

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

2

2

2

2

2

2

2

3

3

3

3

3

3

.

4

Downloaded from http://www.everyspec.com

141L-}TD-2155(AS)

CONTENTS (CS3NTINUED).

Paragraph

5.

5.1

5.2

5.3

5.4

:::

OETAILEO RETIREMENTS

. . ..

Failure

re~rting

. . . .

Failure

analysis

. . . .

Failure

verif!catlon

Correctiveaction..lllll:

Failure

report

close-out

Identification

and control

APPENDIX

APPLICATION

Paragraph

. . ; . . . . . . . . . .

. . . . . . . . . . ...4

. . . . ..l

. . . ...4

4

11111JJ115

. . . . . . . . . . . . .

of failed

Items

. . . .

5

5

ANO TAILORING

GUIOE

10.

10.1

10.2

[0.3

10.4

GENERAL . . . . . . . . . .

Scope . . . . . . . . . .

Tailoring

requirements

.

Duplication

of effort

. .

Relationship

of FRACAS to

20.

REFERENCEO DOCUMENTS

30.

DEFINITIONS

40,

40.1

40.2

GENERAL RETIREMENTS

. . . . . . . . . . . . . ...8

Importance

of FRACAS . . . . . . . . . . . . . . .

Oata items

. . . . . . . . . . . . . . . . . . . .

50.

50.1

50.1.1

50.1.2

50.1.3

50.1.4

50.2

50.2.1

50.2.2

50.2.3

50.2.4

OETAILREOUIREMENTS

. . . . . . .

FRACAS planning

and documentation

Primary

Object ice . . . . . . .

Request of FRKASplan

. . . .

Requirement

addition

Failuredata....:::lj

FRACAS data collection

. . . .

Effect iveness

of FFbWW

. . . . . .

Failures

. . . . . . . . . . .

Failure

analyses

. . . . . . .

Results

of failure

analysis

.

60.

60.1

OATA ITEM DESCRIPTIONS

(DID)

. . . . . . . . .

Oat .

. . . . . . . . . . . . .

. . . . . .

. . .

. . .

. . .

. . .

FMEW

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..~

. .

. .

. .

. .

;

7

. . . . . . . . . . . . . ...8

. . . . . . . . . . . . . ...-....8

. .

.

. .

. .

.

.

.

.

lJII1ll...9

. . .

.

. . .

. . .

. . .

.

.

.

.

.

.

.

.

.

.

.

.

...-8

. . . .

. ...8

. ... . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . . .

. . . .

...-9

. ...9

.

. .

. .

...10

8

8

8

9

9

10

10

Downloaded from http://www.everyspec.com

MI L-ST@2155(AS)

.

THIS

PAGE INTENTIONALLY

v{

LEFT BLANK

Downloaded from http://www.everyspec.com

MI L-STD-2155(AS)

1.

SCOPE

This standard

establ

1.1

Purpose.

for a Fai lure Reporting,

Analysis,

and

implement

the FRACAS requl rement of MI

vide management

visibll!ty

and control

improvement

of hardware

and associated

uti I ization

of fai lure and maintenance

tive

corrective

actions

to prevent

fai

reduce the maintenance

tasks.

lshes untform

requirements

and criteria

Corrective

ActIon

System (FRACAS) to

L-STD-785.

FRACAS is Intended

to profor reliability

and maintainability

. .

software

by timely

and disciplined

data to generate

and implement

effeclure recurrence

and to simplify

or

1.2

Application.

This standard

applies

to acquisitions

for the design,

development,

f abdication,

test,

and operation

of military

systems,

equipment.

This standard

primarily

applies

to the

and associated

canputer

programs.

program phases of demonstration

and validation

and full

scale development.

This standard,

in addition

to

1 .2.1

Relationship

to other

requirements.

implementing

the FFWAS requirement

of MI L-STD-785,

is intended

to complement

the requirements

of MIL-STO-47D,

MI L-STO-781,

MI L-STD-1 679, and MI L-STD-2068.

1 .2.2

Integration

with other activities.

The FRACAS effort

shall

be

coordinated

and integrated

with other

program efforts

such as reliabi

Iity,

qual tty assurance.

maintainabi

1 ity,

human engineering,

system safety,

test,

management,

and

parts,

materials,

and processes

control

, configuration

integrated

logi sties

support

to preclude

duplication

of effort

and to produce

integrated

cost effective

results.

,..

2.

REFERENCED ODUJMENTS

The fol lowing

2.1

Issue of documents.

on the date of invitation

for bid or request

standard

to the extent

specified

herein.

docurents

of

for proposal,

the issue

in effect

form a part of this

STANOARDS

MILITARY

MI L-STD-280

Definitions

of Item Levels,

Models and Related

Terms

Item

MI L-STO-470

Maintai

Systems

ODD-STO-480

Configuration

Deviations

MI L+TD-721

Definitions

ability

nabi 1 i ty

Program

Control

and Haivers

of

Terms

for

- Engineering

for

Reliability

Exchangeabi

and

I i ty,

Equipment

Changes,

and Maintain-

Downloaded from http://www.everyspec.com

i.iIL-STD=215ki(

MI L-STD-781

Reliabii:lty

tance Tests:

HIL-STD-785

Rel iabi 1 ity Program

ment and Product Ion

#iIL-STD-1679

Meapon

MI L-STD-2068

Relatability

(Copies

of speclflcations,

required

by contractors

should be obtained

from

tracting

officer.

)

3.

DEFINITIONS

the

3.1

~.

definitions

3.2

Acquiring

contractor)

which

contract

or other

A5)

L&.~gnQual

if~catlon

and Production

Exponential

Di strlbution

System

for

Software

Systems

,.

Develop-

Oeve lopment

Development

standards,

in connection

the contracting

and Equipment

Accep-

Tests

ha~dbcmks,

drawings,

and publications

Wlthf speclf{c

acquisition

functions

activity

or as directed

by the con-

Mean!ng of terms not defined

in MI L-STO-280

and MI L-STD-721

activity.

That activity

levies

FAA~,5 requirements

document of agreement.

herein

are

(government,

on another

in accordance

contractor,

or

activity

through

with

sub.

a

3.3

Ciosed

loop fai lure reportinq

system.

A controlled

system assuring

that al 1 failures

and faults

are reported,

analyzed

(engineering

or laboratory

anaiysis),

positive

corrective

actions

are. identified,

to prevent

recurrence,

and that the adequacy

of implemented

corrective

actions

is verified

by test.

3.4

Contractor.

The term contractor

1s defined

as any corporation,

comPanY. associ ati On. or ~ndi vi dual Uhi ch undertakes

performance

under the

terms of a contract,

letter

of intent

or purchase

orders,

project

orders,

and

For the

al lotment,

in which this document may be incorporated

by reference.

Purpose of th~s standard,

the term contractor

also includes

Government

operated

activi

ties

undertaking

performance

of a task.

3.5

corrective

its

Corrective

action

3.6

Failure

requi-&ions

3.7

logical

evidence,

action

effectivity.

uil 1 be or has been

The date

Incorporated

An event i n which an i tern does

within

the specified

limits

A determination

Failure

analysis.

reasoning

from examination

of data,

and laboratory

analysis

resul ts.

3.8

Fai lure cause.

mechanism;

e.g. , defective

software

error,

etc.

when

not perform

one or more of

under specified

conditions.

of failure

syasptoms,

The circumstance

that induces

soldering,

design weakness,

or item serial

number

Into the ttem.

cause made by use of

available

physical

or activates

a fai lure

assembly

techniques,

Downloaded from http://www.everyspec.com

,$fIL-.sT~2l55(As)

3.9

A group consisting

of representatives

from

Fai lure Review Board.

appropriate

contractor

0r9anf Zatt0nS

With the level

of .respcwrstbi 1 i ty and

authority

to assure

that fal lure causes are

identified

and corrective

act~ons

are effected.

wfth

3.10

the

3.11

detuning,

Failure

faf lure

~.

Any circumstances,

SYIIP tom.

Irrctlcates

its ex~stence

wtrlch

A degradation

misalignment,

in performance

due to failure

maladjustmmt,

and so forth.

analysts.

3.12 Laboratory

destruct

I ve and nondestructive

tion,

spectrographic

analysts,

4.

event,

or condltlon

or occurrence.

The determination

of

laboratory.

techniques

or microphotography.

of

associated

parts,

a failure

mechan}sm us!ng

such as x-ray,

di ssec-

GENERAL REi)UIREt4ENTS

A ciosed

loop fat lure reporting,

analy4.1

Contractor

responsibi

Iity.

sis, and corrective

action

system (FRACAS) stsal 1 be implemented

by the conThe system shal 1 be maintained

for reporting,

tractor

and his subcontractors.

analysis,

and correction

of hardware

fai lures

and software

errors

that occur

in contractually

specified

levels

of assembly

during

in-plant

tests

and that

occur at installation

or reroute test

sites.

Failures

occurring

in specified

levels

of assemblies

in tests

at subcontractors

facilities

shall

be

integrated

into the contractors

data CO1 lection

system for tracking

and

incorporation

in the fai lure summary and status

reports.

The contractors

existing

data collection,

analysis,

and corrective

action

system shall

be used

with modification

only as necessary

to meet, the. requirements

specified

by the

acquiring

activity.

FRACAS planning

t nvolves

the preparation

of written

4.2

FRACAS planning.

procedures

for the initiation

of fai lure reports,

analysis

Of fa~lure$.

and

the feedback

of corrective

actions

into design,

manufacturing,

and test

process.

The contractors

procedures

for implement i ng FRACAS and for tracking

and nmitoring

fat lure analysis

and corrective

action

status

shal 1 be

described

in the FRACAS plan.

Flow diagrams

that depict

fai led hardware

and

failure

data flow also shall

be documented

in the plan.

4.3

Failure

Review Board.

A Fai lure Review Board (FRB) shal 1 be estab1 i shed to review

fai lure trends.

corrective

act ton status,

and to assure

The personnel

appointed

by the conadequate

corrective

actions

are taken.

tractor

to act on the FR6 sha 11 be identified

i n the FRACAS procedures

and the

scope or extent

of their

authority

shall

be identified.

The FRB shall

meet on

a regular

basis

to review

fai lure data from a~propriate

inspections

and tests

including

subcontractor

test failures.

The FRtS shal I have authority

to

require

Fai lure

investigations

and analyses

by other

contractor

organizations

The acquiring

activity

and to assure

implementation

of corrective

actions.

reserves

the right

to appoint

a representative

to the FRB as an observer.

If

the contractor

can identify

and use an already

exi$ting

function

to perform

the FRB functions,

then a description

of how the existing

function

wi II be

employed

to meet acquiring

activity

requirements

shall,

be provided

for

acquiring

activity

review.

.

Downloaded from http://www.everyspec.com

MI L-STD-:2155(AS)

.. ..

Records

shal 1 be maintained

for al 1 rgported

4.4

Fatlure

documentation.

failures,

.fatlure

investigations

and analySes.

assignable

fat lure causes,

corrective

actions

taken,

and effectiveness

of corrective

actions.

These

records

shal 1 be organl zed to perm!t

effi c$ent retrl eval for fat lure

trendl ng,

fal lure susmrary and status

reports.

knowledge

of previous

fai lures

and fai lure

analyses,

and corrective

action

monitoring.

Failure

documentation

shall

include

a uniform

reference

ident!f

Icatlon

to provide

ccsnplete

traceabl

llty

of

al I records

and actions

taken for each reported

fai lure.

5.

DETAILED

RETIREMENTS

5.1 Failure

reporting.

Fai lures

and faults

that occur during

appropriate

inspections

and tests

shall

be reported.

The fai lure report

shall

include

information

that permits

identification

of the failed

Item,

symptoms of

failure,

test cond{tlons,

built-in-test

(BJT)

Indications,

and item operating

time at time of failure.

811 software

problems

ldenti f 1 ed durt ng the i nspectlons

and tests

shal 1 be reported

in accordance

with the requirements

of

MI L-STD-1679.

Procedures

for initiating

faiiure

reports

shal 1 include

requirements

for verifyfng

fal lures using BIT, when appl i cable,

and for

Coi Iecting

and recording

corrective

maintenance

information

and times.

Al 1

fat 1ure reports

and software

problem reports

shal 1 be verif 1ed for accuracy

and correctness

and subm{ tted on standard

forms.

The format

of the form(s)

used to record

fai lure and associated

data is important

only to the extent

that i t simpllf

ies the task of the data recorder,

provides

for item and data

traceabi

1 i ty, and provides

the information

required

by the acquiring

activity

as lt becomes available

5.2 Failure

analysis.

Reported

fal 1ures shal 1 be evaluated

or analyzed

as appropriate

to determine

the cause of fai lure.

FRACAS procedures

shal 1

include

requirements

for documenting

the results

and conclusions

of fai lure

invest \ gatlons

and analyses.

Analysis

of government

furnished

material

(GFM)

failures

shall

be limited

to verifying

that the GFM fa!lure

was not the result

of the contractors

hardware,

softw$re.

or procedures.

The verification

of

the GFM fai lure shal 1 be documented

for notification

to the acquiring

activity.

The fai lure analysis

of other

than GFM fai lures

shal 1 be conducted

at the lowest

level

of hardware

or software

necessary

to identtfy

the causes,

mechani sins, and potential

effects

of the fai lure and to serve as a basis for

decisions

on the corrective

action

to be implemented.

The investigations

and

analyses

of faflures

shall

consist

of any applicable

method (e.g. , test,

x-ray

analyses,

mtcroscoptc

analysis,

etc. >

application

study,

dissection,

that may be necessary

to determine

fai lure cause.

5.3

Fa!lure

ver!flcat!on.

All reported

fai lures

shall

be verified

as

actual

or an explanation

provided

for lack of verification.

Failure

verification

is determined

either

by repeating

the fai lure mode on the reported

Item

or by evidence

of fai lure (leakage

residue,

damaged hardware,

BIT indication,

etc).

Downloaded from http://www.everyspec.com

MI L-STW2155(AS)

Hhen the cause of a fal lure has been determined,

5.4

Corrective

actibn.

a corrective

action

shal 1 be developed,

documented,

and implemented

to el lml nate or reduce the recurrence

of the fat lure.

Corrective

action

implementation shall

be approved

by responsible

contractor

personnel

(and acquiring

activity

as required).

Unless otherwise

specified,

change control

procedures

shal 1 be i n accordance

with OCIO-STO-480.

5.5

Fai lure report

close-out.

Each reported

fai lure shall

be analyzed

and corrective

action

taken in accordance

with the requirements

of this

standard in a timely

manner so as to obtain

lnxnediate

benefits

of the corrective

action

and to minimize

an unmanageable

backlog

of open failures

from occuraction

suspense

dates

shal 1

ring.

All open reports,

anal YseS, and corrective

be reviewed

to assure

timely

failure

report

close-outs.

A fai lure report

shal 1 be considered

closed-out

upon completion

of corrective

action

implementation

and verification

or rationale

In those instances

where corrective

action

was not implemented.

The rationale

to support

no corrective

action

shal 1 be documented

and approved

by responsible

authority.

5.6

Identification

and control

of failed

items.

All failed

items shall

be conspicuously

marked or tagged and control led to assure

disposition

per

contract

requirements.

Fai led items shal 1 not be opened,

distributed,

or

mishandled

to the extent

of obliterating

facts

which might be pertinent

to an

analysis.

Fai led items shal I be control led pending

authorized

disposition

after

completion

of fai lure analyses.

Downloaded from http://www.everyspec.com

THIS

PAGE INTENTIONALLY

LEFT BL4NK

Downloaded from http://www.everyspec.com

t41~-STO-2155(AS)

APPENDIX

.,

APPLICATION

10.

AND TAILORIMG

GUIDE

GENERAL

10.1

acquiring

reporting,

*.

Thls appendix

provl des notes for the guidance

of the

activl

ty in generating

the contractual

requirements

for. fal lure

. . . .~.

analysfs,

and corrective

action

syst~

(F~~S).

-:

10.2

Tailoring

re@rements.

Each provi slon of this

standard

should

be

reviewed

to determine

the extent

of appl tcabi i ity.

Tailoring

of requirements

may take the form of deletion,

addition,

or alteration

to the statements

In

Sections

3, 4, and 5 to adapt the requirements

to specific

i tern characterssties, acquiring

activity

options,

contractual

structure.

or acquisition

phase.

The tailored

FIWAS

requirements

are specified

in the contractual

provisions

to include

Input

to the statement

of work. contract

data requ{ rements

1 Ist (CORL). and other

contractual

means.

The depth and detai 1 of the FRACAS

effort

WI 11 be defined

in appropriate

contractual

and other

program documentation.

10.3

Dupl lcatton

of effort.

A review of the contractual

requirements

Is

necessary

to avoid

duplication

of effort

between the reliability

program and

other

program efforts

such as qual ity,

maintainabi

1 i ty, test,

safety,

and

integrated

logi sties

support.

Identification

of the coincident

generation

of

FRACAS tasks or use of such tasks by the reliability

program and other

disciplinary

areas

is required

in the rel iabi 1i ty program plan or other

appropriate program documentation

to avoid dupl icatlon

of effort

by the acquiring

activity

and the contractor.

10.4

Relationship

of FRACAS to FMECA.

Al th&gh

the respective

FRACAS

and Fai lure Mode Effects

and Critical

ity Anaiysts

(FMECA) effort

are designed

and capable

of being performed

Independent

1y of each other,

there

1s a

synergistic

effect

when the two efforts

are coupled.

An FMECA is an

analytical

ly derived

identif

i cation

of the conceivable

hardware

fai lure modes

of an i tern and the potential

adverse

effects

of those modes on the system and

misston.

The FMECAs primary

purpose

is to inf Iuence

the system and i tern

design

to either

eliminate

or minimize

the occurrences

of a hardware

failure

The f~ms

represents

the real

UOrl d

or the consequences

of the fai lure.

An FMECA benefits

the

experience

of actual

failures

and the!r

consequences.

FRACAS by providing

a source of comprehensive

fai lure effect

and fai lure

severity

information

for the assessment

of actual

hardware

fai lure

Actual

failure

experience

reported

and analyzed

in FRACAS

occurrences.

provides

a means of verifying

the completeness

and accuracy

of the FMECA.

worid

experience

as reported

and

There should be agreement

between

the real

assessed

in the FRACAS and the analytical

world

as documented

in an FMECA.

Significant

differences

between

the two worlds

are cause for a reassessment

of

the item design

and the differing

fai iure criteria

that separates

the FFWXS

and FUECA.

Downloaded from http://www.everyspec.com

%f%w

,.

,.

;.

,.20..

REFER$~E~:~E~~$~

@#

$~o~;jA9~~1

30:

DEF~NITIONS;

40.

~ENERAL-REQUIRENENT5

@~~:

A~~l !,c~b Ie)

. .

.

..

~0. I ;fmportarici

.of .Fi@CAS i. the reg,~tr%st;

for a F~CAS norcna 11 y WI 11

eq,ui@ent,

and associated

software

subapply to#Ie

deyelop~nt

et., systems,

ject

.to valida~lon-or,ful

1 scale

development

(FSD) . This early

implementation

.of a FRACA5 1s i~rtant

because

corre,ctt Ye action option:

and flexibtl

ity are

~ qreatest

,duricsg des{gn evolution.

The eatl ter fat lure causes are tdenttf

ied,

the easier

it 1s to- implement corrective

actions.

As the design

matures,

corrective

actions

st.t 11 can be identified,

but the opticms

become limited

and

implementation

is rore difficult.

..40 .2. .Oata i tens.

.The ,implementatiop

of F.RACAS requirements

Wi 11 involve

If any of these

some form of. contractor

prepared

plan,

document,

form, or data.

are to be rgcetved

by the acquiring

acttv~ty,

they are del tverable

1 terns.

Each

separate

data item -!dentifiedfor

del f very ust be included

on a 00 Form 1423

yhich must be. included

as apart

of the req,uest

for proposal

(RFP)

and contract.

Each 00 FOTrn,1 423 entry

aui&t refer

to an .authorf zed Oata Item

Description

(OID) and must incftide

a Specffiic contract

reference

that specifies

Refer

to governing

and author! zes. the work to be done for each data 1 tern.

directives

for spec,ific

information

on how to ccatplete

the 00 Form 1423.

,

50.:

.ilETAIL

iEoiJIRE14ENTS

50~1 . FRACAS ~lanning

>,

and documentation.

The primary

objective

of a closed-loop

FRACAS

5.0.ii. 1 Pri&ry

objective.

is to document fal 1ures and faults

and to disseminate

the data.

The timely

di ssemlnatlon

of accurate

fat lure information

is necessary

so remedial

actions

nay be taken promptly

to prevent

the recurrence

of the fal lure or fault.

50.1.2

Request of FRACAS plan.

If a FRACAS plan is requested

In the. RFP,

the ,contractor

should be asl(ed to describe

how he plans to ispiement

the

FRAC4S.

He should be asked to identify

and discuss

the procedures

that wil 1 be

: used to control

f ai lure report

WI! tlation,

f ai \ ure analyses,

and the feedback

of

corrective

actions

into the design,

manufacturing.

and test process.

The plan

submitted

.foc review

should de<crlbe

the flow of fai led hardware

and failure

data thro:~g~~t}the

contractor

~s organ,i zat Ion.

.50.1:3

Requirement

addition.

The addition

of

Revieu

Board (FRB) wi 11 provide

added assurance

that

and corrective

actions

taken on jdentif

ied fai lures

may be, however,

other

closely

related

functions

or

the FRB that should be closely

coordinated

to assure

is avoided.

bihen an FRB is required

by the acquiring

should be asked to identify

the personnel

appointed

of their

authori ty.

indicate

the scope or extent

8

a requirement

for a Failure

the reporting,

analysis,

wi 11 be control led.

There

efforts

that are similar

to

that duplication

of effort

activity.

the contractor

to act on the FRB and to

Downloaded from http://www.everyspec.com

MIL+TD>2155(AS)

(IRPENL)IXA

1

I

I

I

I

I

1

Failure

data,ls,

us Fpl on y.ti,~n

as mb ed in

50.1.4

Fatlure

data.

manageable

aggregates

for purposeful

~~aludtio 1 %y b6 !-h ti(e .coir

~he

w kc or-and

<

The fal lure data system .:h~l~

,be designed

t~,co~~~ct,.

,

acqu{ring

actfvlty.

store,

and retrieve

faflure

Information

and to p?ovide the rseans-for

displaying

the data tn a meaningful

form.

The outputs

of a f ai lure data

system should be tailored

to prov!de

sumnarles

and spectalreports

for Iioth

of.?

failure

data

A useful output

management and engineering

personnel.

system ts the fal lure sunsnary and status

report.

Thi s:report

.u! 1 ~...provtde

info~tion

about the fai lure of Ilke

Items or slmflar.

functi@:,uislch

can be

used. to provide

Indications

of failure

treftds:and

to evaluate

the tiiid

for and

the extent

of contemplated

corrective

actions.

l%d contractor.

should be asked

to define

the scope and content

of hls fai 1ure data system,: and to lndi cate how

it will

be maintained.

~.

50.2

FRACAS data

collection.

50.2.1

Effectiveness

of FRAC4S.

input data in reports

documenting

fai

inputs

should document all conditions

faci I itate

cause determination.

The

information

on who discovered

the fai

it failed,

and how future

faflures

wi

A FRACAS will

be effecttve

only if the

lures and faults

.is accurate.

Essential

surrounding

a failufe

or fault

to

fai lure documentation

must proylde

lure,

what fai led, here

It fa! led, when

11 be prevented.

50.2.2

Failures.

During

development.

system or equipment

fat lures

typically

occur during

tests

or operation

by the contractor

or the acquiring

#(hen a fai lure occurs,

the fai led item should be identified

and al 1

activity.

pertinent

i nformat ion about the fai lure should be docussanted

on a f al 1ure

report

form.

The contractors

procedure

for failure

report

i ni tia.tion

should

identify

and describe

the data that should be recorded

for both hardware

fai lures and software

errors

to assure

that fai lures are adequately

described

and that the proper

harduare

or software

has been reported.

In addi t ion. the

contractor

should have a method for accounting

for fat 1ure reports

and should

audit

the completed

forms periodical

ly to verify

that failure

reports

are

being submitted

prcmptl y.

50.2.3

Failure

analysis.

Failure

analysis

isthe

determinationof

tk

cause of a fai lure.

One of the first

steps tn any fai lure analysis

is the

review of the fat lure information

by cognizant

personnel.

A failure

analysis

plan then should be developed

to describe

the steps the analysis

wil 1 take and

to preclude

pre- mature disposal

of f ai led i terns prior

to being subjected

to

required

analyses.

Each failure

should be verified

nd then ana!wed

to the

extent

necessary

to identify

the cause of fai lure and any contributing

factors.

The fa) 1ure analysts

can range from a simple

Investigation

of the

circumstances

surrounding

the failure

to a sophisticated

laboratory

analysis

of the failed

parts.

The level

of analysis

always

should be sufficient

to

provide

an understanding

of the cause of fat lure so that

logically

derived

.

.

.

corrective

acrlons

can be aevelopea.

Downloaded from http://www.everyspec.com

-i41kSTD~2

155(AS)

APPENDIX A

The results

of fal lure analysts

Results

of failure

analysis.

should be fed-back

to cognizant

petsoiinel

so they can decide

on an appropriate

course of action

to al leviate

the problem.

COriectlve

action

to alleviate

a

problem may range f rcm new controls

implemented

! o manufacturing

or test

to a

change in design or changing

a part

to one better

sui ted to operational

The generated

corrq$i

ve +c:t!on should be documented

i n detai I

requ~rements.

so that i t can be impi emented and verif6ed~Z~

the ProPer

level.

After

a

corrective

action

is implemented,

{t shoulId lke aonjtored

to assure

that the

corrective

action

has removed the fai lure causes and has not introduced

new

problems.

50.2.4

60.

DATA ITEM DESCRIPTIONS

(DIO)

60. I Q@.

Hhen thfs standard is uqed in an acquisition

that

incorporates

CDRL, DD Form 1423, the data requirements

identified

below shal I

be develooed

as sDecified

bv an aooroved

DID. DD Form 1664. and delivered

in

accordance

with the approve~

CORL ~ncorporat~d

into the contract.

Hhen the

provisions

of DAR 7-104.9

(n) (2) are invoked

and DD Form 1423 is not used,

the contractor

shal 1 deliver

the data specified

below in accordance

with the

Del iverable

data sourced

to this

order

requirements.

contract

or purchase

standard

are ci ted in the fol lowing paragraphs.

Paragraph

Applicable

4.2

01-R-21597

4.4

DI-R-21599

DID

Data

Fai lure Reporting.

Corrective

Action

ReDOrt.

Fail ure

5.1

DI-R-21598

DI-R-2 178

Reciul rement

Development

Susmsary

Analysis,

and

System Plan

and Production

Fai lure Report

Computer

Software

Trouble

Report

DIDs reiated

to this standard

wil 1 be apprcwed

and i isted

as such in EK)O

5000. 19L. Vol . 11, AMDSL.

Copies of EsIDs required

by the contractors

in

connection

with specific

acquisition.

functions

should be obtained

from the

by the Contracting

Officer.

Naval Pub] ications

and Forms Center,

or as directed

Preparing

activity:

Navy - AS

Project

No. RELI-N035

10

Downloaded from http://www.everyspec.com

.-

.i

. .. . ..

1

NAME

OF SUSUllTINO

0ROAN17.ATION

& Tv-

Of

OmOANIZAT#ON

f--J

ADORE=

(s-t,

IxY.

Sti..

a?

C-J

Wsn

Ormn

mmdfr,:

TELEPHONE

NWSER

AmEAS

Nnml.

WO.81w

W.-dh#:

. -m.1-

1.

&

-,

MAw.cru,

f-J

ROWLEM

(U

VzImO

R--L.:

nEblARcS

NAME

OF SUOMITTE

R (La,.

Mm,.

Ml,

00,iond

b, WORK

(1-=IM*

CA) -

MA, L,NG

ADD.

ESS ,S1-.,.

City, Stiw.

ZIP Cdl

Oullonti

t. OATE

DD &::. 1426

PR~v,0u9

EOITIOId

IS OCSOI.ETE.

O*

SU8U1SS1ON

[YYMMDD1

Arm

Downloaded from http://www.everyspec.com

(Fold daaJ

*b

Mu)

1(

0EPARThlEN7

OF lHE

.. . . .

NAVY

111111

No POSTME

w-m

mAILED

an

uN#TeO

OFFICIAL

U61NES

*EWAI.TV

Porn

PRIVATE

USE UOO

I BUSINESS REPLY MAIL t

1WmAGE WILL m w

1

F,ST

CL-

P6RM,T

PAID

o.

12s03

THE

Commander

Naval

Air Systems ~nd

Washington, DC 20361

WASMING1ON

OEMRTMENTOF

0.

THE

(AIR 51122)

C.

NAVY

Tm

STATES

Вам также может понравиться

- Robot Reliability Through Fuzzy Markov M PDFДокумент6 страницRobot Reliability Through Fuzzy Markov M PDFDaniel CarvalhoОценок пока нет

- Failure and Reliability Prediction by SVMДокумент8 страницFailure and Reliability Prediction by SVMuamiranda3518Оценок пока нет

- TPM Reliability FormulasДокумент35 страницTPM Reliability FormulasjapeleОценок пока нет

- Condition Based Reliability, Availability, Maintainability, and Safety (CB-RAMS) ModelДокумент15 страницCondition Based Reliability, Availability, Maintainability, and Safety (CB-RAMS) ModelganeshdhageОценок пока нет

- RAM Methodology Review PresentationДокумент24 страницыRAM Methodology Review PresentationAli Akram100% (1)

- A Two-Stage Failure Mode and Effect Analysis of Offshore Wind Turbines - 2020Документ24 страницыA Two-Stage Failure Mode and Effect Analysis of Offshore Wind Turbines - 2020johnОценок пока нет

- CBM & RCM Applied On Nuclear Power PlantsДокумент11 страницCBM & RCM Applied On Nuclear Power PlantsGeert Henk WijnantsОценок пока нет

- A Simpli Ed Method For Reliability and Integrity-Based Design of Engineering Systems and Its Application To Offshore Mooring SystemsДокумент17 страницA Simpli Ed Method For Reliability and Integrity-Based Design of Engineering Systems and Its Application To Offshore Mooring Systemsmandrake1985Оценок пока нет

- Mil HDBK 217FДокумент205 страницMil HDBK 217FolivierbelОценок пока нет

- CS-25 Amendment 11 - AMC 25.1309Документ30 страницCS-25 Amendment 11 - AMC 25.1309leopoldor_5100% (1)

- Reliability Data of Omron ComponentsДокумент1 страницаReliability Data of Omron Componentsastojadin1873Оценок пока нет

- Reliability, Availability and Maintainability: ©2020, Monaco Engineering Solutions - ALL RIGHTS RESERVEDДокумент7 страницReliability, Availability and Maintainability: ©2020, Monaco Engineering Solutions - ALL RIGHTS RESERVEDFabio Kazuo OshiroОценок пока нет

- Determining The Scratch Hardness and Scrape Adhesion of Prints and CoatingsДокумент3 страницыDetermining The Scratch Hardness and Scrape Adhesion of Prints and CoatingsAhmad Zubair RasulyОценок пока нет

- Navair 00 25 403 2005Документ195 страницNavair 00 25 403 2005freddy_gОценок пока нет

- Reliability EngineeringДокумент18 страницReliability EngineeringSanti KunduОценок пока нет

- Mil STD 756bДокумент85 страницMil STD 756bgeoffxyz0Оценок пока нет

- Applications of Risk Management Tools in Maintenance Operations of Swedish Industries - A Survey AnalysisДокумент111 страницApplications of Risk Management Tools in Maintenance Operations of Swedish Industries - A Survey AnalysisStanislavОценок пока нет

- Reliability Centered Maintenance (RCM2) : Well-Defined, Most Used RCM Process in Industry Compliant To RCM Sae StandardДокумент4 страницыReliability Centered Maintenance (RCM2) : Well-Defined, Most Used RCM Process in Industry Compliant To RCM Sae Standardtuyul sapuОценок пока нет

- TM 5-698-6 - Reliability - Data - Collection - 2006 PDFДокумент118 страницTM 5-698-6 - Reliability - Data - Collection - 2006 PDFWurzel1946Оценок пока нет

- GR 468 TOC.i02Документ8 страницGR 468 TOC.i02Steven ChaiОценок пока нет

- Methods and Tools Used in Criticality Analysis in Industrial SystemsДокумент18 страницMethods and Tools Used in Criticality Analysis in Industrial SystemsLeandro Baran100% (1)

- Failure Mode Effect AnalysisДокумент7 страницFailure Mode Effect AnalysisRewati KumarОценок пока нет

- AV ME SOP 02 Criticality AnalysisДокумент4 страницыAV ME SOP 02 Criticality AnalysisjfejfeОценок пока нет

- RealScan-10 MTBFДокумент40 страницRealScan-10 MTBFpoukhflsjkabdsalcОценок пока нет

- Guidelines For The Naval Aviation RCM PDFДокумент126 страницGuidelines For The Naval Aviation RCM PDFCESARALARCON1Оценок пока нет

- FMECA of PUMP Pumping Water From Coalescer To Second Stage Recycler and DegasserДокумент12 страницFMECA of PUMP Pumping Water From Coalescer To Second Stage Recycler and DegasserM Ahmad TauqeerОценок пока нет

- 217 PlusДокумент3 страницы217 PlusArunkumar SundararajanОценок пока нет

- M180-07 Functional FailuresДокумент17 страницM180-07 Functional FailuresAbdul Raheman MohammedОценок пока нет

- PERD Where For Art Thou Failure Rate Data PDFДокумент10 страницPERD Where For Art Thou Failure Rate Data PDFganeshdhageОценок пока нет

- AvailabilityWorkbench A4Документ501 страницаAvailabilityWorkbench A4Rodrigo Vargas100% (1)

- Reliability, Availability and Maintainability AnalysisДокумент10 страницReliability, Availability and Maintainability AnalysisEli PaleОценок пока нет

- DNV RAM FPSO White PaperДокумент7 страницDNV RAM FPSO White PaperOkonji C Stephen100% (1)

- PFD CalculationДокумент6 страницPFD CalculationFordОценок пока нет

- FMEA Wind Turbine GeneratorДокумент10 страницFMEA Wind Turbine Generatorscorpionking888Оценок пока нет

- Reliability Blueprint PDFДокумент30 страницReliability Blueprint PDFFabioPaixaoОценок пока нет

- FMEA: Failure Modes and Effects AnalysisДокумент24 страницыFMEA: Failure Modes and Effects AnalysisAlvaro CotaquispeОценок пока нет

- RAM Guide 080305Документ266 страницRAM Guide 080305osbertodiazОценок пока нет

- Failure Mode Effect Analysis: Dr. Ir. Muhammad SabriДокумент42 страницыFailure Mode Effect Analysis: Dr. Ir. Muhammad Sabricalvin100% (1)

- System and Equipment Troubleshooting Guide - Update To 1003093Документ138 страницSystem and Equipment Troubleshooting Guide - Update To 1003093ahmad.ghazi.adaro100% (1)

- Availability Simulation - IsographДокумент1 страницаAvailability Simulation - IsographsaospieОценок пока нет

- Barringer Analyzer ReliabilityДокумент9 страницBarringer Analyzer ReliabilityTessfaye Wolde Gebretsadik100% (2)

- Norsok Z-008-2011Документ17 страницNorsok Z-008-2011Fredy Alexander Roldan FigueredoОценок пока нет

- Mil STD 704Документ25 страницMil STD 704josebrigas4530Оценок пока нет

- 7H RAM PredictionДокумент11 страниц7H RAM Predictionpartha6789Оценок пока нет

- Reliability Best Practices: Review TheseДокумент18 страницReliability Best Practices: Review TheseSV SANKARAMOORTHYОценок пока нет

- Operations & Maintenance Engineering RCM Handbook: Eni S.p.A. Exploration & Production DivisionДокумент124 страницыOperations & Maintenance Engineering RCM Handbook: Eni S.p.A. Exploration & Production DivisionGlad BlazОценок пока нет

- SIL Checklist PDFДокумент11 страницSIL Checklist PDFsteven.songОценок пока нет

- 4.5 May2019-Repairable SystemДокумент10 страниц4.5 May2019-Repairable SystemAlexander GejetanusОценок пока нет

- Eia 632Документ138 страницEia 632Edward KernОценок пока нет

- 04 Reliability DefinitionsДокумент3 страницы04 Reliability DefinitionsSidney LinsОценок пока нет

- Using and Introducing Precision MaintenanceДокумент13 страницUsing and Introducing Precision MaintenanceTofan NugrohoОценок пока нет

- Maintenance Management System Guideline For Maintenance Operating Procedures Maintenance Work ManagementДокумент29 страницMaintenance Management System Guideline For Maintenance Operating Procedures Maintenance Work ManagementGlad BlazОценок пока нет

- Ac 23-1309-1C PDFДокумент50 страницAc 23-1309-1C PDFLuis CrespoОценок пока нет

- Reliability Growth and Repairable System Analysis ReferenceДокумент392 страницыReliability Growth and Repairable System Analysis Referencehelton_bsb100% (1)

- Evaluating FMEA, FMECA and FMEDAДокумент6 страницEvaluating FMEA, FMECA and FMEDAZakaria RadaОценок пока нет

- RCM Template3Документ16 страницRCM Template3huguer1Оценок пока нет

- MIL-HDBK-2155 FracasДокумент18 страницMIL-HDBK-2155 FracasAndreas Meyer100% (1)

- Mil STD 2155Документ17 страницMil STD 2155mariobasile5063Оценок пока нет

- FRACAS Military Standard PDFДокумент17 страницFRACAS Military Standard PDFFirdaus TahirОценок пока нет

- Gage Repeatability and Reproducibility StudyДокумент5 страницGage Repeatability and Reproducibility StudyB Srinivasa RaoОценок пока нет

- Basic Problem Solving TemplateДокумент2 страницыBasic Problem Solving TemplateB Srinivasa RaoОценок пока нет

- Cause & Effect Diagram, 3 Leg Why Why FormДокумент3 страницыCause & Effect Diagram, 3 Leg Why Why FormB Srinivasa RaoОценок пока нет

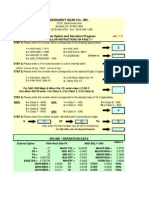

- Spline Program Ver 1.1Документ6 страницSpline Program Ver 1.1B Srinivasa RaoОценок пока нет

- Pre Control - Process Control ChartДокумент2 страницыPre Control - Process Control ChartB Srinivasa RaoОценок пока нет

- Why Do We Need Work Orders - We Don't !! - BMA IncДокумент3 страницыWhy Do We Need Work Orders - We Don't !! - BMA IncB Srinivasa RaoОценок пока нет

- Chowdhury - The Power of Six Sigma 4AHДокумент5 страницChowdhury - The Power of Six Sigma 4AHHanZan100% (1)

- CLIR Points StatusДокумент2 страницыCLIR Points StatusB Srinivasa RaoОценок пока нет

- TQM MapДокумент1 страницаTQM MapB Srinivasa RaoОценок пока нет

- List of Quality RecordsДокумент1 страницаList of Quality RecordsB Srinivasa RaoОценок пока нет

- TQM MapДокумент1 страницаTQM MapB Srinivasa RaoОценок пока нет

- Electronic DiaryДокумент127 страницElectronic DiaryZen FosysОценок пока нет

- Pare ToДокумент1 страницаPare ToB Srinivasa RaoОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Appian Traing Pdf7Документ3 страницыAppian Traing Pdf7Svr Ravi100% (1)

- Chapter 8 QuizДокумент4 страницыChapter 8 QuizAstron Smart TVОценок пока нет

- Introduction To Object Oriented Programming: by Megha V Gupta, NHITMДокумент34 страницыIntroduction To Object Oriented Programming: by Megha V Gupta, NHITMMegha GuptaОценок пока нет

- Presentasi Laporan PKL KEL 1Документ29 страницPresentasi Laporan PKL KEL 1Rido EsaputraОценок пока нет

- CP7301Документ6 страницCP7301DevakumarОценок пока нет

- Online Auction: Mini Project ReportДокумент51 страницаOnline Auction: Mini Project Reportpranay guptaОценок пока нет

- Detroit Diesel Series 71 - WikipediaДокумент7 страницDetroit Diesel Series 71 - Wikipediahanan mОценок пока нет

- BPMN, CMMN and DMN Specifications at OmgДокумент2 страницыBPMN, CMMN and DMN Specifications at OmgRodrigo Ignacio SalinasОценок пока нет

- Application ModernizationДокумент2 страницыApplication ModernizationLászló DianОценок пока нет

- How To Write SecureДокумент6 страницHow To Write Securemijat99180Оценок пока нет

- 07Документ15 страниц07vinodОценок пока нет

- Synopsis AgvДокумент5 страницSynopsis AgvskmaniaОценок пока нет

- CPU Scheduling Program in C++ - Code With CДокумент4 страницыCPU Scheduling Program in C++ - Code With CHabtieОценок пока нет

- Industrial Automation Security Design Guide 2.0Документ96 страницIndustrial Automation Security Design Guide 2.0Febryn Pradana Rifanda PutraОценок пока нет

- Description: 2Gr-Fe Engine Control System - Sfi SystemДокумент7 страницDescription: 2Gr-Fe Engine Control System - Sfi SystemImtiaz Imtiaz AliОценок пока нет

- L.CNCF - Io: Certified Kubernetes - DistributionДокумент1 страницаL.CNCF - Io: Certified Kubernetes - Distributionsuveer698Оценок пока нет

- Uvm Transaction RecordingДокумент11 страницUvm Transaction Recordingnvenkatesh485Оценок пока нет

- Aircraft Maintenance ManagementДокумент4 страницыAircraft Maintenance ManagementBandaru SwethaОценок пока нет

- Zbook Django-Reactjs-Content 16438Документ10 страницZbook Django-Reactjs-Content 16438Isaek IsberabahОценок пока нет

- Principles of Software Testing: Satzinger, Jackson, and BurdДокумент86 страницPrinciples of Software Testing: Satzinger, Jackson, and BurdVicky VickyОценок пока нет

- Introduction-Business Analyst - HealthcareДокумент2 страницыIntroduction-Business Analyst - Healthcarerahul parekhОценок пока нет

- 2021 Roadmap Web Final 5-11-2021Документ1 страница2021 Roadmap Web Final 5-11-2021TomОценок пока нет

- Assignment Scenario: Ct111-2-3 Computing TheoryДокумент6 страницAssignment Scenario: Ct111-2-3 Computing TheoryElissa Jane NesanОценок пока нет

- Ds04108bf Data Sheet (Nm4-108b)Документ2 страницыDs04108bf Data Sheet (Nm4-108b)johnnygabrielОценок пока нет

- Cloud Application Development: Morgan Kauffman, USAДокумент59 страницCloud Application Development: Morgan Kauffman, USAjagaenatorОценок пока нет

- Visitor Management SystemДокумент40 страницVisitor Management SystemKeerthi Vasan LОценок пока нет

- Lean Manufacturing Case Study With Kanban System ImplementationДокумент7 страницLean Manufacturing Case Study With Kanban System Implementationpitho.3Оценок пока нет

- 0216 Takasu - Real-Time PPP With RTKLIB and IGS Real-Time Satellite Orbit and Clock (Newcastle 2010)Документ16 страниц0216 Takasu - Real-Time PPP With RTKLIB and IGS Real-Time Satellite Orbit and Clock (Newcastle 2010)mauricioparedesw100% (1)

- Oodj ApuДокумент16 страницOodj ApuAiman Bin Idris100% (1)

- M. Gopal - Control Systems - Principles and Design (2008, Tata McGraw Hill Publishing Co. LTD.) - Libgen - LiДокумент810 страницM. Gopal - Control Systems - Principles and Design (2008, Tata McGraw Hill Publishing Co. LTD.) - Libgen - LiDhanush Dhundasi67% (3)