Академический Документы

Профессиональный Документы

Культура Документы

Functional Design Specifications: CX-140507-FDS-001 0 24-Sep-2014 Ref #: Rev #: Date

Загружено:

wqs_19Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Functional Design Specifications: CX-140507-FDS-001 0 24-Sep-2014 Ref #: Rev #: Date

Загружено:

wqs_19Авторское право:

Доступные форматы

FUNCTIONAL DESIGN SPECIFICATIONS

Ref #: CX-140507-FDS-001

Rev #: 0

Date: 24-Sep-2014

Project Title:

Customer:

End User:

Gas Pipeline 18"x 0.438 (Zubair/1- FAO)

China Petroleum Engineering and

Construction Corporation

South Oil Company

INTECH Process Automation Inc.

4903 W Sam Houston Parkway N, Suite A100, Houston, Texas 77041, USA

Tel: +1 713 849 1000 Fax: +1 713 856 0785

Email: info@intechww.com URL: www.intechww.com

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

REVISION HISTORY

24-Sep-14

15-Jul-2014

Rev #

Date

Issued for Comments and

Approval

Issued for Comments and

Approval

Description

WH

SIA

SIA

WH

MR

SIA

WRT

By

RVW

By

APP

By

INTECH

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

APP

By

CUST

APP

By

END

USER

Comments

Page 2 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

NOTICES, COPYRIGHTS AND TRADEMARKS

Electronic controlled copy is available to all corresponding, on the corporate intranet

with secure access controls and respective rights. This Document contains proprietary

information of INTECH Process Automation.

Information contained herein is for the sole use of the customer receiving this

document. Acceptance of the document by the customer constitutes agreement by

the customer that they shall not disclose proprietary information by INTECH Process

Automation to any third party and shall not transmit any documents or copies thereof

containing proprietary information of INTECH Process Automation to any third party

except as may by authorized in writing by INTECH Process Automation.

No part of this document may be used, translated into another language, stored in a

retrieval system, or transmitted, in any form or by any means, electronic, mechanical,

photocopying, recording or otherwise, without the prior written consent of INTECH

Process Automation.

While every effort has been made to ensure the accuracy of this document, INTECH

Process Automation assumes no responsibility for omissions and errors. Neither is

any liability assumed for damages resulting from the use of information contained

herein.

Questions or comment regarding this document or the product to which it relates

should be directed to:

INTECH Process Automation Inc.

4903 W Sam Houston Parkway N, Suite A100

Houston, Texas 77041, USA

Tel: +1 713 849 1000

Fax: +1 713 856 0785

Email: info@intechww.com

URL: www.intechww.com

INTECH, TAP and FPM are registered logotypes and trademarks of INTECH Process

Automation.

Copyright 2004 INTECH Process Automation Inc. All Rights Reserved.

All other logotypes, trademarks, brands and product names in this document are

acknowledged as properties of their respective companies/owners.

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 3 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

TABLE OF CONTENTS

1.

INTRODUCTION ............................................................................................. 8

1.1

1.2

1.3

1.4

2.

SCOPE OF DOCUMENT ...................................................................................................... 8

CUSTOMER REFERENCE DOCUMENTS............................................................................ 9

INTECH REFERENCE DOCUMENTS................................................................................... 9

ACRONYM AND ABBREVIATIONS .....................................................................................10

HARDWARE.................................................................................................. 11

2.1

2.2

2.3

2.4

2.5

3.

ENCLOSURE.......................................................................................................................11

2.1.1 SPECIFICATION ......................................................................................................11

CONTROL HARDWARE ......................................................................................................11

2.2.1 PAC8000 RTU CONTROLLER .................................................................................11

OPERATOR INTERFACES..................................................................................................13

POWER SUPPLY AND DISTRIBUTION...............................................................................13

ENVIRONMENTAL CONDITIONS........................................................................................14

SYSTEM INTERFACES ................................................................................ 15

3.1

4.

I/O SIGNAL INTERFACES ...................................................................................................15

3.1.1 ANALOG INPUTS.....................................................................................................15

3.1.2 DISCRETE INPUTS .................................................................................................15

3.1.3 DISCRETE OUTPUTS..............................................................................................15

HMI SOFTWARE DESIGN GUIDELINES ..................................................... 16

4.1

4.2

4.3

4.4

4.5

4.6

5.

INTRODUCTION..................................................................................................................16

SOFTWARE ENVIRONMENT SETTINGS............................................................................16

HMI SYSTEM CONFIGURATION ........................................................................................16

HMI COLOR CONVENTION ................................................................................................17

PROCESS SCREENS .........................................................................................................17

4.5.1 ZUBAIR/1 PIGGING STATION (SOCGP-LIN-PR-DW-0203) ......................................17

4.5.2 FAO TERMINAL STATION (SOCGP-LIN-PR-DW-0204) ............................................18

4.5.3 GAS CONDENSATE SEPARATING SYSTEM (SOCGP-LIN-PR-DW-0207) ..............19

4.5.4 MAIN MENU ..............................................................................................................20

MISCELLANEOUS SCREENS ..............................................................................................22

4.6.1 ALARM WINDOW......................................................................................................22

4.6.2 TREND SCREENS ....................................................................................................23

4.6.3 MISCELLANEOUS TAGS..........................................................................................26

4.6.3 HEADER ...................................................................................................................28

4.6.4 FOOTER ...................................................................................................................28

4.6.5 TOOLBAR BUTTON DETAILS ..................................................................................29

4.6.6 POP UP WINDOW ....................................................................................................30

OPERATOR INTERACTION ......................................................................... 31

5.1

5.2

6.

NAMING CONVENTION .......................................................................................................31

5.1.1 HMI TITLE NAMING CONVENTION ..........................................................................31

5.1.2 HMI STATICS GUIDELINES......................................................................................31

HMI SCREEN LIST ...............................................................................................................32

PLC SOFTWARE DESIGN GUIDELINES ..................................................... 33

6.1.

INTRODUCTION..................................................................................................................33

6.1.1 ALARM MANAGEMENT CYCLE .............................................................................33

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 4 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

6.2.

6.3.

7.

SOFTWARE ENVIRONMENT SETTINGS............................................................................34

APPLICATION STRUCTURE ...............................................................................................35

6.3.1 RESOURCE ............................................................................................................35

6.3.2 PROGRAM ..............................................................................................................35

6.3.3 FUNCTION BLOCK .................................................................................................36

OBJECT FUNCTIONALITY........................................................................... 37

7.1

7.2

7.3

8.

Date : 24-Sep-2014

OBJECT: DISCRETE INPUT................................................................................................37

7.1.1 OBJECT OVERVIEW ................................................................................................37

7.1.2 DISCRETE INPUT STATES ......................................................................................37

OBJECT: ANALOG INPUT ....................................................................................................38

7.2.1 OBJECT OVERVIEW ................................................................................................38

7.2.2 GRAPHICAL REPRESENTATION ON SCREEN .......................................................38

7.2.3 ANIMATION DETAILS ...............................................................................................39

7.2.4 AI STATES ................................................................................................................40

OBJECT: VALVES ................................................................................................................41

7.3.1 MOV STATES ...........................................................................................................41

7.3.2 GHV STATES............................................................................................................42

USER SECURITY .......................................................................................... 43

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 5 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

LIST OF FIGURES

Figure 1: Zubair/1 Pigging Station ......................................................................................................17

Figure 2: FAO Terminal Station ..........................................................................................................18

Figure 3: Gas Condensate Separating System ...................................................................................19

Figure 4: Main Screen Pigging Station ................................................................................................20

Figure 5: Main Screen FAO Terminal Station ......................................................................................21

Figure 6: Alarm Window .....................................................................................................................22

Figure 7: Trend Overview Pigging Station ...........................................................................................23

Figure 8: Trend Overview FAO Terminal Station ................................................................................24

Figure 9: Trend Window .....................................................................................................................25

Figure 10: Trend Overview Pigging Station .........................................................................................26

Figure 11: Trend Overview FAO Terminal Station ..............................................................................27

Figure 12: HMI Screen Header ...........................................................................................................28

Figure 13: Zubair1 HMI Screen Footer................................................................................................28

Figure 14: FAO Terminal Station HMI Screen Footer ..........................................................................29

Figure 15: FAO Scaling Popup Window ..............................................................................................30

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 6 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

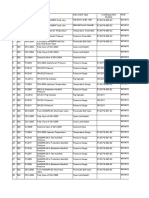

LIST OF TABLES

Table 1: Customer Reference Documents ........................................................................................... 9

Table 2: INTECH Reference Documents ............................................................................................. 9

Table 3: Control Panel Dimensions.....................................................................................................11

Table 4: Hardware Zubair/1 Pigging Station........................................................................................12

Table 5: Hardware FAO Terminal Station ...........................................................................................12

Table 6: Zubair/1 Pigging Station Operator Interface...........................................................................13

Table 7: FAO Terminal Station Operator Interface ..............................................................................13

Table 8: Software Environment Settings .............................................................................................16

Table 9: HMI System Configuration ....................................................................................................16

Table 10: Pipeline Color Convention...................................................................................................17

Table 11: HMI Tool Bar Button Detail..................................................................................................29

Table 12: Pop Up Window Detail ........................................................................................................30

Table 13: HMI Statics Guidelines ........................................................................................................31

Table 14: Zubair/1 Pigging Station Screen List ...................................................................................32

Table 15: FAO Terminal Station Screen List .......................................................................................32

Table 16: Alarms Summary ................................................................................................................33

Table 17: Alarms History ....................................................................................................................34

Table 18: PAC8000 RTU Software Environment Settings ...................................................................34

Table 19: Object List ..........................................................................................................................37

Table 20: DI States.............................................................................................................................37

Table 21: HMI Animations ..................................................................................................................39

Table 22: AI States .............................................................................................................................40

Table 23: MOV States ........................................................................................................................41

Table 24: GHV States.........................................................................................................................42

Table 25: User Groups and their Privileges.........................................................................................43

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 7 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

1. INTRODUCTION

INTECHs project scope includes supply of two (2) Remote Terminal Units (RTUs),

one at Zubair/1 Pigging Station and one at FAO Terminal Station. Overall project

responsibilities of INTECH are as follows:

Design and engineering;

Supply of all materials, hardware and software, required for the Remote

Terminal Units (RTUs);

Panel assembly;

Panel configuration;

FAT, SAT testing;

Supply of start-up and commissioning spares;

Supply of 2-year spare parts list;

Drawing & documentation;

Start-up and commissioning assistance;

Training;

Assistance during the guarantee period.

1.1

SCOPE OF DOCUMENT

This document describes overall functionality of the objects used in the software

applications and how the control philosophy is implemented in the project. The

functionality as described is restricted to the devices/instruments that are part of

INTECHs scope; any third party instruments process functionality description is not

part of this documents scope.

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 8 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

1.2

Date : 24-Sep-2014

CUSTOMER REFERENCE DOCUMENTS

Document Number

Rev #

SOCGP-PR-DW-0203

Document Title

Piping & Instrumentation Drawing Zubair/1

Pigging Station, FAO Terminal Station, Gas

Condensate Separating System

SOCGP-PR-DW-0204

SOCGP-PR-DW-0207

SOCGP-IN-DL-0205

SOCGP-IN-DL-0206

IO List Zubair/1 Pigging Station, FAO Terminal

Station

SOCGP-IN-SP-0204

Specification for Remote Terminal Unit

Table 1: Customer Reference Documents

1.3

INTECH REFERENCE DOCUMENTS

Document Number

CPECC/SOC Document Number

Rev #

Document Title

CX-140507-IOLST-001

P-SOCGP-IN-MR-0212-1306

IO List

CX-140507-BOM-001

P-SOCGP-IN-MR-0212-1305

Bill Of Materials

CX-140507-GL-001

P-SOCGP-IN-MR-0212-1500

Drawings

Table 2: INTECH Reference Documents

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 9 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

1.4

ACRONYM AND ABBREVIATIONS

DI

Digital Input

AI

Analog Input

MOV

Motor Operated Valve

GHV

Gas Hydraulic Valve

HMI

Human Machine Interface

RTU

Remote Terminal Unit

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Date : 24-Sep-2014

Page 10 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

2.

Date : 24-Sep-2014

HARDWARE

2.1

2.1.1

ENCLOSURE

SPECIFICATION

All control equipment is mounted within Hoffman CSD483610 series panels.

The enclosure dimensions are:

S. No.

Cabinet

Dimension (HxWxD)

PAC 8000 RTU Control Panel Zubair/1 Pigging

Station

1219H x 914W x 254D mm

PAC 8000 RTU Control Panel FAO Terminal

Station

1219H x 914W x 254D mm

Table 3: Control Panel Dimensions

The enclosure is made from 14 gauge steel finished externally with RAL 7035 Light

Gray color.

2.2

CONTROL HARDWARE

The following sections detail the main equipment components that are included.

2.2.1

PAC8000 RTU CONTROLLER

A GE PAC8000 RTU Controller will provide the means of controlling the process

functionality of the control system.

The control PLC will consist of a Simplex Controller Carrier, along with an I/O carrier

for 8 modules.

Details are given below:

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 11 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

GE PAC8000 based RTU System

Zubair/1 Pigging Station PAC8000 RTU Rack 1

Description

Part No.

Slot No.

Controller Carrier

Controller Carrier, Simplex or Redundant, Power

8750-CA-NS

Monitoring

1

PAC8000 RTU Controller

8521-RT-DE

I/O Modules Carrier

1

8-channel Isolated Universal AI

8132-AI-UN

8-channel Isolated Universal AI

8132-AI-UN

16 Channels, isolated, sinking DI

8122-DI-DC

8-channel Discrete Output

260 V dc, isolated, unpowered

8117-DO-DC

Table 4: Hardware Zubair/1 Pigging Station

GE PAC8000 based RTU System

FAO Terminal Station PAC8000 RTU Rack 1

Description

Part No.

Slot No.

Controller Carrier

Controller Carrier, Simplex or Redundant, Power

8750-CA-NS

Monitoring

1

PAC8000 RTU Controller

8521-RT-DE

I/O Modules Carrier

1

8-channel Isolated Universal AI

8132-AI-UN

8-channel Isolated Universal AI

8132-AI-UN

16 Channels, isolated, sinking DI

8122-DI-DC

8-channel Discrete Output

260 V dc, isolated, unpowered

8117-DO-DC

Table 5: Hardware FAO Terminal Station

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 12 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

2.3

Date : 24-Sep-2014

OPERATOR INTERFACES

Feedback from field transmitters and control of valves will be provided via an HMI

screen, interaction with which will be via a touch screen panel view mounted on the

front door of the PAC8000 RTU Control cabinets of Zubair/1 Pigging Station and FAO

Terminal Station. The details of the door mounted equipment are as follows:

Zubair/1 Pigging Station

S. No.

1

Quantity

1

Description

Part No.

Quick Panel+ View & Control, 12" Color TFT IC755CSS12CDA

Table 6: Zubair/1 Pigging Station Operator Interface

FAO Terminal Station

S. No.

1

Quantity

1

Description

Part No.

Quick Panel+ View & Control, 12" Color TFT IC755CSS12CDA

Table 7: FAO Terminal Station Operator Interface

2.4

POWER SUPPLY AND DISTRIBUTION

In Zubair/1 Pigging Station and FAO Terminal Station, both AC, DC power

distributions are available.

System and Field Devices have separate power supplies which are powered from

230VAC 50Hz coming from outside the panel through UPS.

For details regarding the power distribution refer to the document P/SOCGP-IN-MR0212-1500 on Sheet Number 13 and 14.

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 13 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

2.5

Date : 24-Sep-2014

ENVIRONMENTAL CONDITIONS

The minimum degree of protection against ingress of water and dust for control

panels will be IP52, minimum.

Panels and equipment are suitable for operation at 0 to 60 C ambient

temperature.

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 14 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

3. SYSTEM INTERFACES

3.1

I/O SIGNAL INTERFACES

Following are the field IOs for PAC8000 RTU Control System of Zubair/1 Pigging

Station and FAO Terminal Station.

3.1.1

ANALOG INPUTS

General Electric 8132-AI-UN Analog Input Cards will be used be for analog signals.

Each card will be configured for 8 single ended 4-20mA input channels. Card faults

will be monitored with front mounted LED indicators. These are universal Analog Input

cards which mean that they can be used for various Thermocouple, RTD and Voltage

signals as well.

3.1.2

DISCRETE INPUTS

General Electric 8122-DI-DC 16 channel Digital Input Cards will be used for the Digital

Input Signals. Card faults can be monitored with front mounted LED indicators.

3.1.3

DISCRETE OUTPUTS

General Electric 8117-DO-DC 8 channel Digital Input Cards will be used for the Digital

Output Signals. Card faults can be monitored with front mounted LED indicators.

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 15 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

4. HMI SOFTWARE DESIGN GUIDELINES

4.1

INTRODUCTION

The HMI system will be based on GEs Proficy Machine Edition 8.5.

The HMI provides monitoring and control window for the Process systems. It will

enable the operator to view the data being gathered by the PLCs and provide limited

control over the process. This section of the document defines the operational

requirement and design basis for the project.

Quick Panel+ HMI will be mounted on the front door of RTU panels of Pigging Station

and FAO Terminal Station.

4.2

SOFTWARE ENVIRONMENT SETTINGS

Items

Details

Quick Panel+ View & Control, 12",

Operator Interface (HMI)

IC755CSS12CDA

HMI Development Software Name & Version

Proficy Machine Edition

Firmware Version

8.5

Table 8: Software Environment Settings

4.3

HMI SYSTEM CONFIGURATION

Items

Details

640 x 480

800 x 600

1280 x 1024

1600 x 1200

Small

Medium

1024 x 768

1152 x 864

Resolution

Font Size

Screen

Background

Color

Others _____________

Large

Color Code (RGB): 192 192 192

Table 9: HMI System Configuration

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 16 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

4.4

Date : 24-Sep-2014

HMI COLOR CONVENTION

Following color convention is applied on the whole HMI application Process Flow Line Colors.

Line Description

Natural Gas

Line Color

Snapshot

Black

RGB

0, 0, 0

Table 10: Pipeline Color Convention

4.5

PROCESS SCREENS

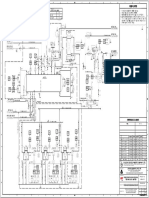

4.5.1 ZUBAIR/1 PIGGING STATION (SOCGP-LIN-PR-DW-0203)

Figure 1: Zubair/1 Pigging Station

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 17 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

4.5.2 FAO TERMINAL STATION (SOCGP-LIN-PR-DW-0204)

Figure 2: FAO Terminal Station

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 18 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

4.5.3 GAS CONDENSATE SEPARATING SYSTEM (SOCGP-LIN-PR-DW-0207)

Figure 3: Gas Condensate Separating System

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 19 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

4.5.4 MAIN MENU

4.5.4.1 Zubair/1 Pigging Station

Figure 4: Main Screen Pigging Station

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 20 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

4.5.4.2 FAO Terminal Station

Figure 5: Main Screen FAO Terminal Station

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 21 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

4.6

Date : 24-Sep-2014

MISCELLANEOUS SCREENS

Alarm Window

Trend Screens

Miscellaneous Tags

Header

Footer

Toolbar Button Details

Pop Up Windows

4.6.1 ALARM WINDOW

Figure 6: Alarm Window

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 22 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

4.6.2 TREND SCREENS

4.6.2.1 Zubair/1 Pigging Station

Following window opens up when trend button is clicked.

Figure 7: Trend Overview Pigging Station

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 23 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

4.6.2.2 FAO Terminal Station

Following window opens up when trend button is clicked.

Figure 8: Trend Overview FAO Terminal Station

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 24 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

4.6.2.3

Date : 24-Sep-2014

Trend Window

Trend Window opens up if we click any tag in trend overview window.

Figure 9: Trend Window

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 25 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

4.6.3 MISCELLANEOUS TAGS

4.6.3.1 Zubair/1 Pigging Station

Following window opens up when Misc. Tags is clicked.

Figure 10: Trend Overview Pigging Station

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 26 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

4.6.3.2 FAO Terminal Station

Following window opens up when Misc. Tags is clicked.

Figure 11: Trend Overview FAO Terminal Station

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 27 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

4.6.3 HEADER

4.6.3.1

Zubair/1 Pigging Station and FAO Terminal Station:-

The Header will be common to all screens. Located at the top of each screen,

the header provides:

Figure 12: HMI Screen Header

Project Name

User Logon

User Logoff

Exit Screen

Date and Time

Logged On User

4.6.4 FOOTER

4.6.4.1

Zubair/1 Pigging Station:-

The Footer will be common to all screens. Located at the bottom of each screen,

the footer provides links of the following screens:

Figure 13: Zubair1 HMI Screen Footer

Home Screen

Zubair/1 Screen

Miscellaneous Tags

Trends Screen

Alarms Window

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 28 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

4.6.4.2

Date : 24-Sep-2014

FAO Terminal Station:-

The Footer will be common to all screens. Located at the bottom of each screen,

the footer provides links of the following screens:

Figure 14: FAO Terminal Station HMI Screen Footer

Home Screen

Zubair/1 Screen

Gas Condensate Screen

Miscellaneous Tags

Trends Screen

Alarms Window

4.6.5 TOOLBAR BUTTON DETAILS

Button Name

Description

Main Screen

Displays Main Menu screen

Log Out

Logs out Current user

Log In

Logs in screen for all user

Home

Displays System Overview Screen

Alarms Window

Displays Alarm Summary screen

Trends

Displays Trend screen for the current screen

Exit Client

Close the current Client

Table 11: HMI Tool Bar Button Detail

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 29 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

4.6.6 POP UP WINDOW

When any Analog Input display present on the process screens and miscellaneous

tags is clicked a pop up window appears in which we can enter the high and low

range of the tag and we can enter the alarm set points for the tags. We can also

select which alarms of the specific tags the would be displayed on the HMI screens

and which would not be displayed with the help of the Y or N button available in front

of every set point value. The pop up screen is shown below:

Figure 15: FAO Scaling Popup Window

The detailed description of the objects in above figure is given below:

HMI Element

Description

Max EU

Maximum Engineering Unit (High Limit of AI tag)

Min EU

Minimum Engineering Unit (Low Limit of AI tag)

HH_SP

High High Set Point

H_SP

High Set Point

L_SP

Low Set Point

LL_SP

Low Low Set Point

Alarm is Enabled

Alarm is Disabled

Table 12: Pop Up Window Detail

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 30 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

5.

Date : 24-Sep-2014

OPERATOR INTERACTION

Operator interactions with the Panel View HMI will be by touch screen technology.

The system discriminates between the following categories of status:

Healthy -

System is running healthy.

Alarm - Equipment or system being monitored by the instrumentation and control

Systems are in an undesirable state (e.g. process alarm, emergency alarm).

Fault - Failure exists in the instrumentation and control, or electrical systems

(E.g. System communications failure, Module failure)

5.1

NAMING CONVENTION

5.1.1 HMI TITLE NAMING CONVENTION

Screens will be named according to P&IDs Equipment Name.

5.1.2 HMI STATICS GUIDELINES

''Static Objects' are the graphics on the screen that are not animated. This includes

the vessels, piping, equipment and other required information.

The whole of this information is picked up from the P&ID drawings. The live

instrumentation is later put on top of this basic static structure. The following

guidelines will apply:

One P&ID will be translated to one screen (exceptions can be made as needed)

Each screen will show the graphic window name on its Top center

Non-electronically instrumented or non-instrumented piping/vessels/equipment will not

be shown

Tag names/Titles for all displayed instruments/vessels/equipment will be shown

Pipe arrow to show flow directions, are shown

Vessels and pipes have a 2D line-drawing look

Table 13: HMI Statics Guidelines

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 31 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

5.2

Date : 24-Sep-2014

HMI SCREEN LIST

Based on the current set of P&IDs, the following screens have been identified:

S. No.

Screen name/Title

Zubair/1 Pigging Station List of Screens

1.

Home Screen

2.

Zubair/1 Pigging Station

3.

Miscellaneous Tags

4.

Trend Selection

5.

Trends Screen

6.

Alarm Summary

Table 14: Zubair/1 Pigging Station Screen List

S. No.

Screen name/Title

FAO Terminal Station List of Screens

1.

Home Screen

2.

FAO Terminal Station

3.

Gas Condensate Separating System

4.

Miscellaneous Tags

5.

Trend Selection

6.

Trends Screen

7.

Alarm Summary

Table 15: FAO Terminal Station Screen List

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 32 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

6. PLC SOFTWARE DESIGN GUIDELINES

6.1.

INTRODUCTION

This section outlines the basis on which the Controller Application will be developed.

This includes the structure and naming convention to be used for developing the

application. This will ensure that the program structure and tagging convention used is

consistent throughout the application. The document also describes the object

oriented approach used by INTECH for implementation of the Process Control

requirements.

6.1.1

ALARM MANAGEMENT CYCLE

There are two windows for Alarm management functions which are discussed below:

6.1.1.1

Alarms Summary Window:There is no indication of alarm on Alarm

Summary.

STEP1 (Normal Conditions)

STEP2 (When the Alarm occurs)

Whenever a new unacknowledged alarm

appears, it emerges in Alarm Summary and its

foreground is red and most recent alarm is shown

at the top.

STEP3 (When the Acknowledge

When an alarm is acknowledged, its foreground

Button is pressed)

in alarm summary turns yellow.

STEP4

Normal)

(Condition

If an unacknowledged alarm returns to normal, it

becomes stays on alarm summary.

If an alarm appears and returns to normal (unacknowledged), it will keep showing.

Table 16: Alarms Summary

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 33 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

6.1.1.2

Date : 24-Sep-2014

Alarms History Window:There is no indication of alarm on Alarm

Summary.

STEP1 (Normal Conditions)

STEP2 (When the Alarm occurs)

Whenever a new alarm appears, it emerges in

Alarm History and its foreground is red and most

recent alarm is shown at the top.

STEP3 (When the Acknowledge

When an alarm is acknowledged, its foreground

Button is pressed)

in alarm summary turns yellow.

STEP4

Normal)

(Condition

If an unacknowledged alarm returns to normal, it

becomes turns green.

If an alarm appears and returns to normal (unacknowledged), its foreground turns green.

Table 17: Alarms History

6.2.

SOFTWARE ENVIRONMENT SETTINGS

Following table lists the software environment settings that shall be followed for

developing the PAC8000 RTU Controller Application:

Controller Application Development

Software

PAC8000 Workbench 8.4

Firmware Support

Latest

Programming Language

Ladder Diagram,FBD

Controller Type

8521-RT-DE

Number of Applications

2 Applications in total. (1 each for

Zubair/1 Pigging Station and FAO

Terminal Station )

Table 18: PAC8000 RTU Software Environment Settings

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 34 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

6.3.

Date : 24-Sep-2014

APPLICATION STRUCTURE

A Project is composed of configurations. A configuration is a hardware platform

composed of one or more resources. A resource represents a target kernel. A

resource is divided into several programming units called POUs (Program

Organization Unit). The POUs of a resource are linked together in a tree-like

architecture. POUs can be described using any of SFC, FC, FBD, LD, ST or IL

graphic or literal languages. POUs can be programs, functions or function blocks.

6.3.1

RESOURCE

A resource is where a PLC loop is defined. The PLC loop is executed by one kernel.

Resources can have links with other resources, locally to a configuration or via the

network.

Each resource is displayed as a separate window within the link architecture view.

The resource window title bar includes:

An icon indicating the operative state and security state of the resource.

The resource name and comment.

A Windows control button to maximize or restore the resource window.

A Data Link button enabling you to graphically create data links between

resource.

6.3.2

PROGRAM

A program belongs to a Resource. It is executed by the Kernel, depending on its

location (order) in the Resource.

A Program is a logical programming unit that describes operations between variables

of the process. Programs describe either sequential or cyclic operations. Cyclic

programs are executed at each target system Cycle. The execution of sequential

programs has a Dynamic Behavior.

Programs are linked together in a hierarchy tree. Programs placed on the top of the

hierarchy are activated by the system.

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 35 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

6.3.3

Date : 24-Sep-2014

FUNCTION BLOCK

Any program or function block can call a function block. A function cannot call a

function block. Function blocks are also known as POUs. Function blocks are written

in ST, LD, or FBD. The order in which function blocks appear within their section is

not important; function blocks are called from a POU.

Although the editor allows function blocks to be created using SFCs, the controller

does not support this type of function block. An SFC function block will be rejected by

the compiler.

You can move or copy all function blocks to the Programs section and all but the SFC

function block to the Functions section. You can also move or copy functions and

programs, written with languages supported by function blocks, to the Functions

section. When moving or copying a program to the Function Blocks section, all local

variables defined in the program are converted to function block parameters.

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 36 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

7. OBJECT FUNCTIONALITY

Sr.

Object Descriptive Name

Brief Description

1.

Discrete Input

Object for Discrete Input

2.

Analog Input

Object for Analog Input

3.

Valves

Object for Valves

Table 19: Object List

7.1

OBJECT: DISCRETE INPUT

7.1.1 OBJECT OVERVIEW

This object incorporates one discrete input. The alarm is set according to the status of

the discrete input.

7.1.2 DISCRETE INPUT STATES

CONDITIONS

STATES

NORMAL STATE

Shown object represents the DI Alarm in

Normal state. Object will appear in solid

Green color. As shown in object state.

ALARM STATE

Shown object represents the DI Alarm in

Alarm state. Object will appear in solid Red

color and Blink. As shown in object state.

Table 20: DI States

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 37 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

7.2

Date : 24-Sep-2014

OBJECT: ANALOG INPUT

7.2.1 OBJECT OVERVIEW

Main features:

Four alarms.

Alarm set-points are configurable from HMI with given privileges.

The process value from transmitter (PV Raw) is scaled in PLC to calculate

process value in engineering units.

The process value is compared against the advisory alarm set-points.

If alarm condition is detected, alarm is generated.

Real Time Trending will be provided.

7.2.2 GRAPHICAL REPRESENTATION ON SCREEN

Device Tag Name

Alarm

Engineering Unit

Process Value

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 38 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

7.2.3 ANIMATION DETAILS

The animation details of AI objects are as follows:

HMI ANIMATIONS

Device State

Normal

Condition

Normal No alarm rectangle

HH Alarm (Unacknowledged) Alarm status HH Alarm (Unacknowledged) Alarm status

rectangle blinking

rectangle blinking

HH Alarm (Acknowledged)

HH Alarm (Acknowledged) Alarm status

rectangle visible but steady

H Alarm (Unacknowledged)

H Alarm (Unacknowledged) Alarm status

rectangle blinking

H Alarm (Acknowledged)

H Alarm (Acknowledged) Alarm status

rectangle visible but steady

L Alarm (Unacknowledged)

L Alarm (Unacknowledged) Alarm status

rectangle blinking

L Alarm (Acknowledged)

L Alarm (Acknowledged) Alarm status

rectangle visible but steady

LL Alarm (Unacknowledged)

LL Alarm (Unacknowledged) Alarm status

rectangle blinking

LL Alarm (Acknowledged)

LL Alarm (Acknowledged) Alarm status

rectangle visible but steady

Table 21: HMI Animations

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 39 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

7.2.4 AI STATES

The following table depicts AI states of as follows:

Device State

Condition

Normal Condition

Shown object represents the Normal

State, i.e. no alarm conditions or faults

High High Alarm (UnAck):

Alarm rectangle- blinking in Red color

High High Alarm (Ack):

Alarm rectangle- steady in Red color

High Alarm (UnAck):

Alarm rectangle- blinking in Red color

High Alarm (Ack):

Alarm rectangle- steady in Red color

Low Alarm (UnAck):

Alarm rectangle- blinking in Red color

Low Alarm (Ack):

Alarm rectangle- steady in Red color

Low Low Alarm (UnAck):

Alarm rectangle- blinking in Red color

Low Low Alarm (Ack):

Alarm rectangle- steady in Red color

Table 22: AI States

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 40 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

7.3

Date : 24-Sep-2014

OBJECT: VALVES

There are two types of valves as follows:

7.3.1 MOV STATES

The following table depicts the states of Motor Operated Valves in different conditions.

Solid Green state of Valve legs indicates Valve open and solid Red indicates that

Valve is close.

CONDITIONS

STATES

CLOSED STATE

Shown object represents the Valve in Closed

state. Objects legs will appear in solid Red

color if Status value equal to 0. As shown in

object state.

OPENED STATE

Shown object represents the Valve in

Opened state. Objects legs will appear in

solid green color if Status value equal to 1. As

shown in object state.

INTERMEDIATE STATE

Shown object represents the Valve in

intermediate state. Object will appear in solid

grey color if Status value neither opened nor

closed. As shown in object state.

FAULT STATE

Shown object represents the Valve in fault

state. Objects legs will appear in magenta

color in case of fault condition. As shown in

object state.

Table 23: MOV States

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 41 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

7.3.2 GHV STATES

These valves have commands and status values to be depicted as follows:

CONDITIONS

STATES

OPEN COMMAND

Valves square head turns green when open

command is given. The open button also

turns blue. As shown in object state.

CLOSE COMMAND

Valves square head turns red when close

command is given. The close button also

turns blue. As shown in object state.

CLOSE TO OPEN

TRAVELLING STATE

OPEN TO CLOSE

Shown object represents the Valve in

intermediate state. Objects legs will appear

in solid grey color if Status value neither

opened nor closed. As shown in object state.

OPEN FAIL

FAULT STATE

CLOSE FAIL

Shown object represents the Valve in fault

state after it does not open or close in

predefined time after command is given.

Table 24: GHV States

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Page 42 of 44

FUNCTIONAL SPECIFICATION DOCUMENT

Project Title : GAS PIPELINE 18 x 0.438 (Zubair/1 FAO)

INTECH Project Code : CX-140507

Customer : China Petroleum Engineering and Construction Corporation

Customer Project # : P/SOCGP-IN-MR-0212-1303

End User : South Oil Company

End User Project # : P/SOCGP-IN-MR-0212-1303

Ref # : CX-140507-FDS-001

Rev # : 0

Date : 24-Sep-2014

8. USER SECURITY

Sr.

User Group

Description

1.

View Only

Users that belong to this user group will have read only rights

2.

Operator

Users that belong to this user group can acknowledge / Reset alarms

3.

Engineer

FRM # : OPS-WI-06-FD (15)

Issue # : 01

Date of Issue: 30-Jan-2014

Users that belong to this user group have all rights of operator and can also

enter data.

Table 25: User Groups and their Privileges

Page 43 of 44

Вам также может понравиться

- OV 141113 FDS JR Comments - Revision - 1Документ56 страницOV 141113 FDS JR Comments - Revision - 1wqs_19Оценок пока нет

- Specification For Foundation Fieldbu EssarДокумент22 страницыSpecification For Foundation Fieldbu Essarvio_tani4812Оценок пока нет

- 3210-8550-FS-0008 Foundation Fieldbus Functional RequrementДокумент34 страницы3210-8550-FS-0008 Foundation Fieldbus Functional Requrementsuhailfarhaan100% (2)

- PUB060-001-00 - 1110 RCL NetworksДокумент8 страницPUB060-001-00 - 1110 RCL NetworksapisituОценок пока нет

- SNBP-EPC-00-INS-DBS-001 Rev.B - Instrument Telecomunication Design BasisДокумент19 страницSNBP-EPC-00-INS-DBS-001 Rev.B - Instrument Telecomunication Design Basissugeng wahyudiОценок пока нет

- 7650-8550-DS-500-6211 DoneДокумент11 страниц7650-8550-DS-500-6211 DoneKhan Akhtar HusainОценок пока нет

- Spi FFДокумент17 страницSpi FFjose_johnОценок пока нет

- 7J48N-00-15-17-005 Distributed Control SystemДокумент134 страницы7J48N-00-15-17-005 Distributed Control SystemAhmed FayedОценок пока нет

- BPCL Digital TenderДокумент99 страницBPCL Digital TenderKANADARPARОценок пока нет

- Ai 230 PLCДокумент106 страницAi 230 PLCOG100% (1)

- 71.0402 General Construction - Substructures - AssemblyДокумент201 страница71.0402 General Construction - Substructures - Assemblythanhphucbr87Оценок пока нет

- 1333 Ess 00 in 076 - 0Документ63 страницы1333 Ess 00 in 076 - 0WОценок пока нет

- FPF1-ST-G00001-E-SPE-0009 - CableДокумент49 страницFPF1-ST-G00001-E-SPE-0009 - Cablebmanojkumar16Оценок пока нет

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979От EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonОценок пока нет

- FISCOДокумент19 страницFISCOsayedmhОценок пока нет

- QSA37T0005-1P (Proposal Technical Basis Assumption)Документ10 страницQSA37T0005-1P (Proposal Technical Basis Assumption)anon_832516663Оценок пока нет

- Project One - Ecr Epcm Services Contract: Level Instruments DatasheetsДокумент105 страницProject One - Ecr Epcm Services Contract: Level Instruments DatasheetsKhan Akhtar HusainОценок пока нет

- Fire Gas Detection Philosophy 1641849168Документ44 страницыFire Gas Detection Philosophy 1641849168f5crdfwhg9Оценок пока нет

- Iooc Idhc BDP Ins SPC 015 016 Dcs r2Документ29 страницIooc Idhc BDP Ins SPC 015 016 Dcs r2Fatholla SalehiОценок пока нет

- GTCL Draft Specification Master Working Copy LatestДокумент286 страницGTCL Draft Specification Master Working Copy LatestHarun RashidОценок пока нет

- PH Analyser Manual PH-13-SДокумент22 страницыPH Analyser Manual PH-13-SSunil Chouhan100% (1)

- CV - Mohd Nadim - 01-06-2017Документ6 страницCV - Mohd Nadim - 01-06-2017Mohammad NadimОценок пока нет

- Ges C0201 01 Sis HW FDS R4.01.00Документ105 страницGes C0201 01 Sis HW FDS R4.01.00Priyansh SaxenaОценок пока нет

- Junction Box Requirements For Foundation FieldbusДокумент3 страницыJunction Box Requirements For Foundation FieldbuszhangyiliОценок пока нет

- Signal Exchange Between Power Plant - Substation &Документ16 страницSignal Exchange Between Power Plant - Substation &Nasiruddin Abdullah HussainОценок пока нет

- A Ele Spe 800 30018 0Документ26 страницA Ele Spe 800 30018 0ZaidiОценок пока нет

- Users: Communication Solutions ForДокумент12 страницUsers: Communication Solutions Forpmg1380Оценок пока нет

- Qcs 2010 Part 10.02 Telemetry-SCADAДокумент29 страницQcs 2010 Part 10.02 Telemetry-SCADARotsapNayrb100% (1)

- Foundation Fieldbus Segment Drawing (FF Cable Schedule) - ModifДокумент721 страницаFoundation Fieldbus Segment Drawing (FF Cable Schedule) - ModifLakshman KaretiОценок пока нет

- HART Vs Foundation Fieldbus - ComparisonДокумент10 страницHART Vs Foundation Fieldbus - ComparisonrajkumarpandeyОценок пока нет

- S10332300-3002 - 0 Instrument InstallationДокумент20 страницS10332300-3002 - 0 Instrument Installationappril26Оценок пока нет

- Org Arw Imt SPR 00001 - 4.0 - 1Документ22 страницыOrg Arw Imt SPR 00001 - 4.0 - 1abha singhОценок пока нет

- Urhoud: Specification FOR Integrated Control SystemДокумент39 страницUrhoud: Specification FOR Integrated Control SystemhapinefeОценок пока нет

- SECTION VI Inst Installation General SpecsДокумент29 страницSECTION VI Inst Installation General SpecsgulavОценок пока нет

- BCD3-315-48-DS-4-001-00 Data Sheet For Fiber Optic Cable - Rev 1Документ7 страницBCD3-315-48-DS-4-001-00 Data Sheet For Fiber Optic Cable - Rev 1rofingi ajiОценок пока нет

- Operation and Control Philosophy: PROJ Kurdistan Pumping Station (KPS2)Документ21 страницаOperation and Control Philosophy: PROJ Kurdistan Pumping Station (KPS2)Nobar GulajanОценок пока нет

- NG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedДокумент16 страницNG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedFolarin AyodejiОценок пока нет

- Integrated Control SystemsДокумент8 страницIntegrated Control SystemsAnonymous FFMmIJyОценок пока нет

- MKP-05-En-IC-SPC-005 Specification For Fire & Gas DetectorДокумент12 страницMKP-05-En-IC-SPC-005 Specification For Fire & Gas Detectorsugeng wahyudiОценок пока нет

- 305.icm-Ou-11.07 Programmable Logic ControllerДокумент28 страниц305.icm-Ou-11.07 Programmable Logic ControllerTpОценок пока нет

- ECA-00-PCS-SPE-0015 - Rev1-TEMPERATURE INSTRUMENT SPECIFICATIONДокумент14 страницECA-00-PCS-SPE-0015 - Rev1-TEMPERATURE INSTRUMENT SPECIFICATIONhcsharma1967Оценок пока нет

- Rtu FDSДокумент30 страницRtu FDSroopchandanОценок пока нет

- 7J48N-00-15-17-006-1 Emergency Shutdown SystemДокумент49 страниц7J48N-00-15-17-006-1 Emergency Shutdown SystemAhmed FayedОценок пока нет

- 6-66 KV SF6 BKR R3 May12Документ26 страниц6-66 KV SF6 BKR R3 May12PB MehtaОценок пока нет

- CP 201Документ36 страницCP 201kattabommanОценок пока нет

- Papua LNG Upstream Project: Instrumentation Control and Safeguarding Systems Design BasisДокумент46 страницPapua LNG Upstream Project: Instrumentation Control and Safeguarding Systems Design BasisSangaranОценок пока нет

- Attachment 1 - I-O SiIOgnals List For Indoor PSSДокумент14 страницAttachment 1 - I-O SiIOgnals List For Indoor PSSRahil TasawarОценок пока нет

- Technical Specification For Motor Operated ValvesДокумент6 страницTechnical Specification For Motor Operated ValvesĐặng Trung AnhОценок пока нет

- SPI Typical Loops PDFДокумент39 страницSPI Typical Loops PDFanoopsreОценок пока нет

- SNO-I-DS-005 - B Instrument Datasheet For Radar Level TransmitterДокумент46 страницSNO-I-DS-005 - B Instrument Datasheet For Radar Level Transmitterono_czeОценок пока нет

- Sharing Bpcs - SisДокумент4 страницыSharing Bpcs - Sissatan556Оценок пока нет

- Instrumentation - Control Design BasisДокумент40 страницInstrumentation - Control Design BasisRajesh Barkur100% (2)

- DS Pressure Transmitter PDFДокумент3 страницыDS Pressure Transmitter PDFadrian bargasОценок пока нет

- SATR-J-6601 Rev 0 PDFДокумент4 страницыSATR-J-6601 Rev 0 PDFAdel Klk100% (1)

- 10080-1-ENGG-DBD-CI-003 - 1 - Design Basis For Fundation Field BUSДокумент69 страниц10080-1-ENGG-DBD-CI-003 - 1 - Design Basis For Fundation Field BUSDinesh Boopalan100% (1)

- Instrument Index Platform: Domain: Finalproject Plant: AreaДокумент3 страницыInstrument Index Platform: Domain: Finalproject Plant: AreaJasJusОценок пока нет

- Presentacion TelventДокумент39 страницPresentacion TelventLuisОценок пока нет

- S Op Surface Peratio e Hydra (OD Nal Phi Aulic Co DIN Valv Ilosoph Ontrol S Ve) Hy System MДокумент28 страницS Op Surface Peratio e Hydra (OD Nal Phi Aulic Co DIN Valv Ilosoph Ontrol S Ve) Hy System Mwqs_19Оценок пока нет

- Object Functionality: Functional Design SpecificationДокумент113 страницObject Functionality: Functional Design SpecificationAdil AhsanОценок пока нет

- NOF Plant Softwares ListДокумент3 страницыNOF Plant Softwares Listwqs_19Оценок пока нет

- S.No. Tasks 1 Make Sales Gas Compressor Logs 2 Make Turbo Expander Indent 3 Update Indent/ Approval Statuses 4 Working On Indents 5 Instrument Air Compressor Package UnderstandingДокумент1 страницаS.No. Tasks 1 Make Sales Gas Compressor Logs 2 Make Turbo Expander Indent 3 Update Indent/ Approval Statuses 4 Working On Indents 5 Instrument Air Compressor Package Understandingwqs_19Оценок пока нет

- Muhammad Ibrar - ResumeДокумент4 страницыMuhammad Ibrar - Resumewqs_19Оценок пока нет

- Load List of EquipmentДокумент2 страницыLoad List of Equipmentwqs_19Оценок пока нет

- CA LiberationДокумент2 страницыCA Liberationwqs_19Оценок пока нет

- NOF Plant Softwares ListДокумент3 страницыNOF Plant Softwares Listwqs_19Оценок пока нет

- Control Valves (Fisher)Документ6 страницControl Valves (Fisher)wqs_19Оценок пока нет

- NGP-000-INS-15.02-0001-00-00-Instrument IndexДокумент267 страницNGP-000-INS-15.02-0001-00-00-Instrument Indexwqs_19Оценок пока нет

- FACP Fire Alarm System Cabinet DrawingДокумент8 страницFACP Fire Alarm System Cabinet Drawingwqs_19Оценок пока нет

- Control Philosophy ACДокумент10 страницControl Philosophy ACwqs_19Оценок пока нет

- Solenoid Valves 3 - 2 5 - 2 Stainless Steel Body 551 553 CAT 80114GBДокумент8 страницSolenoid Valves 3 - 2 5 - 2 Stainless Steel Body 551 553 CAT 80114GBwqs_19Оценок пока нет

- Ngp-000-Ele-15.71-0004-A Ms For Instrument & Utility Air System TestДокумент5 страницNgp-000-Ele-15.71-0004-A Ms For Instrument & Utility Air System Testwqs_19Оценок пока нет

- Ngp-001-Pcs-15.71-0009!17!001 Sat For Instrument & Utility Air and Nitrogen Generation System-EndДокумент5 страницNgp-001-Pcs-15.71-0009!17!001 Sat For Instrument & Utility Air and Nitrogen Generation System-Endwqs_19Оценок пока нет

- Sat Practice Answer SheetДокумент5 страницSat Practice Answer SheetJasonОценок пока нет

- S.No. Tagnames Description Type Old NameДокумент2 страницыS.No. Tagnames Description Type Old Namewqs_19Оценок пока нет

- This Feeder Marked in Red Is Not Working in Link 1 and Link 2Документ2 страницыThis Feeder Marked in Red Is Not Working in Link 1 and Link 2wqs_19Оценок пока нет

- 118 4417593 D03Документ106 страниц118 4417593 D03wqs_19Оценок пока нет

- Cover Letter For Turbo Expander Indent - InstrumentДокумент1 страницаCover Letter For Turbo Expander Indent - Instrumentwqs_19Оценок пока нет

- Turbo Expander PDFДокумент105 страницTurbo Expander PDFwqs_1960% (5)

- PROGRAM UPLOAD FROM AC500 (Upload Programming AC500 Programs)Документ2 страницыPROGRAM UPLOAD FROM AC500 (Upload Programming AC500 Programs)wqs_19Оценок пока нет

- Zishan Engineers (PVT.) LTD.: Instrument List For HP, MP & LP SeparatorДокумент9 страницZishan Engineers (PVT.) LTD.: Instrument List For HP, MP & LP Separatorwqs_19Оценок пока нет

- NGP-001-PCS-15.09-2001!15!00 PID Hot Oil Expansion Vessel and Circulation PumpДокумент1 страницаNGP-001-PCS-15.09-2001!15!00 PID Hot Oil Expansion Vessel and Circulation Pumpwqs_19Оценок пока нет

- HMC Separator Analog SignalsДокумент1 страницаHMC Separator Analog Signalswqs_19Оценок пока нет

- List of HTML TagsДокумент5 страницList of HTML TagsdorinadidОценок пока нет

- Perturbation MethodsДокумент29 страницPerturbation Methodsmhdr100% (1)

- P66 M10 CAT B Forms and Docs 04 10Документ68 страницP66 M10 CAT B Forms and Docs 04 10VinayОценок пока нет

- Parker HPD Product Bulletin (HY28-2673-01)Документ162 страницыParker HPD Product Bulletin (HY28-2673-01)helden50229881Оценок пока нет

- Exam First Grading 2nd Semester - ReadingДокумент3 страницыExam First Grading 2nd Semester - ReadingArleneRamosОценок пока нет

- The Serious Student of HistoryДокумент5 страницThe Serious Student of HistoryCrisanto King CortezОценок пока нет

- Assessment 4 PDFДокумент10 страницAssessment 4 PDFAboud Hawrechz MacalilayОценок пока нет

- Vintage Airplane - May 1982Документ24 страницыVintage Airplane - May 1982Aviation/Space History LibraryОценок пока нет

- Big Bang Theory EpisodesДокумент24 страницыBig Bang Theory EpisodesBroly dbzОценок пока нет

- Current Surgical Therapy 13th EditionДокумент61 страницаCurrent Surgical Therapy 13th Editiongreg.vasquez490100% (41)

- 2011-11-09 Diana and AtenaДокумент8 страниц2011-11-09 Diana and AtenareluОценок пока нет

- Introduction To FluidizationДокумент9 страницIntroduction To FluidizationEriCisacОценок пока нет

- Advantages Renewable Energy Resources Environmental Sciences EssayДокумент3 страницыAdvantages Renewable Energy Resources Environmental Sciences EssayCemerlang StudiОценок пока нет

- SRS Document Battle Royale Origins - V2Документ36 страницSRS Document Battle Royale Origins - V2Talha SajjadОценок пока нет

- Electromagnetism WorksheetДокумент3 страницыElectromagnetism WorksheetGuan Jie KhooОценок пока нет

- TAC42055 - HO01 Edition I2.0: Section 1 Module 1 Page 1Документ69 страницTAC42055 - HO01 Edition I2.0: Section 1 Module 1 Page 1matheus santosОценок пока нет

- Profibus Adapter Npba-02 Option/Sp Profibus Adapter Npba-02 Option/SpДокумент3 страницыProfibus Adapter Npba-02 Option/Sp Profibus Adapter Npba-02 Option/Spmelad yousefОценок пока нет