Академический Документы

Профессиональный Документы

Культура Документы

Yidro Poutsesqwerfqwefvqwerfgvqrvqerfvgqrf

Загружено:

Travelergr KallogiroyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Yidro Poutsesqwerfqwefvqwerfgvqrvqerfvgqrf

Загружено:

Travelergr KallogiroyАвторское право:

Доступные форматы

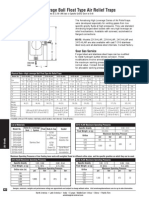

Free Floating Lever Air/Gas VentsCast Iron

For Pressures to 300 psig (21 bar) or Specific Gravity Down to 0.40

A

B

D

L

Model 2-AV, 3-AV and 6-AV

Model 1-AV

Armstrong free floating lever Air/Gas Vents use the same

bodies, caps, lever mechanisms, valves and seats of

Armstrong inverted bucket steam traps that have been

proven in years of service.

1-AVA cast iron air vent that uses a positive-closing

free floating lever to ensure leaktight closing under all

conditions. This vent is good for low capacity air/gas

venting up to 300psi.

Elliptical floats and high leverage make it possible to open

large orifices to provide adequate capacity for vent size and

weight. The hemispherical valve, seat and leverage are

identical in design, materials and workmanship to those for

saturated steam service up to 1,000 psig, with the exception

of the addition of a guidepost to assure a positive, leaktight

valve closing under all conditions.

For a fully detailed certified drawing, refer to CD #1070.

2-AV, 3-AV and 6-AVCast iron vents using the same

proven free floating lever mechanisms used in Armstrong

steam traps. For applications where high air/gas venting

capacity is required up to 250 psi.

For a fully detailed certified drawing, refer to CD #1034.

Physical Data

Model No.

1-AV**

in

1/2*, 3/4*

3-3/4

5-1/2

13/16

-

Air Vents

Pipe Connections

A

B

D

K

L

Weight, lb (kg)

Max. Allowable Pressure (Vessel

Design)

mm

15, 20

89

140

21

-

4 (1.8)

300 psig @ 200F (21 bar @ 93C )

250 psig @ 450F (17 bar @ 232C)

Cast Iron

2-AV

in

mm

1/2, 3/4

15, 20

5-1/4

133

8-3/4

222

5-1/8

130

2-7/16

62

12 (5.5)

3-AV

in

3/4, 1

6-3/8

11-1/2

7

2-7/8

mm

20, 25

162

292

188

73

21 (9.5)

6-AV

in

mm

1-1/2, 2

40, 50

10-3/16

259

18

457

9-3/8

238

4-5/8

78 (35.5)

250 psig @ 450F (17 bar @ 232C)

*Outlet connection 1/4" (7 mm). **1-AV available with side connection if specified on order. On models 2-AV, 3-AV and 6-AV, pipe size of side connections is

same as that of inlet and outlet connections. Some floats are oil filled. Consult factory for details.

List of Materials

Model No.

1-AV

2-AV

3-AV

6-AV

456

Valve & Seat

Leverage System

Stainless Steel

Float

Body & Cap

Gasket

ASTM A48

Class 30 Cast

Iron

Non-asbestos

Bolts

ASTM A193 Gr. B7

SAE Gr. 2

Nuts

ASTM A563 Gr. A

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacific Rim

armstronginternational.com

Free Floating Lever Air/Gas VentsCast Iron

For Pressures to 300 psig (21 bar) or Specific Gravity Down to 0.40

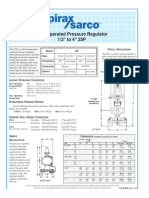

1-AV Maximum Operating Pressures

Minimum Specific Gravity

0.80

Maximum Operating Pressure

psi

bar

146

10

173

12

219

15

300

21

Orifice Size (in)

1/8

7/64

#38

5/64

Maximum Operating Pressures of free floating lever vents with weighted floats for different orifice sizes, and the specific gravities on which they can be used.

2-AV Maximum Operating Pressures

Specific Gravity*

1.00

0.95

Float wt., oz (g)

7.7 (217)

7.3 (206)

Orifice Size (in)

5/16

1/4

3/16

5/32

1/8

7/64

#38

5/64

psi

27

44

97

167

250

250

250

250

bar

1.8

3.0

6.7

12

17

17

17

17

psi

25

42

92

159

250

250

250

250

bar

1.8

2.9

6.4

11

17

17

17

17

3-AV Maximum Operating Pressures

Specific Gravity*

1.00

Float wt., oz (g)

14.9 (423)

Orifice Size (in)

psi

21

45

72

96

144

206

250

250

bar

1.5

3.1

5.0

6.6

9.9

14

17

17

6-AV Maximum Operating Pressures

Specific

1.00

0.95

Gravity*

Float wt.,

69.8

73.5 (2,084)

oz(g)

(1,979)

Orifice Size

(in)

psi bar psi bar

1-1/16

22 1.5 21 1.5

7/8

35 2.4 33 2.3

3/4

50 3.5 48 3.3

5/8

77 5.3 73 5.0

9/16

102 7.0 97 6.7

1/2

148 10.2 140 9.7

7/16

210 14 200 14

3/8

250 17 250 17

11/32

250 17 250 17

5/16

250 17 250 17

9/32

250 17 250 17

1/4

250 17 250 17

0.85

6.5 (184)

psi bar psi

24 1.7 23

40 2.7 38

88 6.0 83

151 10.4 142

250 17 244

250 17 250

250 17 250

250 17 250

bar

1.6

2.6

5.7

9.8

17

17

17

17

0.95

14.2 (402)

0.90

13.4 (381)

psi

20

43

69

91

137

196

250

250

psi

19

41

65

87

130

186

250

250

bar

1.4

3.0

4.7

6.3

9.4

13

17

17

bar

1.3

2.8

4.5

6.0

8.9

13

17

17

0.90

0.85

0.80

66.2

(1,875)

62.5

(1,771)

58.8

(1,667)

psi

20

31

45

69

92

133

189

250

250

250

250

250

bar

1.4

2.2

3.1

4.8

6.3

9.2

13

17

17

17

17

17

psi

19

30

43

66

87

126

179

250

250

250

250

250

bar

1.3

2.0

3.0

4.5

6.0

8.7

12

17

17

17

17

17

psi

18

28

40

62

82

119

168

250

250

250

250

250

bar

1.2

1.9

2.8

4.3

5.6

8.2

12

17

17

17

17

17

0.80

0.75

0.70

6.1 (174)

5.7 (163)

5.4 (152)

Maximum Operating Pressure

psi bar psi bar psi bar

22 1.5 20 1.4 19 1.3

35 2.4 33 2.3 31 2.1

78 5.4 73 5.0 68 4.7

134 9.3 126 8.7 118 8.1

230 16 216 15 202 14

250 17 250 17 250 17

250 17 250 17 250 17

250 17 250 17 250 17

0.65

5.0 (141)

0.60

4.6 (130)

0.55

4.2 (119)

0.50

3.8 (109)

psi

18

29

64

110

187

240

250

250

psi

16

27

59

101

173

222

250

250

psi

15

24

54

93

159

204

250

250

psi bar

14 0.9

22 1.5

49 3.4

85 5.8

145 10.0

186 13

231 16

250 17

0.85

0.80

0.75

12.7 (360)

12.0 (339)

11.2 (318)

Maximum Operating Pressure

psi

bar

psi

bar

psi

bar

18

1.3

17

1.2

16

1.1

38

2.7

36

2.5

34

2.3

61

4.2

58

4.0

54

3.8

82

5.6

77

5.3

72

5.0

123

8.5

116

8.0

109

7.5

176

12

165

11

155 10.7

250

17

249

17

234

16

250

17

250

17

250

17

0.75

0.70

0.65

55.1

47.8

51.5 (1,459)

(1,563)

(1,354)

Maximum Operating Pressure

psi bar psi bar psi bar

17 1.2 16 1.1 14 1.0

26 1.8 24 1.7 23 1.6

38 2.6 35 2.4 33 2.3

58 4.0 54 3.7 50 3.5

77 5.3 72 4.9 67 4.6

111 7.7 104 7.2 97 6.7

158 11 148 10.2 137 9.5

249 17 233 16 216 15

250 17 250 17 250 17

250 17 250 17 250 17

250 17 250 17 250 17

250 17 250 17 250 17

bar

1.2

2.0

4.4

7.6

13

17

17

17

bar

1.1

1.8

4.1

7.0

12

15

17

17

0.70

10.5 (296)

psi

15

32

51

68

102

145

218

250

0.65

9.7 (275)

bar

1.0

2.2

3.5

4.7

7.0

10.0

15

17

psi

14

30

47

63

94

135

203

250

0.60

0.55

0.50

44.1

(1,250)

40.4

(1,146)

36.8

(1,042)

psi

13

21

30

46

62

89

127

200

250

250

250

250

bar

0.9

1.5

2.1

3.2

4.2

6.2

8.7

14

17

17

17

17

psi

12

19

28

43

57

82

116

184

245

250

250

250

bar

0.8

1.3

1.9

2.9

3.9

5.6

8.0

13

17

17

17

17

bar

1.0

1.7

3.7

6.4

11

14

17

17

psi

11

18

25

39

51

75

106

167

223

250

250

250

bar

0.8

1.2

1.8

2.7

3.6

5.1

7.3

12

15

17

17

17

bar

1.0

2.0

3.3

4.3

6.5

9.3

14

17

0.45

0.60

9.0 (254)

psi

13

27

44

58

87

125

188

250

bar

0.9

1.9

3.0

4.0

6.0

8.6

13

17

Air Vents

1/2

3/8

5/16

9/32

1/4

7/32

3/16

5/32

0.90

6.9 (195)

0.40

33.1 (938) 29.4 (833)

psi bar psi bar

10 0.70 9 0.62

16 1.1 14

1

23 1.6 20 1.4

35 2.4 31 2.2

46 3.2 41 3.9

67 4.6 60 4.1

96 6.6 85 5.9

151 10.4 134 9.3

201 14 179 12

250 17 230 16

250 17 250 17

250 17 250 17

*If specific gravity falls between those shown, use next lowest: e.g., if actual gravity is 0.73, use 0.70 specific gravity data.

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com for up-to-date information.

Next

North America Latin America India Europe / Middle East / Africa China Pacific Rim

armstronginternational.com

457

Вам также может понравиться

- Flowserve Lined Flush BottomДокумент32 страницыFlowserve Lined Flush BottomDevdatt WaghuleОценок пока нет

- Full Lift Spring Loaded Open PDFДокумент4 страницыFull Lift Spring Loaded Open PDFVenkatespatange RaoОценок пока нет

- Antlies Hudro Pumps ServiceqwerfvqervqerДокумент2 страницыAntlies Hudro Pumps ServiceqwerfvqervqerTravelergr KallogiroyОценок пока нет

- Ver.8.1.9. Control Valve - Gas or Steam Flow - Calculate Valve SizeДокумент3 страницыVer.8.1.9. Control Valve - Gas or Steam Flow - Calculate Valve Sizerudi 01Оценок пока нет

- BelGAS P627 2014 RegulatorДокумент10 страницBelGAS P627 2014 RegulatorkaviarasuОценок пока нет

- Regulador American Meter PDFДокумент6 страницRegulador American Meter PDFjmcg1974Оценок пока нет

- Vctds 02324 Figure 4020a enДокумент5 страницVctds 02324 Figure 4020a enFreddy Gómez GuillénОценок пока нет

- Fainger Leser Catalogue' 11Документ68 страницFainger Leser Catalogue' 11rudrakrОценок пока нет

- 'C' Series Control ValvesДокумент12 страниц'C' Series Control Valvesابزار دقیق100% (1)

- Econ Gate ValvesДокумент22 страницыEcon Gate ValvesRiyas Udheen100% (1)

- App B Piping Specifications PDFДокумент4 страницыApp B Piping Specifications PDFirawan_epОценок пока нет

- Trampas de Vapor Armstrong, Series880 PDFДокумент2 страницыTrampas de Vapor Armstrong, Series880 PDFLuis Guillermo Gallardo BoscanОценок пока нет

- Tour & Andersson Circuit Balancing Valves and Koil-Kit ComponentsДокумент1 страницаTour & Andersson Circuit Balancing Valves and Koil-Kit ComponentslesnikimagesОценок пока нет

- ValvesДокумент24 страницыValvesaaa100% (1)

- Spirax Sarco 25 PДокумент2 страницыSpirax Sarco 25 Pmairimsp2003Оценок пока нет

- Armstrong Lever Drain Trap SpecificationsДокумент6 страницArmstrong Lever Drain Trap Specificationscivil270986Оценок пока нет

- SG-FTV BrochureДокумент8 страницSG-FTV BrochurevvgОценок пока нет

- LP-GAS SHUTOFF VALVES - UL Product IqДокумент3 страницыLP-GAS SHUTOFF VALVES - UL Product IqsarmientollocllajОценок пока нет

- AI - Automatic Air Vent (Cast Iron)Документ2 страницыAI - Automatic Air Vent (Cast Iron)Rakhmad sugih hartonoОценок пока нет

- 01CS1S02Документ5 страниц01CS1S02raobabar21Оценок пока нет

- AДокумент64 страницыAjuanca_eduОценок пока нет

- TVS 80-DC Series Automatic Differential Condensate ControllersДокумент2 страницыTVS 80-DC Series Automatic Differential Condensate ControllersJozsef MagyariОценок пока нет

- Velan Forged Steel Gate, Globe & ChecksДокумент25 страницVelan Forged Steel Gate, Globe & Checksmhorst1Оценок пока нет

- Kunkle OverviewДокумент8 страницKunkle Overviewsamix999Оценок пока нет

- Triple Duty 1Документ6 страницTriple Duty 1Diana Andreina Linarez ContrerasОценок пока нет

- Válvulas Bola SegmentadaДокумент12 страницVálvulas Bola SegmentadarehynaldoОценок пока нет

- 6400-6600 Series Catalog (394C) PDFДокумент8 страниц6400-6600 Series Catalog (394C) PDF20106285Оценок пока нет

- Gaugeable SAF 2507™ Super Duplex Tube Fittings, (MS-01-174, R5)Документ12 страницGaugeable SAF 2507™ Super Duplex Tube Fittings, (MS-01-174, R5)김윤식Оценок пока нет

- Vctds-02233 Model 171c (Asme) - enДокумент12 страницVctds-02233 Model 171c (Asme) - enDGWОценок пока нет

- Kunkle Safety RV Model 91Документ6 страницKunkle Safety RV Model 91gbogboiweОценок пока нет

- EZR Installation ManualДокумент40 страницEZR Installation ManualRoberto Aldayuz HerediaОценок пока нет

- Manual de TrampasДокумент2 страницыManual de TrampasHector MagallonОценок пока нет

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsДокумент31 страницаBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Seal Ball ValvesДокумент45 страницSeal Ball Valvesmetasoniko2014Оценок пока нет

- One Company Unlimited SolutionsДокумент20 страницOne Company Unlimited SolutionsjobinjsОценок пока нет

- Series 805YD Specification SheetДокумент2 страницыSeries 805YD Specification SheetFEBCOОценок пока нет

- Belgas R627 IOMДокумент6 страницBelgas R627 IOMSMcОценок пока нет

- ASV 10 20 BrochureДокумент8 страницASV 10 20 BrochureThomas Duane DavidsonОценок пока нет

- Control Choke Valve 9000Документ8 страницControl Choke Valve 9000sabi_shi100% (2)

- VALVULAS - Series2200, NORRISEALДокумент8 страницVALVULAS - Series2200, NORRISEALAndrea Hernández CarreñoОценок пока нет

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFДокумент8 страницTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4Оценок пока нет

- ACS11Документ3 страницыACS11Ebby OnyekweОценок пока нет

- Gate Valve CataogueДокумент4 страницыGate Valve CataogueAditya B. RyantoОценок пока нет

- Tescom RegulatorДокумент4 страницыTescom RegulatormiaberyОценок пока нет

- Fuel Oil PumpДокумент8 страницFuel Oil PumprezashahalamОценок пока нет

- EZR ManualДокумент40 страницEZR Manualdancuk99Оценок пока нет

- Especificaciones Tecnicas DezurikДокумент24 страницыEspecificaciones Tecnicas DezurikdieferjimenezОценок пока нет

- Series 800 Specification SheetДокумент2 страницыSeries 800 Specification SheetFEBCOОценок пока нет

- 8356 - nsfr4 Asco Mini ValveДокумент4 страницы8356 - nsfr4 Asco Mini ValveNandor KermeciОценок пока нет

- Ra 92711Документ39 страницRa 92711Agus Yulfizar100% (3)

- Catalogo de Shut Off (PF)Документ8 страницCatalogo de Shut Off (PF)luis_d_mОценок пока нет

- RMG by Honeywell BD 277 Hi-Flo GB 2010-10Документ8 страницRMG by Honeywell BD 277 Hi-Flo GB 2010-10Jorge Henostroza IntiОценок пока нет

- RVC 05 FLG PDFДокумент5 страницRVC 05 FLG PDFengp3077Оценок пока нет

- RedvalvE 90 01Документ4 страницыRedvalvE 90 01Rizal FalevyОценок пока нет

- Singer ValveДокумент5 страницSinger ValveDGWОценок пока нет

- Triple Duty Valve BrochureДокумент8 страницTriple Duty Valve Brochuresas999333Оценок пока нет

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Starkville Dispatch Eedition 12-9-18Документ28 страницStarkville Dispatch Eedition 12-9-18The DispatchОценок пока нет

- Awais Inspector-PaintingДокумент6 страницAwais Inspector-PaintingMohammed GaniОценок пока нет

- Manuscript - Batallantes &Lalong-Isip (2021) Research (Chapter 1 To Chapter 3)Документ46 страницManuscript - Batallantes &Lalong-Isip (2021) Research (Chapter 1 To Chapter 3)Franzis Jayke BatallantesОценок пока нет

- Czech Republic GAAPДокумент25 страницCzech Republic GAAPFin Cassie Lazy100% (1)

- 133 The Science and Understanding of TheДокумент14 страниц133 The Science and Understanding of TheCarlos RieraОценок пока нет

- SMK Techno ProjectДокумент36 страницSMK Techno Projectpraburaj619Оценок пока нет

- ML7999A Universal Parallel-Positioning Actuator: FeaturesДокумент8 страницML7999A Universal Parallel-Positioning Actuator: Featuresfrank torresОценок пока нет

- Acevac Catalogue VCD - R3Документ6 страницAcevac Catalogue VCD - R3Santhosh KumarОценок пока нет

- Staircase and Lintel As-03Документ1 страницаStaircase and Lintel As-03Divith B SannakkiОценок пока нет

- Exercise 23 - Sulfur OintmentДокумент4 страницыExercise 23 - Sulfur OintmentmaimaiОценок пока нет

- PanasonicДокумент35 страницPanasonicAsif Shaikh0% (1)

- Delta PresentationДокумент36 страницDelta Presentationarch_ianОценок пока нет

- Intro S4HANA Using Global Bike Solutions EAM Fiori en v3.3Документ5 страницIntro S4HANA Using Global Bike Solutions EAM Fiori en v3.3Thăng Nguyễn BáОценок пока нет

- Prevalence of Peptic Ulcer in Patients Attending Kampala International University Teaching Hospital in Ishaka Bushenyi Municipality, UgandaДокумент10 страницPrevalence of Peptic Ulcer in Patients Attending Kampala International University Teaching Hospital in Ishaka Bushenyi Municipality, UgandaKIU PUBLICATION AND EXTENSIONОценок пока нет

- Flow Chart For SiFUS Strata Title ApplicationДокумент5 страницFlow Chart For SiFUS Strata Title ApplicationPhang Han XiangОценок пока нет

- Quantity DiscountДокумент22 страницыQuantity Discountkevin royОценок пока нет

- Kompetensi Sumber Daya Manusia SDM Dalam Meningkatkan Kinerja Tenaga Kependidika PDFДокумент13 страницKompetensi Sumber Daya Manusia SDM Dalam Meningkatkan Kinerja Tenaga Kependidika PDFEka IdrisОценок пока нет

- CRC Implementation Code in CДокумент14 страницCRC Implementation Code in CAtul VermaОценок пока нет

- 1.mukherjee - 2019 - SMM - Customers Passion For BrandsДокумент14 страниц1.mukherjee - 2019 - SMM - Customers Passion For BrandsnadimОценок пока нет

- Sealant Solutions: Nitoseal Thioflex FlamexДокумент16 страницSealant Solutions: Nitoseal Thioflex FlamexBhagwat PatilОценок пока нет

- VISCOROL Series - Magnetic Level Indicators: DescriptionДокумент4 страницыVISCOROL Series - Magnetic Level Indicators: DescriptionRaduОценок пока нет

- QCM Part 145 en Rev17 310818 PDFДокумент164 страницыQCM Part 145 en Rev17 310818 PDFsotiris100% (1)

- Payment of GratuityДокумент5 страницPayment of Gratuitypawan2225Оценок пока нет

- Customer Satisfaction-ICICI Bank-Priyanka DhamijaДокумент85 страницCustomer Satisfaction-ICICI Bank-Priyanka DhamijaVarun GuptaОценок пока нет

- MCoal Coal July Investor SlidesДокумент26 страницMCoal Coal July Investor SlidesMCoaldataОценок пока нет

- Sangeetahealingtemples Com Tarot Card Reading Course in UsaДокумент3 страницыSangeetahealingtemples Com Tarot Card Reading Course in UsaSangeetahealing templesОценок пока нет

- A Survey On Multicarrier Communications Prototype PDFДокумент28 страницA Survey On Multicarrier Communications Prototype PDFDrAbdallah NasserОценок пока нет

- Projects: Term ProjectДокумент2 страницыProjects: Term ProjectCoursePinОценок пока нет

- Journal of Economic LiteratureДокумент28 страницJournal of Economic LiteratureEkoKurniadiОценок пока нет

- Huawei Core Roadmap TRM10 Dec 14 2011 FinalДокумент70 страницHuawei Core Roadmap TRM10 Dec 14 2011 Finalfirasibraheem100% (1)