Академический Документы

Профессиональный Документы

Культура Документы

3054 Ajuste de Valvulas

Загружено:

Chrissz NoxdАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3054 Ajuste de Valvulas

Загружено:

Chrissz NoxdАвторское право:

Доступные форматы

12/6/2015

416BBackhoeLoader8ZK0000105999(MACHINE)POWEREDBY3054Engine(SEBP220245)Documentacin

Pantallaanterior

Bienvenido:r095rz1

Producto:BACKHOELOADER

Modelo:416BBACKHOELOADER8ZK

Configuracin:416BBackhoeLoader8ZK0000105999(MACHINE)

POWEREDBY3054Engine

PruebasyAjustes

3054EngineforCaterpillarBuiltMachines

NmerodemedioSENR581612

Fechadepublicacin01/08/2004

Fechadeactualizacin10/08/2004

i01670136

EngineValveLashInspect/Adjust

SMCS1102025

Accidentalenginestartingcancauseinjuryordeathtopersonnel.

Topreventaccidentalenginestarting,turntheignitionswitchtothe

OFFposition,placeadonotoperatetagattheignitionswitchlocation

anddisconnectandtapetheelectricalconnectiontothestopsolenoid

thatislocatedonthefuelinjectionpump.

NOTICE

Keepallpartscleanfromcontaminants.

Contaminantsmaycauserapidwearandshortenedcomponentlife.

NOTICE

Caremustbetakentoensurethatfluidsarecontainedduring

performanceofinspection,maintenance,testing,adjustingandrepair

oftheproduct.Bepreparedtocollectthefluidwithsuitablecontainers

beforeopeninganycompartmentordisassemblinganycomponent

containingfluids.

RefertoSpecialPublication,NENG2500,"CaterpillarToolsandShop

ProductsGuide"fortoolsandsuppliessuitabletocollectandcontain

fluidsonCaterpillarproducts.

Disposeofallfluidsaccordingtolocalregulationsandmandates.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sis

1/4

12/6/2015

416BBackhoeLoader8ZK0000105999(MACHINE)POWEREDBY3054Engine(SEBP220245)Documentacin

ValveLashSetting

Thetemperatureoftheenginedoesnotchangethevalvelashsetting.

ValveLashSetting

Inletvalve...0.20mm(0.008inch)

Exhaustvalve...0.45mm(0.018inch)

ValveLashAdjustment

Ifthevalvelashrequiresadjustmentseveraltimesinashortperiodoftime,excessivewearexistsina

differentpartoftheengine.Repairtheprobleminordertopreventmoredamagetotheengine.

Notenoughvalvelashcanbethecauseofrapidwearofthecamshaftandvalvelifters.Notenough

valvelashcanindicatethattheseatsforthecylinderheadvalvesareworn.

Cylinderheadvalvesbecomedamagedduetothefollowingcauses:

Fuelinjectionnozzlesthatoperateincorrectly

Excessivedirtandoilarepresentonthefiltersfortheinletair.

Incorrectfuelsettingsonthefuelinjectionpump.

Theloadcapacityoftheengineisfrequentlyexceeded.

Toomuchvalvelashcancausebrokenvalvestems,springs,andspringretainers.Toomuchvalve

lashcanbeanindicationofthefollowingproblems:

Worncamshaftandvalvelifters

Wornrockerarms

Bentpushrods

Brokensocketontheupperendofapushrod

Looseadjustmentscrewforthevalvelash

Ifthecamshaftandvalveliftersshowrapidwear,lookforfuelinthelubricationoilordirty

lubricationoilasapossiblecause.

Thevalvelashismeasuredbetweenthetopofthevalvestemandtherockerarmlever.

Note:Number1cylinderisatthefrontoftheengine.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sis

2/4

12/6/2015

416BBackhoeLoader8ZK0000105999(MACHINE)POWEREDBY3054Engine(SEBP220245)Documentacin

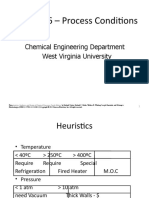

Illustration1

g00323903

Settingthevalvelash

(1)Adjustmentscrew

(2)Feelergauge

Accidentalenginestartingcancauseinjuryordeathtopersonnel.

Topreventaccidentalenginestarting,turntheignitionswitchtothe

OFFposition,placeadonotoperatetagattheignitionswitchlocation

anddisconnectandtapetheelectricalconnectiontothestopsolenoid

thatislocatedonthefuelinjectionpump.

Removethevalvemechanismcoverandperformthefollowingprocedureinordertoadjustthevalve

lash:

1. SetthetopcenterpositionforNo.1pistononthecompressionstroke.Beforeadjustmentsare

made,lightlytapeachrockerarmatthetopoftheadjustmentscrew.Useasoftmallettoensure

thatthelifterseatsagainstthecamshaft'sbasecircle.

Note:Later3054enginesrequiretheuseofaTORXT27drivertoadjustvalvelash.

2. Rotatethecrankshaftinthenormalrotationoftheengine.WhentheinletvalveoftheNo.4

cylinderhasopenedandtheexhaustvalveoftheNo.4cylinderhasnotcompletelyclosed

measurethevalvelashoftheinletvalveandtheexhaustvalveofNo.1cylinder.Ifnecessary,

makeanadjustmenttotheinletvalveandtheexhaustvalveonNo.1cylinder.

a. Loosenthevalveadjustmentscrewlocknutthatisonadjustmentscrew(1).

b. Placeappropriatefeelergauge(2)betweentherockerarmandthevalve.Turnadjustment

screw(1)whilethevalveadjustmentscrewlocknutisbeingheldfromturning.Adjustthe

valvelashuntilthecorrectspecificationisachieved.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sis

3/4

12/6/2015

416BBackhoeLoader8ZK0000105999(MACHINE)POWEREDBY3054Engine(SEBP220245)Documentacin

c. Aftereachadjustment,tightenthevalveadjustmentscrewlocknutwhilevalveadjustment

screw(1)isbeingheldfromturning.

3. Rotatethecrankshaftinthenormalrotationoftheengine.WhentheinletvalveoftheNo.2

cylinderhasopenedandtheexhaustvalveoftheNo.2cylinderhasnotcompletelyclosed

measurethevalvelashoftheinletvalveandtheexhaustvalveofNo.3cylinder.Ifnecessary,

makeanadjustmenttotheinletvalveandtheexhaustvalveonNo.3cylinder.

a. Loosenthevalveadjustmentscrewlocknutthatisonadjustmentscrew(1).

b. Placeappropriatefeelergauge(2)betweentherockerarmandthevalve.Turnadjustment

screw(1)whilethevalveadjustmentscrewlocknutisbeingheldfromturning.Adjustthe

valvelashuntilthecorrectspecificationisachieved.

c. Aftereachadjustment,tightenthevalveadjustmentscrewlocknutwhilevalveadjustment

screw(1)isbeingheldfromturning.

4. Rotatethecrankshaftinthenormalrotationoftheengine.WhentheinletvalveoftheNo.1

cylinderhasopenedandtheexhaustvalveoftheNo.1cylinderhasnotcompletelyclosed

measurethevalvelashoftheinletvalveandtheexhaustvalveofNo.4cylinder.Ifnecessary,

makeanadjustmenttotheinletvalveandtheexhaustvalveonNo.4cylinder.

a. Loosenthevalveadjustmentscrewlocknutthatisonadjustmentscrew(1).

b. Placeappropriatefeelergauge(2)betweentherockerarmandthevalve.Turnadjustment

screw(1)whilethevalveadjustmentscrewlocknutisbeingheldfromturning.Adjustthe

valvelashuntilthecorrectspecificationisachieved.

c. Aftereachadjustment,tightenthevalveadjustmentscrewlocknutwhilevalveadjustment

screw(1)isbeingheldfromturning.

5. Rotatethecrankshaftinthenormalrotationoftheengine.WhentheinletvalveoftheNo.3

cylinderhasopenedandtheexhaustvalveoftheNo.3cylinderhasnotcompletelyclosed

measurethevalvelashoftheinletvalveandtheexhaustvalveofNo.2cylinder.Ifnecessary,

makeanadjustmenttotheinletvalveandtheexhaustvalveonNo.2cylinder.

a. Loosenthevalveadjustmentscrewlocknutthatisonadjustmentscrew(1).

b. Placeappropriatefeelergauge(2)betweentherockerarmandthevalve.Turnadjustment

screw(1)whilethevalveadjustmentscrewlocknutisbeingheldfromturning.Adjustthe

valvelashuntilthecorrectspecificationisachieved.

c. Aftereachadjustment,tightenthevalveadjustmentscrewlocknutwhilevalveadjustment

screw(1)isbeingheldfromturning.

Copyright19932015CaterpillarInc.

Todoslosderechosreservados.

RedprivadaparalicenciadosdelSIS.

FriJun12201520:24:19GMT0500(EasternStandardTime)

r095rz1

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sis

4/4

Вам также может понравиться

- PowerSurfacingHelp PDFДокумент77 страницPowerSurfacingHelp PDFKeviin CruzОценок пока нет

- LubricationДокумент25 страницLubricationf_mo_meОценок пока нет

- Front Axle and Suspension PDFДокумент62 страницыFront Axle and Suspension PDFChrissz NoxdОценок пока нет

- Clutch PDFДокумент13 страницClutch PDFNam TranОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Detroit Diesel-MTU S4000Документ134 страницыDetroit Diesel-MTU S4000Dino Martin Mercado Quispe93% (30)

- 89 Integra FSM With WDMs 07Документ792 страницы89 Integra FSM With WDMs 07Chrissz NoxdОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- LCD Menu Tree For Marlin FirmwareДокумент1 страницаLCD Menu Tree For Marlin FirmwarecharuatreОценок пока нет

- Improvised Torque WrenchДокумент5 страницImprovised Torque WrenchChrissz NoxdОценок пока нет

- 980b Wheel Loader HydraДокумент13 страниц980b Wheel Loader HydraChrissz Noxd0% (1)

- 950H Hnydra 2 PDFДокумент13 страниц950H Hnydra 2 PDFChrissz Noxd100% (1)

- Using DDDL and DDEC ReportsДокумент37 страницUsing DDDL and DDEC ReportsChrissz Noxd100% (1)

- Accuulator Charging PDFДокумент28 страницAccuulator Charging PDFChrissz NoxdОценок пока нет

- 950F Frenos OperacionДокумент19 страниц950F Frenos OperacionChrissz Noxd50% (2)

- Eaton OrbitrolДокумент100 страницEaton OrbitrolChrissz Noxd100% (3)

- 980b Wheel Loader HydraДокумент13 страниц980b Wheel Loader HydraChrissz Noxd0% (1)

- FAI 80 P Transmission 80DTДокумент16 страницFAI 80 P Transmission 80DTChrissz NoxdОценок пока нет

- Operation & Maintenance Manual: Wheel LoaderДокумент392 страницыOperation & Maintenance Manual: Wheel LoaderChrissz Noxd100% (5)

- 938g II ElectricoДокумент14 страниц938g II ElectricoChrissz Noxd100% (3)

- D37PX-21 M Eeam024300 D31 37 39 Ex PX 21 0509Документ258 страницD37PX-21 M Eeam024300 D31 37 39 Ex PX 21 0509Chrissz Noxd100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Asme B31.8-2007Документ6 страницAsme B31.8-2007SUHANI CHANDELОценок пока нет

- Sihi Aeh enДокумент12 страницSihi Aeh enIrvan NouriОценок пока нет

- Chapter 06 - Understanding Process ConditionsДокумент20 страницChapter 06 - Understanding Process ConditionsMohammed DaghurОценок пока нет

- Martillo Hyd Atlas Copco SB 150Документ12 страницMartillo Hyd Atlas Copco SB 150Nain murilloОценок пока нет

- Sugar Industrial ValvesДокумент9 страницSugar Industrial ValvesRajeev KumarОценок пока нет

- PTSC MC-Piping Design Training-Basic Piping-LATESTДокумент31 страницаPTSC MC-Piping Design Training-Basic Piping-LATESTNguyen Anh Tung50% (2)

- PHYSICS (CE & ME) (PH-21102) Introduction To Mechanics: Module 1: (8 Lectures)Документ1 страницаPHYSICS (CE & ME) (PH-21102) Introduction To Mechanics: Module 1: (8 Lectures)Supratim RoyОценок пока нет

- EE402 Special Electrical MachinesДокумент2 страницыEE402 Special Electrical MachinesAsok Rawat0% (1)

- MY Pajero Sport VGT Service Plan & PriceДокумент1 страницаMY Pajero Sport VGT Service Plan & PriceNugroho FamОценок пока нет

- Safari - 21Документ1 страницаSafari - 21bernardОценок пока нет

- Almas-Tower Structural DesignДокумент12 страницAlmas-Tower Structural DesignBalaji PalaniОценок пока нет

- Altronic Agv5 Operating Manual Gas Fuel Valve Form Agv5 Om 8-03Документ12 страницAltronic Agv5 Operating Manual Gas Fuel Valve Form Agv5 Om 8-03SMcОценок пока нет

- ZoellerДокумент4 страницыZoellerWharfedaleОценок пока нет

- The New 911 GT3 RS and 911 GT3: Extreme TruthДокумент52 страницыThe New 911 GT3 RS and 911 GT3: Extreme TruthGonzalo Bautista Gatica100% (2)

- N R P F W G: Direction of Impending MotionДокумент28 страницN R P F W G: Direction of Impending MotionAbdullah Ahsan AhmedОценок пока нет

- Refrigerant Piping 20Документ1 страницаRefrigerant Piping 20organicspolybondОценок пока нет

- Daihatsu Terios II J200, J210, J211 2006-2014 Air ConditionerДокумент68 страницDaihatsu Terios II J200, J210, J211 2006-2014 Air ConditionerBadis Ait HammouОценок пока нет

- Method Statement Asc Power PlantДокумент13 страницMethod Statement Asc Power PlantBennyОценок пока нет

- Power Plant and Calculations - Boiler Calculations For Boiler Operation Engineer Exam (BOE)Документ12 страницPower Plant and Calculations - Boiler Calculations For Boiler Operation Engineer Exam (BOE)RajeshОценок пока нет

- IIT GUWAHATI Lec1Документ25 страницIIT GUWAHATI Lec1DCОценок пока нет

- Modelling and SimulationДокумент16 страницModelling and SimulationWajdi SadikОценок пока нет

- Tensile Test Lab Report MAE 361Документ3 страницыTensile Test Lab Report MAE 361mrm3zaОценок пока нет

- DFG/TFG 316-550: Operating InstructionsДокумент144 страницыDFG/TFG 316-550: Operating InstructionsbenjaminОценок пока нет

- Nissan RB Engine - WikipediaДокумент60 страницNissan RB Engine - WikipediaZedrick Nell100% (2)

- FRR 500 - 500S Igm0087 - 6-CylДокумент4 страницыFRR 500 - 500S Igm0087 - 6-CylMarvin White0% (1)

- CH2 - Heating System PDFДокумент10 страницCH2 - Heating System PDFAaron AngОценок пока нет

- WINMAN Solenoid Valf (5/2 Yollu, 5/3 Yollu) / Solenoid Valve (5/2 Way, 5/3 Way)Документ2 страницыWINMAN Solenoid Valf (5/2 Yollu, 5/3 Yollu) / Solenoid Valve (5/2 Way, 5/3 Way)Durulsan MakinaОценок пока нет

- Instruction Book: TAMD162C, TAMD163A, TAMD163PДокумент84 страницыInstruction Book: TAMD162C, TAMD163A, TAMD163PAlan PereiraОценок пока нет

- Staad Input FileДокумент18 страницStaad Input FileKP SahuОценок пока нет

- Stallion MK II & IIIДокумент31 страницаStallion MK II & IIIgokulmane117Оценок пока нет