Академический Документы

Профессиональный Документы

Культура Документы

3-Pinping Material Specification

Загружено:

Anouar BouhajaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3-Pinping Material Specification

Загружено:

Anouar BouhajaАвторское право:

Доступные форматы

Page 1 of 76

OCP

Piping Material Specification

Project No: Q6521

Sub Project No: 00

Phase: III

Project Name: Laayoune Washing Plant

Sub-Project Name:

Jacobs Document No: JEC-Q6521-00-III/L.02r/00001

Client Document No:

Revision: C

Prepared

by

Checked

by

Discipline

Project

Approved by Approved by

Rev.

Issue Date

Revision Description

12 Mar 2014

For Comments

GLAA

KAA

CA

2 Apr 2014

For Approval

GLAA

KAA

CA

For Validation

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 2 of 68

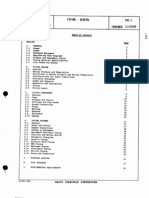

TABLE of CONTENTS

1

SCOPE................................................................................................................ 3

LINE NUMBERING SYSTEM .............................................................................. 3

2.1

Pipeline designation shall include the following information: ................................ 3

2.2

Service Index....................................................................................................... 4

2.3

Piping Class Code Numbering System ................................................................ 5

CLASS CODE INDEX ......................................................................................... 6

3.1

CLASS CODE: BA1............................................................................................ 7

3.2

CLASS CODE: BB1.......................................................................................... 10

3.3

CLASS CODE: BB3.......................................................................................... 14

3.4

CLASS CODE: BD2 ......................................................................................... 18

3.5

CLASS CODE: BK1.......................................................................................... 22

3.6

CLASS CODE: BL5 .......................................................................................... 28

3.7

CLASS CODE: CD1 ......................................................................................... 35

3.8

CLASS CODE: CG1 ......................................................................................... 38

3.9

CLASS CODE: GD1 ......................................................................................... 41

VALVE INDEX ................................................................................................... 44

4.1

PLUG VALVES.................................................................................................. 45

4.2

BUTTERFLY VALVES....................................................................................... 46

4.3

GATE VALVES.................................................................................................. 48

4.4

CHECK VALVES .............................................................................................. 56

4.5

BALL VALVES................................................................................................... 66

4.6

NEEDLE VALVES ............................................................................................. 68

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 3 of 68

SCOPE

This specification provides the numbering system for pipelines, the index for

various service requirements and the index for valve identification.

LINE NUMBERING SYSTEM

2.1

PIPELINE DESIGNATION SHALL INCLUDE THE FOLLOWING INFORMATION:

XXXX

A

XXXX

B

XXXX

C

XXX

D

XXX

E

XX

F

XX

G

A = Line size in Millimeters

B = Service Identification - See Paragraph 2.2

C = Plant Area Number

D = Sequential Number

E = Piping Class Code - See Paragraph 3.0

F = Insulation Code (If applicable)

G = Tracing Code (If applicable)

Example without Insulation or Tracing:

100 WW-107B-101-BB1

Example with Insulation and Tracing:

100 APS-107B-121-CG1-HC-ST

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

2.2

, rev. C

Page 4 of 68

SERVICE INDEX

SERVICE SERVICE DESCRIPTION

PRIMARY CLASS

SECONDARY CLASS

(*)

AF

Flocculating Agent

BB3

NONE

AI

Instrument Air

BA1

BD2

AS

Plant Air

BB1

BD2

CFA

Chemical Feed, Amine

BD2

NONE

CFP

Chemical Feed, Phosphate

BD2

CD1

PA

Strong Phosphoric Acid

BD2

BK1/CG1

PB

Weak Phosphoric Acid

BD2

BK1

PRA

Process Air

BB3

NONE

RS

Rock Slurry

BL5

NONE

SW

Seal Water

BB1

BD2

WD

Potable Water

BA1

NONE

WE

Waste Water

BK1

-------WF

Fire Water**

BB1

----WP

Acidic Process Water

BK1

BD2

WT

Treated Water

BD2

NONE

* Secondary classes are limited to use at process branch connection unless noted otherwise in this

column or within the pipe class.

** (By civil in case of a Sub Contract)

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

2.3

, rev. C

Page 5 of 68

PIPING CLASS CODE NUMBERING SYSTEM

Code for specification classes consist of three letters. The first letter represents

the flange rating, the second letter represents the pipe material, the third letter

distinguishes between similar specifications.

First

Digit

A

B

C

D

E

F

G

H

Flange

Rating

CL 125

CL 150

CL 300

CL 400

CL 600

CL 900

CL 1500

CL 2500

Special

Second Digit

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Q

R

Pipe

Material

Carbon Steel (Galv.)

Carbon Steel

304L SS

316L SS

317L SS

Alloy 20

904L/Jessop 700

HDPE

Alloy Steel

FRP

CS/RL

Ductile Iron

CS/Teflon

CS/Jacketed

310L SS

CPVC

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Third

Digit

Distinguishing Numeral

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 6 of 68

CLASS CODE INDEX

Class

Flange

Rating

Class Limits

Pipe Material

BA1

16.8 Kg/ cm g @ 93C (240 psig @ 200F);

For Fire Water - Spray system : 10.55 Kg/cm2g @ 650C ( 150 psi @ 1490F )

150#

CS Galv.

150#

CS

150#

CS

150#

316L

150#

FRP

150#

PTFE Lined

CS / RLCS

10.5 Kg/ cm2g @ 82C (150 psig @ 180F);

BB1

7.0 Kg/ cm2g @ 71C (100 psig @ 160F) See Spec. Notes;

For Fire Water - General system : 10.55 Kg/cm2g @ 650C ( 150 psi @ 1490F )

BB3

13.73 Kg/ cm2g @210C (200 psig @ 400F)

2

11.36 Kg/ cm g @ 204C(as per 316L),13.83 Kg/ cm g @ 204C (as per 316), (180 psig @ 400F)

BD2

BK1

11.13 Kg/ cm2g @ 220C(as per 316L), 13.06 Kg/ cm2g @ 220C(as per 316), (170 psig @ 428F)

See Spec. Notes

Size 25mm 600mm (10.5kg/cm2g @ 104C 150 psig @ 220F) & Full Vacuum

Size 750mm 900mm (7.0kg/cm2g @ 93C 100 psig @ 200F) & Full Vacuum

Size 1000mm 1500 mm (10.0Kg/Cm2g@ 50C-150psig @ 122F) & Full Vacuum

Size 2000mm 2000 mm (2.04kg/Cm2g@ 90C-150psig @ 194F) & Full Vacuum

BL5

7.7 kg/cm2g and Full Vacuum @ 88C (110 psig @ 190F) - RLCS

15.1 kg/cm2g and Full Vacuum @ 150C (215 psig @ 302F) PTFE Lined Carbon Steel

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

3.1

, rev. C

Page 7 of 68

CLASS CODE: BA1

SERVICE:

BASIC MATERIAL:

VALVE MATERIAL:

ASME RATING:

CLASS LIMITS:

CORROSION ALLOW:

VALVES

Potable Water (WD) Fire Water ( FW ), instrument air (AI)

Carbon Steel, Carbon Steel Galvanized

Carbon Steel

150 Lb.

16.8 Kg/cm2g @ 93C (240 psi @ 200F)

For Fire Water - Spray system : 10.55 Kg/cm2g @ 650C ( 150 psi @ 1490F )

1.5 mm

TYPE

15 mm - 50 mm

Globe

15 mm - 50 mm

Check

80mm - 200mm

Check

15 mm - 50 mm

Ball

80mm - 200mm

Ball

50 mm

Gate

USE

Throttling

Normal

Normal

Normal

Normal

Normal

END CONN

Threaded

Threaded

150 Lb. RF

Threaded

150 Lb. RF

150 Lb. RF

V-401

JEG TAG NO.

V-508

V-616

V-617

V-703

V-702

PIPE

SCHEDULE

END CONN.

15 mm - 50 mm

80

Threaded, NPT & Coupled

80 mm

Std. Wt.

Threaded, NPT & Coupled

100 mm - 200

mm

FITTINGS

Std. Wt.

Grooved (Note 2 & 3)

SCHEDULE

END CONN.

15 mm - 80 mm

300 Lb

Threaded, NPT

100 mm - 200

mm

Std. Wt.

Grooved (Note 2 & 3)

SCHEDULE

300 Lb

END CONN.

Threaded, NPT

DESCRIPTION

Malleable Iron, 300 Lb Ground Jt., Iron to Iron

Seats, ASTM A197 Galvanized, per ASME B16.39

SWAGES

SCHEDULE

END CONN.

DESCRIPTION

15 mm - 50 mm

80

Threaded, NPT

Seamless Carbon Steel, Hot Dipped Galvanized, ASTM

A106, GR B, MSS-SP 95.

PLUG

SCHEDULE

END CONN.

DESCRIPTION

15 mm - 50 mm

Threaded, NPT

Carbon Steel, A105, Round Head, Hot Dipped Galvanized,

ASME B16.11

MECHANICAL COUPLINGS

END CONN.

DESCRIPTION

100 mm - 200 mm

Note 2 & 3

Rigid or Flexible D.I., ASTM A536, GR 65-45-12, Hot

Dipped Galvanized

UNIONS

15 mm - 50 mm

DESCRIPTION

Seamless Carbon Steel, Hot Dipped Galvanized, ASTM A106,

GR B, B36.10M

ERW Carbon Steel, Hot Dipped Galvanized, ASTM A53, GR

B, B36.10M, (Ej = 0.85)

ERW Carbon Steel, Hot Dipped Galvanized, ASTM A53, GR

B, B36.10M, (Ej = 0.85)

DESCRIPTION

Galvanized Malleable Iron, 300 Lb., ASTM A197, per ASME

B16.3

D.I., ASTM A536, GR 65-45-12 or ASTM A53, GR B, Hot

Dipped Galvanized

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 8 of 68

CLASS CODE: BA1

FLANGES

15 mm - 80 mm

15 mm - 200 mm

100 mm - 200

mm

100 mm - 200

mm

GASKETS

EQUAL

100 mm - 200 mm

15 mm - 80 mm

100 mm - 200 mm

BOLTING

15 mm 200 mm

Flange Bolts

100mm 200 mm

Coupling Bolts

USE

RATING/FACE

Flg'd. Eqpt.&

Valves

Normal

Normal

150 Lb FF

Normal

150 Lb FF

Coupling

Flat Ring

150# FF

Full Face

150# FF

Threaded,

NPT

Blind

Flange

Adapter

(Note 2 & 3)

Flange

Adapter

(Note 2 & 3)

150 Lb FF

150 Lb FF

TYPE

END CONN.

THICKNESS/MATERIAL

DESCRIPTION

Carbon Steel, ASTM A105 Galvanized, per ASME B16.5

Carbon Steel, ASTM A105. per ASME B16.5, Galvanized

D.I, ASTM A536, GR 65-45-12, Hot Dipped Galvanized

ASTM A105, GR B, ASME B16.5, Std. Wt. Hot Dipped

Galvanized

MANUFACTURER & MODEL NO. OR APPROVED

EPDM

1.5 mm Neoprene

Manufactures Standard for Grooved Coupling.

Self Centering Ring per ASME B16.21

3 mm Neoprene

ASME B16.21

TYPE

DESCRIPTION

Stud Bolts

Alloy Steel, Threaded Full Length, ASTM A193 GR B7 With

Two Heavy Hex Nuts each ASTM A194 GR 2H, Galvanised

Track Head Bolts, PLT, ASTM A183 Gr. 2 with Nuts, PLT,

ASTM A563, Galvanised

Track Head Bolts, Note 3

HEADER SIZE

BRANCH SIZE

INST. CONN.

All

All

All

TYPE

Pressure

Temperature

Orifice Tap

TYPE FITTING

NOTES

Refer to branch connection table within this class code.

SIZE/TYPE CONN.

20 mm Threaded

25 mm Threaded

15 mm Threaded

GENERAL NOTE

1. "Approved Equal" substitutions will only be permitted upon written acceptance by Buyer.

2. Grooved = Roll Grooved ends.

3. All roll grooving dimensions and procedures shall be in accordance with manufacturers recommendations and with

ANSI/AWWA C606. Roll grooving tool shall be provided by the same manufacturer as the couplings. Parts or components from

different manufacturers shall not be interchanged.

4. Use Equal Tee and concentric reducer or Reducing Tee.

5. Use Bolt-on branch outlet.

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

, rev. C

Page 9 of 68

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

3.2

, rev. C

Page 10 of 68

CLASS CODE: BB1

SERVICE:

BASIC MATERIAL:

VALVE MATERIAL:

ASME RATING:

CLASS LIMITS:

CORROSION ALLOW:

VALVES

Plant Air (AS), Lime, Dry (LI); Lime Slurry (LY); Seal Water (SW); Vent, Atmos. (VENT); Cooling Water

Blow down (WCB); Cooling Water Return (WCR); Cooling Water Supply (WCS); Filtered Water (WFI);

Low Chloride Water (WLC); Raw Water (WW); Ammonia Vapor -29C Atmos. Drains & Relief Vents

(AG); Ammonia Liquid Atmos. Drains & Relief Vents (AL), See Notes 3 & 4; Fire Water ( FW )

Carbon Steel

Carbon Steel/ Ductile iron; Stainless Steel / 13% Cr. Trim.

150 Lb.

10.5 Kg/cm2g @ 82C (150 psig @ 180F); 7.0 Kg/cm2g @ 71C (100 psig @ 160F) Note 6

For Fire Water - General system : 10.55 Kg/cm2g @ 650C ( 150 psi @ 1490F )

1.5 mm

TYPE

USE

END CONN.

JEG TAG NO.

80 mm - 150 mm

Butterfly

200 mm - 300 mm Butterfly

350 mm - 600 mm Butterfly

750 mm - 900 mm Butterfly

80 mm - 150 mm

Gate

200 mm - 300 mm Gate

80 mm - 150 mm

Knife Gate

200 mm - 600 mm Knife Gate

15 mm - 50 mm

Globe

80 mm - 350 mm

Globe

15 mm - 50 mm

Ball Check

80 mm - 600 mm

Wafer Check

750 mm - 900 mm Wafer Check

15 mm - 50 mm

Ball

80mm - 150mm

Ball

10mm - 50mm

Needle

15 mm - 50 mm

Plug

25 mm

Gate

PIPE

SCHEDULE

15 mm - 50 mm

XS

B36.10M

80 mm - 600 mm

Std. Wt.

750 mm1500 mm Std. Wt.

Normal (Note 8)

Normal (Note 8)

Normal (Note 8)

Normal (Note 8)

Normal

Normal

Normal (Note 5 & 6)

Normal (Note 5 & 6)

Throttling

Normal

Horiz/Vert Up

Horiz/Vert Up

Horiz/Vert Up

Normal

Normal

Instr./Normal

Normal

note 11

END CONN.

Threaded, NPT & Coupled

150 Lb Lug

V-301

150 Lb Lug

V-302

150 Lb Lug

V-303

Flange Type-RF

V-304

150 Lb RF

V-401

150 Lb RF

V-402

150 Lb FF

V-439

150 Lb FF

V-440

Threaded

V-508

150 Lb RF

V-502

Threaded

V-616

Wafer

V-617

Wafer

V-617-A

Threaded

V-703

150 Lb. RF

V-702

Threaded

V-801

Socket Weld

V-102

800 Lb SC

V-406

DESCRIPTION

Seamless Carbon Steel, ASTM A106 GR B, Ej=1.00,

Beveled

Beveled

ERW Carbon Steel, ASTM A53 GR B, Ej=0.85, B36.10M

DSAW or ERW Carbon Steel, API 5L Gr. B PSL2, Ej=0.85,

Straight Seam, B36.10M

FITTINGS

SCHEDULE

15 mm - 50 mm

300 Lb

80 mm - 350 mm

Std. Wt.

400 mm - 1200 mm Std. Wt.

END CONN.

Threaded, NPT

Butt Weld

Butt Weld

DESCRIPTION

Malleable Iron, 300 Lb., ASTM A197, per ASME B16.3

Carbon Steel, ASTM A234 GR WPB, per ASME B16.9

Carbon Steel, ASTM A234 GR WPBW, per ASME B16.9

THREDOLETS

(Note 7)

15 mm - 50 mm

SCHEDULE

END CONN.

DESCRIPTION

3000 Lb

Threaded, NPT

Carbon Steel, ASTM A105, MSS SP-97

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 11 of 68

CLASS CODE: BB1

WELDOLETS

80 mm - 300 mm

SCHEDULE

Std. Wt.

PLUG

15 mm - 50 mm

B16.11

END CONN.

Butt Weld

DESCRIPTION

Carbon Steel, ASTM A105, MSS SP-97

END CONN.

Threaded, NPT

DESCRIPTION

Carbon Steel, ASTM A105, Round Head, ASME

SWAGES

15 mm 50-mm

SCHEDULE

XS

END CONN.

PE / TE

DESCRIPTION

CS, ASTM A234-WPB-S, MSS SP-95

UNIONS

15 mm - 50 mm

SCHEDULE

300 Lb

END CONN.

Threaded, NPT

DESCRIPTION

Malleable Iron, 300 Lb Ground Jt., Iron to Iron

Seats, ASTM A197

FLANGES

USE

RATING/FACE

END CONN.

15 mm - 50 mm

80 mm - 600 mm

80 mm - 600 mm

Flg'd Eqpt.

Normal

Agst. Fitg.

150 Lb RF

150 Lb RF

150 Lb RF

Threaded, NPT

Slip-on

Weld Neck

15 mm - 50 mm

Orifice

300 Lb RF

80 mm - 600 mm

Orifice

300 Lb RF

750 mm-1500 mm Normal

150 Lb RF

15 mm - 600 mm

15 mm - 50 mm

100 mm - 200 mm

Blind

Instrument.

Instrument

150 Lb RF

300 Lb RF

300 Lb RF

GASKETS

EQUAL

All

TYPE

THICKNESS/MATERIAL

MANUFACTURER & MODEL NO. OR APPROVED

Flat Ring

(Per B16.21)

2 mm Synthetic Fiber

with EPDM Binder

Garlock Bluegard #3700 Non-asbestos

BOLTING

All

HEADER SIZE

Carbon Steel, ASTM A105, per ASME B16.5 (Note-10)

Carbon Steel, ASTM A105, per ASME B16.5

Carbon Steel, ASTM A105, Std. Wt. Bore, per ASME

B16.5

Weld Neck

Carbon Steel, ASTM A105 Sch. XS Bore, per ASME

B16.36

Weld Neck

Carbon Steel, ASTM A105 Std. Wt. Bore, per ASME

B16.36

Weld Neck

Carbon Steel, ASTM A105 Std. Wt. Bore, per ASME

B16.47

Series A

Blind

Carbon Steel, ASTM A105, per ASME B16.5

Threaded, NPT(F)

Carbon Steel, ASTM A105, per ASME B16.5 (Note-10)

Slip-on

Carbon Steel, ASTM A105, per ASME B16.5 (Note-10)

TYPE

Stud Bolts

BRANCH SIZE

DESCRIPTION

DESCRIPTION

Alloy Steel, Threaded Full Length, ASTM A193 GR B7

With Two Heavy Hex Nuts each ASTM A194 GR 2H

TYPE FITTING

NOTES

Refer to branch connection table within this class code.

INST. CONN.

TYPE

SIZE/TYPE CONN.

All

All

All

Pressure

Temperature

Orifice Tap

20 mm threaded

25 mm threaded

15 mm threaded

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 12 of 68

GENERAL NOTE

1. "Approved Equal" substitutions will only be permitted upon written acceptance by Buyer.

2. Radiography test shall be 5% of all butt welds , For Ammonia lines (AG & AL), Liquid Penetration test &

Radiography test shall be 100%

3. Ammonia Liquid and Gas service in this class code applies for low pressure drain lines and relief vents

only.

4. Lime Dry (LI), Lime Slurry (LY) & Rock Slurry (RS) lines shall be sloped per P&ID and shall have no

pockets. Flanges as a minimum shall be provided on one end of elbows, two branches of tees and every

6.0M distance of pipe.

5. Valve use limited to Lime Dry (LI), Lime Slurry (LY) and Rock Slurry (RS).

6. Pressure Temperature limitation due to valve V-439 and V-440.

7. Includes Elbolets and Laterolets (threaded).

8. Valve use limited to Seal Water (SW); Cooling Water Return (WCR); Cooling Water Supply (WCS); Raw

Water (WW) and Vent Atmospheric (VENT).

9.

Threaded joints are permitted only at outlets of vents and drains, hydrostatic testing connections, outlet of instrumentation

isolation valves and to match threaded valves, specialties and equipment. Threaded hydrotest connections shall be seal

welded after testing.

10. Use only for vent, drains and instru conns

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

, rev. C

Page 13 of 68

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

3.3

, rev. C

Page 14 of 68

CLASS CODE: BB3

SERVICE:

BASIC MATERIAL:

VALVE MATERIAL:

ASME RATING:

CLASS LIMITS:

CORROSION. ALLOW:

Flocculating Agent (AF); Defoamer (AM); Blowdown (BD); Boiler Feed Water, Low (BFL);

Boiler Feed Water, Suction (BFS); Condensate, 5 Barg (C5); Coating Oil (CO);

Desuperheating Water, Low (DWL); Fuel Oil (FO); Gas Oil, Diesel (GO); Caustic (NA); Process Air

(PRA); Propane (Note 7) (PG); Steam, 5 Barg (S5); Steam, 10 Barg (S10) Desuperheater Drain Water

(SD)

Carbon Steel

Carbon Steel, 13% Chrome Trim / Stainless steel Trim

150 Lb

13.73 Kg/cm2g @210C (200 psig @ 400F)

1.5 mm

VALVES

TYPE

USE

END CONN.

JEG TAG NO.

15 mm - 50 mm

15 mm - 25 mm

50 mm - 150 mm

200 mm - 600 mm

750 mm - 750 mm

15 mm - 50 mm

80 mm - 350 mm

15 mm - 50 mm

80 mm - 400 mm

450 mm - 600 mm

15 mm - 50 mm

Gate

Gate

Gate

Gate

Gate

Globe

Globe

Ball Check

Swing Check

Wafer Check

Ball

Normal

V, DR, Instr Conns

Normal (Note 8)

Normal

Normal

Normal

Normal

Horiz/Vert Up

Horiz/Vert Up

Horiz/Vert Up

Normal (Note 6)

Socket Weld

SW x SCR'D

150 Lb RF

150 Lb RF

150 Lb RF

Socket Weld

150 Lb RF

Socket Weld

150 Lb RF

150 Lb Wafer

Socket Weld

V-405

V-406

V-401

V-402

V-454

V-501

V-502

V-601

V-603

V-637

V-701

PIPE

15 mm - 50 mm

B36.10M

65 mm - 600 mm

750mm 1050mm

SCHEDULE

XS

END CONN.

Plain

DESCRIPTION

Seamless Carbon Steel, ASTM A106 GR B, (Ej=1.00),

Std. Wt.

Std. Wt.

Beveled

Beveled

ERW Carbon Steel, ASTM A53 GR B (Ej=0.85) B36.10M

EFSW, Carbon Steel, DSAW, API 5L-B, PSL2, Single

Straight Seam, (Ej=.95), B36.10M

DESCRIPTION

Forged Carbon Steel, ASTM A105, per ASME B16.11

Carbon Steel, ASTM A234 GR WPB, per ASME B16.9

Carbon Steel, ASTM A234 GR WPBW, per ASME B16.9

Forged Carbon Steel, ASTM A105, per ASME B16.11 (Note

4)

FITTINGS

SCHEDULE

15 mm - 50 mm

3000 Lb

80 mm - 350 mm

Std. Wt.

400 mm - 1050 mm Std. Wt.

15 mm - 50 mm

3000 Lb

END CONN.

Socket Weld

Butt Weld

Butt Weld

Threaded (NPTF)

OLETS (Note 3)

15 mm 50-mm

SCHEDULE END CONN.

3000 Lb

SW / Thrd

DESCRIPTION

CS, ASTM A105, MSS SP-97

WELDOLET

80 mm 300 mm

SCHEDULE

Std. Wt

END CONN.

Butt Weld

DESCRIPTION

CS, ASTM A105, MSS SP-97

PLUG

15 mm 50 mm

3000 Lb

END CONN.

Threaded (NPTF)

DESCRIPTION

CS, ASTM A105, Round Head, ASME B16.11

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 15 of 68

CLASS CODE: BB3

SWAGES

15 mm 50-mm

SCHEDULE

XS

END CONN.

PE

DESCRIPTION

CS, ASTM A234-WPB-S, MSS SP-95

REDUCING INSERT SCHEDULE END CONN.

15 mm 50-mm

3000 Lb

Socket Weld

DESCRIPTION

CS, ASTM A105, MSS SP-79

NIPPLES

SCHEDULE

END CONN.

DESCRIPTION

15 mm 50-mm

XS (Note 4)

PE / Thrd

CS, SMLS, ASTM A106-B (Ej=1.00)

FLANGES

15 mm - 50 mm

80 mm - 600 mm

750mm 1050mm

USE

Normal

Normal

Normal

RATING/FACE

150 Lb RF

150 Lb RF

150 Lb RF

END CONN.

Socket Weld

Slip-on

Weld Neck

80 mm - 600 mm

40 mm - 50 mm

80 mm - 300 mm

15 mm - 600 mm

15 mm - 50 mm

Agst. Fttgs.

Orifice

Orifice

Blind

Normal

150 Lb RF

300 Lb RF

300 Lb RF

150 Lb RF

300 Lb RF

Weld Neck

Weld Neck

Weld Neck

Blind

Socket Weld

GASKETS

EQUAL

TYPE

THICKNESS/MATERIAL

All

Spiral Wound

(Per B16.20)

150/300 Lb

4.5 mm, 304/Flexicarb

DESCRIPTION

Carbon Steel, ASTM A105, per ASME B16.5

Carbon Steel, ASTM A105, per ASME B16.5

Carbon Steel, ASTM A105 Std Wt. Bore, per ASME B16.47

Series B

Carbon Steel, ASTM A105 Std Wt. Bore, per ASME B16.5

Carbon Steel, ASTM A105 XS Bore, per ASME B16.36

Carbon Steel, ASTM A105 Std. Wt. Bore, per ASME B16.36

Carbon Steel, ASTM A105, per ASME B16.5

Carbon Steel, ASTM A105, per ASME B16.5

MANUFACTURER & MODEL NO. OR

APPROVED

Flexitallic Style CGI Spiral Wound for ASME B16.5 flanges,

Class 150 or 300, Per ASME B16.20, 304SS winding with

Flexible graphite filler, Stainless Steel Inner ring, Carbon Steel

Outer Ring.

BOLTING

TYPE

DESCRIPTION

All

Stud Bolts

HEADER SIZE

BRANCH SIZE

INST. CONN.

TYPE

SIZE/TYPE CONN.

Alloy Steel, Threaded Full Length, ASTM A193 GR B7

With Two Heavy Hex Nuts each ASTM A194 GR 2H

NOTES

Refer to branch connection table within this class code.

NOTES

All

All

All

Pressure

Temperature

Orifice Tap

20 mm Threaded

40 mm flanged

15 mm Threaded

Seal weld connections

TYPE FITTING

GENERAL NOTE

1. "Approved Equal" substitutions will only be permitted upon written acceptance by Buyer.

2. Radiography test shall be 5% of all butt welds.

3. Olets include Threadolet, Sockolet, Laterolet and Elbolet.

4. Threaded joints are permitted only at outlets of vents and drains, hydrostatic testing connections, outlet of instrumentation

isolation valves and to match threaded valves, specialties and equipment. Threaded hydrotest connections shall be seal

welded after testing.

5. For 50 mm x 15 mm branch reduction use equal tee with 50 mm x 15 mm SW reducing insert.

6. For use in the following services only: Flocculating Agent (AF); Defoamer (AM); Coating Oil (CO); Fuel Oil (FO); Gas Oil, Diesel

(GO); and Caustic (NA).

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

7.

8.

Restrict usage of this pipe class to maximum 50 mm for Propane (PG) service.

V-401 in 50 mm size shall be used against equipment nozzles only.

9.

Use Flat face connection when matching to Flat face Cast Iron, FRP or Plastic flange.

, rev. C

Page 16 of 68

10. For 900mm Pipe -schedule XS pipe shall be used only for PID 415A-PI-006F (Refer note 3 on PID)

11. For non corrosive services, swages (PE X TE) may be used only for instrument connections.

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

, rev. C

Page 17 of 68

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

3.4

, rev. C

Page 18 of 68

CLASS CODE: BD2

Instrument Air (AI); Plant Air Note 6 (AS); Ammonia Vapor -29C Note 6 (AG); Defoamer Note 6

(AM); Boiler Feed Water (Low) Note 6 (BFL); Chemical Biocide (BIO); Bleach (BL); Condensate, 5

Barg Note 6 (C5); Hydrazine (HY); Scrubber Liquor Slurry (LL); Non-Condensible Gas (NCG); Strong

Phosphoric Acid Note 11 (PA); Weak Phosphoric Acid Note 11 (PB); Steam, 5 Barg Note 6 (S5);

Steam, 10 Barg Note 6 (S10); Sulfuric Acid 97-99% <45C (SA); Seal Water, Note 6 (SW); Treated

Water (WT); Trisodium Phosphate (TSP); Demineralized Water (WDS); Acidic Process Water (WP);

Raw Water Note 6 (WW), Lube Oil ( OL ); Cooling Water Supply (WCS); Cooling Water Supply (WCR),

Chemical feed Amine (CFA); Chemical Feed phosphate (BD2)

316/316L Stainless Steel

316 Stainless Steel/ UB6PM (Plug Valves)

150 Lb.

11.36 Kg/cm2g @ 204C (SS316L) & 13.83 Kg/cm2g @ 204C (SS316) (180 psig @ 400F) (See Note 2

SERVICE:

BASIC MATERIAL:

VALVE MATERIAL:

ASME RATING:

CLASS LIMITS:

& 5)

11.13 Kg/cm2g @ 220C (SS316L) & 13.06 Kg/cm2g @ 220C (SS316) (170 psig @ 428F) (See Note 2

& 5)

CORROSION ALLOW:

0.000 mm

VALVES

TYPE

USE

END CONN.

JEG TAG NO.

15 mm - 50 mm

15 mm - 80 mm

100 mm - 300 mm

80 mm - 100 mm

150 mm - 500 mm

80 mm 150 mm

200 mm 450 mm

15 mm - 50 mm

80 mm - 650 mm

15 mm - 50 mm

15 mm - 50 mm

80mm - 200 mm

250 mm

15 mm - 50 mm

150 mm - 250 mm

50 mm

25 mm

PIPE

Plug

Plug

Plug

Butterfly

Butterfly

Butterfly

Butterfly

Swing Check

Wafer Check

Ball

Ball

Ball

Ball

Globe

Globe

Gate

Gate

SCHEDULE

Normal

Normal (Note 9)

Normal (Note 9)

Normal (Note 2)

Normal (Note 2)

(Note 10)

(Note 10)

Horiz/Vert Up (Note 9)

Horiz/Vert Up (Note 9)

Normal

V, DR, Instr Conns

Normal

Normal

Normal

Normal

Note14

Note16

END CONN.

Socket Weld

150 Lb RF

150 Lb RF

150 Lb Lug Type

150 Lb Lug Type

150 Lb Lug Type

150 Lb Lug Type

Socket Weld

Wafer

Socket Weld

SW x SCR'D

150 Lb RF

socket weld

Socket Weld

150 Lb RF

150 Lb RF

800 Lb SCRF

DESCRIPTION

V-102

V-103

V-104

V-306

V-307

V-308

V-309

V-608

V-614

V-718

V-719

V-720

V-721

V-528

V-531

V-454

V-456

15 mm - 50 mm

80S

Seamless ASTM A312 Gr TP316/316L (Dual

80 mm - 450 mm

40S

Plain

Certified),B36.19M

Beveled (Note 7)

FITTINGS

15 mm - 50 mm

SCHEDULE

3000 Lb

END CONN.

Socket Weld

80 mm - 200 mm

40S

Butt Weld (Note 7)

(Ej = 1.00)

EFSW ASTM A312 Gr TP316/316L, DSAW (Dual

Certified), B36.19M, (Ej = 0.85)

DESCRIPTION

ASTM A182, Gr. F316/316L (Dual Certified), per ASME

B16.11

ASTM A403 Gr. WP316/ 316L-S (Dual Certified), per ASME

B16.9

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 19 of 68

250 mm - 450 mm

40S

Butt Weld (Note 7)

15 mm - 50 mm

3000 Lb

Threaded NPT(F)

STUB-ENDS

SCHEDULE

END CONN.

80 mm - 200 mm

40S

Butt Weld (Note 7)

250 mm - 450 mm

40S

Butt Weld (Note 7)

ASTM A403 Gr. WP316/ 316L-WX (Dual Certified), per ASME

B16.9

ASTM A182, Gr. F316/316L (Dual Certified), per ASME

B16.11(Note-17)

DESCRIPTION

MSS SP43 Type A short, ASTM A403 GR WP316/316L-S

(Dual Certified)

MSS SP43 Type A short, ASTM A403 GR WP316/316LWX

(Dual Certified)

SOCKLOETS

SCHEDULE

END CONN.

DESCRIPTION

15 mm - 50 mm

3000Lb

SW

SS, ASTM A182, Gr. F316/316L (Dual Certified), per MSS

SP-97

WELDOLETS

SCHEDULE

END CONN.

DESCRIPTION

80 mm - 300 mm

40S

Butt Weld (Note 7)

SWAGES

15 mm 50 mm

SCHEDULE

80S

END CONN.

PBE

FLANGES

USE

RATING/FACE

SS, ASTM A182, Gr. F316/316L (Dual Certified), per MSS

SP-97

DESCRIPTION

SS, ASTM A403 Gr. WP316/ 316L-WX (Dual Certified),

MSS SP-95

END CONN.

DESCRIPTION

15 mm - 50 mm

Normal

150 Lb RF

Socket Weld

15 mm - 50 mm

80 mm - 450 mm

80 mm - 450 mm

Normal

Reducing

Normal

150 Lb RF

150 Lb RF

150 Lb RF

Blind

Slip-on

Lap Joint

40 mm - 450 mm

Orifice

300 Lb RF

80 mm - 300 mm

Normal

300 Lb RF

Weld Neck

(Note 7)

Lap Joint

GASKETS

EQUAL

All

TYPE

Spiral Wound

(Per B16.20)

150/300 Lb

THICKNESS/MATERIAL

4.5 mm, 316L/PTFE

ASTM A182 GR F316/316L (Dual Certified), Sch. 80S Bore, per

ASME B16.5

ASTM A182 GR F316/316L (Dual Certified), per ASME B16.5

ASTM A182 GR F316/316L (Dual Certified), per ASME B16.5

Carbon Steel, ASTM A105 (use with Type A Stub-Ends), per

ASME B16.5, Hot Dipped Galvanized

ASTM A182 GR F316/316L (Dual Certified), Sch. Bore to match

pipe, per ASME B16.36

Carbon Steel, ASTM A105 (use with Type A Stub-Ends), per

ASME B16.5, Hot Dipped Galvanized

MANUFACTURER & MODEL NO. OR APPROVED

Flexitallic Style CGI Spiral Wound for ASME B16.5 flanges,

316L inner and outer rings, 316L windings with PTFE filler.

BOLTING

TYPE

DESCRIPTION

All

Stud Bolts

Alloy Steel, Threaded Full Length, ASTM A193 GR B7 With

Two Heavy Hex Nuts each ASTM A194 GR 2H

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

TYPE FITTING

, rev. C

Page 20 of 68

HEADER SIZE

BRANCH SIZE

NOTES

Refer to branch connection table within this class code.

INST. CONN.

SIZE/TYPE CONN.

NOTES

Pressure

Pressure

All Temperature

All Orifice Tap

Pressure

Pressure

80 mm Flanged

40 mm Flanged

40 mm Flanged

15 mm Threaded

25 mm Flanged

20 mm Threaded

Slurry Services - Chemical seals will be used

Non-Slurry Services - Chemical seals will be used, except sulfuric acid service.

Non-Slurry Services only

SA service, - Chemical seals will be used

Services w/o chemical seal requirement.

GENERAL NOTE

1.

"Approved Equal" substitutions will only be permitted upon written acceptance by Buyer.

2.

Butterfly valves not to be used in hot service over 120 0C and not for use in Strong Phosphoric Acid (PA) or

Weak Phosphoric Acid (PB) services (Note 11)

3.

External pickling shall be carried out for all weld joints.

4.

All the lines are to be passivated.

5.

De-rate pipelines with Expansion Joints per Pressure / Temperature limits of components.

6.

For the following services, the use of this class is limited to process connections subject to abnormal

corrosive conditions: Plant Air (AS), Ammonia Vapor -29C (AG), Defoamer (AM), Condensate, 5 Barg

(C5), Steam, 5 Barg (S5), Steam, 10 Barg (S10), Seal Water (SW) and Raw Water (WW).

7.

All buttwelds shall have a root pass made with the Gas Tungsten Arc (GTAW) welding process with the

8.

For 50 mm x 15 mm branch reduction use equal tee with 50 mm x 15 mm SW reducing insert.

9.

Use only noted valves with Sulfuric Acid 97-99% <45C (SA) service. These valves may be used for other

back side purged and without the use of inserts.

services within this class.

10. For use in Strong Phosphoric Acid (PA) or Weak Phosphoric Acid (PB) services only.

11. Strong Phosphoric Acid (PA) or Weak Phosphoric Acid (PB) services covered within this piping class is for

Weak and Strong Phosphoric within DAP plant only.

12. Radiography test shall be 10% of butt welds.

13. Use Flat face connection when matching to Flat face Cast Iron, FRP or Plastic flange.

14. For non corrosive services, Full couplings (FTE) may be used only for instrument connections.

15. Use for casing drains on economizer 3B (401AAE10) and economizer 4A / 4C (401AAE08 & 09) only.

16. Use for SAP convertor pressure connections only.

17. Threaded joints are permitted only at outlets of vents and drains, hydrostatic testing connections, outlet of instrumentation

isolation valves and to match threaded valves, specialties and equipment. Threaded hydrotest connections shall be seal

welded after testing.

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

, rev. C

Page 21 of 68

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

3.5

, rev. C

Page 22 of 68

CLASS CODE: BK1

Polluted Air (AP); Strong Phosphoric Acid Sludge (BA); Weak Phosphoric Acid Sludge (BB); Process

Condensate (CP); Gypsum Slurry (GY); Strong Phosphoric Acid (PA); Weak Phosphoric Acid (PB);

Recovered Water (RW); Sulfuric Acid 5% (SA5); Sulfuric Acid Vent (SAV); Vapor (VA); Waste Water

(WE); High Chloride Water (WHC); Acidic Process Water; (WP); Sea Water Return (WSR); Sea Water

Supply (WSS); Raw Water Note 2 (WW)

Fiberglass Reinforced Pipe

Rubber/Elastomer Lined / UB6PM/SS316 Trim, 2205 Duplex stainless steel Trim (for sea water

SERVICE:

BASIC MATERIAL:

VALVE MATERIAL:

application)

ASME RATING:

CLASS LIMITS:

150 Lb

Size 15mm 40mm (10.5kg/cm2g @ 104C 150 psig @ 220F) & Full Vacuum

Size 50mm 600mm (10.5kg/cm2g @ 104C 150 psig @ 220F) & Full Vacuum

Size 750mm 900mm (7.0kg/cm2g @ 93C 100 psig @ 200F) & Full Vacuum

Size 1000mm Size 1500mm (10.0kg/cm2g @ 50C 150 psig @ 122F) & Full Vacuum

Size 2000mm Size 2000mm (2.04kg/cm2g @ 90C 150 psig @ 194F) & Full Vacuum

CORROSION. ALLOW:

VALVES

0 mm

TYPE

50 mm - 80 mm

Plug

100 mm - 450 mm Plug

80 mm - 100 mm

Butterfly

150 mm - 600 mm Butterfly

750 mm 1500 mm Butterfly

50 mm 150 mm Butterfly

200 mm 600 mm Butterfly

300 mm

Butterfly

300 mm 600 mm Knife Gate

80 mm 650 mm Wafer Check

100 mm 600 mm Check

150 mm - 600mm Butterfly

15 mm- 50 mm

Ball

250 mm

Ball

25 mm

Gate

50 mm-150 mm

Gate

PIPE

15 mm 40 mm

USE

END CONN.

JEG TAG NO.

Normal

Normal

Normal (Note 5)

Normal (Note 5)

Normal (Note 8)

Normal (Note 6)

Normal (Note 6)

Normal (Note 7)

Normal (Note 6)

Horizontal/Vertical Up (Note 5)

Horizontal/Vertical Up (Note 8)

Normal (Note 8)

Normal

Normal

note 11

Normal

150 Lb FF

150 Lb FF

150 Lb Lug (Note 3)

150 Lb Lug (Note 3)

150 Lb. Flanged

150 Lb. Lug

150 Lb. Lug

150 Lb. Lug

150 Lb FF

150 Lb. Wafer

150 Lb. Wafer

150 Lb Lug (Note 3)

socket weld CS

socket weld

800 Lb SC

150 Lb. RF

V-106

V-107

V-306

V-307

V-313

V-308

V-309

V-310

V-414

V-614

V-647

V-314

V-701

V-721

V-406

V-401

SCHEDULE

END CONN.

Suitable for

Butt Wrap Joint

150 PSIG

specification 62002S-2 & (Note 10)

DESCRIPTION

FRP Filament wound. Double layer of Nexus

Surfacing veil on all interior surfaces Construction

per

per specification 62002S-2 & (Note 10)

.

50 mm - 2000 mm

Suitable for

150 PSIG

FITTINGS

15 mm 40 mm

SCHEDULE

Suitable for

Butt Wrap Joint

END CONN.

Butt Wrap Joint

FRP Filament wound. Double layer of Nexus Surfacing

veil on all interior surfaces. Construction per

specification 62002S-2.

DESCRIPTION

FRP Filament wound .Double layer of nexus surfacing veil

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 23 of 68

150PSIG

on all Interior surfaces. Construction per specification

62002S-2 & (Note 10)

50 mm - 1050 mm

Suitable for

150 PSIG

Butt Wrap Joint

1100 mm 2000 mm

Suitable for

150 PSIG

Butt Wrap Joint

FRP Filament wound. Double layer of Nexus Surfacing veil on

all interior surfaces. Construction per specification 62002S-2.

Dimensions per Fitting Dimension Table (this class code)

FRP Filament wound. Double layer of Nexus Surfacing veil on

all interior surfaces. Construction per specification 62002S-2.

Dimensions per Fitting Dimension Table (this class code)

END CONN.

DESCRIPTION

Butt Wrap Joint

FRP integral stub flange, FRP hand lay-up. Double layer of

Nexus Surfacing veil on all interior surfaces. Stub end to match

pipe. Flange O.D. and drilling to ASME B.16.5. Construction

per specification 62002S-2 & (Note 10)

FLANGES

15 mm - 40 mm

USE

Normal

RATING/FACE

ASME 150# FF

50 mm - 600 mm

Normal

ASME 150# FF

15 mm - 40 mm

Blind

ASME 150# FF

FRP Blind flange, FRP hand lay-up. Double layer of Nexus

Surfacing veil on all interior surfaces.

Flange O.D. and drilling to ASME B.16.5. Construction per

specification 62002S-2 & (Note 10)

50 mm - 600 mm

Blind

ASME 150# FF

FRP Blind flange, FRP hand lay-up. Double layer of Nexus

Surfacing veil on all interior surfaces.

Flange O.D. and drilling to ASME B.16.5.

Dimensions per Fitting Dimension Table (this class code)

650

mm

Blind

ASME 150# FF

FRP Blind flange, FRP hand lay-up. Double layer of Nexus Surfa

on all interior surfaces.

Flange O.D. and drilling to ASME B.16.47 Series A .

Dimensions per Fitting Dimension Table (this class code)

mm-

2000

GASKETS

EQUAL

TYPE

Butt Wrap Joint

THICKNESS/MATERIAL

P integral stub flange, FRP hand lay-up. Double layer of Nexus

Surfacing veil on all interior surfaces. Stub end to match pipe.

Flange O.D. and drilling to ASME B.16.5.

Dimensions per Fitting Dimension Table (this class code)

(Note: 25 and 40mm stub flanges may be used to form branch

connections for Instruments, Vents and drains only)

MANUFACTURER & MODEL NO. OR APPROVED

15 mm 400 mm

150 Lb FF

3 mm PTFE

Garlok, Stress Saver 370

450 mm 2000 mm

150 Lb FF

3 mm PTFE

Garlok, Gylon Style 3545

BOLTING

All

B8M CL2

TYPE

Stud Bolts

DESCRIPTION

Stainless Steel, Threaded Full Length, ASTM A193 GR

With Two Heavy Hex Nuts each ASTM A194 GR 8M.

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

TYPE FITTING

, rev. C

Page 24 of 68

HEADER SIZE

BRANCH SIZE

NOTES

Refer to branch connection table within this class code.

INST. CONN.

TYPE

SIZE/TYPE CONN.

NOTES

All

Pressure

50 mm Flanged

Chemical Seals will be used

All

Temperature

50 mm Flanged

GENERAL NOTE

1.

Approved equal substitutions will only be permitted upon written acceptance by Buyer.

2.

The use of this class is limited to process connections subject to abnormal corrosive conditions for raw water (WW)

3.

Flanges should always be bolted to full flat faced flanges. Where full flat faced flanges are not used, proper spacers

must be used to build-up the flange to a flat surface and prevent overstressing the flange. When existing equipment

cannot be modified to produce full flat faced flange, extreme care shall be used.

4.

Vents and Drains shall be a minimum of 15 mm.

5.

This type of valve not to be used in hot services over 120C and not for use in Strong Phosphoric Acid Sludge (BA),

Weak Phosphoric Acid Sludge (BB); Strong Phosphoric Acid (PA) and Weak Phosphoric Acid (PB) services.

6.

For use in Strong Phosphoric Acid Sludge (BA), Weak Phosphoric Acid Sludge (BB); Strong Phosphoric Acid (PA)

and Weak Phosphoric Acid (PB) services.

7.

For use in Sulfuric Acid Vent (SAV) service only.

8.

For use in Sea Water Service only.

9. Use Raise face connection when matching to Raise face flange.

10. These Components shall not be used for slurry, Sludge or solidified clogging services. Safety factor for pressure

Shall be considered as 10:1 & Safety factor for vacuum shall be considered as 5:1.

11.

Use only for vent, drains and instru conns

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

, rev. C

Page 25 of 68

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

, rev. C

Page 26 of 68

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

, rev. C

Page 27 of 68

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

3.6

, rev. C

Page 28 of 68

CLASS CODE: BL5

SERVICE:

BASIC MATERIAL:

VALVE MATERIAL:

ASME RATING:

CLASS LIMITS:

VALVES

25 mm - 80 mm

100 mm - 250 mm

80 mm - 400 mm

80 mm - 150 mm

200 mm - 600 mm

25 mm 150 mm

200 mm

250 mm-600 mm

15 mm- 50 mm

Rock slurry( RS) , Polluted Air (AP); Boiler Feed Water (Low) Note 6 (BFL); Hydrofluosilicic Acid (FSA);

Hydrofluosilicic Sludge (FSB); Sulfuric Acid 97-99% Note 5 (SA); Vapor (VA) , Process Water (WP)

PTFE lined Carbon Steel / Rubber-lined Carbon Steel

PFA Lined

150 Lb FF

7.7 kg/cm2g and Full Vacuum @ 88C (110 Psig and Full Vacuum @ 190F)

TYPE

Plug

Plug

Butterfly

Knife Gate (Note 17)

Knife Gate (Note 17)

Piston Check

Ball Check

Wafer check

Ball

USE

Normal

Normal

Normal

Normal (Note 18)

Normal (Note 18)

Normal

Normal (Horiz)

Normal

Normal

PIPE

25 mm 150 mm

SCHEDULE

40

END CONN.

Lap Joint x Screwed

200 mm - 600 mm

Std. Wt.

Plain

650 mm 750 mm

Std. Wt.

Plain

800 mm 1600 mm

9.53 mm

Plain

1700 mm 1700 mm

11.91 mm

Plain

1800 mm 1800 mm

12.7 mm

Plain

2000 mm 2000 mm

14.27 mm

Plain

FITTINGS

25 mm 150 mm

200 mm

SCHEDULE

150 lb

125 lb

250 mm 750 mm

Std. Wt.

800 mm 1600 mm

9.53 mm.

Flanged

1700 mm 1700 mm 11.91 mm

Flanged

1800 mm 1800 mm 12.70 mm

2000 mm 2000 mm 14.27 mm

END CONN.

150 Lb. Flanged, FF

Flanged (FF)

Flanged

Flanged

Flanged

END CONN.

150 Lb RF

150 Lb RF

150 Lb. Lug

150 Lb FF

150 Lb FF

150 Lb. RF

150 Lb. RF

150 Lb. Wafer

socket weld CS

JEG TAG NO.

V-108

V-109

V-310

V-439

V-440

V-628

V-645

V-630

V-701

DESCRIPTION

Seamless Carbon steel, ASTM A106 Gr.B (PTFE Lined),

Max Spool Length 6m.

ERW Carbon Steel, Rubber-Lined

(Note 1) ASTM A53 GR B (Note 6) (Ej = 0.85)

ERW Carbon Steel, Rubber-Lined (Note 1) API 5L GR B (Note

6) (Ej = 0.85)

ERW Carbon Steel, Rubber-Lined (Note 1) API 5L GR B (Note

6 (Ej = 0.85)

ERW Carbon Steel, Rubber-Lined (Note 1) API 5L GR B (Note

6 & 16) (Ej=0.85)

ERW Carbon Steel, Rubber-Lined (Note 1) API 5L GR B (Note

6 & 16) (Ej=0.85)

ERW Carbon Steel, Rubber-Lined (Note 1) API 5L GR B (Note

6 & 16)(Ej=0.85)

DESCRIPTION

PTFE Lined D.I. / Cast Steel / Fabricated Steel 150 lb Flanged

125# Ductile Iron, short body pattern,

ASTM A-395 to ASME B16.1, rubber-lined (Note 1)

Fabricate as indicated on Table 1 this specification and (Notes 1

& 2)

Fabricate as indicated on Table 1 this specification and (Notes 1

& 2)

Fabricate as indicated on Table 1 this specification and (Notes 1

& 2)

Fabricate as indicated on Table 1 this specification and (Notes 1

& 2)

Fabricate as indicated on Table 1 this specification and (Notes 1

& 2)

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 29 of 68

CLASS CODE: BL5

FLANGES

USE

RATING/FACE

TYPE

DESCRIPTION

Lap & Screwed PTFE Lined D.I. Flange (Pipe) and Fixed

D.I. / Cast Steel / Fabricated Steel, ASME B 16.5.

25 mm 150 mm

Normal

150 Lb FF

200 mm

Normal

150 Lb FF

Lap Joint /

Screwed /

Fixed

Slip on

250 mm

2000mm

25 mm 150 mm

200 mm 200mm

250 mm

2000mm

Normal

150 Lb FF

Slip on

Blind

Blind

Blind

150 Lb FF

150 Lb FF

AWWA

Blind

Blind

Blind

GASKETS

TYPE

25 mm 150 mm Flat Ring

200 mm 2000mm Flat ring

BOLTING

All

THICKNESS/MATERIAL

DESCRIPTION

3 mm Teflon

3 mm Neoprene

Garlok, Gylon Style 3500

Neoprene Style 65-75 Type A AWWA C 207 Cl. D, Table 2

TYPE

Stud Bolts

SIZE

25

40

50

80

100

150

Carbon Steel, Rubber Covered (Note1)ASTM A105,

ASME B 16.5.

Carbon Steel AWWA C207 CL D Table 2 Class D Rubber

Covered (Note 1)

PTFE Lined D.I. , ASME B 16.5.

Rubber Covered (Note 1) ASTM A105, ASME B 16.5

C.S. AWWA C 207 Cl. D, Table 2, Rubber Covered

DESCRIPTION

Alloy Steel, Threaded Full Length, ASTM A193 GR B7 With

Two Heavy Hex Nuts each ASTM A194 GR 2H

Cadmium plated. Recommended bolt torque and tightening

pattern indicated below:

TORQUE

10 ft. lbs.

15 ft. lbs.

25 ft. lbs.

40 ft. lbs.

30 ft. lbs.

60 ft. lbs.

PATTERN

0-180-90-270

0-180-90-270

0-180-90-270

0-180-90-270

0-180-90-270-45-225-135-315

0-180-90-270-45-225-135-315

HEADER SIZE

BRANCH SIZE

TYPE FITTING NOTES

25 mm - 150 mm

40 mm - 150 mm

80 mm 2000mm

Full Size

Reducing

15 mm 1900 mm

INST. CONN.

TYPE

SIZE/TYPE CONN.

NOTES

50 mm & Smaller

50 mm & Smaller

80 mm & Larger

80 mm & Larger

Pressure

Temperature

Pressure

Temperature

25 mm Flanged

40 mm Flanged

80 mm Flanged

80 mm Flanged

Full or Reducing Tees, Chemical seals will be used

Full or Reducing Tees

Chemical seals will be used

Tee

Reducing Tee

Tee/Branch Weld

PTFE lined D.I./Cast Steel / Fabricated Steel 150 lb Flanged

PTFE lined D.I./Cast Steel / Fabricated Steel 150 lb Flanged

(See Diagram Below & Branch table)

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 30 of 68

GENERAL NOTE

1. Unless specifically specified otherwise, all rubber stock shall be nominal 6 mm three ply natural rubber equal to Polymeric

Triflex 1000C, except the faces of flanges shall be lined with 6mm single ply rubber equal to Polymeric 1060C, with full

flange facing rubber cut from a single piece and rolled and lapped onto the rubber on the barrel of the pipe. Rubber from

the barrel of pipe shall not be rolled over to face flange surfaces.

2.

Gaskets, where rubber-lining is mated to similar rubber lining, shall be full face of 3mm Teflon and where rubber lined

flanges mate to metal flanges, gaskets shall be 3mm neoprene.

3.

Vent and drain only as shown on P&ID.

4.

Maximum pipe spool length is 5000 mm for 200 mm & above sizes. For sizes upto 150 mm, maximum pipe spool length

shall be 6000 mm.

5.

Polypropylene spacers to be used on both sides of butterfly valves. Spacers to be 20 mm thick full face. Do not use any

gaskets between valve and spacer. Spacer to have I.D. of bare pipe.

6.

Pipe, fittings and flanges shall be free from oil, grease, or other viscous coating. Pipe shall be free from deep seams,

ridges, laminations or other imperfections. Fittings and flanges shall be free from high or ragged projections, deep or

irregular pits. Plain end pipe shall have both inside and outside reamed and chamfered 45, with no sharp edges.

7.

Dimensions of spools and fabricated fittings shall be from face-to-face (for pipe) and center-to-face (for fittings) of lining,

and each dimension shall have a tolerance of +/- 3 mm. Flanges shall be located with the flange face projected 9 mm

maximum over the end of the pipe spools only, and the face weld shall be ground smooth. Alignment of flanges shall have

a tolerance of +/- 2 mm.

8.

Sandblasting of all surfaces to be covered with rubber, shall be carried out until a clear, bright metal surface, free from rust,

scale, weld splatter, or any other foreign matter is obtained. All sand or other materials used for blasting shall be free of

excessive moisture.

9.

Lining material shall be free from blisters, porosity, irregularities, pitting, tears and any other defects. Flanges shall have full

face coverage of rubber.

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 31 of 68

10. Workmanship shall be first class in all respects, complete and uniform adhesion shall be obtained between the lining and

metal, with no trapped air behind the lining.

CLASS CODE: BL5

11. Lapping of lining for both the longitudinal lap inside the pipe and where the separate flange stock laps into the pipe, shall

be 25 mm for all sizes up to and including 300 mm and 50 mm for all sizes over 300 mm. Rubber from the barrel of the pipe

shall not rolled over to face flange surfaces.

12. Curing of lining shall be in accordance with the manufacturer's recommendations for the rubber stocks to be used.

linings shall attain hardness recommended by the manufacturer. Unless otherwise specified, when the size of the

permits, the lining shall be autoclave cured, and materials compatible with the autoclave process shall be used.

lining is to be field applied, atmospheric curing shall be used, unless otherwise specified. Steam shall be used as a

media. Rubber stocks shall be compatible to atmospheric curing.

Cured

object

When

curing

13. Testing of all rubber-lined pipe shall be subject to Purchaser's inspection prior to shipment.

Standard electrostatic test shall consist of grounding the steel members and a searching electrode with a minimum

potential of 15,000 volts shall be exposed to the entire surface. If any defects are detected, proper repairs are to be made

prior to the

acceptance by the inspector.

14. No Polypropylene lining in BL5 piping class.

15. For Sulfuric Acid 97 99% (SA) and Boiler Feed Water Low (BFL) service this class code shall only be used up to 150 mm.

16. For Sizes 1700 mm & 2000 mm, D/T < 100, as per ASME B31.3 not meeting. (where D - Nominal Pipe Size & T - Nominal

pipe wall thickness) Hence, the supporting span & branching requirements shall be decided accordingly.

17. For Rock Slurry (RS) service only.

18. Pressure Temperature limitation due to valve V-439 and V-440.

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 32 of 68

CLASS CODE: BL5

Table 1

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 33 of 68

NOTES

1.

Fabricated fittings shall be made from plate to ASTM A283 Gr. C, equivalent to pipe thickness.

2.

Fittings not covered by this specification must be detailed on the piping drawing.

3.

Unless otherwise noted on isometric, tees and laterals shall be made from pipe stubbed-in.

4.

Fabricate from carbon steel ASTM A283 Gr. C or purchase carbon steel plate flange per AWWA C207 CL. D Table 2

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

, rev. C

Page 34 of 68

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 35 of 68

CLASS CODE: CD1

3.7

Ammonia Vapor (-29C) (AG) For use at Process Connection Only; Lube Oil (OL), Sulphuric Acid

(SA)

(Note 8), Chemical feed Phosphate (CFP)

BASIC MATERIAL:

316/316L Stainless Steel

VALVE MATERIAL:

316 Stainless Steel

ASME RATING:

300 Lb.

CLASS LIMITS:

24.5 Kg /cm2g @ 204C (348psig @ 400F)

CORROSION. ALLOW: 0.000

SERVICE:

VALVES

TYPE

USE

END CONN.

15 mm - 50 mm Swing Check

15 mm - 50 mm Ball

100 mm

Gate

Horiz/Vert Up

Normal

Note 8

Socket Weld

300 Lb RF

300 Lb RF

PIPE

SCHEDULE

END CONN.

DESCRIPTION

15 mm - 50 mm

40S

Beveled (Note 2 & 6)

80 mm - 250 mm 40S

Beveled (Note 2 & 6)

Seamless ASTM A312 Gr TP316/316L (Dual Certified),

B36.19M

EFSW ASTM A312 GR TP316/316L DSAW (Dual

Certified),B36.19M, (Ej=0.85)

FITTINGS

END CONN.

DESCRIPTION

15 mm - 250 mm 40S

Butt Weld (Note 2 & 6)

ASTM A403 GR WP316/316L-S (Dual Certified), per ASME

B16.9

STUB-ENDS

END CONN.

DESCRIPTION

15 mm - 250 mm 40S

Butt Weld (Note 2 & 6)

Short Pattern Type A short, ASTM A403 WP316/316L

(Dual Certified), per ASME B16.9

FLANGES

RATING/FACE

DESCRIPTION

SCHEDULE

SCHEDULE

USE

END CONN.

15 mm - 250 mm

Normal

300 Lb RF

Lap Joint

40 mm - 250 mm

Orifice

300 Lb RF

Weld Neck

GASKETS

EQUAL

All

TYPE

Spiral Wound

(Per B16.20)

300 Lb

THICKNESS/MATERIAL

4.5 mm, 316L/PTFE

JEG TAG NO.

V-622

V-710

V-455

Carbon Steel, ASTM A105 (use with Type A Stub-Ends), per

ASME B16.5, Hot Dipped Galvanized

ASTM A182 GR F316/316L (Dual Certified), Sch. 40S Bore, per

ASME B16.36 (Note 6)

MANUFACTURER & MODEL NO. OR APPROVED

Flexitallic Style CGI Spiral Wound for ASME B16.5 flanges, Class

300, Per ASME B16.20, 316LSS winding with PTFE filler, 316L SS

Inner ring, 316L Outer Ring.

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 36 of 68

CLASS CODE: CD1

BOLTING

TYPE

DESCRIPTION

All

Stud Bolts

Alloy Steel, Threaded Full Length, ASTM A193 GR B7

With Two Heavy Hex Nuts each ASTM A194 GR 2H

WELDOLETS

15 mm - 100 mm

HEADER SIZE

SCHEDULE

END CONN.

40S

DESCRIPTION

Butt Weld

(Note 2 & 6)

BRANCH SIZE

SS, ASTM A 182 Gr. F316 / 316L (Dual certified), per MSS-SP-97.

TYPE FITTING

NOTES

Refer to branch connection table within this class code.

INST. CONN.

SIZE/TYPE CONN.

Notes

Pressure

Temperature

Orifice Tap

20 mm Threaded

40 mm Flanged

15 mm Threaded

For pressure transmitters, 25mm flanged with chemical seals shall be used

GENERAL NOTE

1.

"Approved Equal" substitutions will only be permitted upon written acceptance by Buyer.

2.

For Ammonia lines (AG), Liquid Penetration test & Radiography test shall be 100% and for other services

Radiography test shall be 10%.

3.

Deleted

4.

External pickling shall be carried out for all weld joints.

5.

All the lines are to be passivated.

6.

All buttwelds shall have a root pass made with the Gas Tungsten Arc (GTAW) welding process with the

back side purged and without the use of inserts.

7.

Use for casing drains on HP Super heater 1B (401AAE05) only.

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

, rev. C

Page 37 of 68

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

3.8

, rev. C

Page 38 of 68

CLASS CODE: CG1

(Note 5)

SERVICE:

BASIC MATERIAL:

VALVE MATERIAL:

ASME RATING:

CLASS LIMITS:

CORROSION. ALLOW:

Ammonia Liquid (-29C) Note 5 (AL); Ammonium Phosphate Slurry (APS); Strong Phosphoric Acid

Note 5 (PA); Steam; 10Barg Note 5 (S10), Ammonia Vapour (AG)

904L Stainless steel

PTFE Lined Cast Or Ductile Iron / Hastelloy C

300 Lb.

24.5 Kg/cm2g @ 204C (350 psig @ 4000F)

0.000 mm / 3 mm (Erosion)

JEG TAG NO

V-116

V-117

V-119

V-623

V-624

VALVES

25 mm - 80 mm

100 mm - 150 mm

200 mm 300 mm

15 mm - 50 mm

80 mm - 200 mm

TYPE

Plug

Plug

Plug

Check

Check

USE

Normal

Normal

Normal

Normal

Normal

END CONN.

300 Lb. RF

300 Lb. RF

300 Lb. RF

300 Lb. RF

300 Lb. RF

PIPE

25 mm - 150 mm

200 mm - 300 mm

SCHEDULE

40S

40S

END CONN.

Beveled (Note 6)

Beveled (Note 6)

DESCRIPTION

Seamless ASTM A312, 904L UNS N08904, B36.19M

Welded ASTM A312, 904L UNS N08904, B36.19M

FITTINGS

20 mm 150 mm

SCHEDULE

40S

END CONN.

Butt Weld (Note 6)

DESCRIPTION

904L, ASTM B366 Seamless, Gr. WP904L, Class S per

ASME B16.9

904L, ASTM B366 welded Gr. WP904L, Class WX, per

200 mm 300 MM 40S

ASME 16.9

Butt Weld (Note 6)

FLANGES

25 mm - 300mm

USE

Normal

RATING

300 Lb

STUB-ENDS

25 mm - 150mm

SCHEDULE

40S

END CONN.

Butt Weld (Note 6)

200 mm - 300mm

GASKETS

EQUAL

All

BOLTING

40S

END CONN.

Lap Joint

Butt Weld (Note 6)

DESCRIPTION

300# forged carbon steel, Hot Dipped Galvanized, lap joint,

ASTM A-105 per ASME B16.5

DESCRIPTION

Short pattern 904L type A, ASTM B366 seamless Gr.

WP904L, Class -S

Short pattern 904L type A, ASTM B366 welded Gr.

WP904L,

Class - WX

TYPE

THICKNESS/MATERIAL

MANUFACTURER & MODEL NO. OR APPROVED

Flat Ring

Per B16.21

300 LB

TYPE

3mm Gylon

Garlok Gylon Style 3500

All

two

Stud Bolts

HEADER SIZE

BRANCH SIZE

DESCRIPTION

Alloy Steel, threaded full length, ASTM A193 GR B7 with

TYPE FITTING

heavy hex nuts each ASTM A194 GR 2H

NOTES

Refer to branch connection table within this class code.

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

, rev. C

Page 39 of 68

CLASS CODE: CG1

WELDOLETS

SCHEDULE

25 mm - 150 mm

40S

END CONN.

Butt Weld

(Note 6)

SS 904L, ASTM B366 Seamless, Gr. WP904L, Class S, per MSS-SP-97.

THREDOLETS

20 mm - 50 mm

SCHEDULE

3000 Lb

INST. CONN.

SIZE/TYPE CONN.

Notes

80mm Flanged Pad

40 mm Flanged

None

Slurry Services - Slurry seals shall be used

Pressure

Temperature

Orifice Tap

END CONN.

Threaded

(Note 7)

DESCRIPTION

DESCRIPTION

SS 904L, ASTM B366 Seamless, Gr. WP904L, Class S, per MSS-SP-97.

GENERAL NOTE

1.

2.

3.

4.

5.

6.

7.

For Ammonia lines (AG & AL), Liquid Penetration test & Radiography test shall be 100% and for other services

Radiography test shall be 10%.

All Ammonia (AG & AL) lines shall be purged with Nitrogen.

External pickling shall be carried out for all weld joints.

All the lines are to be passivated

For the following Services, this Class is limited to use at Process Connections: Ammonia Liquid (-29C) (AL):

Strong Phosphoric Acid (PA) and Steam, 10 Barg (S10).

All buttwelds shall have a root pass made with the Gas Tungsten Arc (GTAW) welding process with the

back side purged and without the use of inserts.

Threaded joints are permitted only for sample connection.

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco

Tl: +212 (0)5 22 87 70 00 / +212 (0)5 22 87 71 50 Fax: +212 (0)5 22 87 72 34

Q6521-00-L-02R-00001

Jacobs Engineering Group Inc.

Project No

: Q6521

JEC-Q6521-00-III/L.02r/00001

Project Name : Laayoune Washing Plant

Imm. 5 - Znith Millenium - Lot. Attaoufik

Route Nouaceur - Sidi Marouf

Casablanca - 20270 Morocco