Академический Документы

Профессиональный Документы

Культура Документы

Selection of TEMA Class of Heat Exchanger

Загружено:

BalkundeАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Selection of TEMA Class of Heat Exchanger

Загружено:

BalkundeАвторское право:

Доступные форматы

7/9/13

SHELL AND TUBE HEAT EXCHANGERS

User's Guide | Editorial Board | Semantic Globe | Network | Directory | Back to Begell House

A-to-Z Guide to Thermodynamics, Heat & Mass Transfer, and Fluids Engineering

Home

A-Z Index

Fundamentals

Computational Methods

in All Articles

Experimental Techniques

Applications

History

SHELL AND TUBE HEAT EXCHANGERS

A

B

Brogan, R.J.

DOI: 10.1615/AtoZ.s.shell_and_tube_heat_exchangers

in Written Articles

in Commissioned Articles

Authors

Information For Authors

Full Text Article

Interlinking between Articles

Visual Navigation

RelatesLinks

D

E

F

General Description

Shell and Tube Heat Exchangers are one of the most popular types of exchanger due to the flexibility the designer has to

allow for a wide range of pressures and temperatures. There are two main categories of Shell and Tube exchanger:

1. those that are used in the petrochemical industry which tend to be covered by standards from TEMA, Tubular

Exchanger Manufacturers Association (see TEMA Standards);

2. those that are used in the power industry such as feedwater heaters and power plant condensers.

L

M

Regardless of the type of industry the exchanger is to be used in there are a number of common features (see Condensers

A shell and tube exchanger consists of a number of tubes mounted inside a cylindrical shell. Figure 1 illustrates a typical

unit that may be found in a petrochemical plant. Two fluids can exchange heat, one fluid flows over the outside of the

tubes while the second fluid flows through the tubes. The fluids can be single or two phase and can flow in a parallel or a

cross/counter flow arrangement.

R

S

SAFETY ASSESSMENT

SAFFMAN LENGTH

SALINE WATER RECLAMATION

SALT

SALT DILUTION METHOD FOR FILM

FLOW RATE MEASUREMENT

Figure 1. Shell and tube exchanger.

SALTATION

SALTING OUT

SAMPLING

SAMPLING METHODS, FOR DROPSIZE

MEASUREMENT

The shell and tube exchanger consists of four major parts:

Front Headerthis is where the fluid enters the tubeside of the exchanger. It is sometimes referred to as the Stationary

Header.

SAND BLASTING

SANDIA NATIONAL LABORATORY,

SNL

SATELLITES

SATURATED FLUID PROPERTIES

SATURATED SURFACES

SATURATED VOLUME

SATURATION PRESSURE

SATURATION TEMPERATURE

SAUTER MEAN DIAMETER

Rear Headerthis is where the tubeside fluid leaves the exchanger or where it is returned to the front header in

exchangers with multiple tubeside passes.

Tube bundlethis comprises of the tubes, tube sheets, baffles and tie rods etc. to hold the bundle together.

Shellthis contains the tube bundle.

The remainder of this section concentrates on exchangers that are covered by the TEMA Standard.

Shell and Tube Exchanger: Geometric Terminology

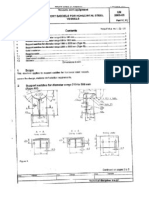

The main components of a shell and tube exchanger are shown in Figure 2 a, b and c and described in Table 1.

SCALE-UP OF PERFORATION PROCESS

SCALES OF TURBULENCE

SCALING

SCATTERING

SCATTERING AMPLITUDE

SCATTERING EFFICIENCY

SCATTERING INDICATRIX

SCATTERING OF RADIATION

SCATTERING PROBLEM FOR

CYLINDRICAL PARTICLES

SCHEIBEL EQUATION FOR DIFFUSION

www.thermopedia.com/content/1121/

1/10

7/9/13

SHELL AND TUBE HEAT EXCHANGERS

IN LIQUIDS

SCHLIEREN INTERFEROMETRY

SCHLIEREN TECHNIQUE

SCHMIDT NUMBER

SCHMIDT, ERNST (1892-1975)

SCHUSTER-HAMAKER MODEL

SCHUSTER-SCHWARZCHILD

APPROXIMATION, FOR COMBINED

RADIATION AND CONDUCTION

SCRAPED SURFACE HEAT

EXCHANGERS

SCREEN SEPARATORS

SCREENS

SCREW ROTARY COMPRESSOR

SCREWS, PLASTICATING

SCROLL DISCHARGE CENTRIFUGE

SCRUBBERS

SEA WATER COMPOSITION

SECOND LAW OF THERMODYNAMICS

SECOND NORMAL STRESS

DIFFERENCE COEFFICIENT

SECONDARY FLOWS

SECONDARY RECOVERY PROCESSES

SEDIMENTATION

SEDIMENTING CENTRIFUGES

SEEPAGE

SEGMENTAL BAFFLES

SEGREGATION

SEIDER-TATE CORRELATION

SELECTIVE FROTH FLOTATION

SELF ORGANIZATION

SELF-SIMILAR HARDENING BEHAVIOR

SELF-SIMILARITY

SEMI-CONDUCTOR THERMOMETERS

Figure 2. Type BEM, CFU and AES exchangers. 1988 by Tubular Exchanger Manufacturers Association.

SEMI-SLUG FLOWS

Table 1. Shell and tube geometric terminology

SEMI-TRANSPARENT MEDIA

CONTAINING BUBBLES

1 Stationary (Front) HeadChannel 20

Slip-on Backing Flange

2 Stationary (Front) HeadBonnet 21

Floating Tubesheet Skirt

Floating Tubesheet Skirt

SEMIANNULAR FLOW

SEMICONDUCTOR DIODE LASERS

SEMICONDUCTORS

Stationary (Front) Head Flange 22

Channel Cover

23

Stationary Head Nozzle

24

Packing

SENSIBLE HEAT STORAGE

Stationary Tubesheet

25

Packing Follower Ring

SEPARATED FLOW MODELS

Tubes

26

Lantern Ring

SEPARATED LIQUID FLOWS

Shell

27

Tie Rods and Spacers

Shell Cover

SEMITRANSPARENT MEDIA

SEPARATION OF BOUNDARY LAYERS

28Transverse Baffles or Support Plates

10Shell FlangeStationary Head End29

SEPARATION OF EMULSIONS

Packing Box Flange

Impingement Baffle or Plate

11

Shell FlangeRear Head End

30

12

Shell Nozzle

31

Pass Partition

SEPARATION OF GAS AND SOLIDS

13

Shell Cover Flange

32

Vent Connection

SEPARATION OF LIQUIDS

14

Expansion Joint

33

Drain Connection

SEPARATION OF LIQUIDS AND SOLIDS

15

Floating Tubesheet

34

Instrument Connection

SEPARATION OF PHASES IN GAS-

16

Floating Head Cover

35

Support Saddle

LIQUID FLOWS

17

Floating Head Flange

36

Lifting Lug

SEPARATION PROCESSES

18

Floating Head Backing Device

37

Support Bracket

19

Split Shear Ring

SEPARATION OF FLUID MIXTURES

SEPARATION, LIQUID/LIQUID

Longitudinal Baffle

SEPARATION, PARTICLES/LIQUID

Tema Designations

SERIES EXPANSIONS

The popularity of shell and tube exchangers has resulted in a standard nomenclature being developed for their

SESSILE DROPS AND BUBBLES

designation and use by the Tubular Exchanger Manufactures Association (TEMA). This nomenclature is defined in terms

SETTLING SLURRIES

letters and diagrams. The first letter describes the front header type, the second letter the shell type and the third letter the

www.thermopedia.com/content/1121/

2/10

7/9/13

SHELL AND TUBE HEAT EXCHANGERS

SEVERE ACCIDENTS, IN NUCLEAR

rear header type. Figure 2 shows examples of a BEM, CFU, and AES exchangers while Figure 3 illustrates the full TEMA

REACTORS, CONTAINMENT OF

nomenclature.

SHADOWGRAPH TECHNIQUE

SHAPE MEMORY

SHAPE OF VAPOR FORMATIONS IN

EXPLOSIVE BOILING

SHAPE SELECTIVE CATALYSIS

SHEAR FLOW

SHEAR LAYER

SHEAR MODULUS

SHEAR STRESS

SHEAR STRESS MEASUREMENT

SHEAR STRESS VELOCITY

SHEAR THICKENING

SHEAR THICKENING FLUIDS

SHEAR THINNING FLUIDS

SHEAR VISCOSITY

SHEARING INTERFEROGRAM

SHEATH CHARACTERISTICS

SHEET SPLITTING, IN DROP

FORMATION

SHELL AND TUBE CONDENSERS

SHELL AND TUBE HEAT EXCHANGERS

SHELL BOILER

SHELL PROGRESSIVE MODEL

SHELL-SIDE REFRIGERATION CHILLERS

SHELLS

SHERWOOD NUMBER

SHERWOOD, THOMAS KILGORE (19031976)

SHOCK TUBES

Figure 3. TEMA nomenclature. 1988 by Tubulare Exchanger Manufacturers Association.

SHOCK WAVE PROPAGATION

SHOCK WAVES

Many combinations of front header, shell and rear header can be made. The most common combinations for an E-Type

SHOCK WAVES, CONICAL

Shell are given in Table 2 but other combinations are also used.

SHORT ROUGHNESS STRIP

Table 2. Shell and tube geometric terminology

SHORT TIME LAPSE PHOTOGRAPHY

Fixed tubesheet exchangersU-tube exchangersFloating head exchangers

SHORT-TUBE VERTICAL EVAPORATOR

SHOT TOWERS

SHRINKING CORE MODEL

SI UNITS

AEL

AEU

AES

AEM

CEU

BES

AEN

DEU

BEL

SIDERITES

BEM

SIEVE, TRAY COLUMN

BEN

SILICA BASED NANOPOROUS

COMPOSITE MATERIALS

SILICA GEL

Essentially there are three main combinations

Fixed tubesheet exchangers

SILICON

SILICON CARBIDE

SILICON SOLAR CELLS

U-tube exchangers

Floating header exchangers

SILOS, GRANULAR FLOW FROM

SILVER

Fixed Tubesheet Exchanger (L, M, and N Type Rear Headers)

SILVER METHOD

In a fixed tubesheet exchanger, the tubesheet is welded to the shell. This results in a simple and economical construction and

SIMILARITY CONDITIONS

the tube bores can be cleaned mechanically or chemically. However, the outside surfaces of the tubes are inaccessible

SIMILARITY, THEORY OF

except to chemical cleaning.

SIMILITUDE

SIMPLEST APPROXIMATIONS OF

DOUBLE SPHERICAL HARMONICS

SIMPLEX ATOMIZER

If large temperature differences exist between the shell and tube materials, it may be necessary to incorporate an expansion

bellows in the shell, to eliminate excessive stresses caused by expansion. Such bellows are often a source of weakness and

failure in operation. In circumstances where the consequences of failure are particularly grave U-Tube or Floating Header

units are normally used.

SIMPLIFIED BOILING WATER REACTOR,

www.thermopedia.com/content/1121/

3/10

7/9/13

SHELL AND TUBE HEAT EXCHANGERS

SBWR

This is the cheapest of all removable bundle designs, but is generally slightly more expensive than a fixed tubesheet design

SIMULATING SUBSURFACE

at low pressures.

TEMPERATURE

SINCLAIR-LA MER AEROSOL

GENERATOR

SINGLET STATE

U-Tube Exchangers

In a U-Tube exchanger any of the front header types may be used and the rear header is normally a M-Type. The U-tubes

permit unlimited thermal expansion, the tube bundle can be removed for cleaning and small bundle to shell clearances can

SINGLET STATE LIFETIME

be achieved. However, since internal cleaning of the tubes by mechanical means is difficult, it is normal only to use this

SINGULARITIES, HYDRAULIC

type where the tube side fluids are clean.

RESISTANCE IN

SINTERING

Floating Head Exchanger (P, S, T and W Type Rear Headers)

SINUOUS JETS

In this type of exchanger the tubesheet at the Rear Header end is not welded to the shell but allowed to move or float. The

SIPHON CENTRIFUGE

tubesheet at the Front Header (tube side fluid inlet end) is of a larger diameter than the shell and is sealed in a similar

SKIMMER PIPE AND KNIFE

manner to that used in the fixed tubesheet design. The tubesheet at the rear header end of the shell is of slightly smaller

CENTRIFUGES

diameter than the shell, allowing the bundle to be pulled through the shell. The use of a floating head means that thermal

SKIN EFFECT

expansion can be allowed for and the tube bundle can be removed for cleaning. There are several rear header types that

SKIN FRICTION

SLAG FORMATION

SLIGHTLY DEFORMED POROUS

CIRCULAR CYLINDER

can be used but the S-Type Rear Head is the most popular. A floating head exchanger is suitable for the rigorous duties

associated with high temperatures and pressures but is more expensive (typically of order of 25% for carbon steel

construction) than the equivalent fixed tubesheet exchanger.

Considering each header and shell type in turn:

SLIGHTLY INCLINED SURFACEMOUNTED PRISMS

SLIP RATIO

A-Type front header

This type of header is easy to repair and replace. It also gives access to the tubes for cleaning or repair without having to

SLIT FLOW METERS

disturb the pipe work. It does however have two seals (one between the tube sheet and header and the other between the

SLIT FLOWS

header and the end plate). This increases the risk of leakage and the cost of the header over a B-Type Front Header.

SLOT-PERFORATED FLAT FINS

SLOW MOTION PHOTOGRAPHY

B-Type front header

SLUG FLOW

This is the cheapest type of front header. It also is more suitable than the A-Type Front Header for high pressure duties

SLUG FLOW, SOLID SUSPENSIONS

because the header has only one seal. A disadvantage is that to gain access to the tubes requires disturbance to the pipe

SLUG FREQUENCY

SLUG LENGTH

SLURRIES

SMALL ANCLE SCATTERING METHOD,

FOR DROPSIZE MEASUREMENT

SMELTING

SMOKE, AS AN AIR POLLUTANT

work in order to remove the header.

C-Type front header

This type of header is for high pressure applications (>100 bar). It does allow access to the tube without disturbing the

pipe work but is difficult to repair and replace because the tube bundle is an integral part of the header.

D-Type front header

This is the most expensive type of front header. It is for very high pressures (> 150 bar). It does allow access to the tubes

SMOKES

without disturbing the pipe work but is difficult to repair and replace because the tube bundle is an integral part of the

SNELL REFRACTION LAW

header.

SNL

SOAVE EQUATION

N-Type front header

SODA ASH

The advantage of this type of header is that the tubes can be accessed without disturbing the pipe work and it is cheaper

SODIUM

than an A-Type Front Header. However, they are difficult to maintain and replace as the header and tube sheet are an

SODIUM CARBONATE

SODIUM CHLORIDE

SODIUM COOLED NUCLEAR REACTOR

integral part of the shell.

Y-Type front header

Strictly speaking this is not a TEMA designated type but is generally recognized. It can be used as a front or rear header

SODIUM HYDROXIDE

and is used when the exchanger is to be used in a pipe line. It is cheaper than other types of headers as it reduces piping

SOFTENING OF WATER

costs. It is mainly used with single tube pass units although with suitable partitioning any odd number of passes can be

SOFTWARE ENGINEERING

allowed.

SOIL, THERMAL PROPERTIES

SOL

SOLAR AIR HEATERS

SOLAR CELLS

SOLAR COOKERS

SOLAR DRYING

E-Type shell

This is most commonly used shell type, suitable for most duties and applications. Other shell types only tend to be used

for special duties or applications.

F-Type shell

This is generally used when pure countercurrent flow is required in a two tube side pass unit. This is achieved by having

SOLAR ENERGY

two shells side passesthe two passes being separated by a longitudinal baffle. The main problem with this type of unit is

SOLAR ENERGY THERMAL

thermal and hydraulic leakage across this longitudinal baffle unless special precautions are taken.

CONVERSION

SOLAR PONDS

SOLAR RADIATION

G-Type shell

This is used for horizontal thermosyphon reboilers and applications where the shellside pressure drop needs to be kept

SOLAR RADIATION SPECTRUM

www.thermopedia.com/content/1121/

4/10

7/9/13

SHELL AND TUBE HEAT EXCHANGERS

SOLAR REFRIGERATION

small. This is achieved by splitting the shellside flow.

SOLAR SELECTIVE SURFACES

SOLAR SODIUM EVAPORATOR

H-Type shell

SOLAR STILLS

This is used for similar applications to G-Type Shell but tends to be used when larger units are required.

SOLAR WATER HEATERS

SOLENOIDAL FLOW

SOLID FUELS

J-Type shell

This tends to be used when the maximum allowable pressure drop is exceeded in an E-Type Shell even when double

segmental baffles are used. It is also used when tube vibration is a problem. The divided flow on the shellside reduces the

SOLID HOLDUP

flow velocities over the tubes and hence reduces the pressure drop and the likelihood of tube vibration. When there are

SOLID PROPELLANT

two inlet nozzles and one outlet nozzle this is sometimes referred to as an I-Type Shell.

SOLID STATE LASERS

SOLID-LIQUID-LIQUID FLOWS

K-Type shell

SOLIDIFICATION

This is used only for reboilers to provide a large disengagement space in order to minimize shellside liquid carry over.

SOLIDIFICATION CONSTANT

SOLIDOSITY

SOLIDS CONCENTRATION

SOLIDS IN LIQUIDS, BOILING HEAT

TRANSFER

SOLIDS SEPARATION

SOLIDS, THERMAL CONDUCTIVITY OF

SOLITARY WAVE

SOLITON

Alternatively a K-Type Shell may be used as a chiller. In this case the main process is to cool the tube side fluid by boiling

a fluid on the shellside.

X-Type shell

This is used if the maximum shellside pressure drop is exceeded by all other shell and baffle type combinations. The main

applications are shellside condensers and gas coolers.

L-Type rear header

This type of header is for use with fixed tubesheets only, since the tubesheet is welded to the shell and access to the

outside of the tubes is not possible. The main advantages of this type of header are that access can be gained to the inside

SOLUBILITY

of the tubes without having to remove any pipework and the bundle to shell clearances are small. The main disadvantage

SOLUBILITY OF GASES IN LIQUIDS

is that a bellows or an expansion roll are required to allow for large thermal expansions and this limits the permitted

SOLUBILITY OF SOLIDS IN LIQUIDS

operating temperature and pressure.

SOLUTE

SOLUTE DIFFUSION

SOLUTE FUNCTIONALITY

SOLUTION ALGORITHM

M-Type rear header

This type of header is similar to the L-Type Rear Header but it is slightly cheaper. However, the header has to be removed

to gain access to the inside of the tubes. Again, special measures have to be taken to cope with large thermal expansions

and this limits the permitted operating temperature and pressure.

SOLUTIONS

SOLUTIONS FOR ONE-DIMENSIONAL

RADIATIVE TRANSFER PROBLEMS

SOLVENT

N-Type rear header

The advantage of this type of header is that the tubes can be accessed without disturbing the pipe work. However, they

are difficult to maintain and replace since the header and tube sheet are an integral part of the shell.

SOLVENT EXTRACTION

SONIC OSCILLATOR

P-Type rear header

SONIC VELOCITY

This is an outside packed floating rear header. It is, in theory, a low cost floating head design which allows access to the

SONOCAPILLARY EFFECT

inside of the tubes for cleaning and also allows the bundle to be removed for cleaning. The main problems with this type

SOOT

of header are:

SORET AND DUFOUR EFFECTS ON

FREE CONVECTION

SORET EFFECT

SORPTION HEAT PUMPS

large bundle to shell clearances required in order to pull the bundle;

it is limited to low pressure nonhazardous fluids, because it is possible for the shellside fluid to leak via the packing

rings;

SOUND ABSORPTION

SOUND GENERATION

SOUND PROPAGATION

only small thermal expansions are permitted.

In practice it is not a low cost design, because the shell has to be rolled to small tolerances for the packing to be effective.

SOUR GASES

SOUTTER-ION PUMP

S-Type rear header

SPACE HEATING

This is a floating rear header with backing device. It is the most expensive of the floating head types but does allow the

SPACERS

SPACERS, EFFECT ON CHF

SPARK-IGNITION ENGINES

SPARSELY PACKED POROUS MEDIUM

bundle to be removed and unlimited thermal expansion is possible. It also has smaller shell to bundle clearances than the

other floating head types. However, it is difficult to dismantle for bundle pulling and the shell diameter and bundle to

shell clearances are larger than for fixed head type exchangers.

T-Type rear header

SPATIAL DISCRETIZATION SCHEMES

This is a pull through floating head. It is cheaper and easier to remove the bundle than with the S-Type Rear Header, but

SPATIAL-TEMPORAL CORRELATION

still allows for unlimited thermal expansion. It does, however, have the largest bundle to shell clearance of all the floating

SPECIFIC HEAT CAPACITY

head types and is more expensive than fixed header and U-tube types.

SPECIFIC WORK, IN TURBINES

SPECKLE METHOD

U-tube

SPECKLE PHOTOGRAPHY

This is the cheapest of all removable bundle designs, but is generally slightly more expensive than a fixed tubesheet design

www.thermopedia.com/content/1121/

5/10

7/9/13

SHELL AND TUBE HEAT EXCHANGERS

SPECTRA, EMISSION AND

at low pressures. However, it permits unlimited thermal expansion, allows the bundle to be removed to clean the outside

ABSORPTION

of the tubes, has the tightest bundle to shell clearances and is the simplest design. A disadvantage of the U-tube design is

SPECTRAL ANALYSIS

that it cannot normally have pure counterflow unless an F-Type Shell is used. Also, U-tube designs are limited to even

SPECTRAL DENSITY FUNCTION

numbers of tube passes.

SPECTRAL EMISSIVITY

SPECTRAL EXTINCTION METHOD

SPECTRAL RADIATIVE PROPERTIES OF

DIESEL FUEL DROPLETS

W-Type rear header

This is a packed floating tubesheet with lantern ring. It is the cheapest of the floating head designs, allows for unlimited

thermal expansion and allows the tube bundle to be removed for cleaning. The main problems with this type of head are:

SPECTRAL RADIATIVE PROPERTIES OF

DISPERSE SYSTEMS: THEORETICAL

the large bundle to shell clearances required to pull the bundle and;

MODELING AND EXPERIMENTAL

CHARACTERIZATION

SPECTRAL RADIATIVE PROPERTIES OF

the limitation to low pressure nonhazardous fluids (because it is possible for both the fluids to leak via the packing

rings).

SOME IMPORTANT MATERIALS:

EXPERIMENTAL DATA AND

THEORETICAL MODELS

SPECTROFLUORIMETRY

It is also possible for the shell and tube side fluids to become mixed if leakage occurs.

Geometric Options

SPECTROSCOPY

SPECULAR REFLECTION

SPEED OF LIGHT

SPEED OF SOUND

Tube diameter layout and pitch

Tubes may range in diameter from 12.7 mm (0.5 in) to 50.8 mm (2 in), but 19.05 mm (0.75 in) and 25.4 mm (1 in) are the

most common sizes. The tubes are laid out in triangular or square patterns in the tube sheets. See Figure 4.

SPENT FUEL

SPHERE, DRAG COEFFICIENT FOR

SPHERES, CONVECTIVE HEAT AND

MASS TRANSFER

SPHERES, DRAG AND LIFT

SPHERES, SOLID, DRAG ON

SPHERICITY

SPIRAL CLASSIFIER

SPIRAL HEAT EXCHANGERS

SPIRAL TUBES, USE IN BENSON

Figure 4. Tube layouts.

BOILERS

SPIROPYRAN

SPLATTERING, EFFECT ON JET

IMPINGEMENT

SPONTANEOUS CONDENSATION

SPRAY CHARACTERISTICS

SPRAY COLUMNS

The square layouts are required where it is necessary to get at the tube surface for mechanical cleaning. The triangular

arrangement allows more tubes in a given space. The tube pitch is the shortest center-to-center distance between tubes.

The tube spacing is given by the tube pitch/tube diameter ratio, which is normally 1.25 or 1.33. Since a square layout is

used for cleaning purposes, a minimum gap of 6.35 mm (0.25 in) is allowed between tubes.

Baffle types

SPRAY CONDENSERS

Baffles are installed on the shell side to give a higher heat-transfer rate due to increased turbulence and to support the

SPRAY COOLING

tubes thus reducing the chance of damage due to vibration. There are a number of different baffle types, which support

SPRAY DRYER

the tubes and promote flow across the tubes. Figure 5 shows the following baffle arrangements:

SPRAY DRYING

SPRAY EQUATION

SPRAY EVAPORATORS

Single Segmental (this is the most common),

Double Segmental (this is used to obtain a lower shellside velocity and pressure drop),

SPRAY FLOWS

SPRAY FORMATION

Disc and Doughnut.

SPRAY NOZZLES

SPRAY TOWERS

SPRAYERS

SPRAYING

SPRAYS

SPREADING OF LIQUIDS ON LIQUIDS

SPUTTERING

STABILITY

STABILITY CRITERIA

STABILITY OF EMULSIONS

STABILITY OF FLOATING BODIES

STACKS, POLLUTION FROM

STAGGERED TUBE BANKS

STAGNANT FILM MODEL

www.thermopedia.com/content/1121/

6/10

7/9/13

SHELL AND TUBE HEAT EXCHANGERS

STAGNATION POINT

STAGNATION PRESSURE

STAGNATION TEMPERATURE

STANDARD CONDITIONS

STANTON GAUGE

STANTON NUMBER

STANTON, SIR THOMAS EDWARD

(1865-1931)

STARK BROADENING

STARK NUMBER

STARS, FUSION REACTIONS IN

STATIC HEAD

STATIC INSTABILITIES IN TWO-PHASE

SYSTEMS

STATIC MIXERS

STATIC REGENERATORS

Figure 5. Baffle arrangements.

STATIONARY PHASE, SP,

CHROMATOGRAPHY

STATISTICAL MECHANICS

STATISTICAL THEORY, OF TURBULENT

The center-to-center distance between baffles is called the baffle-pitch and this can be adjusted to vary the crossflow

velocity. In practice the baffle pitch is not normally greater than a distance equal to the inside diameter of the shell or

FLOW

closer than a distance equal to one-fifth the diameter or 50.8 mm (2 in) whichever is greater. In order to allow the fluid to

STATISTICAL THERMODYNAMICS

flow backwards and forwards across the tubes part of the baffle is cut away. The height of this part is referred to as the

STEAM ENGINES

STEAM GAS TURBINE UNITS

baffle-cut and is measured as a percentage of the shell diameter, e.g., 25 per cent baffle-cut. The size of the baffle-cut (or

baffle window) needs to be considered along with the baffle pitch. It is normal to size the baffle-cut and baffle pitch to

approximately equalize the velocities through the window and in crossflow, respectively.

STEAM GENERATORS, NUCLEAR

STEAM JET EJECTORS

STEAM JET REFRIGERATION

There are two main types of baffle which give longitudinal flow:

Orifice Baffle,

STEAM TABLES

STEAM TURBINE

STEAM-WATER SEPARATION

Rod Baffle.

In these types of baffle the turbulence is generated as the flow crosses the baffle.

STEEL AND TUBE CONDENSERS

STEELS

STEFAN'S LAW

Heat Transfer Enhancements Devices

There are three main types.

STEFAN, JOSEF (1835-1893)

STEFAN-BOLTZMANN CONSTANT

Special surfaces

STEFAN-BOLTZMANN LAW

These tend to be used to promote nucleate boiling when the temperature driving force is small.

STEFAN-MAXWELL EQUATIONS

STEPWISE HEAT RELEASE

STEREOSCOPIC IMAGING

STEWARTSON TYPE FLOW

STIELTJES' INTEGRAL

STIRRED TANK REACTOR

Tube inserts

These are normally wire wound inserts or twisted tapes. They are normally used with medium to high viscosity fluids to

improve heat transfer by increasing turbulence. There is also some evidence that they reduce fouling. In order to use these

most effectively the exchanger should be designed for their use. This usually entails increasing the shell diameter, reducing

the tube length and the number of tubeside passes in order to allow for the increased pressure loss characteristics of the

devices.

STIRRED TANKS

STIRRED VESSEL PHASE INVERSION

Extended surfaces

STOCHASTIC DIFFERENTIAL

These are used to increase the heat transfer area when a stream has a low heat transfer coefficient. The most common type

EQUATIONS

is "low fin tubing" where typically the fins are 1.5 mm high at 19 fins per inch. (See also Augmentation of Heat Transfer.)

STOCHASTIC PROCESS

STOICHIOMETRIC COMBUSTION

Selection Criteria

STOKES EQUATION

In many cases the only way of ensuring optimum selection is to do a full design based on several alternative geometries.

STOKES FLOW

In the first instance, however, several important decisions have to be made concerning:

STOKES LENGTH

STOKES PARADOX

STOKES PROBLEM

allocation of fluids to the shellside and tubeside;

selection of shell type;

STOKES SHIFT

STOKES STREAM FUNCTION

STOKES' LAW FOR SOLID SPHERES

AND SPHERICAL BUBBLES

STOKES-EINSTEIN EQUATION

www.thermopedia.com/content/1121/

selection of front end header type;

selection of rear end header type;

selection of exchanger geometry.

7/10

7/9/13

SHELL AND TUBE HEAT EXCHANGERS

STOKES-EINSTEIN EQUATION, FOR

DIFFERENTIAL COEFFICIENTS IN

To a large extent these often depend on each other. For instance, the allocation of a dirty fluid to the shellside directly

LIQUIDS

affects the selection of exchanger tube layout.

STOMATAL CONTROL OF WATER

LOSS FROM PLANTS

Fluid allocation

STOPPING DISTANCE

When deciding which side to allocate the hot and cold fluids the following need to be taken into account, in order of

STORE'S FORMULA

priority.

STRAIN

STRAIN GAUGES

STRAIN RATE

STRANGE ATTRACTORS

STRATIFICATION, UNSTABLE AND

1. Consider any and every safety and reliability aspect and allocate fluids accordingly. Never allocate hazardous fluids

such they are contained by anything other than conventional bolted and gaskettedor weldedjoints.

2. Ensure that the allocation of fluids complies with established engineering practices, particularly those laid down in

customer specifications.

STABLE

STRATIFIED GAS-LIQUID FLOW

STRATIFIED WAVY FLOW

STRATOSPHERE

3. Having complied with the above, allocate the fluid likely to cause the most severe mechanical cleaning problems (if

any) to the tubeside.

4. If neither of the above are applicable, the allocation of the fluids should be decided only after running two alternative

STREAM ANALYSIS METHOD

designs and selecting the cheapest (this is time consuming if hand calculations are used but programs such as TASC

STREAM AVAILABILITY

from the Heat Transfer and Fluid Flow Service (HTFS) make this a trivial task).

STREAM FUNCTION

STREAMLINE

STREAMLINE FLOW

STREAMLINED BODIES, FLOW OVER

STREAMLINES

Shell selection

E-type shells are the most common. If a single tube pass is used and provided there are more than three baffles, then near

counter-current flow is achieved. If two or more tube passes are used, then it is not possible to obtain pure countercurrent

flow and the log mean temperature difference must be corrected to allow for combined cocurrent and countercurrent flow

using an F-factor.

STREAMLINES, VISUALIZATION

STREAMTUBE

STRESS

STRESS IN SOLID MATERIALS

G-type shells and H shells are normally specified only for horizontal thermosyphon reboilers. J shells and X-type shells

should be selected if the allowable DP cannot be accommodated in a reasonable E-type design. For services requiring

multiple shells with removable bundles, F-type shells can offer significant savings and should always be considered

provided they are not prohibited by customer specifications

STRESS TENSOR

STRESS VECTOR

Front header selection

STRESS, NORMAL

The A-type front header is the standard for dirty tubeside fluids and the B-type is the standard for clean tubeside fluids.

STRESS, SHEAR

The A-type is also preferred by many operators regardless of the cleanliness of the tubeside fluid in case access to the tubes

STRETCHING SHEET

is required. Do not use other types unless the following considerations apply.

STRETCHING SURFACE

A C-type head with removable shell should be considered for hazardous tubeside fluids, heavy bundles or services

STRETCHING/STABILIZING EFFLUX

requiring frequent shellside cleaning. The N-type head is used when hazardous fluids are on the tubeside. A D-type head

FLUID FILMS

or a B-type head welded to the tubesheet is used for high pressure applications. Y-type heads are only normally used for

STROUHAL NUMBER

single tube-pass exchangers when they are installed in line with a pipeline.

STRUCTURED SURFACE

STUART NUMBER

Rear header selection

SUBCHANNEL ANALYSIS

For normal service a Fixed Header (L, M, N-types) can be used provided that there is no overstressing due to differential

SUBCHANNEL MIXING

SUBCOOLED TWISTED FLOW

expansion and the shellside will not require mechanical cleaning. If thermal expansion is likely a fixed header with a

bellows can be used provided that the shellside fluid is not hazardous, the shellside pressure does not exceed 35 bar (500

psia) and the shellside will not require mechanical cleaning.

SUBCOOLING

SUBCOOLING EFFECTS ON POOL

A U-tube unit can be used to overcome thermal expansion problems and allow the bundle to be removed for cleaning.

BOILING

However, countercurrent flow can only be achieved by using an F-type shell and mechanical cleaning of the tubeside can

SUBLAYER FENCE

be difficult.

SUBLIMATION

An S-type floating head should be used when thermal expansion needs to be allowed for and access to both sides of the

SUBMERGED COMBUSTION

exchanger is required from cleaning. Other rear head types would not normally be considered except for the special cases.

SUBMERGED COMBUSTION

EVAPORATORS

Selection of Exchanger Geometry

SUBMERGED JETS

SUBROUTINES

SUBSTITUTE NATURAL GAS (SNG)

SUBSURFACE BARRIER

SUBUNDAL FLOW

Tube outside diameter

For the process industry, 19.05 mm (3/4") tends to be the most common.

Tube wall thickness

Reference must be made to a recognized pressure vessel code to decide this.

SUCTION

SUCTION EFFECTS

Tube length

SULFUR

For a given surface area, the longer the tube length the cheaper the exchanger, although a long thin exchanger may not

SULFUR DIOXIDE

be feasible.

www.thermopedia.com/content/1121/

8/10

7/9/13

SHELL AND TUBE HEAT EXCHANGERS

SULFUR HEXAFLUORIDE

Tube layout

SULFUR POLLUTION

45 or 90 degree layouts are chosen if mechanical cleaning is required, otherwise a 30 degree layout is often selected, because

SULFURIC ACID

it provides a higher heat transfer and hence smaller exchanger.

SUN, HEAT TRANSFER IN

SUPER-PHENIX

SUPERCAVITATION

SUPERCOMPUTING

Tube pitch

The smallest allowable pitch of 1.25 times the tube outside diameter is normally used unless there is a requirement to use a

larger pitch due to mechanical cleaning or tube end welding.

SUPERCONDUCTING MAGNETS

SUPERCONDUCTORS

SUPERCRITICAL HEAT TRANSFER

SUPERFICIAL VELOCITY

SUPERHEATING

Number of tube passes

This is usually one or an even number (not normally greater than 16). Increasing the number of passes increases the heat

transfer coefficient but care must be taken to ensure that the tube side v2 is not greater than about 10,000 kg/ms2.

Shell diameter

SUPERSATURATION

Standard pipe is normally used for shell diameters up to 610 mm (24"). Above this the shell is made from rolled plate.

SUPERSONIC EXTERNAL FLOW

Typically shell diameters range from 152 mm to 3000 mm (6" to 120").

SUPERSONIC FLOW

SUPERSONIC FLOW, IN NOZZLES

Baffle type

SUPERSONIC HETEROGENEOUS FLOW

Single segmental baffles are used by default but other types are considered if pressure drop constraints or vibration is a

SUPERSONIC JET

problem.

SUPERUNDAL FLOW

SUPPRESSION OF NUCLEATE BOILING

SURFACE ACTIVE SUBSTANCES

Baffle spacing

This is decided after trying to balance the desire for increased crossflow velocity and tube support (smaller baffle pitch) and

pressure drop constraints (larger baffle pitch). TEMA provides guidance on the maximum and minimum baffle pitch.

SURFACE ALLOYING OF METALS

SURFACE AND INTERFACIAL TENSION

Baffle cut

SURFACE CONDENSERS

This depends on the baffle type but is typically 45% for single segmental baffles and 25% for double segmental baffles.

SURFACE DIFFUSION

SURFACE DIMPLES

Nozzles and impingement

SURFACE EFFECTS ON BOILING

For shellside nozzles the v2 should not be greater than about 9000 in kg/ms2. For tubeside nozzles the maximum v

SURFACE EFFICIENCY

should not exceed 2230 kg/ms2 for noncorrosive, nonabrasive single phase fluids and 740 kg/ms2 for other fluids.

SURFACE ENERGY

Impingement protection is always required for gases which are corrosive or abrasive, saturated vapors and two phases

SURFACE EXTENSIONS

mixtures. Shell or bundle entrance or exit areas should be designed such that a v2 of 5950 kg/ms2 is not exceeded.

SURFACE FLOW VISUALIZATION

SURFACE ROUGHNESS

SURFACE TENSION

SURFACE TENSION DEVICES

SURFACE TREATMENT

SURFACE, CIRCULAR

SURFACE, PERMEABLE

Materials of Construction

In general, shell and tube exchangers are made of metal, but for specialist applications (e.g., involving strong acids or

pharmaceuticals), other materials such as graphite, plastic and glass may be used.

Thermal Design

The thermal design of a shell and tube exchanger is an iterative process which is normally carried out using computer

programs from organizations such as the Heat transfer and Fluid Flow Service (HTFS) or Heat Transfer Research

SURFACTANT COLLECTORS

Incorporated (HTRI). However, it is important that the engineer understands the logic behind the calculation. In order to

SURFACTANTS

calculate the heat transfer coefficients and pressure drops, initial decisions must be made on the sides the fluids are

SURGE TANKS

allocated, the front and rear header type, shell type, baffle type, tube diameter and tube layout. The tube length, shell

SUSPENSION OF PARTICLES IN LIQUID

SUTHERLAND COEFFICIENT

SWEATING

diameter, baffle pitch and number of tube passes are also selected and these are normally the main items that are altered

during each iteration in order to maximize the overall heat transfer within specified allowable pressure drops.

The main steps in the calculation are given below together with calculation methods in the open literature:

SWEETENING OF GASES

SWIRL BURNERS

SWIRL FLOW DEVICES

1. Calculate the shellside flow distribution [Use Bell-Delaware Method, see Hewitt, Shires, and Bott (1994)].

2. Calculate the shellside heat transfer coefficient (Use Bell- Delaware Method)

SWIRLING FLOW

SWIRLING TAPES, FOR INCREASING

BURNOUT FLUX

SYMMETRIC TENSOR

SYMMETRY ANALYSIS OF SECOND-

3. Calculate tubeside heat transfer coefficient (see, for example, Tubes: Single Phase Heat Transfer In).

4. Calculate tubeside pressure drop (see, for example, Pressure Drop, Single Phase).

5. Calculate wall resistance and overall heat transfer coefficient (see Overall Heat Transfer Coefficient and Fouling).

GRADE FLOW

SYNCHROTON RADIATION

SYNOPTIC SCALE CIRCULATION, OF

ATMOSPHERE

SYNTHETIC ZEOLITES

T

www.thermopedia.com/content/1121/

6. Calculate mean temperature difference (see Mean Temperature Difference).

7. Calculate area required.

8. Compare area required with area of assumed geometry and allowed tubeside and shellside pressure drop with

calculated values.

9/10

7/9/13

SHELL AND TUBE HEAT EXCHANGERS

U

9. Adjust assumed geometry and repeat calculations until Area required is achieved within the allowable pressure drops.

V

W

X

Y

Z

Books by E. A. D. Saunders [Saunders (1988)] and G. F. Hewitt, G. L. Shires, and T. R. Bott [Hewitt et al. (1994)] provides

a good overview of tubular thermal design methods and example calculations.

Mechanical Design

The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange

thickness, etc. These are calculated using a pressure vessel design code such as the Boiler and Pressure Vessel code from

ASME (American Society of Mechanical Engineers) and the British Master Pressure Vessel Standard, BS 5500. ASME is the

most commonly used code for heat exchangers and is in 11 sections. Section VIII (Confined Pressure Vessels) of the code is

the most applicable to heat exchangers but Sections IIMaterials and Section VNon Destructive Testing are also

relevant.

Both ASME and BS5500 are widely used and accepted throughout the world but some countries insist that their own

national codes are used. In order to try and simplify this the International Standards Organization is now attempting to

develop a new internationally recognized code but it is likely to be a some time before this is accepted.

References

1. TEMA Seventh Edition. (1988) Tubular Exchanger Manufacturers Association.

2. Saunders, E. A. D. (1988) Heat ExchangersSelection, Design and Construction, Longman Scientific and Technical.

3. Hewitt, G. F, Shires, G. L., and Bott, T. R. (1994) Process Heat Transfer, CRC Press.

4. Boiler and Pressure Vessel code, ASME (American Society of Mechanical Engineers).

5. British Master Pressure Vessel Standard, BS 5500.

Numbe r of vie ws: 45991

Article a dde d: 2 Fe bruary 2011

Article la st modifie d: 8 Fe brua ry 2011

Copyright 2010-2013

Back to top

Home | Contact Us | A-Z Index | Subscription Policy

www.thermopedia.com/content/1121/

10/10

Вам также может понравиться

- Heat Exchanger FinalДокумент35 страницHeat Exchanger Finalshabirahsan79Оценок пока нет

- Special Flange Joints Used in Floating-Head Shell-And-Tube Heat ExchangersДокумент5 страницSpecial Flange Joints Used in Floating-Head Shell-And-Tube Heat ExchangersBramJanssen76Оценок пока нет

- S&T HeДокумент32 страницыS&T HeArpit Sharma100% (1)

- KochДокумент181 страницаKochRichard FelipОценок пока нет

- Welding of Pressure VesselsДокумент2 страницыWelding of Pressure VesselsDvida PleasureОценок пока нет

- Sample Calculation ReportДокумент9 страницSample Calculation ReportmikimecОценок пока нет

- Saddle Support-Uhde SpecificationДокумент4 страницыSaddle Support-Uhde Specificationsandesh_honraoОценок пока нет

- Branch RF CalcДокумент6 страницBranch RF CalcHarish Harish0% (1)

- SEALING MANWAYSДокумент6 страницSEALING MANWAYSalokbdasОценок пока нет

- TQ - Air Fin Cooler (CS) - ModificationДокумент6 страницTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaОценок пока нет

- Ideas To Achieve Optimal Combination of Axial & Cross FlowДокумент28 страницIdeas To Achieve Optimal Combination of Axial & Cross FlowAmirah SufianОценок пока нет

- Studded Outlet HSB News Letter PDFДокумент4 страницыStudded Outlet HSB News Letter PDFG.SWAMIОценок пока нет

- Burst PR Calculation PDFДокумент1 страницаBurst PR Calculation PDFAranga KeerthiОценок пока нет

- 6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferДокумент35 страниц6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferAthar IqbalОценок пока нет

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsДокумент3 страницыSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- Introduction To Piping EngineeringДокумент33 страницыIntroduction To Piping EngineeringkysucoОценок пока нет

- ANSI FlangeДокумент10 страницANSI FlangemechftpОценок пока нет

- Heat Exchanger Design in PV EliteДокумент3 страницыHeat Exchanger Design in PV EliteShieeplОценок пока нет

- Pipe Thickness CalculationДокумент1 страницаPipe Thickness Calculationananyo_senguptaОценок пока нет

- Purchase Spec. For Nozzles Swage (Sa106b)Документ4 страницыPurchase Spec. For Nozzles Swage (Sa106b)Daison PaulОценок пока нет

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeДокумент18 страницeBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xОценок пока нет

- Installation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersДокумент5 страницInstallation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersCLIFFORDPAОценок пока нет

- Heat Exchanger Sizing E-7010 #1Документ2 страницыHeat Exchanger Sizing E-7010 #1Luis Enrique Leyva OvalleОценок пока нет

- UHX - Osweiller - WhitePaper PDFДокумент20 страницUHX - Osweiller - WhitePaper PDFMichael BasaОценок пока нет

- Tube Expander-Tools PDFДокумент120 страницTube Expander-Tools PDFmarceilinus devaluantoОценок пока нет

- Section IДокумент58 страницSection IARAVINDRAJ V RОценок пока нет

- AES Floating HeadДокумент8 страницAES Floating HeadArjun Singh AroraОценок пока нет

- Tech. Spec. For Heat ExchangersДокумент5 страницTech. Spec. For Heat Exchangerssanjay421Оценок пока нет

- Flange ø1 1/2Документ4 страницыFlange ø1 1/2dhiaa mohammedОценок пока нет

- Shell & Tube Installation, Operation & Maintenance ManualДокумент14 страницShell & Tube Installation, Operation & Maintenance Manualnidhul07Оценок пока нет

- Welcome To: Training Program On GUIDED TOUR OF ASME CodesДокумент120 страницWelcome To: Training Program On GUIDED TOUR OF ASME CodesAndri Konyoa KonyoaОценок пока нет

- BREECH LOCK Presentation Dec2004 Tcm24 226146Документ24 страницыBREECH LOCK Presentation Dec2004 Tcm24 226146Harinarayanan Samsari Kizhake VeetilОценок пока нет

- FRP Flange DesignДокумент29 страницFRP Flange DesignSubhadip RoyОценок пока нет

- What Is Design Interpretation?Документ17 страницWhat Is Design Interpretation?Qaisir MehmoodОценок пока нет

- BN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerДокумент1 страницаBN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerAlexDdd123Оценок пока нет

- Air Cooled Heat ExchangerДокумент15 страницAir Cooled Heat Exchangerros56Оценок пока нет

- ASME B31.3 Valve Selection GuideДокумент18 страницASME B31.3 Valve Selection GuideRyan Goh Chuang HongОценок пока нет

- Cone Design Tool: Pressure Vessel Engineering LTDДокумент1 страницаCone Design Tool: Pressure Vessel Engineering LTDkedubhajjiОценок пока нет

- NTIW Tube Sheet PaperДокумент10 страницNTIW Tube Sheet PaperPankaj SinglaОценок пока нет

- Rack Piping For A Piping Stress EngineerДокумент4 страницыRack Piping For A Piping Stress EngineerFaizal Khan100% (2)

- Pipe Wall THK Calc For External PressureДокумент2 страницыPipe Wall THK Calc For External PressurektejankarОценок пока нет

- 14-A Fluid Flow GeneralДокумент26 страниц14-A Fluid Flow GeneralSuara84Оценок пока нет

- ΔL, SIF, Hoop Stress, API StandardsДокумент3 страницыΔL, SIF, Hoop Stress, API StandardsVijay KumarОценок пока нет

- Pressure Design Straight Pipe (Run Pipe)Документ6 страницPressure Design Straight Pipe (Run Pipe)gembirasekaliОценок пока нет

- Spring Hanger Selection and Design Guidelines For A Piping Engineer Using Caesar IIДокумент6 страницSpring Hanger Selection and Design Guidelines For A Piping Engineer Using Caesar IIRomner CordovaОценок пока нет

- Gas Dehydration (ENGINEERING DESIGN GUIDELINE)Документ23 страницыGas Dehydration (ENGINEERING DESIGN GUIDELINE)Tu Dang TrongОценок пока нет

- 03 Metal Packing Support PlatesДокумент3 страницы03 Metal Packing Support PlatesypatelsОценок пока нет

- The Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeДокумент3 страницыThe Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeSrihari KodimelaОценок пока нет

- Flange Loading CheckДокумент48 страницFlange Loading CheckrefuzerОценок пока нет

- Shell and Tube Heat Exchanger Design ConsiderationsДокумент55 страницShell and Tube Heat Exchanger Design ConsiderationsCc12 22tОценок пока нет

- Questions Related To Stress Analysi1Документ12 страницQuestions Related To Stress Analysi1Jagadish JasОценок пока нет

- Piping TutorialДокумент46 страницPiping Tutorialjtkh1972100% (1)

- Pipe Thickness & RF Pad Calculations As Per Asme b313Документ3 страницыPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeОценок пока нет

- Shell and Tube Heat ExchangersДокумент13 страницShell and Tube Heat ExchangersLieu Dinh PhungОценок пока нет

- ThermopediaДокумент8 страницThermopediaAshwin ShettyОценок пока нет

- Classification According To Construction FeaturesДокумент30 страницClassification According To Construction FeaturesImraan KhanОценок пока нет

- What Is A Shell and Tube Heat ExchangerДокумент16 страницWhat Is A Shell and Tube Heat ExchangermnbОценок пока нет

- Heat Exchanger BasicsДокумент18 страницHeat Exchanger BasicsJefferson WintersОценок пока нет

- Biogas TECHДокумент33 страницыBiogas TECHBalkundeОценок пока нет

- PDF Shortcut KeysДокумент3 страницыPDF Shortcut KeysBalkundeОценок пока нет

- Ac VFDДокумент43 страницыAc VFDBalkundeОценок пока нет

- Distillation ColumnДокумент2 страницыDistillation ColumnBalkundeОценок пока нет

- How To Classify Refractory MaterialsДокумент3 страницыHow To Classify Refractory MaterialsBalkundeОценок пока нет

- FEED for Utilities Training Plant at ADNOC Technical InstituteДокумент10 страницFEED for Utilities Training Plant at ADNOC Technical InstituteBalkunde0% (1)

- Basics of Steam GenerationДокумент15 страницBasics of Steam GenerationsvkatkarОценок пока нет

- Construction of Babcock and Wilcox BoilerДокумент10 страницConstruction of Babcock and Wilcox BoilerBalkunde100% (1)

- Siemens LFE1 Data SheetДокумент14 страницSiemens LFE1 Data SheetJosé Fabio Lou0% (1)

- Unit Conversion All in OneДокумент32 767 страницUnit Conversion All in OneBalkundeОценок пока нет

- Field Bus GuideДокумент41 страницаField Bus GuideSriОценок пока нет

- Tech OverviewДокумент43 страницыTech OverviewVarun KumarОценок пока нет

- Wax PrecipitationДокумент3 страницыWax PrecipitationBalkundeОценок пока нет

- Globe Valve PGДокумент11 страницGlobe Valve PGBalkundeОценок пока нет

- Centrifugal Pumps Fundamentals Description OperationДокумент1 страницаCentrifugal Pumps Fundamentals Description OperationAnonymous ynJByUsОценок пока нет

- Intro To Pumping SystemsДокумент0 страницIntro To Pumping SystemssatstarОценок пока нет

- Flash DesignДокумент14 страницFlash Designdavoin_88Оценок пока нет

- Inlet Nozzles MomentumДокумент9 страницInlet Nozzles Momentum404FileNotFoundОценок пока нет

- Gaussian Plume ModelingДокумент101 страницаGaussian Plume ModelingCharlton Dave AranasОценок пока нет

- Cooling Tower Design Handbook PDF - 2Документ20 страницCooling Tower Design Handbook PDF - 2num0067Оценок пока нет

- YORK Marine Screw Chiller Units: Type MCSH-SДокумент2 страницыYORK Marine Screw Chiller Units: Type MCSH-SMike ErftmierОценок пока нет

- E 2181 - e 2181M - 01 - RtixodevrtixodfnДокумент9 страницE 2181 - e 2181M - 01 - RtixodevrtixodfnAlberto ApolonoОценок пока нет

- Heat Exchangers: The Effectiveness - NTU MethodДокумент15 страницHeat Exchangers: The Effectiveness - NTU MethodVenkitaraj K PОценок пока нет

- 1426kW BG Specs - Avus Biogas PDFДокумент12 страниц1426kW BG Specs - Avus Biogas PDFnavas1972100% (2)

- Round Tube and Plate Fin Air Cooled Condenser CalculationДокумент8 страницRound Tube and Plate Fin Air Cooled Condenser Calculationjamil100% (1)

- KELTEC Technolab CECOELДокумент40 страницKELTEC Technolab CECOELEber.CV100% (1)

- Steam Heating Process - Load CalculatingДокумент6 страницSteam Heating Process - Load CalculatingBi NguyễnОценок пока нет

- PLANT COOLING TOWER OPERATIONSДокумент24 страницыPLANT COOLING TOWER OPERATIONSAsyraf Sabri100% (1)

- Automatic Backflush Valve LeafletДокумент2 страницыAutomatic Backflush Valve LeafletSajane MassadaОценок пока нет

- 30M067 - PN-17 (01) LCI CommentsДокумент4 страницы30M067 - PN-17 (01) LCI Commentssteveh2401Оценок пока нет

- BE - EngGuide - YCAV - AirCooled Screw Liquid Chillers Style A 50 HZДокумент114 страницBE - EngGuide - YCAV - AirCooled Screw Liquid Chillers Style A 50 HZgerman aaron vizcarra alvarezОценок пока нет

- Tellhow Operation ManualДокумент54 страницыTellhow Operation Manualmenale libayeОценок пока нет

- General References On or Related To Heat Exchangers: Fundamentals of Heat Exchanger DesignДокумент5 страницGeneral References On or Related To Heat Exchangers: Fundamentals of Heat Exchanger DesignmnbОценок пока нет

- 1 Hvac Fundamentals 160216143402Документ55 страниц1 Hvac Fundamentals 160216143402ahmaborashedОценок пока нет

- Fairwind Catalogue 2015 PDFДокумент6 страницFairwind Catalogue 2015 PDFAnonymous USQOtosОценок пока нет

- TM MAC (60Hz) 2011 PDFДокумент28 страницTM MAC (60Hz) 2011 PDFgio_flores_4Оценок пока нет

- 04 PVT SamplingДокумент6 страниц04 PVT SamplingMohammad Iqbal Mahamad AmirОценок пока нет

- Product Name / Title Paraflow Plate Heat Exchangers: ApvheatexchangerДокумент8 страницProduct Name / Title Paraflow Plate Heat Exchangers: ApvheatexchangerGỗ MộcОценок пока нет

- Design and measurement of a CO2 refrigeration system with integrated propane subcoolerДокумент177 страницDesign and measurement of a CO2 refrigeration system with integrated propane subcoolerJESUS CATALAN GILОценок пока нет

- Guide to District Cooling Benefits and ImplementationДокумент14 страницGuide to District Cooling Benefits and Implementationاحمد الجزار2007Оценок пока нет

- Steam Consumption at Sulphitation / Raw Sugar Factories (Boiling House - Recent Trends)Документ6 страницSteam Consumption at Sulphitation / Raw Sugar Factories (Boiling House - Recent Trends)Yadav ShwetaОценок пока нет

- Heat Exchanger Mid-Term ReportДокумент18 страницHeat Exchanger Mid-Term ReportkoanakistОценок пока нет

- 30hr, Hs 4pd 1Документ36 страниц30hr, Hs 4pd 1rogel_ganaОценок пока нет

- CL (09,12) 216 - Service Manual - ENДокумент64 страницыCL (09,12) 216 - Service Manual - ENTatiana DiazОценок пока нет

- Transport Air Conditioning: With BT324 Carrier Sutrak Digital Display (CSDD) or 280P/282P Electronic ThermostatДокумент63 страницыTransport Air Conditioning: With BT324 Carrier Sutrak Digital Display (CSDD) or 280P/282P Electronic Thermostatdario castro100% (1)

- KRONES Double-end bottle washersДокумент14 страницKRONES Double-end bottle washersMike MichaelidesОценок пока нет

- PHE01 M6M 102P 1600kWДокумент1 страницаPHE01 M6M 102P 1600kWtsoomoo tsolmonОценок пока нет

- Distillation Column DesignДокумент66 страницDistillation Column Designsalmanmuddsar83% (6)

- Pressure Vessel - For LETHAL ServiceДокумент3 страницыPressure Vessel - For LETHAL ServiceGene Andrew OnaОценок пока нет