Академический Документы

Профессиональный Документы

Культура Документы

CH432 436 Brochure

Загружено:

watson123Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CH432 436 Brochure

Загружено:

watson123Авторское право:

Доступные форматы

P

T E C H N O L O G Y

Stainless Steel Submersible Drainage Pumps

Multi Channel Impeller with 1 1/4 or 1 3/4 Solid Size

2 and 2 1/2 Discharge

CH 432, CH 436

Performance

Total 120

Head

110

(FT)

100

90

80

70

7

60

50

40

30

20

10

0

20

40

60

80

100

120

140

160

180

200

220

240

FLOW (USGPM)

Application

HOMA CH 432 and CH 436 stainless steel submersible drainage

pumps are suitable for pumping

corrosive, abrasive or chemically

aggressive liquids, drainage water

or chemicals*) containing soft

solids up to 13/4 diameter. They

are used in various domestic, industrial or municipal applications.

Typical Fluids Handled are:

Drainage water

Effluent with soft solids

Chemically aggressive liquids*

Liquids to 140 F can be handled

intermittently*

CH Series Pumps are typically

used in:

Industrial and commercial

drainage

Industrial chemical waste or

effluents

Optional Factory Mutual (FM)

label for Class I, Div 1 EX

construction.

* According to specific chemical

resistance of used materials

Features

Integral Lift Handle is

arched to permit self

centering of lifting device

Pump- and Motor Housing

made of stainless steel for

maximum chemical

resistance*)

Extra Long Replaceable power

cable of 33' length

is retained and

sealed with a strain

relief gland

Mechanical Seals

(silicon-carbide/

silicon-carbide)

Adjustable

Stainless Steel

Suction Cover

Upper and Lower High

Capacity Ball Bearings

assure long life and

reliability

Motor windings provided with Class F

insulation and fully

protected by embedded

auto reset thermal

switches

Oil Filled Seal Chamber

positively lubricates

seals and permits a seal

leakage probe to be

installed

Open Multi Channel Impeller

made of Stainless Steel

Motor Construction

Installations

Motor Type :

Enclosed Submersible

NEMA Insulation Code :

Class F

Service Factor :

1.15

NEMA Design Type :

B

Standard Cable Length :

33 ft

Available Motor Voltages :

1 Phase : 115 V, 200 V, 230 V

3 Phase : 200 V, 230 V, 380 V,

460 V, 575 V

Optional Explosion Proof

construction :

Factory Mutual approved for Class I,

Div. 1, Group C & D.

Wet pit with autocoupling

Materials

Dimensions (inches) (Tolerance +/- 1/4)

6 1/2

5

3/4

1/2

15

3

2 M

9 1/4

6 1/4

1/2

5 1/2

6 3/4 O.D.

Anchor

bolt

1/2

9 1/4

2 1/4

1/2

2 1/2 M

7 3/4 O.D.

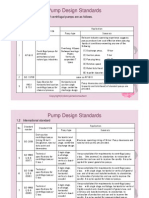

Technical Data

Curve

No.

1

2

3

4

5

6

7

Pump Type

Rated

B.H.P.

Phase

Voltage

(V)

Full Load

Amps

Speed

(rpm)

Discharge

BSP

Weight

(LBS)

NEMA

code

CH432/20/2/1

CH432/19/2/3

CH432/24/2/1

CH432/24/2/3

CH436/28/2/3

CH436/38/2 / 3

CH436/54/2 / 3

1.5

1.4

1.8

1.8

2.2

3.0

4.3

1

3

1

3

3

3

3

230

230/380/460

230

230/380/460

230/380/460

230/380/460

230/380/460

6.9

4.2/2.5/2.1

8.0

5.2/3.2/2.6

6.8/4.1/3.4

8.2/5.0/4.1

11.4/6.9/5.7

3450

3450

3450

3450

3450

3450

3450

2 M

2 M

2 M

2 M

21/2 M

21/2 M

21/2 M

62

62

62

62

88

88

112

G

G

F

H

H

H

F

We reserve the right to alter our specifications without notice!

12 1/4

1/2

5 1/2

9 1/2

15

3 1/2

1/2

9 3/4

6 1/4

9 1/4

18 1/2

2 M

21 - 22 1/4

Flange

2 1/2 ANSI 3 1/2

125 lb/sq. in. RF 5

2 - 11 1/2 NPT

Pipe 1

19 1/4 - 20 1/4

111/4

Pipe 1

3 1/2

Anchor

bolt

4 1/4

3 1/2

19 1/4 - 20 1/4

CH 436

16 1/4

13

1 3/4

4 1/2

7 1/4

8 3/4

7 1/4

6

4 3/4

1/2

1/2

3 1/2

9

22 3/4

Anchor

bolt

3 1/2

3 1/4

1 1/2

16 3/4

Anchor

bolt

CH 432

7 1/4

CH 436

4 1/4

CH 432

7 3/4

Motor Housing, Volute and Impeller

Stainless Steel AISI 316

Mechanical Seals Impeller side

Silicon Carbide vs Silicon Carbide,

Viton

Shaft Seal Motor side

Mechanical Seal

Silicon Carbide vs Silicon Carbide,

Viton

O-Rings : FPM (Viton)

Upper Bearing :

Deep groove Ball Bearing

Lower Bearing :

Double row angular Ball Bearing

Power Cable Protective Hose:

Polyolefine

Shaft : AISI 430 F

Fasteners : AISI 304 SS

Basestand

Вам также может понравиться

- Valvula ASCO Falcon SB2500Документ2 страницыValvula ASCO Falcon SB2500Elmer HuashuayoОценок пока нет

- So Do Binh Tich ApДокумент3 страницыSo Do Binh Tich ApLongTranThienОценок пока нет

- Sta-Rite PRO-Storm DSS Series: Multi-Stage Sprinkler PumpsДокумент2 страницыSta-Rite PRO-Storm DSS Series: Multi-Stage Sprinkler PumpsDagoberto CerrudОценок пока нет

- Burmad 400 Series-Globe Type Deluge ValveДокумент8 страницBurmad 400 Series-Globe Type Deluge Valvenastyn-1Оценок пока нет

- PumpeДокумент4 страницыPumpesah8azОценок пока нет

- Manufacturing Range En-2012Документ32 страницыManufacturing Range En-2012mmihai_popa200650% (2)

- FlowMon Catalogue 2Документ12 страницFlowMon Catalogue 2dhanu_aquaОценок пока нет

- Floor Drains Floor Trap CombinationsДокумент30 страницFloor Drains Floor Trap CombinationsMInhОценок пока нет

- Model 2100bДокумент4 страницыModel 2100bkeyur1109Оценок пока нет

- Spirax Sarco Ball Float PDFДокумент12 страницSpirax Sarco Ball Float PDFchanayireОценок пока нет

- DW PompaДокумент32 страницыDW PompaluxorraОценок пока нет

- Bronze 40 GPM Diaphragm Pump & Pump Out Hose AssemblyДокумент4 страницыBronze 40 GPM Diaphragm Pump & Pump Out Hose AssemblyRoger AklОценок пока нет

- InstrumentationДокумент15 страницInstrumentationLenis Ceron0% (1)

- Pompe EbaraДокумент5 страницPompe EbarafouadОценок пока нет

- Pump Standards ComparisonДокумент4 страницыPump Standards ComparisonAnish Dani50% (2)

- Potopna Crpka PEDROLLO MC I Double Channel BrosuraДокумент4 страницыPotopna Crpka PEDROLLO MC I Double Channel Brosurajose03Оценок пока нет

- Calpeda MXV Pump Product GuideДокумент24 страницыCalpeda MXV Pump Product GuideWayne SeamanОценок пока нет

- Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDДокумент11 страницInline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDAllan ArraisОценок пока нет

- Fire DRY HydrantsДокумент4 страницыFire DRY HydrantsAbdullah RamadanОценок пока нет

- PPA PEMO Filter Press Pumps PresentationДокумент18 страницPPA PEMO Filter Press Pumps Presentationmakinist29Оценок пока нет

- AG Quick Release ENProДокумент4 страницыAG Quick Release ENProNatalia WinataОценок пока нет

- Espec - Tec.bombas Lowara DL A 60HzДокумент39 страницEspec - Tec.bombas Lowara DL A 60HzpapashoОценок пока нет

- Pedrollo 2CPДокумент8 страницPedrollo 2CPBenicio Joaquín Ferrero BrebesОценок пока нет

- Rig 104 InventoryДокумент16 страницRig 104 InventorypetricamafteiОценок пока нет

- Built For Work: Sewage and Wastewater PumpsДокумент2 страницыBuilt For Work: Sewage and Wastewater PumpshuuquantlОценок пока нет

- VX136 105 Pos1 Piggy BackДокумент3 страницыVX136 105 Pos1 Piggy BackCretu DanОценок пока нет

- Products 1. Plastic Pipes & FittingsДокумент5 страницProducts 1. Plastic Pipes & FittingsFredrick Omondi OleweОценок пока нет

- Amacan PДокумент52 страницыAmacan PGogyОценок пока нет

- General Service Gauge Type 1009, ASME B 40.1 Grade 1A ( 1% of Span)Документ1 страницаGeneral Service Gauge Type 1009, ASME B 40.1 Grade 1A ( 1% of Span)yrull24Оценок пока нет

- Fisa Tehnica Pompe MultifreeДокумент10 страницFisa Tehnica Pompe MultifreeOčtáv VátčoОценок пока нет

- PLL 2144Документ80 страницPLL 2144Amit TandelОценок пока нет

- SKUM Over The Top Foam Generators OFG OFGR-0917Документ4 страницыSKUM Over The Top Foam Generators OFG OFGR-0917Lee Liang ChenОценок пока нет

- Hydratron HPU-AZ-1-5 REV1Документ2 страницыHydratron HPU-AZ-1-5 REV1Youtube For Education0% (1)

- Sandpiper HDF2Документ6 страницSandpiper HDF2samago20Оценок пока нет

- 12S Series: High Pressure FiltersДокумент6 страниц12S Series: High Pressure FiltersPartsGopher.comОценок пока нет

- ASCO 35-1 General Service 3-Way Valves PDFДокумент36 страницASCO 35-1 General Service 3-Way Valves PDFprsiva2420034066Оценок пока нет

- Bombas Plasticas MANUAL PDFДокумент41 страницаBombas Plasticas MANUAL PDFcapry_cornio@yahoo.com100% (1)

- Rambha HiДокумент4 страницыRambha Hianon_764661013Оценок пока нет

- Flutec High Pressure Ball ValveДокумент2 страницыFlutec High Pressure Ball ValvefahazumeeОценок пока нет

- (Level Switch) DS - MS50-EN - X - 07 - 2016Документ8 страниц(Level Switch) DS - MS50-EN - X - 07 - 2016galih santosoОценок пока нет

- Liq TurbineFM Series1500 DSДокумент12 страницLiq TurbineFM Series1500 DSElinton De Jesus SarmientoОценок пока нет

- Descote 2100BДокумент4 страницыDescote 2100BarrikanОценок пока нет

- Electro Válvula Del CompresorДокумент4 страницыElectro Válvula Del CompresorneumaticoОценок пока нет

- 8214 200aДокумент8 страниц8214 200aisaac-espinosa-430Оценок пока нет

- Technical Specifications For Centrifugal Pumps PDFДокумент12 страницTechnical Specifications For Centrifugal Pumps PDFVicky GautamОценок пока нет

- Angus (Fire Monitor)Документ2 страницыAngus (Fire Monitor)Zack LeeОценок пока нет

- 1 6001 PDFДокумент12 страниц1 6001 PDFoleg-spbОценок пока нет

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileОт EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileОценок пока нет

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1От EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Рейтинг: 3.5 из 5 звезд3.5/5 (3)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerОт EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerРейтинг: 5 из 5 звезд5/5 (1)

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldОт EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldРейтинг: 3 из 5 звезд3/5 (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceОт EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceРейтинг: 5 из 5 звезд5/5 (1)

- Gridgen VersionДокумент34 страницыGridgen Versionwatson123Оценок пока нет

- Econ 501 A L1Документ6 страницEcon 501 A L1watson123Оценок пока нет

- A Series Dry Pit Closed Loop Horizontal MT Tech SpecДокумент2 страницыA Series Dry Pit Closed Loop Horizontal MT Tech Specwatson123Оценок пока нет

- Meet. Abstr. 2010 Alzate 272Документ1 страницаMeet. Abstr. 2010 Alzate 272watson123Оценок пока нет

- License AgreementДокумент1 страницаLicense Agreementwatson123Оценок пока нет

- VSpace Server 6.6.9.1 Release NotesДокумент8 страницVSpace Server 6.6.9.1 Release NotesCleber Fabio Dos SantosОценок пока нет

- IT Administrator CV TemplateДокумент2 страницыIT Administrator CV TemplateJake Mends NarhОценок пока нет

- Pitot Probes PDFДокумент1 страницаPitot Probes PDFwatson123Оценок пока нет

- 05 Flyer Testo 330 EN PDFДокумент2 страницы05 Flyer Testo 330 EN PDFwatson123Оценок пока нет

- WinCC FelxibleДокумент2 страницыWinCC Felxiblewatson123Оценок пока нет

- Kerosene: Cautionary Response InformationДокумент2 страницыKerosene: Cautionary Response InformationMohsin KhanОценок пока нет

- Heating Value of Different FuelДокумент1 страницаHeating Value of Different Fuelwatson123Оценок пока нет

- Homework 11Документ2 страницыHomework 11watson123Оценок пока нет

- Fake LatexДокумент3 страницыFake LatexkinthavongОценок пока нет

- This Is The Title: Author One Author Two 29 February 2004Документ1 страницаThis Is The Title: Author One Author Two 29 February 2004watson123Оценок пока нет

- visualNastran4D PDFДокумент2 страницыvisualNastran4D PDFwatson123Оценок пока нет

- How To Read A MicrometerДокумент1 страницаHow To Read A Micrometerwatson123Оценок пока нет

- SolidmodelingДокумент21 страницаSolidmodelingwatson123Оценок пока нет

- License AgreementДокумент1 страницаLicense Agreementwatson123Оценок пока нет

- MechanismsДокумент14 страницMechanismswatson123Оценок пока нет

- TestoДокумент5 страницTestowatson123Оценок пока нет

- Press AltДокумент2 страницыPress Altm_ciarelliОценок пока нет

- TestoДокумент2 страницыTestowatson123Оценок пока нет

- Protea 3.6SPДокумент3 страницыProtea 3.6SPwatson123Оценок пока нет

- TR 95 51Документ13 страницTR 95 51watson123Оценок пока нет

- Diffrence Between Phase and Group VelocityДокумент1 страницаDiffrence Between Phase and Group VelocityMark GutierrezОценок пока нет

- Asme-Ansi B36Документ2 страницыAsme-Ansi B36pepelefuuОценок пока нет

- PUMPSДокумент24 страницыPUMPSwatson123Оценок пока нет

- A Guide To The ANSI Z358.1-2009 StandardДокумент3 страницыA Guide To The ANSI Z358.1-2009 Standardwatson123Оценок пока нет

- Product Management PRELIM EXAMДокумент24 страницыProduct Management PRELIM EXAMAlyssa marieОценок пока нет

- Management Information Systems and Corporate Decision - Making: A Literature ReviewДокумент5 страницManagement Information Systems and Corporate Decision - Making: A Literature Reviewvaaz205Оценок пока нет

- UT Dallas Syllabus For Math3303.501.10f Taught by Phillip Kisunzu (pxk091000)Документ7 страницUT Dallas Syllabus For Math3303.501.10f Taught by Phillip Kisunzu (pxk091000)UT Dallas Provost's Technology GroupОценок пока нет

- Pre-Test Chapter 19 Ed17Документ8 страницPre-Test Chapter 19 Ed17Sarah ZeidatОценок пока нет

- One Word SubstitutionДокумент5 страницOne Word SubstitutionPranaykant Singh PanwarОценок пока нет

- Cop4600 Exam1 sp13Документ2 страницыCop4600 Exam1 sp13chavОценок пока нет

- Mae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3Документ38 страницMae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3زهديابوانسОценок пока нет

- Purchasing Process Models Inspiration For Teac 2019 Journal of Purchasing AДокумент11 страницPurchasing Process Models Inspiration For Teac 2019 Journal of Purchasing ASunita ChayalОценок пока нет

- Metaphor-Spatiality-Discourse - 10-11 July 2020 - Programme - FINALДокумент6 страницMetaphor-Spatiality-Discourse - 10-11 July 2020 - Programme - FINALkostyelОценок пока нет

- Pascal LawДокумент17 страницPascal LawJasmandeep brarОценок пока нет

- Department of Education: Activity Completion ReportДокумент1 страницаDepartment of Education: Activity Completion ReportJanineJavier100% (1)

- 1-Perceived Threat of Covid-19 and T.I (Reference Article)Документ10 страниц1-Perceived Threat of Covid-19 and T.I (Reference Article)Hassan NadeemОценок пока нет

- Report - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222Документ23 страницыReport - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222jawwadraja100% (1)

- Lecture 12 Public Administration and Development 2017Документ23 страницыLecture 12 Public Administration and Development 2017Raheel Joyia100% (1)

- Elephant Catalog V13 PDFДокумент96 страницElephant Catalog V13 PDFsamuelОценок пока нет

- Module 6: Stresses Around Underground Openings: 6.6 Excavation Shape and Boundary StressДокумент10 страницModule 6: Stresses Around Underground Openings: 6.6 Excavation Shape and Boundary Stressفردوس سليمانОценок пока нет

- Lesson4 1515Документ14 страницLesson4 1515gm hashОценок пока нет

- Survey 2 Module 2Документ76 страницSurvey 2 Module 2veereshОценок пока нет

- Fashion Design and Product DevelopmentДокумент6 страницFashion Design and Product DevelopmentYona Tasya AzizieОценок пока нет

- Antennas L01Документ15 страницAntennas L01Domenico RizzoОценок пока нет

- 136 OsgoodeДокумент8 страниц136 Osgoodejawaid6970Оценок пока нет

- 78-SAFETY - QUESTIO in PDFДокумент21 страница78-SAFETY - QUESTIO in PDFIndermohan MehtaОценок пока нет

- TSS Training Package Implementation Guidefinal 0Документ18 страницTSS Training Package Implementation Guidefinal 0hanabbecharaОценок пока нет

- USDP Shehzore02Документ39 страницUSDP Shehzore02Feroz GullОценок пока нет

- NewspaperДокумент1 страницаNewspaperMustafa Nabeel ZamanОценок пока нет

- Review Chapter 2Документ46 страницReview Chapter 2JennysanОценок пока нет

- Simulation & Role PlayДокумент10 страницSimulation & Role Playpreeti sharma100% (2)

- Anti FoundationalismДокумент4 страницыAnti FoundationalismKostasBaliotisОценок пока нет

- GE 8 ETHICS Week2 9Документ54 страницыGE 8 ETHICS Week2 9Jay Ar OmbleroОценок пока нет