Академический Документы

Профессиональный Документы

Культура Документы

Wash Pipe or No Wash Pipe That Is The Question

Загружено:

zbhdzpОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Wash Pipe or No Wash Pipe That Is The Question

Загружено:

zbhdzpАвторское право:

Доступные форматы

OTC 16051

Wash Pipe Or No Wash Pipe? That is The Question

Francisco Pineda, SPE, Bryce Traweek, and James Curtis, SPE, BJ Services Company

Copyright 2004, Offshore Technology Conference

This paper was prepared for presentation at the Offshore Technology Conference held in

Houston, Texas, U.S.A., 36 May 2004.

This paper was selected for presentation by an OTC Program Committee following review of

information contained in an abstract submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Offshore Technology Conference and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Offshore Technology Conference or officers. Electronic reproduction,

distribution, or storage of any part of this paper for commercial purposes without the written

consent of the Offshore Technology Conference is prohibited. Permission to reproduce in print

is restricted to an abstract of not more than 300 words; illustrations may not be copied. The

abstract must contain conspicuous acknowledgment of where and by whom the paper was

presented.

Abstract

Conventional gravel pack or frac pack completions typically

require the use of wash pipe to act as a conduit for fluid

returns as well to carry a shifting mechanism to open or close

a return port. Using properly sized wash pipe can enhance the

placement of the gravel across the entire annular space and the

formation. It can be used in conjunction with a shifting

mechanism and a sliding sleeve to force the fluid returns to

pass through the bottom of the screen. It can allow a washdown capability while running the assembly into hole. In

specialty systems, it can even act as a pumping conduit for

post-gravel pack stimulation.

However, the use of wash pipe, especially in long

horizontal wells, means the loss of valuable rig time due to

make up and break up of the wash pipe, or recovery if the

wash pipe is stuck. Economic considerations, along with

completion efficiencies, are especially important on deepwater

completions.

Not using wash pipe reduces rig time,

generating significant cost savings, and also eliminates the risk

of sticking it.

This paper reviews conventional wash pipe applications

and describes new systems that accomplish the same goal with

a minimum amount of wash pipe or no wash pipe at all.

Uses of Wash Pipe

The production of formation sand into a well is one of the

oldest problems plaguing the oil and gas industry because its

adverse effects on well productivity and equipment.1

Gravel packing and frac packing are the methods of choice

for sand control. In combination with sand screens they

provide downhole filters to prevent production of formation

sand. During the execution of these methods, a properly sized

sand or proppant has to be placed in the formation as well as

the annulus of the screen-casing or screen-open hole using a

gravel pack packer assembly with a gravel pack service tool

and wash pipe inside the sand screen, with its bottom hanging

as close as possible to the end of the screen. This

configuration aids the placement of the sand or proppant by

allowing the gravel pack fluids to travel down the tubing,

through and out the ports of the gravel pack service tool and

assembly, down the blank/screen-casing or open hole annulus,

into the perforations or open hole, through the screen, up the

wash pipe and gravel pack service tool, and into the gravel

pack packer-casing annulus.

Wash pipe can also be use as a conduit to allow washdown capabilities when installing screens or liners. In

isolation systems, wash pipe is used to run shifting tools to

activate sliding sleeves in order to achieve returns during

gravel packing.

There are also other economic factors to consider when

using wash pipe, such as the valuable rig time necessary for

making up, running in and breaking up, especially in

horizontal wells, and also in the unfortunate case of fishing if

the wash pipe becomes stuck.

Wash Pipe Selection Criteria

Proper selection criteria include strength, material, connection

type, and diameter. Strength must exceed the maximum

expected tensile load, however the internal diameter should

also be maximized in order to minimize flow friction and

facilitate fluid returns. The preferred connection type is a

flush joint to prevent sticking and to allow downward flow in

the wash pipe screen annulus near the end of the treatment.

Properly sized wash pipe is as important as properly sized

sand screen. The generally accepted optimum ratio of the ID

of the screen to the OD of the wash pipe is 0.8 or greater, in

order to facilitate return flow up the wash pipe.2 This also

results in a narrow wash pipe screen annulus, which favors

fluid flow on the outside rather than the inside of the screen,

due to the higher friction pressure in the inner annulus.

Premature bridging and a possible screen out is discouraged.

This could occur when the fluid enters the screen/wash pipe

annulus, depositing gravel in the outer annulus and possibly

causing premature bridging. The most common screen/wash

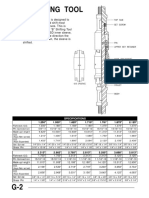

pipe configurations are shown in Table 1.

RATIO

Washpipe (FJ)

Nom.

lb/ft

OD (in)

*

Size (in)

1.995

1

2.25

1.315

0.7

2.441

1 1/4

5.18

1.660

0.7

2.992

2 3/8

5.95

2.375

0.8

3.548

2 7/8

6.40

2.875

0.8

3.875

2 7/8

6.40

2.875

0.7

4.276

3 1/2

9.20

3.500

0.8

4.892

0.8

4

11.60

4.000

4.670

0.7

3 1/2

9.20

3.500

5.675

4

11.60

4.000

0.7

* Washpipe screen OD - ID ratio - 0.8 Optimum

BLANK & SCREEN

Size (in)

lb/ft

2 3/8

2 7/8

3 1/2

4

4 1/2

5

4.70

6.50

9.30

9.50

11.60

18.00

17.00

23.00

32.00

5 1/2

6 5/8

ID (in)

Table 1 Wash Pipe Selection Table

OTC 16051

Gravel Pack Systems with Wash Pipe

Hydraulic setting tool

Standard Gravel Pack Assembly

In this conventional system the wash pipe serves as a conduit

to aid circulation of the gravel pack fluids to the bottom of the

annulus of the screen/casing or screen/open hole, as shown in

Fig. 1. Wash pipe OD - screen ID ratio should optimally be

0.8. This basic system has been in use in the industry for

decades.

GP Packer

Multi-Service Closing

Sleeve

Service tool with shifting and

circulating valve

Safety Joint

Hydraulic setting tool

Blank

Isolation Tubing

GP Packer

Sliding Sleeves

(Production)

Screen

Multi-Service

Closing Sleeve

Service tool with shifting

and circulating valve

Sliding Sleeves

(GP & Prod.)

Sump Seals

(Polished ID)

Wash pipe with multi-service

shifting tool (spaced out below

lower sliding sleeve)

Sump Packer

Isolation Seals

Safety Joint

Fig. 2 Standard Gravel Pack Assembly w/ Isolation Assembly

Blank

Screen

Wash pipe with mule shoe

(spaced out close to end of

screen)

Sump Packer

Sump Seals

Fig. 1 Standard Gravel Pack Assembly

Standard Gravel Pack Assembly w/ Retrievable Isolation

Assembly

In this system the isolation assembly serves as a conduit to aid

circulation of the gravel pack fluids to the bottom of the

annulus of the screen/casing or screen/open hole, obtaining

fluid returns through the screen and lower sliding sleeve. The

wash pipe serves as shifting tool carrier to open or close lower

sliding sleeve, as shown in Fig. 2. Isolation tubing OD - screen

ID ratio should optimally be 0.8.

This system has shown to be effective for controlling fluid

losses and for zonal isolation in stacked multi-zonal

completions, yet still requires rig time for wash pipe handling,

especially in longer intervals.

At the time of writing, for standard offshore as well as

deep-water applications, 636 systems with 431 sliding sleeves

had been run since 1995 in the United States. For deep-water

application in South America, 55 systems with 134 sliding

sleeves had been run since 2000.

Single Trip Horizontal Gravel Pack And Selective

Stimulation (SHGPSS) System

This system, shown in Fig. 3, allows the gravel pack assembly

to be installed, the gravel pack to be pumped, and a selective

stimulation of the entire packed interval to be performed all

in a single trip.

The fluid path during gravel packing mode is the normal

crossover type configuration. Slurry is pumped down the

workstring and out the closing sleeve and down into the open

hole section while returns are achieved through the ported

subs in the washpipe assembly to the annulus above the

packer. Once a sand-out is achieved the service tool is

positioned in the reverse position changing the fluid path

direction. After excess slurry is reversed from the workstring,

a secondary ball is dropped and converts the tool from gravel

packing mode to stimulation mode.

The stimulation mode relies on the bullplugged washpipe

incorporating polished stingers and ported subs that seal

between screen sections to allow for selective stimulation

placement. The fluid path is thus changed to exit the

workstring through the service tool and directly enter the

inside of the washpipe.

The service tool is then picked up in order to position the

straddled polished stingers across the inverted molded seals

placed between screen joints. Between the polished stingers,

at the end of the washpipe, the ported subs that were

previously used to take returns during the gravel pack now

create flow path for the stimulation treatment to be squeezed

into selected intervals. Once the first screen joint/open hole

section has been stimulated, the service tool and washpipe are

picked up to straddle the next screen section and pumping

resumes. This can be repeated as many times as necessary to

selectively stimulate the entire open hole section.

After the stimulation treatment is complete, the service

tool is pulled from the wellbore until the polished stinger trips

the double flapper valve isolating the formation from fluid

losses.3

OTC 16051

activation tool. This actuation string is removed from the well

after completion of the treatment.

At the time of writing, for standard offshore as well as

deep-water applications, 81 systems with 94 sliding sleeves

had been run since 1999 in the United States. For deep-water

application in South America, 5 systems with 5 sliding sleeves

had been run since 2001.

.

POOH, Isolate

Well

Stimulate

Well

Convert

Tool

Hydraulic setting tool

Set Packer

Gravel Pack

GP Packer

RIH

Washdown

Fig. 3 SHGPSS System

At the time of writing, this relatively new system had been

installed in twelve wells, as shown in Table 2, with good

results.

Item

Region

Environment

Year

Installed

1

2

3

4

5

6

7

8

9

10

11

12

South Am.

South Am.

South Am.

South Am.

South Am.

South Am.

South Am.

South Am.

South Am.

South Am.

South Am.

South Am.

Deep-Water

Deep-Water

Deep-Water

Deep-Water

Deep-Water

Deep-Water

Deep-Water

Deep-Water

Deep-Water

Deep-Water

Deep-Water

Deep-Water

2001

2002

2002

2002

2002

2002

2003

2003

2003

2003

2003

2003

Type

Injector

Injector

Injector

Injector

Injector

Injector

Injector

Injector

Injector

Producer

Producer

Injector

Casing Open Hole Open Hole

Size

Size

Length

(in)

(in)

(ft)

9 5/8"

8 1/2"

1696

9 5/8"

8 1/2"

2116

9 5/8"

8 1/2"

2297

9 5/8"

8 1/2"

2106

9 5/8"

8 1/2"

2110

9 5/8"

8 1/2"

1818

9 5/8"

8 1/2"

3435

9 5/8"

8 1/2"

2625

9 5/8"

8 1/2"

2133

9 5/8"

8 1/2"

2103

9 5/8"

8 1/2"

1923

9 5/8"

8 1/2"

2031

Table 2 Horizontal Single Trip GP/ Stimulation Completions

Gravel Pack Systems with out Wash Pipe

In areas of the world where transportation, access, availability,

and maintenance of equipment are difficult, utilizing a gravel

pack system that requires no wash pipe is advantageous.

The need for such washpipeless systems has been

increasing due to high rig rates in the event of fishing

operations. In a frac pack operation, one of the most common

problems is stuck wash pipe, soon after screen out or reverse

out is accomplished. Utilizing a gravel pack system that

requires no wash pipe eliminates that unforeseen event in

addition to reducing costs.

The following systems incorporate the previously

mentioned isolation assemblies to obtain zonal isolation and to

control fluid losses.

Standard Gravel Pack Assembly w/ High Pressure

Retrievable Isolation Assembly

This system is mechanically actuated and hydraulically

powered, and is shown in Fig. 4. The isolation assembly

serves as a conduit to aid circulation of the gravel pack fluids

to the bottom of the screen/casing annulus, where fluid returns

are obtained through the screen. The fluid enters the isolation

tubing through a screen-wrapped port on the bottom of the

assembly, which later becomes isolated after system actuation.

The isolation tubing OD screen ID ratio should optimally be

0.8.

The system uses a short actuation string section, less than

20 feet, which is composed of flush joint tubing and an

Multi-Service

Closing Sleeve

Safety Joint

Service tool with shifting

and circulating valve

Actuation String

Blank

Isolation tubing

Sliding Sleeves

(Production)

Screen

Sump Seals

(Polished ID)

Ported Isolation Seals

(Spaced out in polished

ID seals) (fluid returns)

Sump Packer

Fig. 4 Standard Gravel Pack Assembly w/ High Pressure

Retrievable Isolation Assembly

Standard Gravel Pack Assembly w/ Ball Drop Retrievable

Isolation Assembly

This system is hydraulically actuated and powered, and is

shown in Fig. 5. The isolation assembly serves as a conduit to

aid circulation of the gravel pack fluids to the bottom of the

screen/casing annulus. Fluid returns are obtained through the

screen and a multi-service valve (MSV) on the bottom of the

isolation tubing. The MSV is closed after system actuation.

The isolation tubing OD screen ID optimum ratio should be

0.8. This system does not use any wash pipe or actuation

string.

This system has been developed and tested and at the time

of writing, was ready to go in the field. This kind of system

has particular application in deep-water, sand control

environments, where minimization of rig time and risk

mitigation are of paramount importance.

OTC 16051

References

Hydraulic setting tool

GP Packer

1.

2.

3.

Multi-Service Closing

Sleeve

Service tool with shifting and

circulating valve

Hydraulic drop sub and valve

actuator

Safety Joint

Blank

Isolation tubing

Sliding Sleeve

(Production)

Screen

Sliding Sleeve

(GP & Production)

Isolation Seals

Sump Packer

Sump Seals

(Polished ID)

Fig. 5 Standard Gravel Pack Assembly w/ Ball Drop Retrievable

Isolation Assembly

Conclusions

1. In gravel packing, a conduit is needed to ensure

circulation to the bottom of the screen. The conduit

may be retrievable (wash pipe) or permanent/

retrievable (isolation assembly).

2. In frac packing, taking returns through the bottom of

the screen is not as important, but having a conduit is

necessary in the event that gravel packing the

screen/casing annulus is required afterwards.

3. Especially in deep-water environments, and wells with

long intervals, the trend is to reduce or eliminate the

usage of washpipe.

4. Washpipeless systems can save rig time and prevent

fishing operations.

5. When possible, choose a washpipeless gravel pack

or frac pack system that accomplishes the same

functions as systems that use washpipe.

Acknowledgments

The authors of this paper would like to express the

appreciation of the members of their respective engineering

and operations staff. Without their combined efforts, this

accomplishment would not be possible. We also thank BJ

Services for the permission to publish this paper.

Nomenclature

GP

ID

MSV

OD

SHGPSS system

=

=

=

=

=

Gravel pack

Internal diameter

Multi-service valve

Outside diameter

Single trip horizontal gravel pack and

selective stimulation system

Sand Control SPE Series on Special Topics Volume 1,

Penberthy, W.L. Jr. and Shaughnessy, C.M., Society of

Petroleum Engineers, Richardson, TX (1992) 1.

Gravel Pack Manual Version 2, BJ Services Company,

Houston, TX (1999) 20.

Vilela, A., et al., Novel Single Trip Horizontal Gravel Pack and

Selective Stimulation System Improves Injectivity in Deepwater

Wells, paper SPE 84260 presented at the 2003 Annual

Technical Conference and Exhibition, Denver, Oct. 5 8.

SI Metric Conversion Factors

ft 3.048*

E 01 = m

in 2.54*

E + 01 = mm

lbm 4.535 924

E 01 = kg

* Conversion factor is exact.

Вам также может понравиться

- Cut and Thread ProcedureДокумент4 страницыCut and Thread ProcedurezapspazОценок пока нет

- Oilfield Services Training - Section MillingДокумент51 страницаOilfield Services Training - Section Millingvodaiuy100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!От EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Рейтинг: 5 из 5 звезд5/5 (2)

- Baker: Liner Hanger SystemsДокумент11 страницBaker: Liner Hanger SystemsMohamed ElabbasyОценок пока нет

- Circulation Junk Baskets ManualДокумент22 страницыCirculation Junk Baskets ManualAnonymous R4VU5fxIОценок пока нет

- Rtts PackerДокумент2 страницыRtts Packersaeed65100% (2)

- Bowen-Lebus Knuckle Joints: Instruction Manual 4810Документ11 страницBowen-Lebus Knuckle Joints: Instruction Manual 4810Foros Isc100% (2)

- Laboratory InstrumentsДокумент8 страницLaboratory InstrumentsPauline PascuaDОценок пока нет

- St. Paul University Philippines: College of Medical TechnologyДокумент14 страницSt. Paul University Philippines: College of Medical TechnologyJulius FrondaОценок пока нет

- PVC & Hdpe Pipes Weight ChartДокумент4 страницыPVC & Hdpe Pipes Weight ChartRathnakar Naik68% (25)

- Diverter Drilling System For Well Control Full GuideДокумент19 страницDiverter Drilling System For Well Control Full GuiderahulОценок пока нет

- Sand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!От EverandSand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!Рейтинг: 5 из 5 звезд5/5 (1)

- Fundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyОт EverandFundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyОценок пока нет

- Chapter 20 - FishingДокумент21 страницаChapter 20 - FishingBlanca OrtegaОценок пока нет

- Fishing ToolДокумент17 страницFishing ToolKaleem UllahОценок пока нет

- Reverse Circulation Junk Basket: Instruction Manual 3100Документ14 страницReverse Circulation Junk Basket: Instruction Manual 3100Foros IscОценок пока нет

- K-1 Cement RetainerДокумент1 страницаK-1 Cement RetainerErick100% (1)

- D430 Z Type Hydraulic Fishing Jars ManualДокумент38 страницD430 Z Type Hydraulic Fishing Jars Manualnjava1978Оценок пока нет

- Side Pocket MandrelДокумент3 страницыSide Pocket MandrelSyameer109Оценок пока нет

- 2003 Liner Hangers CatalogДокумент104 страницы2003 Liner Hangers CatalogFABGOILMAN100% (1)

- Fish Tools ExternalДокумент50 страницFish Tools Externalahmedhussien1Оценок пока нет

- Production and Test Packer - RetrievableДокумент30 страницProduction and Test Packer - RetrievableHendra JurbonОценок пока нет

- Fishing ToolsДокумент10 страницFishing Toolsdanarkurniadi123Оценок пока нет

- Bridge Plug-Cement RetainerДокумент7 страницBridge Plug-Cement RetainerhabibimarioОценок пока нет

- 3 ", 5 ", 8 " & 11 " Pipe Cutter With Knife Return System: Operating InstructionsДокумент23 страницы3 ", 5 ", 8 " & 11 " Pipe Cutter With Knife Return System: Operating InstructionsRazvan RaduОценок пока нет

- Jarring Operation by WeatherfordДокумент10 страницJarring Operation by WeatherfordGordonОценок пока нет

- RTTS Packer: Technical Data SheetДокумент5 страницRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- Subsea - Page 4Документ79 страницSubsea - Page 4lulalala8888100% (2)

- Fishing Techniques For Drilling OperationsДокумент14 страницFishing Techniques For Drilling OperationsJuan Lozano ArevaloОценок пока нет

- Fishing Techniques For Drilling Operations2Документ14 страницFishing Techniques For Drilling Operations2Rosalie EdwardsОценок пока нет

- 7" Liner Running ProcedureДокумент2 страницы7" Liner Running ProcedureYougchu Luan100% (2)

- Davis Stage Cementing Collar and Equipment PDFДокумент5 страницDavis Stage Cementing Collar and Equipment PDFPdax FirdausОценок пока нет

- Fishing Options in Horizontal WellsДокумент16 страницFishing Options in Horizontal WellsGrigore BalanОценок пока нет

- Fishing ToolsДокумент45 страницFishing ToolsEswar Prasad100% (1)

- Wellbore Departure DPA RioДокумент32 страницыWellbore Departure DPA RioAdriana Rezende100% (1)

- Reverse Circulating Junk BasketДокумент7 страницReverse Circulating Junk BasketLove KumarОценок пока нет

- Pressure Rating For SSII Float EquipmentДокумент2 страницыPressure Rating For SSII Float EquipmentMahmoud Ahmed Ali AbdelrazikОценок пока нет

- SwabbingДокумент3 страницыSwabbingMohamed KableОценок пока нет

- MSP Drillex BOP AnularДокумент21 страницаMSP Drillex BOP AnularDavid GonzalezОценок пока нет

- Griffith Drilling JarДокумент1 страницаGriffith Drilling JarFakhrurrozi ArbianОценок пока нет

- 30575.fishing Services CatalogДокумент180 страниц30575.fishing Services CatalogACDОценок пока нет

- Prevention, Fishing and Casing Repair - Jim Short - Part 2Документ249 страницPrevention, Fishing and Casing Repair - Jim Short - Part 2MitsúMilagrosToroSayasОценок пока нет

- Casing Running and Drilling ToolsДокумент33 страницыCasing Running and Drilling Toolsfffggg777Оценок пока нет

- Packer Setting MechanismДокумент3 страницыPacker Setting MechanismYougchu Luan67% (3)

- Radial Cutting Torch 070415Документ4 страницыRadial Cutting Torch 070415Carlos Alberto Aguilera MendezОценок пока нет

- 06 Openhole IsolationДокумент24 страницы06 Openhole IsolationMuhammad ShahrukhОценок пока нет

- Case Study of Wireline Fishing - Hany MetwallyДокумент5 страницCase Study of Wireline Fishing - Hany Metwallyazareiforoush100% (1)

- 15 Fishing Tools PDFДокумент15 страниц15 Fishing Tools PDFjoo123456789Оценок пока нет

- Section 5 - Milling Tools & Washover EquipДокумент22 страницыSection 5 - Milling Tools & Washover EquipMichèle SpiteriОценок пока нет

- 5 Main Junk Basket TypesДокумент7 страниц5 Main Junk Basket TypesrahulОценок пока нет

- AADE Open Hole SideTrack Technology PDFДокумент20 страницAADE Open Hole SideTrack Technology PDFIsaac MuñozОценок пока нет

- Slickline: Slickline Refers To A Single Strand WireДокумент40 страницSlickline: Slickline Refers To A Single Strand Wirewilliam MadingОценок пока нет

- Whipstock 9.625 Mechanical Running ProceduresДокумент16 страницWhipstock 9.625 Mechanical Running ProceduresTudor virgil100% (1)

- Instruction Manual 6460: Lead Seal Cementing Type Casing PatchДокумент10 страницInstruction Manual 6460: Lead Seal Cementing Type Casing PatchRagui StephanosОценок пока нет

- Plug Setting Tool and Junk Basket: Purpose of The ServiceДокумент15 страницPlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806Оценок пока нет

- CTD Liner Running & CementingДокумент6 страницCTD Liner Running & CementingAdel Ahmed AlkhaligyОценок пока нет

- Chapter One: Diverter SystemДокумент29 страницChapter One: Diverter SystemsyedainahmadОценок пока нет

- Bridge PlugsДокумент9 страницBridge Plugskaveh-bahiraeeОценок пока нет

- Measurement While Drilling: Signal Analysis, Optimization and DesignОт EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignОценок пока нет

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsОт EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsОценок пока нет

- TIC-Wireline Tools and Equipment Catalog - 部分335Документ1 страницаTIC-Wireline Tools and Equipment Catalog - 部分335zbhdzpОценок пока нет

- TIC-Wireline Tools and Equipment Catalog - 部分177 PDFДокумент1 страницаTIC-Wireline Tools and Equipment Catalog - 部分177 PDFzbhdzpОценок пока нет

- TIC-Wireline Tools and Equipment Catalog - 部分225Документ1 страницаTIC-Wireline Tools and Equipment Catalog - 部分225zbhdzpОценок пока нет

- TIC-Wireline Tools and Equipment Catalog - 部分301 PDFДокумент1 страницаTIC-Wireline Tools and Equipment Catalog - 部分301 PDFzbhdzpОценок пока нет

- TIC-Wireline Tools and Equipment Catalog - 部分135 PDFДокумент1 страницаTIC-Wireline Tools and Equipment Catalog - 部分135 PDFzbhdzpОценок пока нет

- TIC-Wireline Tools and Equipment Catalog - 部分301Документ1 страницаTIC-Wireline Tools and Equipment Catalog - 部分301zbhdzpОценок пока нет

- TIC-Wireline Tools and Equipment - 部分347 PDFДокумент1 страницаTIC-Wireline Tools and Equipment - 部分347 PDFzbhdzpОценок пока нет

- TIC-Wireline Tools and Equipment Catalog - 部分351 PDFДокумент1 страницаTIC-Wireline Tools and Equipment Catalog - 部分351 PDFzbhdzpОценок пока нет

- Materials 14 02743Документ15 страницMaterials 14 02743Esteban SepulvedaОценок пока нет

- Aakaash Test Class 11 MedicalДокумент13 страницAakaash Test Class 11 MedicalkrishnaОценок пока нет

- Oxymax H COS21D: Operating InstructionsДокумент32 страницыOxymax H COS21D: Operating InstructionsRabah AmidiОценок пока нет

- J Jtumed 2016 11 006Документ4 страницыJ Jtumed 2016 11 006yulyansyah susantoОценок пока нет

- INT2010 Practice ExamДокумент12 страницINT2010 Practice ExamAren EiríksdóttirОценок пока нет

- Topic 5 Energetics-Thermochemistry MCQsДокумент32 страницыTopic 5 Energetics-Thermochemistry MCQsADEEL AHMADОценок пока нет

- Clearfrac XT PsДокумент1 страницаClearfrac XT PsMiguel CastilloОценок пока нет

- Safety RuleДокумент8 страницSafety RuleWakshume AdugnaОценок пока нет

- Corrosion MCQДокумент9 страницCorrosion MCQDr. Harish Raju mОценок пока нет

- Chloride Removal From Cooling WaterДокумент234 страницыChloride Removal From Cooling WaterLekhamani Yadav100% (1)

- Mindray BS200 User ManualДокумент6 страницMindray BS200 User ManualMichael OkekeОценок пока нет

- Datasheet BASF Entertite G SPF PDFДокумент2 страницыDatasheet BASF Entertite G SPF PDFKhin Sandi KoОценок пока нет

- Stopping StuffДокумент28 страницStopping StuffaОценок пока нет

- Group 1 - Alkali Metals: Introduction & DataДокумент2 страницыGroup 1 - Alkali Metals: Introduction & Datarafeyatif06Оценок пока нет

- C E P E P: Olorado Nvironmental Esticide Ducation RogramДокумент2 страницыC E P E P: Olorado Nvironmental Esticide Ducation RogramKevin EsmunaldoОценок пока нет

- Carbohydrates, Fats, and Proteins 31 August 2022 FullДокумент29 страницCarbohydrates, Fats, and Proteins 31 August 2022 FullGita FarokaОценок пока нет

- Unit 4 - System of MedicineДокумент4 страницыUnit 4 - System of MedicineKrishnendu RayОценок пока нет

- Biodek CatalogueДокумент17 страницBiodek CatalogueSourabh ManujaОценок пока нет

- JabirДокумент1 страницаJabirLeandro PerinОценок пока нет

- Polymerisation 1 Addition Polymerisation PDFДокумент7 страницPolymerisation 1 Addition Polymerisation PDFMete ÖzözgürОценок пока нет

- Pesticide Analysis of Bee and Bee Product SamplesДокумент14 страницPesticide Analysis of Bee and Bee Product SamplesCarlos LopesОценок пока нет

- Interview ASME SEC IX & General QUESTIONSДокумент45 страницInterview ASME SEC IX & General QUESTIONSabdo50% (2)

- Reduction, Oxidation - Hydrolysis Theory PDFДокумент14 страницReduction, Oxidation - Hydrolysis Theory PDFGOURISH AGRAWALОценок пока нет

- Avelino Activity3Документ4 страницыAvelino Activity3Debbie S. AvelinoОценок пока нет

- Electron Transfer in BiologyДокумент20 страницElectron Transfer in BiologyVani KaushikОценок пока нет

- Plasma-Sprayed Hydroxylapatite-Based CoatingsДокумент24 страницыPlasma-Sprayed Hydroxylapatite-Based CoatingsDenny DelvianoОценок пока нет

- 2 Recycling and Formulation of Aluminum Scrap Via Mass Balance Die Casting and FormingДокумент7 страниц2 Recycling and Formulation of Aluminum Scrap Via Mass Balance Die Casting and FormingRobby AnugrahОценок пока нет