Академический Документы

Профессиональный Документы

Культура Документы

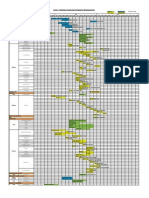

Qa/Qc Mechanical Monthly Progress Report For June 2015: Area/System Description Status Remarks

Загружено:

Ren SalazarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Qa/Qc Mechanical Monthly Progress Report For June 2015: Area/System Description Status Remarks

Загружено:

Ren SalazarАвторское право:

Доступные форматы

QA/QC MECHANICAL MONTHLY PROGRESS REPORT FOR JUNE 2015

Area/System

Description

TOP Documentation and Filing

Open Package Inspection

Incoming Delivery Material Inspection (Accpetance)

NOI Documentation and Filing

Checking of Hydrotest package (sprinkler, CAFS and BOP piping

Status

Remarks

Closing of punchlist issued by DMCI and SLPGC

ESP2

Checking of cleaning and painting of ESP piping, equipment, supports and structure.

ESP2

Checking of ESP #2 insulation inspection and acceptance.

MPH

Checking of thermal insulation for all level of steam extraction pipe.

Incomplete work; they do not put sealant in the opening of pipe and hanger connection. Rejected

MPH

Checking of thermal insulation for auxiliary steam pipe.

Incomplete work; they do not put sealant in the opening of pipe and hanger connection. Rejected

MPH

Checking of thermal insulation for condensed water pipe

Incomplete work; they do not put sealant in the opening of pipe and hanger connection. Rejected

MPH

Checking of thermal insulation of heating steam, gland sealing steam.

Incomplete work; they do not put sealant in the opening of pipe and hanger connection. Rejected

DEMIN

Closure of as built (red marks) drawing with Engr. D. Alcones

DEMIN

Closure of as built (red marks) drawing with Engr. D. Alcones

WORKSHOP

Line checking of Fire Protection Pipe and Punchlisting

BOTTOM ASH

Closure of as built (red marks) drawing with Engr. J. Ballo

ESP2

Closure of as built (red marks) drawing with Engr. J. Ballo

FLY ASH

Closure of as built (red marks) drawing with Engr. J. Ballo

WORKSHOP

Hydrotesting of fire hydrant

DEMIN

Line checking of Fire Protection Pipe installed by First Pilipinas

ESP CONTROL ROOM

Line checking of Fire Protection Pipe installed by First Pilipinas

ESP2

FABRICATION

FUEL OIL PUMP HOUSE

Punchlist some support that not already installed and red marks the the actual installation of pipe

that are different in drawing.

Qualified and accepted

Checking of cleaning and painting of ESP piping, equipment, supports and structure.

Qualified and accepted

Initial inspection of sandblasting and painting pipe for sewer line lift station.

Request for polishing due to occurrence of bubbles

Closure of as built (red marks) drawing with Engr. W. Flores

BOTTOM ASH

Checking of cleaning and painting of steel structure in bottom ash.

WAREHOUSE

Leak test of aircon piping

WAREHOUSE

Bolt tightening of column in warehouse

RAW WATER

Closure of as built (red marks) drawing with Engr. A. LIBREA

BOILER2

Monitor welding of boiler cyclone separator damaged pipe.

Incomplete work; Rejected

Visual inspection is accepted

MPH

Checking of main steam valve and reheat steam valve recover inspection after blowing pipe.

MPH

Checking of bearing seat before covering.

Rejected: incomplete work

MPH

Checking of main oil system and EH oil system recover inspection after blowing pipe.

Rejected: incomplete work

Checking for repair of refractory damaged by blowing

Qualified and accepted

BOTTOM ASH

Rechecking of cleaning and painting of steel structure in bottom ash.

Qualified and accepted

FABRICATION

Final inspection of sandblasting and painting pipe for sewer line lift station.

Qualified and accepted

Final inspection for cleaning and painting of equipment and steel structure

Qualified and accepted

Checking of dye penetrant test in cyclone separator inlet flue gas duct sealing.

Inspection is rejected: dye penetrant test is not ok

WORKSHOP

Checking of reinnstatement of test package in workshop(STR)

Qualified and accepted

SITE OFFICE

Completion of accomplished inspection report.

BOILER1

ESP2

BOILER2

Вам также может понравиться

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Hydro TestДокумент12 страницHydro TestEndika Alfan100% (2)

- Rubik Solution (3x3x3)Документ24 страницыRubik Solution (3x3x3)fembarОценок пока нет

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsОт EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsОценок пока нет

- Over Current & Earth Fault RelayДокумент2 страницыOver Current & Earth Fault RelayDave Chaudhury67% (6)

- InSaleh Blowdown IncidentДокумент3 страницыInSaleh Blowdown IncidentHandriansyah DoelОценок пока нет

- Vibration Induced Fatigue Safety MomentДокумент9 страницVibration Induced Fatigue Safety MomentAnthony BarnesОценок пока нет

- Heat Exchanger InspectionДокумент11 страницHeat Exchanger InspectionVivek Bhangale100% (1)

- Boiler SurveyДокумент7 страницBoiler SurveyrajishrrrОценок пока нет

- Chemical CleaningДокумент22 страницыChemical Cleaningamareshscribd100% (1)

- Boilers: - Asit MondalДокумент29 страницBoilers: - Asit MondalAJITSPATILОценок пока нет

- Pre-Employment Requirements (List)Документ5 страницPre-Employment Requirements (List)Ren SalazarОценок пока нет

- Commissioning Procedure For A Boiler PDFДокумент24 страницыCommissioning Procedure For A Boiler PDFpothan83% (6)

- Piping Q.C Ag& UgДокумент12 страницPiping Q.C Ag& UgGokulPrasad88% (8)

- Resume of Qaqc Welding-Mechanical InspectorДокумент5 страницResume of Qaqc Welding-Mechanical InspectorMohammed Illiasuddin100% (1)

- 2.2.4 Construction Schedule For Mechanical WorkДокумент2 страницы2.2.4 Construction Schedule For Mechanical WorkĐình Nam100% (1)

- Commissioning ProcedureДокумент24 страницыCommissioning ProcedureSumitskb100% (14)

- Inspection Of: Piping Systems (In-Service) 570Документ36 страницInspection Of: Piping Systems (In-Service) 570g_jeyasankar100% (2)

- Heat Exchanger Inspection PDFДокумент8 страницHeat Exchanger Inspection PDFreezmanОценок пока нет

- Delay in Opening of LP Bypass ValveДокумент94 страницыDelay in Opening of LP Bypass ValveCharu ChhabraОценок пока нет

- Boiler Survey & ConstДокумент18 страницBoiler Survey & ConstAmit ChouguleОценок пока нет

- ITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CДокумент2 страницыITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CAmel Rayhan Aira100% (5)

- Heat Exchanger InspectionДокумент7 страницHeat Exchanger InspectionHamid Albashir100% (1)

- Method Statement Water Supply Work For BuildingДокумент3 страницыMethod Statement Water Supply Work For BuildingRosnani Ambo sakkaОценок пока нет

- Marriage HalldocxДокумент50 страницMarriage HalldocxBalaji Kamalakannan100% (2)

- Civil Quality Control ProcedureДокумент37 страницCivil Quality Control ProcedureRen Salazar100% (2)

- Tubular Air HeaterДокумент50 страницTubular Air HeaterBalaji NatarajanОценок пока нет

- Std-Insp-0127 Procedure For Commissioning ProcedureДокумент54 страницыStd-Insp-0127 Procedure For Commissioning ProcedureAkshay KalraОценок пока нет

- Guide To Greyhawk PDFДокумент108 страницGuide To Greyhawk PDFAnonymous PtMxUHm9RoОценок пока нет

- TUV India HEAT EXCHANGER InspectionДокумент43 страницыTUV India HEAT EXCHANGER InspectionParthiban NCОценок пока нет

- Heat Exchanger InspectionДокумент6 страницHeat Exchanger Inspectionjamaljamal20Оценок пока нет

- Training R&M of BoilersДокумент45 страницTraining R&M of BoilersSamОценок пока нет

- Good Stuff Courage, Resilience, Gratitude, Generosity, Forgiveness, and Sacrifice (Akhtar, Salman)Документ221 страницаGood Stuff Courage, Resilience, Gratitude, Generosity, Forgiveness, and Sacrifice (Akhtar, Salman)madhugaggar999Оценок пока нет

- ASME CODE Requirements - Heat ExchangerДокумент9 страницASME CODE Requirements - Heat ExchangerJithin FrancizОценок пока нет

- Knowledge Management Series-Low Vacuum in Steam Turbine PDFДокумент4 страницыKnowledge Management Series-Low Vacuum in Steam Turbine PDFMadhusudhan Pasumarty100% (1)

- Boiler InspectionДокумент6 страницBoiler Inspectiondaimahesh100% (1)

- Leaflet CycleManager Ep CycleManager ErДокумент7 страницLeaflet CycleManager Ep CycleManager ErValeska ArdilesОценок пока нет

- Panasonic Refrigeraor NR-B472TZ - B412TZ v1.1Документ24 страницыPanasonic Refrigeraor NR-B472TZ - B412TZ v1.1Anonymous 2iQ1B59Оценок пока нет

- 5.NTPC Simhadri Presentation On Best Practices of O&MДокумент22 страницы5.NTPC Simhadri Presentation On Best Practices of O&Mswaroop351100% (1)

- Bill of Quantity - BoilerДокумент18 страницBill of Quantity - BoilerVijay Raj100% (1)

- Vertical Tubeless Gas Fired IOMДокумент102 страницыVertical Tubeless Gas Fired IOMElvis RivadeneiraОценок пока нет

- Turbin Bulan Oktober 2011 NEWДокумент4 страницыTurbin Bulan Oktober 2011 NEWTri Utami DewiОценок пока нет

- Survey Works Rev 1Документ12 страницSurvey Works Rev 1Abraham JyothimonОценок пока нет

- Rogers Water Utilities Water System Rogers, ArkansasДокумент4 страницыRogers Water Utilities Water System Rogers, ArkansasrohalestatОценок пока нет

- Hydronic PipingДокумент11 страницHydronic PipingLjubomir DjurinОценок пока нет

- Pub Insp Wtic (Sep 09) RevisedДокумент2 страницыPub Insp Wtic (Sep 09) RevisedagitentОценок пока нет

- CSB - Safety Bulletin - Removal of Hazardous Material From Piping Systems (2004)Документ4 страницыCSB - Safety Bulletin - Removal of Hazardous Material From Piping Systems (2004)sl1828Оценок пока нет

- Shutdown Observation Report - M/s SRHHL: Grid - Air Nozzle Refractory Dismantling and Dents On TubesДокумент4 страницыShutdown Observation Report - M/s SRHHL: Grid - Air Nozzle Refractory Dismantling and Dents On TubesJacky KaruppaiahОценок пока нет

- Conocophillips Response To The Saturate Gas Plant Fire and Explosion IncidentДокумент9 страницConocophillips Response To The Saturate Gas Plant Fire and Explosion IncidentvengielОценок пока нет

- Recall Points CH1 To CH5Документ5 страницRecall Points CH1 To CH5Chiheb KaanicheОценок пока нет

- TCCC 1 SD 439 0001 R0Документ11 страницTCCC 1 SD 439 0001 R0Luis Angel PatiñoОценок пока нет

- Installation Piping R2Документ65 страницInstallation Piping R2Riski Neutron RizendraОценок пока нет

- 1 CHKLSTДокумент5 страниц1 CHKLSTsardarmkhanОценок пока нет

- Condition Assessment Services (B&W)Документ6 страницCondition Assessment Services (B&W)Dilio A. Rojas QОценок пока нет

- Case Study 1 - Commissioning A Gas Fired Steam BoilerДокумент7 страницCase Study 1 - Commissioning A Gas Fired Steam Boilersopian320Оценок пока нет

- Boiler & Pressure Vessel Safety: To Provide Guidance For The Safe Operation and Maintenance of Pressure VesselsДокумент11 страницBoiler & Pressure Vessel Safety: To Provide Guidance For The Safe Operation and Maintenance of Pressure VesselsGaapchu100% (2)

- Quality HDPEДокумент2 страницыQuality HDPEFrancisco Javier Villegas AndersonОценок пока нет

- Bui Van Diep Bui Van Diep: Thông Tin ChungДокумент7 страницBui Van Diep Bui Van Diep: Thông Tin Chunganon_33553517Оценок пока нет

- Monthly Report No.-2 Coating Welspun DammamДокумент5 страницMonthly Report No.-2 Coating Welspun Dammammdsajidalam100% (1)

- 22 11 17 - Gas Pipe and AppurtenancesДокумент7 страниц22 11 17 - Gas Pipe and AppurtenancesTeguh SetionoОценок пока нет

- Pipex Inspection Chambers PDFДокумент5 страницPipex Inspection Chambers PDFskodgeОценок пока нет

- Cts-091222-40 Fpso Ess STBD Boiler Inspection Report Tag-o-V1502 - Compressed 1Документ59 страницCts-091222-40 Fpso Ess STBD Boiler Inspection Report Tag-o-V1502 - Compressed 1Raylane MenezesОценок пока нет

- PCT Patoqs Jolas Waterline&Sanitary&FcudrainДокумент39 страницPCT Patoqs Jolas Waterline&Sanitary&FcudrainRegine Dela Fuente100% (1)

- Overhauling Surprises of Unit # 4: Electrical & C&IДокумент4 страницыOverhauling Surprises of Unit # 4: Electrical & C&ISony RamaОценок пока нет

- Specification Plumbing SystemДокумент16 страницSpecification Plumbing SystemGhiovani DayananОценок пока нет

- What Is Hot TappingДокумент26 страницWhat Is Hot Tappingashish shrivastavОценок пока нет

- Mps SDM 2014 Tp042Документ37 страницMps SDM 2014 Tp042Janardhan Surya100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- BucklingДокумент1 страницаBucklingRen SalazarОценок пока нет

- From Simple To ComprehensiveДокумент1 страницаFrom Simple To ComprehensiveRen SalazarОценок пока нет

- BucklingДокумент1 страницаBucklingRen SalazarОценок пока нет

- You Have To Think On All Those StuffДокумент1 страницаYou Have To Think On All Those StuffRen SalazarОценок пока нет

- Dynamic BucklingДокумент1 страницаDynamic BucklingRen SalazarОценок пока нет

- TheДокумент1 страницаTheRen SalazarОценок пока нет

- 321Документ1 страница321Ren SalazarОценок пока нет

- Bifurcation Static EquilibriumДокумент1 страницаBifurcation Static EquilibriumRen SalazarОценок пока нет

- To: Project Director - 2x150MW SLPGC Project Subject: Resignation As CQC Engineer (CE)Документ1 страницаTo: Project Director - 2x150MW SLPGC Project Subject: Resignation As CQC Engineer (CE)Ren SalazarОценок пока нет

- Drywall1 19 11Документ3 страницыDrywall1 19 11Benjo FaustoОценок пока нет

- Corrective / Preventive Action Request: Improper Installation in BTGДокумент2 страницыCorrective / Preventive Action Request: Improper Installation in BTGRen SalazarОценок пока нет

- Slenderness RatioДокумент1 страницаSlenderness RatioRen SalazarОценок пока нет

- PL#6 SLPGCДокумент4 страницыPL#6 SLPGCRen SalazarОценок пока нет

- Closure of Issued NCR'S, CPAR's and PunchlistsДокумент1 страницаClosure of Issued NCR'S, CPAR's and PunchlistsRen SalazarОценок пока нет

- Redro Se Redro Se Redro Se Redro Se Redro Se Redro SeДокумент1 страницаRedro Se Redro Se Redro Se Redro Se Redro Se Redro SeRen SalazarОценок пока нет

- CPAR New Form Warehouse WallДокумент2 страницыCPAR New Form Warehouse WallRen SalazarОценок пока нет

- MaterialsДокумент4 страницыMaterialsRen SalazarОценок пока нет

- Summary of Activities - Nov.Документ2 страницыSummary of Activities - Nov.Ren SalazarОценок пока нет

- Photo Details For Boiler Area InspectionДокумент3 страницыPhoto Details For Boiler Area InspectionRen SalazarОценок пока нет

- Photo Details For Heat Recovery Area InspectionДокумент5 страницPhoto Details For Heat Recovery Area InspectionRen SalazarОценок пока нет

- It Matters Whom You MarryДокумент5 страницIt Matters Whom You MarryMichael Ngugi MОценок пока нет

- The Wall Housing Is Obstruction For Camera of Boiler Drum Level and Same With The Conduit. It Should Be Relocated Left and Right at Boiler Drum SteamДокумент7 страницThe Wall Housing Is Obstruction For Camera of Boiler Drum Level and Same With The Conduit. It Should Be Relocated Left and Right at Boiler Drum SteamRen SalazarОценок пока нет

- 2X150Mw SLPGC CFB Power Plant: ProjectДокумент1 страница2X150Mw SLPGC CFB Power Plant: ProjectRen SalazarОценок пока нет

- SLPGC1-EE-31035-03 - Lighting For 4.2m Floor of DM Water BuildingДокумент1 страницаSLPGC1-EE-31035-03 - Lighting For 4.2m Floor of DM Water BuildingRen SalazarОценок пока нет

- 42-F2421s-D1307-Contents Lighting of The Roads in The PlantДокумент1 страница42-F2421s-D1307-Contents Lighting of The Roads in The PlantRen SalazarОценок пока нет

- 42-F2421s-D1307-List-Lighting of The Roads in The PlantДокумент1 страница42-F2421s-D1307-List-Lighting of The Roads in The PlantRen SalazarОценок пока нет

- Toptica AP 1012 Laser Locking 2009 05Документ8 страницToptica AP 1012 Laser Locking 2009 05Tushar GuptaОценок пока нет

- Chuyên Đề ConjunctionДокумент5 страницChuyên Đề ConjunctionKhánh Linh TrịnhОценок пока нет

- AdPoe The Hunting of The HareДокумент2 страницыAdPoe The Hunting of The HarePI CubingОценок пока нет

- M1-Safety StandardsДокумент9 страницM1-Safety StandardscarlОценок пока нет

- Faujifood Pakistan PortfolioДокумент21 страницаFaujifood Pakistan PortfolioPradeep AbeynayakeОценок пока нет

- Advanced Steel Structure Concepts: 2 MonthsДокумент4 страницыAdvanced Steel Structure Concepts: 2 MonthsAnkit SoniОценок пока нет

- Mechanical Advantage HomeworkДокумент8 страницMechanical Advantage Homeworkafeurbmvo100% (1)

- Asynchronous ChipsДокумент27 страницAsynchronous ChipsSai TejaОценок пока нет

- NCERT Solutions For Class 12 Maths Chapter 10 Vector AlgebraДокумент51 страницаNCERT Solutions For Class 12 Maths Chapter 10 Vector AlgebraKavin .J.S (KingK)Оценок пока нет

- Most Important One Liner Questions and Answers May 2022Документ15 страницMost Important One Liner Questions and Answers May 2022pradeepОценок пока нет

- Study of Mosquito Larvicidal Effects of (Bitter Gourd) Extracts As NanopowderДокумент3 страницыStudy of Mosquito Larvicidal Effects of (Bitter Gourd) Extracts As NanopowderAnonymous AkoОценок пока нет

- Infrastructure Definition:: Economic Infrastructure Includes BroadlyДокумент3 страницыInfrastructure Definition:: Economic Infrastructure Includes Broadlyabraha gebruОценок пока нет

- TR189 Kathuria PDFДокумент168 страницTR189 Kathuria PDFuqiОценок пока нет

- IMS Institute BelgradeДокумент10 страницIMS Institute BelgradeBoško JanjuševićОценок пока нет

- Mobile Communication Networks: Exercices 4Документ2 страницыMobile Communication Networks: Exercices 4Shirley RodriguesОценок пока нет

- Class 28: Outline: Hour 1: Displacement Current Maxwell's Equations Hour 2: Electromagnetic WavesДокумент33 страницыClass 28: Outline: Hour 1: Displacement Current Maxwell's Equations Hour 2: Electromagnetic Wavesakirank1Оценок пока нет

- 1 28701-FGC+101+3441+Router+6471+Datasheet+Rev+FДокумент2 страницы1 28701-FGC+101+3441+Router+6471+Datasheet+Rev+FВладимир ЕгоровОценок пока нет

- Ansible Automation SA Technical Deck Q2FY19Документ43 страницыAnsible Automation SA Technical Deck Q2FY19daniel_vp21Оценок пока нет

- Thesis 1-15Документ15 страницThesis 1-15hewelirОценок пока нет

- Diesel Rotary UPS Configurations V1 - 00 - Jan2008Документ10 страницDiesel Rotary UPS Configurations V1 - 00 - Jan2008Karim SenhajiОценок пока нет

- Neuromuscular Diseases. ALSДокумент7 страницNeuromuscular Diseases. ALSjalan_zОценок пока нет

- Mwangi, Thyne, Rao - 2013 - Extensive Experimental Wettability Study in Sandstone and Carbonate-Oil-Brine Systems Part 1 - Screening ToДокумент7 страницMwangi, Thyne, Rao - 2013 - Extensive Experimental Wettability Study in Sandstone and Carbonate-Oil-Brine Systems Part 1 - Screening ToMateo AponteОценок пока нет

- KZPOWER Perkins Stamford Genset Range CatalogueДокумент2 страницыKZPOWER Perkins Stamford Genset Range CatalogueWiratama TambunanОценок пока нет