Академический Документы

Профессиональный Документы

Культура Документы

First Monitoring Report: Installation of Low Green House Gases (GHG) Emitting Rolling Stock Cars in Metro System

Загружено:

rajaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

First Monitoring Report: Installation of Low Green House Gases (GHG) Emitting Rolling Stock Cars in Metro System

Загружено:

rajaАвторское право:

Доступные форматы

DMRC 1st Monitoring Report

Page 1 of 17

FIRST MONITORING REPORT

Version: 01

Dated: 15/02/2008

Delhi Metro Rail Corporation (DMRC)

Installation of Low Green House Gases (GHG) emitting rolling stock

cars in metro system

CDM Project Reference No. UNFCCC 1351

Monitoring Period: 29th December 2007 to 31st January 2008

ADDRESS

Delhi Metro Rail Corporation (DMRC)

Bhishma Pitamah Marg, Pragati Vihar

IIIrd NBCC Place

New Delhi

Delhi - 110003

DMRC 1st Monitoring Report

INDEX

1. Title of the Project

2. Introduction

3. Reference

4. Project Description

5. Monitoring Methodology and Plan

6. Emission Reduction Calculation

Annexure 1: Data

Annexure 2: Contact Information

Annexure 3 : Data Capture and Power Flow in Rolling Stock

Page 2 of 17

DMRC 1st Monitoring Report

Page 3 of 17

1. Title of the Project

Title: Installation of Low Green House Gases (GHG) emitting rolling stock cars

in metro system

Date of CDM Project Registration with UNFCCC: 29/12/2007

2. Introduction

The purpose of the monitoring report is to calculate the Greenhouse Gas (GHG)

emission reductions achieved by the DMRC project for CER verification.

The monitoring report covers the project activity from 29/12/2007 till 31/01/2008

(Both days inclusive).

3. Reference

3.1. Sectoral Scope

7: Transport

3.2. Approved baseline and monitoring methodology

Type III Other project activities,

Category III.C.: Emission reduction by low greenhouse gas emitting vehicles

(version 10, 23 December 2006)

Reference: Appendix B- Indicative Simplified Baseline and monitoring

Methodologies for Selected Small Scale CDM Project Activities

3.3. Project Design Document

Title: Installation of Low Green House Gases (GHG) emitting rolling stock cars in

metro system

Version: 03

Date: 30/08/2007

4. Project Description

Project Activity

The project activity operates low GHG emitting rolling stocks having regenerative

braking system in Delhi Metro Rail Corporation (DMRC). The project activity

replaces the conventional electro-dynamic rheostatic braking technology, with

regenerative braking technology fitted rolling stocks. The regenerated electrical

energy reduces the consumption of equivalent grid electrical energy required by

the powering trains, thereby conserving electrical energy and subsequently leading

to GHG emission reduction.

Salient Features of the Project

Delhi Metro Rail Corporation (DMRC) has electrical driven Mass Rapid

Transport System which uses 4 car rolling stocks on different service lines. A

typical rolling stock used by DMRC consists of two units, each comprising of two

cars, a Driving Trailer car (DT) and a Motor Car (M). The Delhi Metro System is

designed for rolling stock where coaches are equipped with 3 phase AC traction

motors with regenerative braking system. The regenerative braking technology

employed in DMRC is different from the prevalent system adopted by metro

system in the country which is use of conventional electro-dynamic rheostatic

DMRC 1st Monitoring Report

Page 4 of 17

braking system. The electro-dynamic rheostatic braking system converts the

kinetic energy of decelerating Rolling stock into the thermal energy of rheostats

which is dissipated as heat without regenerating electrical energy while

decelerating. Hence, the choice made by DMRC for using regenerative braking

technology displays the environmental consciousness of the management.

The technology for regenerative braking system in the rolling stock is provided by

Mitsubishi Electric Corporation, Japan without any technology transfer. The

regenerative braking system works on the principle of converting kinetic energy of

the rolling stock while decelerating, into electrical energy using 3 phase Induction

motor and Variable Voltage Variable Frequency Control (VVVF) Technology. In

the regenerative mode, the traction motors work as generators and the ConverterInverter (CI) converts the electrical energy regenerated to Direct Current (DC).

The DC is subsequently converted to single-phase line frequency AC voltage,

which is stepped up by transformer to the level of 25 kV. The single phase line

frequency AC voltage is then fed back to the Over Head Equipment (OHE). The

regenerated electrical energy supplied back to the OHE is used by other

accelerating Rolling stock in the same service line. The regenerated electrical

energy reduces the consumption of equivalent amount of grid electrical energy

which would otherwise have been consumed by the accelerating trains, thereby

conserving electrical energy and reducing GHG emissions.

The introduction of low GHG emitting rolling stocks having regenerative braking

system in Delhi Metro Rail Corporation (DMRC) has been commissioned in the

three corridors (service lines) as follows:

Service

line

1

2

3

Year

of commissioning

March 04

July 05

November 06

Corridor

Shahdara- Rithala

Vishvavidyalaya- Central Sectt.

Indraprastha - Dwarka

Total

No. of

rolling

stocks

25

14

31

70

The project has been completed as described in the Project Design Document (PDD).

The trains in the 3 service lines of the project activity are in operation continuously

(with outages forced & planned) since the respective commissioning dates.

Project Participants

The project participants are:

Delhi Metro Rail Corporation; and

Japan Carbon Finance Limited

Project Location

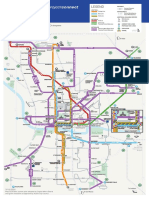

The project activity has been implemented in Delhi on the following metro

corridors:

Shahdara Rithala

Vishvavidyalaya- Central Secretariat

Indraprastha - Dwarka

DMRC 1st Monitoring Report

Page 5 of 17

The map of these metro corridors is as follows:

Rithala

Vishwa Vidyalaya

Shahadara

Indraprastha

Central Sectt

Dwarka

Red Line Rithala to Shahadra

Yellow Line Vishwa Vidyalaya to Central Sectt

Blue Line Dwarka to Indraprastha

DMRC 1st Monitoring Report

Page 6 of 17

5.0 Monitored data and parameters

For the project, following data and parameters are monitored during the reported

monitoring period:

Data / Parameter:

Data unit:

Description:

Source of data used:

Value of data

Description of

measurement

methods and

procedures applied:

QA/QC procedures

applied:

Data / Parameter:

Data unit:

Description:

Source of data used:

Value of data

Description of

measurement

methods and

procedures applied:

QA/QC procedures

applied:

EGi, Wr

kWh

Electrical energy consumed by the operational rolling stock i

Train Integration and Management System (TIMS) reading

10298021 (for further details refer Annex 1 of this Monitoring

Report)

Electrical energy consumed by each rolling stock is the sum of

the electrical energy consumed by the rolling stock i for

motoring (M) and the Auxiliary electricity consumption (SIV),

both of which are monitored by TIMS. The energy data for

monitoring is downloaded from TIMS of Rolling Stock using

a maintenance terminal. Since TIMS is software based

electronic equipment it has a high degree of accuracy (+

0.01%) and as per manufacturer specifications requires no

calibration from time to time.

The TIMS data is recorded by CDM team member (From each

service line depot) of the Rolling Stock Department and is

forwarded to the CDM Coordinator of the project. A data

review meeting is conducted once in 6 months which is

chaired by CDM Chairman. In this meeting, data compiled by

CDM coordinator is cross checked with service line data of all

the rolling stock. Subsequently to check further the data

authenticity and accuracy, data is verified, audited and signed

by senior officials from DMRC.

EGi, R

kWh

Electrical energy regenerated by the operational rolling stock

i

TIMS reading

3945780 (for further details refer Annex 1 of this Monitoring

Report)

Electrical energy regenerated by each rolling stock is

monitored by TIMS. The energy data for monitoring is

downloaded from TIMS of Rolling Stock using a maintenance

terminal. Since TIMS is software based electronic equipment

it has a high degree of accuracy (+ 0.01%) and as per

manufacturer specifications requires no calibration from time

to time.

The TIMS data is recorded by CDM team member (From each

service line depot) of the Rolling Stock Department and is

forwarded to the CDM Coordinator of the project. A data

review meeting is conducted once in 6 months which is

chaired by CDM Chairman (Head of Maintenances

department). In this meeting, data complied by CDM

DMRC 1st Monitoring Report

Page 7 of 17

coordinator is cross checked with service line data of all the

rolling stock. Subsequently to check further the data

authenticity and accuracy, data is verified, audited and signed

by senior officials from DMRC.

Data / Parameter:

Data unit:

Description:

Source of data to be

used:

Value of data

Description of

measurement

methods and

procedures to be

applied:

QA/QC procedures

to be applied:

Data / Parameter:

Data unit:

Description:

Source of data to be

used:

Value of data

Description of

measurement

methods and

procedures to be

applied:

QA/QC procedures

to be applied:

Si

Km

Total distance covered by the rolling stock i

TIMS reading

946078 (for further details refer Annex 1 of this Monitoring

Report)

The distance travelled by each rolling stock is monitored by

TIMS. The energy data for monitoring is downloaded from

TIMS of Rolling Stock using a maintenance terminal. Since

TIMS is software based electronic equipment it has a high

degree of accuracy (+ 0.01%) and as per manufacturer

specifications requires no calibration from time to time.

The data is monitored by the operation and maintenance

department of DMRC

N

-Total number of operational Rolling stocks in the three service

lines

Rolling Stock Department Log Book

70

Unique Identification number of each Rolling stock is

identified and verified at the regular monitoring interval

The data is monitored by the operation and maintenance

department of DMRC

Note: EGi, Wr , EGi, R, Si were monitored continuously. As annual units of these 3

parameters have not yet generated, these are reported in units appropriate to actual

monitored vintage.

DMRC 1st Monitoring Report

Page 8 of 17

Flow Chart for CDM Data Monitoring, Recording and Storage

Monitoring of parameters associated

with Emission Reduction calculation

Procedure for monitoring

and calibration

Rolling

Stock Car

Recording of monitored parameters and

converting into monthly reports

Data receiving, compilation and documentation

(monthly reports) by CDM controller

Procedure for review

meetings

Review meeting -Review of

data and verification

Procedure for NonConformance and Corrective

Any disparity in Data

during review meeting

Emission reduction

calculations

Data Storage / Protection

Procedure for data

protection and handling

The monitoring of the all electrical energy data required for estimation of baseline and

project emissions for the project activity is through state of the art electronic

equipments like TIMS. This is an electronic device with very high accuracy for

measurement and recording.

The operation and maintenance (O&M) staff downloads the TIMS recorded data from

the rolling stock on a regular basis and stores this data on a Computer for further

records. The parameters concerned are well documented and numbered. The

documented parameters are duly signed by respective Rolling Stock Depot in-charges

and forwarded to CDM co-coordinator on a monthly basis. The parameters are

documented according to the standard procedures. The report received from O&M

department is compiled and maintained by CDM coordinator. The data capture and

power flow scheme is pictorially depicted given in Annexure 3.

Measures to ensure the results/uncertainty analysis

The monitoring of the all electrical energy data required for estimation of baseline and

project emissions for the project activity is continuous using state of the art electronic

DMRC 1st Monitoring Report

Page 9 of 17

equipments Train Integration Management system (TIMS). This is an electronic

device with very high accuracy for measurement and recording.

The operation and maintenance (O&M) staff downloads the TIMS recorded data from

the rolling stock on a regular basis and stores this data on a Computer for further

records. The parameters concerned are well documented and numbered. The

documented parameters are duly signed by respective Rolling Stock Depot in-charges

and forwarded to CDM co-coordinator for archiving on a monthly basis. The

parameters are documented according to the standard procedures. The report received

from O&M department is compiled and maintained by CDM coordinator. The reports

will be retained till 2 years after the end of crediting period or the last issuance of

CERs for the project activity whichever occurs later.

6.0 Emission Reduction Calculation

6.1 Baseline Emissions:

BE = EGWr * EF

Where:

EGWr = [

(EGi,,Wr / Si ) * Si ]

i =1

EF

CO2 emission factor of the northern grid (t CO2 e / GWh)

total electrical energy consumed by rolling stocks without regenerative

EGWr

braking (GWh)

EGi, Wr

total energy consumed by the rolling stock i without regenerative

braking (GWh)

Si

total distance covered by the rolling stock i (km)

N

total number of operational rolling stocks

6.2 Project Emissions:

N

PE =

[{ {(EG

i,,Wr

/ Si

) - (EG

i,,R

/ Si

)} * S }] * EF

i

i =1

Where,

N

EGR =

[ (EG

i,,R

/ Si

) *S ]

i

i =1

EF

EGR

EGi,R

CO2 emission factor of the northern grid (t CO2 e / GWh)

total electrical energy regenerated with regenerative braking (GWh)

total energy regenerated by the rolling stock i with regenerative

braking (GWh)

6.3 Emission Reductions:

ER = BE - PE

DMRC 1st Monitoring Report

Page 10 of 17

Summary of emission reduction:

Line

Total Energy

consumed (EGwr),

kWh

Total energy

regenerated (EGr),

kWh

Distance

covered (S),

km

Line 1

Line 2

Line 3

Total

3,449,267

2,022,922

4,825,832

10,298,021

1,413,914

624,886

1,906,980

3,945,780

294,283

144,981

506,814

946,078

The values of EGwr and EGr are converted in GWh prior to calculating the baseline

emission and project emission as below:

Emission factor

of northern

regional grid

Baseline

emissions

Project

emissions

Emission

reduction

800 tCO2/GWh (ex-ante value of registered PDD)

8,238 tCO2

3,157 tCO2

5,081 tCO2

Further details on each rolling stock in the respective service lines (1, 2 & 3) are

detailed in following Annexure 1.

DMRC 1st Monitoring Report

Page 11 of 17

Annexure 1: Data

Service

Line 1

TS 01

TS 02

TS 03

TS 04

TS 05

TS 06

TS 07

TS 08

TS 09

TS 10

TS 11

TS 12

TS 13

TS 14

TS 15

TS 16

TS 17

TS 18

TS 19

TS 20

TS 21

TS 22

TS 23

TS 24

TS 25

Sub-total

Electrical Energy

Energy regenerated

Distance covered

consumed

(kWh)

(km)

(kWh)

29-Dec.07 to 01-Jan.08 to 29-Dec.07 to 01-Jan.08 to 29-Dec.07 to 01-Jan.08 to

31-Dec. 07

31-Jan.08 31-Dec. 07

31-Jan.08 31-Dec. 07 31-Jan.08

11396

82209

4584

35205

951

7031

8023

123015

3107

50493

651

10322

14228

129243

5691

53177

1191

10795

13561

137472

5531

59594

1167

12045

15613

129797

6499

54922

1335

10872

12793

111019

5124

45291

1068

9243

12177

142532

4782

57626

1024

12222

13271

122697

5265

48746

1083

10361

15423

124620

6173

50040

1284

10240

16656

126387

6943

53700

1415

10650

14532

137504

5944

55802

1268

11832

15611

133105

6576

56652

1361

11525

14775

132881

6069

56057

1268

11285

14552

128175

5934

53045

1231

11864

17974

142534

7454

59375

1596

12474

5211

138284

1975

61250

409

12229

2003

119793

745

48000

155

10308

8044

97966

3213

38258

650

8247

8654

110677

3294

42693

723

9378

16563

113217

6308

42128

1432

9303

13021

117531

5025

46581

1062

9978

15662

119765

6249

47099

1354

10088

14043

137755

5431

54502

1167

11753

4285

131834

1510

54906

324

11309

9117

152067

3883

65463

756

13004

3449267

1413914

294283

DMRC 1st Monitoring Report

Service

Line 2

MC 01

MC 02

MC 03

MC 04

MC 05

MC 06

MC 07

MC 08

MC 09

MC 10

MC 11

MC 12

MC 13

MC 14

Sub-total

Page 12 of 17

Electrical Energy

Energy regenerated

Distance covered

consumed

(kWh)

(km)

(kWh)

29-Dec.07 to 01-Jan.08 to 29-Dec.07 to 01-Jan.08 to 29-Dec.07 to 01-Jan.08 to

31-Dec. 07

31-Jan.08 31-Dec. 07

31-Jan.08 31-Dec. 07 31-Jan.08

9989

123797

2469

33866

674

8901

10214

133544

3199

43633

752

9613

7061

136942

1851

43828

457

10206

15824

147401

4925

47927

1153

10658

4923

123789

1493

40184

326

8687

11299

115881

3442

37441

819

8204

6354

136852

1722

39758

426

9788

11021

134567

2973

36562

802

9750

10791

135460

3355

44569

787

9933

15946

154794

4326

44098

1119

10903

10362

122638

3230

39325

774

8994

15842

128510

4753

39209

1173

9224

16593

120482

5406

38814

1219

8583

16429

145617

5262

47266

1136

9920

2022922

624886

144981

DMRC 1st Monitoring Report

Service

Line 3

TS 01

TS 02

TS 03

TS 04

TS 05

TS 06

TS 07

TS 08

TS 09

TS 10

TS 11

TS 12

TS 13

TS 14

TS 15

TS 16

TS 17

TS 18

TS 19

TS 20

TS 21

TS 22

TS 23

TS 24

TS 25

TS 26

TS 27

TS 28

TS 29

TS 30

TS 31

Sub-total

Page 13 of 17

Electrical Energy

Energy regenerated

Distance covered

consumed

(kWh)

(km)

(kWh)

29-Dec.07 to 01-Jan.08 to 29-Dec.07 to 01-Jan.08 to 29-Dec.07 to 01-Jan.08 to

31-Dec. 07

31-Jan.08 31-Dec. 07

31-Jan.08 31-Dec. 07 31-Jan.08

10541

140752

834

63983

4433

10226

19718

121383

1534

53904

8716

9156

10192

148968

755

65756

4372

12311

10436

147521

798

62450

4372

11365

19119

168062

1484

71895

8220

13022

14959

125098

1143

51154

6094

9555

12091

144104

872

66118

4749

10787

762

144326

15

60707

20

11432

16971

152078

1362

64104

7071

11861

18586

116309

1460

51197

7972

8905

6244

133980

474

55841

2692

10566

17360

140025

1357

58077

7250

11196

16516

144017

1267

61831

7018

11132

12660

142780

967

60011

5128

11099

12452

134816

957

56486

5255

10158

16351

141673

1243

58397

6954

10690

17355

130975

1336

56587

7386

10115

6642

124983

514

52373

2889

9267

13364

137638

1003

57751

5647

10319

17658

142156

1408

61069

7657

10829

17135

141078

1345

61269

7473

10731

15527

160910

1182

66774

6552

11746

8781

148921

662

63959

3882

11349

6613

105504

490

44762

2857

7731

11518

170005

836

70123

4699

12555

14668

158335

1061

63796

5913

11561

17744

160601

1310

66950

7108

11989

3351

163451

198

66722

1084

11505

10947

138831

818

59371

4757

10431

15290

155557

1135

66924

6521

11821

16199

133245

1229

55590

6772

9891

4825832

1906980

506814

DMRC 1st Monitoring Report

Page 14 of 17

Summary Sheet for the three service lines:

Service

Lines

Line 1

Line 2

Line 3

Total

Total Electrical Energy

consumed

(kWh)

3449267

2022922

4825832

10298021

Total Energy regenerated

(kWh)

Total Distance covered

(km)

1413914

624886

1906980

294283

144981

506814

3945780

946078

DMRC 1st Monitoring Report

Anexure 2 : Contact Information

Organization

Street / P.O. Box

Building

City

State / Region

Postfix / Zip

Country

Telephone

FAX

URL

Represented by

Title

Salutation

Last Name

Middle Name

First Name

Department

Mobile

Direct FAX

Direct Tel

Personal E-Mail

Delhi Metro Rail Corporation

Bhishma Pitamah Marg Pragati Vihar

IIIrd NBCC Place

New Delhi

Delhi

110003

India

91-11-24366238

91-11-24366238

Ed_cp@dmrc.org

www.delhimetrorail.com

Executive Director

Mr.

Singh

Mangu

arunkr_2k@rediffmail.com

Page 15 of 17

DMRC 1st Monitoring Report

Organization

Street / P.O. Box

Building

City

State / Region

Postfix / Zip

Country

Telephone

FAX

E-Mail

URL

Represented by

Title

Salutation

Last Name

Middle Name

First Name

Department

Mobile

Direct FAX

Direct Tel

Personal E-Mail

Japan Carbon Finance, Ltd.

6th Floor, 1-3, Kudankita 4-Chome,

Chiyoda-ku

Tokyo

102-0073

Japan

+81-3-5212-8870

+81-3-5212-8886

jcf@jcarbon.co.jp

http://www.jcarbon.co.jp

Director General

Mr.

Ari

Masato

Carbon Finance Department

+81-3-5212-8886

+81-3-5212-8878

m-ari@jcarbon.co.jp

Page 16 of 17

DMRC 1st Monitoring Report

Page 17 of 17

Annexure 3 : Data Capture and Power Flow in Rolling Stock

OHE

Pantograph

VCB

Main

Transformer

C/I

TIMS

SIV

Traction Motor

Aircon

(recording)

Main

compressor

220V

Load

Gear case

Oil pump and

blower

Power to

Wheels

The data capture from rolling stock takes place in TIMS, which receives the electronic

pulses (depicted in blue dots) from the Convertor-Invertor (C/I) and Auxiliary (SIV).

110 V

load

Вам также может понравиться

- Clean Development Mechanism Project Design Document Form (CDM-SSC-PDD) Version 03 - in Effect As Of: 22 December 2006Документ32 страницыClean Development Mechanism Project Design Document Form (CDM-SSC-PDD) Version 03 - in Effect As Of: 22 December 2006MOHISH MAHESHWARIОценок пока нет

- Regen BrakingДокумент6 страницRegen BrakingNyakazaОценок пока нет

- IET Electric Power Appl - 2017 - Ballal - Online Condition Monitoring System For Substation and Service TransformersДокумент10 страницIET Electric Power Appl - 2017 - Ballal - Online Condition Monitoring System For Substation and Service TransformersbenlahnecheОценок пока нет

- PDD GHCLДокумент36 страницPDD GHCLNiroj MohantyОценок пока нет

- Final SynopsisДокумент8 страницFinal SynopsisSameer Kapoor100% (1)

- Summer Internship Report Abhishek 06Документ63 страницыSummer Internship Report Abhishek 06Amber GuptaОценок пока нет

- Annual Report: Central Electricity Regulatory CommissionДокумент242 страницыAnnual Report: Central Electricity Regulatory CommissionKuldeep RupareliaОценок пока нет

- Synchronization of Speed of DC Motors For Rolling Mills: D.Reddy PranaiДокумент5 страницSynchronization of Speed of DC Motors For Rolling Mills: D.Reddy PranaiBandi GaneshОценок пока нет

- Energy MeterДокумент171 страницаEnergy MeterK S Prabha KaranОценок пока нет

- DPR - IPDS Jammu - 30.4.2015Документ82 страницыDPR - IPDS Jammu - 30.4.2015Manoj ManhasОценок пока нет

- Speed Control of DC Motor Using Three Phase Fully Controlled Bridge Converter: Matlab Simulation and AnalysisДокумент36 страницSpeed Control of DC Motor Using Three Phase Fully Controlled Bridge Converter: Matlab Simulation and AnalysisRaoKrishanОценок пока нет

- 2 1 1633607149 5ijaerddec20215Документ8 страниц2 1 1633607149 5ijaerddec20215TJPRC PublicationsОценок пока нет

- Regen Braking PDFДокумент6 страницRegen Braking PDFfake fОценок пока нет

- CIGRE US National Committee 2018 Grid of The Future SymposiumДокумент8 страницCIGRE US National Committee 2018 Grid of The Future Symposiumhari kurniawanОценок пока нет

- Singapore's Rapid SystemДокумент10 страницSingapore's Rapid SystemAli AkbarОценок пока нет

- BBMG Cement WHR For 10.5 MW Power Generation Project in BeijingДокумент8 страницBBMG Cement WHR For 10.5 MW Power Generation Project in BeijingYogendra PalОценок пока нет

- Journal Jpe 15-5 1658292190Документ12 страницJournal Jpe 15-5 1658292190Nuri KaraoğlanОценок пока нет

- Project ThesisДокумент12 страницProject Thesismuhammd umerОценок пока нет

- Gmrt2045 Iss 2Документ25 страницGmrt2045 Iss 2bijendrakumar1991Оценок пока нет

- Grid Connected 3MWp Solar PV Power Plant at Raichur District of Karnataka State, IndiaДокумент27 страницGrid Connected 3MWp Solar PV Power Plant at Raichur District of Karnataka State, Indiaakarimi7961Оценок пока нет

- EV Impact on Power Demand and CostsДокумент15 страницEV Impact on Power Demand and CostsChino PlagaОценок пока нет

- Electrical Energy Audit GuidelinesДокумент36 страницElectrical Energy Audit Guidelinesjustusfr4ntz100% (6)

- Optimization Approaches and Techniques For Automotive Alternators: Review StudyДокумент26 страницOptimization Approaches and Techniques For Automotive Alternators: Review StudyMAHMOOD OMAR TALAL MAHMOOD / UPMОценок пока нет

- FYP-II PresentationДокумент21 страницаFYP-II PresentationM UsamaОценок пока нет

- Grid and Ev FaultДокумент4 страницыGrid and Ev Faultarshid aliОценок пока нет

- A Data-Driven Method For Energy Consumption Prediction and Energy-Efficient Routing of Electric Vehicles in Real-World ConditionsДокумент18 страницA Data-Driven Method For Energy Consumption Prediction and Energy-Efficient Routing of Electric Vehicles in Real-World ConditionsMuhammed AlhanoutiОценок пока нет

- The Framework of Advanced Distribution Management SystemДокумент5 страницThe Framework of Advanced Distribution Management SystemBehrouz AzimianОценок пока нет

- 5-1 DPR - Project Development and DPRДокумент19 страниц5-1 DPR - Project Development and DPRSayed NagyОценок пока нет

- Digital Control of A Three Phase Induction MotorДокумент60 страницDigital Control of A Three Phase Induction MotorKeshavamurthy MurthyОценок пока нет

- An Induction Motor Design For Urban Use Electric Vehicle: September 2016Документ7 страницAn Induction Motor Design For Urban Use Electric Vehicle: September 2016izzaty ariffОценок пока нет

- Optimal Location of Remote Terminal Units in Distribution System Using Genetic AlgorithmДокумент6 страницOptimal Location of Remote Terminal Units in Distribution System Using Genetic Algorithmrasim_m1146Оценок пока нет

- 1 s2.0 S2666546821000641 MainДокумент9 страниц1 s2.0 S2666546821000641 MainSidharth MaheshОценок пока нет

- NRG Mod3-2Документ2 страницыNRG Mod3-2Abhinandh MenonОценок пока нет

- Guide to Special Energy Meter Data Processing in North East IndiaДокумент93 страницыGuide to Special Energy Meter Data Processing in North East IndiaKrishna Venkataraman100% (1)

- Chassis Dynamometer For Electric Two WheelersДокумент5 страницChassis Dynamometer For Electric Two Wheelersdani chОценок пока нет

- Work Done in Seventh SemesterДокумент1 страницаWork Done in Seventh SemestersreekanthaОценок пока нет

- Scope and Work RAPDRP AДокумент55 страницScope and Work RAPDRP AMurali PssОценок пока нет

- Simulation of Energy Efficiency Improvements On Commuter Railways PDFДокумент9 страницSimulation of Energy Efficiency Improvements On Commuter Railways PDF曾乙申Оценок пока нет

- Applications of Power Electronics Prof. Frede BlaabjergДокумент7 страницApplications of Power Electronics Prof. Frede BlaabjergmychristОценок пока нет

- Applications of Power Electronics PDFДокумент7 страницApplications of Power Electronics PDFTumenbayar LkhagvatserenОценок пока нет

- 8.5 MW Wind Power Project in ChitradurgaДокумент29 страниц8.5 MW Wind Power Project in ChitradurgaSanil KollaraОценок пока нет

- Matlab Simulink Based Energy ConsumptionДокумент5 страницMatlab Simulink Based Energy ConsumptionJovana NikolicОценок пока нет

- Automatic Toll Collection Using MicrocontrollerДокумент13 страницAutomatic Toll Collection Using MicrocontrollerShalabh AgarwalОценок пока нет

- Unit-2 Smart Grid Measurement and Automation TechnologiesДокумент85 страницUnit-2 Smart Grid Measurement and Automation TechnologiessujithОценок пока нет

- Data SheetДокумент30 страницData SheetAmzad AliОценок пока нет

- 12222017102528AMAIS-039 (Rev.1) With Corrigendum 1Документ13 страниц12222017102528AMAIS-039 (Rev.1) With Corrigendum 1vivekpattniОценок пока нет

- Projects: Dfid Hyderabad Integrated SCADA Project APCPDCL in The Reform ModeДокумент7 страницProjects: Dfid Hyderabad Integrated SCADA Project APCPDCL in The Reform ModeToroomОценок пока нет

- Efficient Recovery of Braking Energy Through A Reversible DC SubstationДокумент9 страницEfficient Recovery of Braking Energy Through A Reversible DC SubstationnpfhОценок пока нет

- Pi Viii 02 PDFДокумент10 страницPi Viii 02 PDFThechangemakerОценок пока нет

- Dynamic Line RatingДокумент39 страницDynamic Line Ratingbocioroaga_marian7333Оценок пока нет

- Souad TOUAIRI R2Документ13 страницSouad TOUAIRI R2sayyouriОценок пока нет

- Solar Auto RickshawДокумент6 страницSolar Auto RickshawDida KhalingОценок пока нет

- Performance Analysis of Wheeling Charges DeterminaДокумент13 страницPerformance Analysis of Wheeling Charges DeterminasvvsnrajuОценок пока нет

- Telecommunications Traffic : Technical and Business ConsiderationsОт EverandTelecommunications Traffic : Technical and Business ConsiderationsОценок пока нет

- Papers on the field QoS Measurement Of Services in mobile networks Using Aggregation MethodОт EverandPapers on the field QoS Measurement Of Services in mobile networks Using Aggregation MethodРейтинг: 4 из 5 звезд4/5 (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Microsoft Excel-Based Tool Kit for Planning Hybrid Energy Systems: A User GuideОт EverandMicrosoft Excel-Based Tool Kit for Planning Hybrid Energy Systems: A User GuideОценок пока нет

- Improving Energy Efficiency and Reducing Emissions through Intelligent Railway Station BuildingsОт EverandImproving Energy Efficiency and Reducing Emissions through Intelligent Railway Station BuildingsОценок пока нет

- Energy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyОт EverandEnergy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyChristine JuniorОценок пока нет

- Handbook on Battery Energy Storage SystemОт EverandHandbook on Battery Energy Storage SystemРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Ticket 3586662689Документ2 страницыTicket 3586662689dev dОценок пока нет

- DR - Sugandha Raha As DG RHSДокумент2 страницыDR - Sugandha Raha As DG RHSMahipal ReddyОценок пока нет

- 295HR - Operator's Manual PDFДокумент96 страниц295HR - Operator's Manual PDFHarry Wart Wart100% (1)

- Staffordshire - WikipediaДокумент45 страницStaffordshire - WikipediabilalОценок пока нет

- Da 560 DafДокумент110 страницDa 560 DafJakaОценок пока нет

- 10b MapДокумент1 страница10b MapAnonymous Pb39klJОценок пока нет

- Inggris BeritaДокумент1 страницаInggris BeritaKimino UdinОценок пока нет

- 204 Pending 23.5.23Документ13 страниц204 Pending 23.5.23VAIBHAV MEHRAОценок пока нет

- Inventive Pricing of Urban Public TransportДокумент19 страницInventive Pricing of Urban Public TransportSean100% (1)

- Indian Navy Call Up LetterДокумент1 страницаIndian Navy Call Up LetterLakshmi KruthigaОценок пока нет

- ProiectДокумент18 страницProiectIoana IzabelaОценок пока нет

- Bouldering Boston by BusДокумент7 страницBouldering Boston by BusLochie FerrierОценок пока нет

- Notes - Bridge Design - Box Girder BridgesДокумент20 страницNotes - Bridge Design - Box Girder BridgesBobby Wong100% (4)

- Code Review MatrixДокумент7 страницCode Review MatrixAndrei GrigoreОценок пока нет

- EU Railway Agency Report on Derailment Detection DevicesДокумент111 страницEU Railway Agency Report on Derailment Detection DevicesAbdulhmeed MutalatОценок пока нет

- Trolley Assist To Optimise Hauling Cycles With Electric Trucks PDFДокумент16 страницTrolley Assist To Optimise Hauling Cycles With Electric Trucks PDFSACHIDHANANDHAM A100% (1)

- Talgo AVRILДокумент23 страницыTalgo AVRILRailway 20Оценок пока нет

- MCQs Test Preparation GuideДокумент3 страницыMCQs Test Preparation GuideAhsan Rao0% (1)

- LDC - V - 1 - 0.pdsprj 13-01-2019 LDC - V - 1 - 0.pdsprjДокумент5 страницLDC - V - 1 - 0.pdsprj 13-01-2019 LDC - V - 1 - 0.pdsprjsureshpawan2010Оценок пока нет

- Chemist Upload FormatsДокумент295 страницChemist Upload FormatsKeshav JhaОценок пока нет

- Inland Port StudyДокумент24 страницыInland Port StudyAnonymous eQEPnOOZvJОценок пока нет

- Intelligent Train Engine To Avoid Accidents and Railway Gate ControllingДокумент3 страницыIntelligent Train Engine To Avoid Accidents and Railway Gate ControllingInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Risk Management for Infrastructure PPPДокумент41 страницаRisk Management for Infrastructure PPPkhoiОценок пока нет

- Railway Engineering Exam QuestionsДокумент2 страницыRailway Engineering Exam QuestionsKundan SalunkeОценок пока нет

- Transport Infrastructure in NigeriaДокумент12 страницTransport Infrastructure in Nigeriadonafutow2073Оценок пока нет

- Energy Efficient Vande Bharat SpecificationДокумент86 страницEnergy Efficient Vande Bharat SpecificationNasim UddinОценок пока нет

- NYC Tunnels Assessment ReportДокумент57 страницNYC Tunnels Assessment Reportkatehinds100% (3)

- Strategic Parking Review QuestionnaireДокумент10 страницStrategic Parking Review QuestionnaireRichie Juls BacalsoОценок пока нет

- Electric Monorail SystemДокумент1 страницаElectric Monorail Systemjenny martinezОценок пока нет

- Straight Prohibited or No EntryДокумент12 страницStraight Prohibited or No EntryKavi KumarОценок пока нет