Академический Документы

Профессиональный Документы

Культура Документы

1 s2.0 0043135494E0115M Main PDF

Загружено:

dmelotorresИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1 s2.0 0043135494E0115M Main PDF

Загружено:

dmelotorresАвторское право:

Доступные форматы

War. Res. Vol. 29, No. 1, pp.

137-145, 1995

Pergamon

0043-1354(94)E0115-M

Copyright 1994 Elsevier Science Ltd

Printed in Great Britain. All rights reserved

0043-1354/95 $7.00 + 0.00

A STEADY-STATE MODEL FOR THE SINGLE SLUDGE

ACTIVATED SLUDGE SYSTEM--I. MODEL DESCRIPTION

YERACHMIEL ARGAMAN @

Environmental and Water Resources Engineering, Technion-Israel Institute of Technology,

Haifa 32000, Israel

(First received July 1993; accepted in revised form April 1994)

A b s t r a e t - - A steady-state model for activated sludge with or without nitrogen control is proposed. It

pertains to real activated sludge systems in that both soluble and particulate influent organics are

addressed and various fractions of the mixed liquor solids are distinguished. The pseudo first-order kinetic

law is used for soluble BOD removal and first-order kinetic for the hydrolysis of particulate organics.

Biodegradation of hydrolyzed particulates is treated in a simlar way to the soluble organics by using an

"effective soluble B O D " term which combines both BOD sources. M o n o d rate law is used for nitrification

while denitrification is controlled by BOD removal under anoxic conditions. The model equations are

solved by an iterative procedure developed for this problem.

Key words--activated sludge, steady-state model, nitrification, denitrification

NOMENCLATURE

K A = nitrification half saturation coefficient for a m m o nia nitrogen, m g IK o = nitrification half saturation coefficient for dissolved oxygen, mg 1Kp = particulate BOD hydrolysis rate coefficient, 1

(rag. day)- t

g s , a e r = half saturation coefficient for BOD removal in

the aerobic zone, m g l K~.~,= half saturation coefficient for BOD removal in

the anoxic zone, m g lKp(20) = particulate BOD decay rate coefficient at 20'~C, 1

(nag. day) i

MLSS = Mixed Liquor Suspended Solids

MLVSS = Mixed Liquor Volatile Suspended Solids

No = i n f l u e n t nitrate nitrogen concentration, m g l

N~ = n i t r a t e nitrogen concentration entering the

anoxic zone, mg 1-L

N 2 = nitrate nitrogen concentration in the anoxic zone,

m g l -t

N e = nitrate nitrogen concentration in the emuent,

m g l -~

02 = oxygen requirement, mgO2/liter of flow

r = overall recycle ratio

So = influent soluble BOD, mg 1$6 = effective influent BOD, m g 1S'L = effective B O D entering the anoxic zone, mg IS~ = effective BOD leaving the anoxic zone, mg 1-L

S~ = effluent soluble BOD, mg 1- '

SeT = effluent total BOD, m g 1- '

SRT = Solids Retention Time

SS = Suspended Solids

t = system nominal H R T , day

t~er = nominal H R T in aerobic zone, day

t~. = nominal H R T in anoxic zone, day

t~n = single pass H R T in anoxic zone, day

T = aeration basin temperature, C

TSS = Total Suspended Solids

VSS = Volatile Suspended Solids

Xe = effluent total suspended solids, m g l

X~ = influent total suspended solids, m g l

XN = nitrogen content of biological solids, gN

(gVSS)-'

a = yield coefficient, gVSS ( g B O D ) a ' = oxygen utilization coefficient, gO 2 (gBOD)-l

a~, = dissimilatory nitrate utilization coefficient,

gN/(gBOD)- 1

A 0 = concentration of a m m o n i a nitrogen in the influent, m g l L

A e = concentration of a m m o n i a nitrogen in the effluent and the nitrification zone, m g lb = endogenous decay rate coefficient of heterotrophic biomass, d a y b(20) = e n d o g e n o u s decay rate coefficient for heterotrophic biomass at 20C, day -~

b' = endogenous oxygen consumption rate coefficient,

gO2 (gVSS day)-I

b N = endogenous decay rate coefficient of nitrifiers,

day- i

b N(20) = endogenous decay rate coefficient for nitrifiers at

20C, day -I

b~n = e n d o g e n o u s nitrate utilization rate coefficient,

g N O 3-N (gVSS. day)-i

b'~,(20) = endogenous nitrate utilization rate coefficient, at

20C, g N O 3 - N (gVSS. day) -I

B O D = 5 day, 20C Biochemical Oxygen D e m a n d

DO = dissolved oxygen concentration in the aerobic

zone, rng l- 1

fb = biological fraction of mixed liquor volatile suspended solids

f0 = degradable fraction of influent volatile suspended solids

fr = remaining (not hydrolyzed) fraction of infiuent

degradable volatile suspended solids

f~ = volatile fraction of influent suspended solids

H R T = Hydraulic Retention Time

K~er = pseudo first order B O D removal rate coefficient

in the aerobic zone, d a y K(20) = pseudo first order BOD removal rate coefficient

under aerobic conditions with no oxygen limitation at 20C, d a y Ka, = pseudo first order BOD removal rate coefficient

in the anoxic zone, d a y 137

138

YERACHM1EL ARGAMAN

Xv= mixed liquor volatile suspended solids, mgl '

AA,, = ammonia nitrogen nitrified, mgN (liter of flow)

ANdeni t = nitrate nitrogen denitrified, mgN (liter of flow) '

AXT= total suspended solids leaving the system, mgTSS

(liter of flow)- '

AX~= VSS leaving the system, mgVSS (liter of flow)-'

q = aerobic volume fraction

/lN= actual growth rate of nitrifiers, day~!m~,x= maximum growth rate of nitrifiers at 20C, day-'

~b= ratio between BOD removal rate coefficients in

anoxic and aerobic zones at 20C and no substrate limitations

0 = temperature correction coefficient for BOD removal

0b= temperature correction coefficient for endogenous decay and nitrate utilization rates

0p = temperature correction coefficient for Kp

0c = system SRT, day

Oc,a = aerobic SRT, day

zd=degradable ("active") fraction of biological

MLVSS

INTRODUCTION

The activated sludge process has been the subject

of numerous studies and modeling efforts. Some of

the existing models are strictly empirical or over

simplified, thus restricting their usefulness in a system

design. On the other extreme, some models exist

which are highly theoretical and thus have not been

widely used by practicing engineers. The work presented herein accommodates most of the current

process knowledge in a mechanistic model that can be

used as a design tool by practicing engineers.

Unlike some of the recent models such as the

IAWPRC Task Group model (1987), the model

proposed herein is a steady-state one. Hence, in

principle, it is restricted to constant flow and load

conditions. In practice, it can be used for quasi

steady-state conditions and provide the basic design

information. The complete dynamic model can then

be used for optimizing the operation and control of

the system.

The present model uses BOD as the carbonaceous

organics parameter, whereas most of the recent

models are based on COD. The latter parameter is

considerably more convenient to use both in terms

of laboratory analysis and in stoichiometric and

materials balance expressions. However, in many

countries, BOD is still the main parameter used by

regulatory authorities and predicting its concentration is of great importance in systems design. BOD

also reflects the concentration of biodegradable organics which are the subject of interest in biological

treatment models. Also, the present model uses some

kinetic and materials balance approaches that differ

from the former ones.

Many of the existing steady-state models are limited to the soluble fraction of the wastewater organics

even though the particulate fraction often exceeds the

soluble. In the proposed model both fractions are

addressed. It is assumed that the particulate organics

are solubilized before being degraded. Hence, an

"effective BOD", which is defined as the summation

of the soluble and the actually solubilized particulate

BOD, is proposed in this model.

The proposed model is most applicable in the

preliminary phases of a system design, when various

process alternatives are evaluated. This is because for

comparative purposes, steady-state analyses are often

adequate and the absolute accuracy of all process

parameters is less critical. Use of the detailed dynamic

models requires accurate calibration for the specific

plant, a task which is often difficult to achieve.

Compared to the dynamic models, the present one

contains a smaller number of parameters and coefficients. Although this results in a somewhat lesser

detailed analysis, it is believed that for certain design

purposes it represents the right balance between

model sophistication and ease of use. In the model

presented here, many of the stoichiometric and kinetic coefficients are fairly well known for domestic

wastewater. Experimental evaluation of some of these

coefficients is described in associated publications

(Eliosov, 1994; Argaman and Papkov, 1995).

Use of the model for design purposes is achieved

by simultaneous solution of a set of equations. Any

commercially available software may be used for this

purpose. However, this paper presents a solution

procedure which was specifically developed for

this problem and can be easily used by practicing

engineers.

CARBONACEOUS ORGANIC REMOVAL

The first part of this work deals with carbonaceous

BOD removal. However the system under consideration is one that can be used for nitrogen control as

well, as seen in Fig. 1.

Definitions and nomenclature o f influent and M L S S

components

For modeling and design purposes the influent to

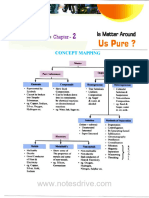

a biological wastewater treatment plant is characterized by the following parameters (see Fig. 2):

Soluble BOD, So

Total suspended solids (TSS), X~

Volatile fraction of influent SS, fv

Biodegradable fraction of influent VSS, fd

Ammonia (and oxidizable organic) nitrogen, A0

All BODs mentioned in this paper are 5 day,

20C BOD. The influent insoluble BOD is attributed

to the degradable portion of the influent VSS. The

ratio between these two values depends on the composition of the degradable VSS. In the present work,

a 1 : 1 ratio is assumed, as suggested by Eckenfelder

(1990).

Solids composition and mass balance

In the aeration basin a mixture of biological,

non-biological, fixed or volatile, degradable or

Steady-state model of activated sludge---I

139

It

BOD (effective):

Ammonia

N:

Nitrate

N:

Flow = Q

-

Aerobic Zone

HRT = t

[ Anoxic Zone

---] HRT=tan

aer

ludge

Total Recycle Flow = r, Q

Fig. 1. Flow scheme and symbols definitions for nitrogen--removing activated sludge.

non-degradable SS is present. Its composition is a

result of feed make up and process variables. Biological solids, i.e. volatile particulates of microbial origin,

are only a fraction of the MLVSS present in an

aeration basin. The remaining VSS are organic particulates originating from the influent SS. Of the

biological VSS only a fraction is active, while the

remaining consists of inactive solids such as dead or

fragmented cells. The MLSS is characterized by the

following parameters:

MLSS, X T

MLVSS, X v

Biological fraction of MLVSS, fb

Biodegradable ("active") fraction of biological

MLVSS, ;~d

The concentration of active biological solids has

been correlated with the degradable portion of the

solids. By using material balance equations Quirk

and Eckenfelder (1986) showed that the degradable

portion of the biological VSS can be related to the

system's SRT by:

z~ =

0.8

1 + 0.2b0

(1)

where:

Zd = degradable ("active") fraction of biological

MLVSS in the system

b = endogeneous decay rate coefficient of heterotrophic biomass, d a y 0c = system SRT, day

EFFLUENT & S L U D G E

W A S T A G E CONSTITUENTS

INFLUENT CONSTITUENTS

BOD

S~

BOD

(l-f0 Xl

~gXi

"Remaining" VSS

Non - Desradable

Biolosical V$S

AXT

Degradable

Biological VSS

-3-

S~-S,

Biological FSS

i// /t*///fA~

Fig. 2. Symbols definition and mass balance.

WR ~/l--J

>S~T

140

YERACHMIEL ARGAMAN

The VSS leaving the system through wastage of

sludge and solids carry over from the secondary

clarifier consists of three components:

Cellular material formed by the growth of microorganisms

Non-biodegradable VSS in the influent

Remaining portion of influent degradable VSS

which was not degraded within the system

Part of the generated VSS is

endogenous decay. Under steady

VSS leaving the system through

final effluent is, therefore, given

eliminated through

state conditions, the

sludge wastage and

by:

A X ~ = a(So - S~) + (1 - fd)fvX~

+ f~faf~Xi--bfbZdXvt

(2)

where:

AXv = VSS leaving the system, expressed as mgVSS

per liter of wastewater flow, mg 1a = yield coefficient, gVSS (gBOD)-1

S~ = effective influent BOD, mg 1-1

X i = influent total SS, mg 1S~ = effluent soluble BOD, mgl 1

fv = volatile fraction of influent SS

fd = degradable fraction of influent VSS

f~ = remaining (not hydrolyzed) fraction of influent degradable VSS

t ~ system nominal HRT, day

Xv= MLVSS, mg 1-a

L = biological fraction of MLVSS

The "effective" influent BOD used in this model

is defined as the summation of the soluble and the

solubilized BOD. The latter is proportional to

the particulate BOD that is actually hydrolyzed in the

system. Thus the effective influent BOD depends

on the system operation parameters. Based on

the 1:1 ratio assumption between hydrolized VSS

and its 5 day BOD, the effective BOD is expressed

by

S; = S O+ (1 --fr)fvfdX~

(3)

where

S o = influent soluble BOD, mg 1-1

From the definition of the SRT, the hydraulic residence time is given by:

t=

AXvo

X~ c

(4)

Substituting equation (2) in equation (4) and solving

for t yields:

t =

Oc{a(S'o - Se) -1- Xifv[1 +fd~r -- 1)]}

Xv(l +

bfbzdOc)

(5)

Since the bulk of the mixed liquor solids originate

from the recycle of secondary clarifier underflow,

the MLSS composition is nearly equal to that of the

excess sludge. Hence the biological fraction of the

MLVSS is the same as in the excess sludge (AXe).

Using equation (2), this fraction can be expressed by:

fb =

AXv - ~ f d + 1 - f a ) f v X ~

ax~

(6)

Kinetics o f substrate removal

In the kinetic approach adopted herein, the removals of soluble and insoluble BOD are treated

separately as shown below. The effect of particulate

BOD loading on the removal kinetics of soluble BOD

is accounted for by assuming that the portion of the

insoluble BOD which is hydrolyzed in the aeration

basin exerts an additional soluble BOD load. Thus,

in the kinetic equations which will follow, the "effective" influent soluble BOD defined in equation (3) is

used. A somewhat analogous approach was taken by

Rittman et al. (1987) in evaluating the fate of degradable microbial products in activated sludge systems.

The BOD of municipal wastewater is made of

multiple cabonaceous organic compounds. The

biodegradation rate of the individual compounds

follows the Monod Kinetics. Assuming that the concentration of each of these compounds in the reactor

exceeds its half-saturation parameter, the degradation of each compound approaches a zero-order

kinetics (Tischler and Eckenfelder, 1969). Hence the

rate of BOD conversion is independent of the reactor

flow regime (Argaman, 1991). Based on this assumption and following the kinetic approach of Adams

et al. (1975) and Grau et al. (1975), the effluent BOD

from a two-zone system as shown in Fig. 1 can be

expressed by:

(s;) 2

S~ --

S ; + (Kaer taer +

Kantan)fbZdXv

(7)

where:

K,er, K,n = pseudo first-order BOD removal rate

coefficients in the aerobic and anoxic

zones, respectively, day -1

t .... t,. = HRT in the aerobic and anoxic zones,

respectively, day.

A two-zone system (aerobic and anoxic) was selected

as a general scheme that can also apply to a singlesludge nitrogen removal system.

The BOD removal rate coefficient in the aerobic

zone is affected by the dissolved oxygen concentration while in the anoxic zone it depends on the

nitrate level. These substrate effects are assumed to

follow a Monod type expression. In both zones it also

depends on temperature. It is also assumed that for

a given wastewater, the basic rates of degradation

under aerobic and anoxic conditions are interrelated

(Kayser, 1993). Hence,

DO

Kaer = K ( 2 0 ) D O + Ks....

K~. = 0K(20)

0T 20

N~

0v_2 o

N2 + K~,,n

(8)

(9)

Steady-state model of activated sludge---I

where:

K(20) = pseudo first-order BOD removal rate

coefficient under aerobic conditions

with no oxygen limitation at 20C,

day DO = dissolved oxygen concentration in

aerobic zone, mg 1-'

N 2 = n i t r a t e nitrogen concentration in

anoxic zone, mg l Ks..... Ks,~n= half saturation coefficients for BOD

removal in aerobic and anoxic zones,

respectively, mg 1-1

0 = temperature correction coefficient for

BOD removal rate coefficient

= ratio between BOD removal rate coefficients in anoxic and aerobic zone

at 20C and no substrate limitations

T = aeration basin temperature, C

The particulate BOD is rapidly removed from the

liquid stream and becomes adsorbed and enmeshed

within the biomass flocs. Although these particulates

are rapidly removed from the wastestream, they are

only partially degraded within the system. They

are typically slower to degrade since they must be

solubilized by extracellular enzymes before they can

penetrate the bacterial cell wall.

However, their residence time in the system is equal

to the SRT which, in most cases, is considerably

longer than the HRT.

Based on the work of Barth (1979) and Balmat

(1957), hydrolysis of particulate organics is considered to be first-order with respect to the concentration of degradable particulates. This approach was

also adopted by Eckenfelder (1990) and Goronszy

and Eckenfelder (1991). In the current model the first

order rate constant was taken as proportional to the

active biological solids since it is logical to assume

that the release of extracellular hydrolytic enzymes

would be proportional to the concentration of active

biomass. Hence, the fraction of the influent degradable VSS which remains unhydrolyzed is given by

fr =

1

l + KpfbXdXvO c

(10)

where

Kp = particulate BOD hydrolysis rate coefficient, 1

(mg day)- 1

The rate coefficients Kp is also temperature dependent:

K. = K.(20)0pr-2

It should be reemphasized that equation (10) describes the rate of hydrolysis of the particulate organics, i.e. its conversion to soluble BOD. This rate is

dependent on the concentration of active biomass in

the system. Removal of particulate organics from the

liquid phase via enmeshment in the mixed liquor floes

is considered instantaneous and complete. The fraction remaining of these organics leave the system

mainly through sludge wastage with minute quantities in the solids carryover from the secondary

clarifier.

NITROGEN REMOVAL

The treatment system discussed herein consists of

two completely mixed reactors, one anoxic and the

other aerobic. Mixed liquor from the aerobic reactor

is recycled to the anoxic reactor for denitrification, as

illustrated in Fig. 1.

Several simplifying assumptions are made in the

subsequent development. These are:

All reduced nitrogen is in the form of ammonia.

All oxidized nitrogen is in the form of nitrate.

The nitrifiers biomass concentration is negligible

compared to the heterotrophic biomass.

The heterotrophic yield coefficients under

aerobic and anoxic conditions are the same.

The specific growth rate of nitrifying microorganisms depends on the concentrations of ammonia

nitrogen and dissolved oxygen, as well as the ambient

temperature:

-- ~//(20)

I~N --

Kp(20) = hydrolysis rate coefficient at 20C for

particulate BOD, i (mg day)-)

0p = temperature coefficients for particulate

BOD

n ....

Ae

DO

- - .

KA + A " Ko + D 0

exp[0.098(T - 20)]

(12)

where

actual growth rate of nitrifiers, day i

maximum growth rate of nitrifiers at

20C, d a y m e = concentration of ammonia nitrogen in

the effluent and the nitrification zone,

mgl -~

KA, K0 = nitrification half saturation coefficients

for ammonia nitrogen and DO, respectively, mg l~N

/g(2o)

N,rnax

As indicated by Ekama and Marais (1984) in a

two-zone system as depicted in Fig. 2, the aerobic

SRT is related to the net nitrifiers growth rate by

0c., =

(ll)

where:

141

(13)

r/# n -- b n

where

0c.~ = aerobic SRT, day.

bs = endogenous decay rate coefficient of nitrifiers, d a y r/= aerobic volume fraction

142

YERACHM1EL ARGAMAN

The aerobic SRT is related to the overall SRT by

0c,~ = q0

(14)

The HRTs in the aerobic and anoxic zones are given

by

taer = qt

(15)

t,n = (1 --t/)t

(16)

A mass balance of nitrogen yields the following

expression for the overall recycle:

r -

(A0 - Ae) - X N f b A X v

- 1

N~ - N 2

(17)

where:

A0 = concentration of ammonia nitrogen in the

influent, mg 1- t

Ne = concentration of nitrate nitrogen in the effluent, mg lXN=nitrogen content of biological SS, gN

(gVSS)- l

r = overall (mixed liquor + return sludge) recycle

ratio

The nitrate nitrogen utilized in the anoxic zone is

related to the BOD oxidized in this zone. If nitrate is

viewed as an oxygen substitute in this zone, its

utilization rate can be expressed in analogy with

oxygen consumption in aerobic systems. Thus,

(N~ -- N2) = a'~.(Sj - S'2) + b'.nt'..ZdfbX~

(18)

where:

N l = concentration of nitrate nitrogen entering the

anoxic zone, mg 1-1

Sj =effective BOD entering the anoxic zone,

mgl

St=effective BOD leaving the anoxic zone,

mg 1-~

a~. =dissimilatory nitrate utilization coefficient,

gNO3-N (gBOD) 1

b~,=endogenous nitrate utilization rate coefficient, gNO3-N (gVSS day)t~,. = single pass HRT, based on total flow, in

anoxic zone, day

The single pass HRT is related to the nominal

HRT by

/an

ta~ = - l+r

(19)

This form of relationship also applies to the aerobic

and total HRT.

Substitution of equation (19) and rearrangement of

equation (18) yields

l+r

t,. = - [N. - N 2 - a'~.(S{ - S~)]

b'~.)~afbX.

(20)

Materials balance around point P of Fig. 1 yields

No + r Ne

N~ = - l+r

(21)

S~ + rS~

Sj - - l+r

(22)

where

No = influent nitrate concentration, mg lUsing the same kinetic approach as in deriving

equation (7), the fraction of BOD removed in the

anoxic zone in a system without recycle can be

calculated as

S~ - S 2

Sj-S~

Kantan[S~ + (Kantan + Kaertaer)fb%dXv]

(Ka. tan+Kaertaer)(S'o+KantanfbZdXv)

(23)

Since the BOD is made of multiple zero-order

decaying substrates the same expression holds for a

system with mixed liquor and sludge recycle.

The endogenous decay rates and endogenous

nitrate consumption rate are also temperature

dependent:

b = b (20)0tbT- 2m

(24a)

bN = bN (20)0~bT- 20)

(24b)

b~n = b~.(20)0~br 20)

(24c)

where

b (20), b~ (20) = endogenous decay rate coefficients

for heterotrophs and nitrifiers, respectively 20C, day

0 b = temperature correction coefficient

for endogenous decay and nitrate

utilization rates

ba.(20 ) = endogenous nitrate utilization rate

coefficient at 20C, gNO3-N

(gVSS day)MODEL APPLICATION

The model can be used for design of a new system

or for analyzing the performance of an existing one.

In both cases, a set of 23 equations has to be solved

simultaneously. The set consists of equations (1-3),

(5-17), (20-24c), with the following 35 design and

operation variables:

Influent characteristics: So, A0, No, Xi,fv,fd

Effluent characteristics: Se, At, N~

Intermediate quality parameters:

S(~, Sj, St, NI, N2

Kinetic parameters:

]AN. . . . . Kaer, Kan, Kp, b, bN, ban

Design and operation parameters:

DO, T , f , t , Xv,AXv, Oc, O,a, Zd, rl, r,t .... ta.,r

In order to obtain a solution of the set of

equations, all model kinetic and stoichiometric coefficients must be known and 12 of the parameters

must be specified. Selection of the variables to be

specified depends on the nature of the problem.

For a design application, the specified parameters

include all six influent characteristics, two of the

effluent characteristics, preferably ammonia and

143

Steady-state model of activated sludge--I

nitrate nitrogen, the system DO, MLVSS and temperature, and the nitrate concentration leaving the

anoxic zone (N:). Any commercial solver can be used

for this purpose. A trial and error solution flow chart

is illustrated in Fig. 3.

After solving the model equations, one can calculate the total sludge produced, the effluent total BOD

and the oxygen requirement, as shown below.

The total sludge leaving the system is made of the

volatile fraction AXv given in equation (2), the fixed

portion of the biological sludge, and the fixed SS

contained in the influent. Assuming that newly

formed cells consist of approx. 75% degradable VSS,

20% non-degradable VSS and 5% fixed SS, the fixed

portion amounts to 25% of the non-degradable biological VSS. Hence, the TSS leaving the system is

given by:

A , ~ T : A . ~ v --F 0 . 2 5 f b ( 1 -- ~(d)A.'tVv + (1 - - f v ) x ~ i

where:

AXr = TSS leaving the system expressed as mgSS

per liter of wastewater flow, mg 1The effluent total BOD can be approximated if the

effluent TSS is known. This BOD is made up of the

soluble portion, Se, and an insoluble portion contributed by degradable VSS in the effluent. The latter,

KnownVariables

[

So'Xi'fv ' fd' Ao'No'X v' DO'T'Ae' Ne' N2

'i,

I Calculate KP'lb' bN

24c.

aandrespectively

b~n

n bYeq"

d 11'24a''b42

I

>i

I

Assume ~ =I] o

I!

I

fb, o= fb, o+Afb,o

>1

>1

II

CalculateOc,a byeq. 13

Assutae Se = Se, o

..

Assume fb = fb, o

Calculate Oc , Zd, fr, SO, t, AXv, and fb l

by eq. 14,1,10,3,5,2, and 6, respectively l

Calculater, taet, tan, Ka~ r ,Kan,and

Se

by eq. 17,15,16, 8,9, and 7, respectively

(25)

C.mcma~ N I , s'I, s 2, t,~,and

by eq, 21,22,23,20, and 16, respectivdy

@

I Calcula~AXT, AAaa, ANdaaa,O2,amd Se,T

I byeq. 25,28,29,27,and26,res~-fively

Fig. 3. Nitrogen-removing activated sludge model solution flow chart.

144

YERACHMIELARGAMAN

in turn, consists of residual influent VSS which did

not degrade in the process and the degradable portion

of the biological VSS which were formed in the

process. Assuming that the SS composition in the

effluent is similar to that of the MLSS, and using a

BOD/degradable VSS ratio of 1.0 the effluent total

BOD can be expressed by:

Se,r = Se + ,Ye

f, ALxi +AzdAxv

AXT

(26)

where

Xe -----effluent TSS, mg 1Sex = effluent total BOD, mg 1-1

Oxygen utilization in a nitrogen removing system

includes oxygen consumed for BOD removal, nitrification and endogenous decay. Part of the oxygen is

derived from denitrification. Hence the overall oxygen consumption is given by

02 = a'(S~ -- S~) + b'fbZdXv t

+ 4.6AAnit -- 2.86ANdenit (27)

where:

02 = oxygen requirement, mg O2 (1 of flow)a ' = oxygen utilization coefficient, g 02

(gBOD)- J

b' = endogenous oxygen consumption rate, g

O2 (gVSS day) -1

AAnit = ammonia nitrified, mg lANdenit = nitrate denitrified, mg 1- l

b' is also temperature dependent in an expression

similar to equation (24).

The 4.6 factor is the stoichiometric amount of

oxygen required for nitrification of a unit mass

of ammonia nitrogen, and the 2.86 factor is the

oxygen equivalent of one unit mass of nitrate

nitrogen.

The nitrified and denitrified nitrogen concentrations, based on throughput flow are given by

AA.~t = Ao - Ae - XNfbAXv

(28)

ANdenit= AA.i, - Ne

(29)

and

The model can also be used for a variety of other

purposes such as predicting the performance of an

existing system, retrofitting a system for nitrogen

control, design or analysis of a single basin system

and more. All applications require knowledge of all

process coefficients. Many of these are fairly well

known for domestic wastewater. Experimental evaluation of the hydrolysis constant for particulate organics was performed by Eliosov (1994). Many of the

remaining coefficients were estimated by Argaman

and Papkov (1995) based on bench-scale studies of

domestic wastewater.

SUMMARY

A steady-state model for the activated sludge process with or without nitrogen control was proposed.

Its special features include:

Degradation kinetics of soluble and particulate

organics are addressed separately.

The effect of particulate organics on the degradation of soluble organics is accounted for

by defining an "effective" soluble BOD which is

the summation of soluble BOD and actually

hydrolyzed particulate BOD.

The pseudo-first order kinetic law is used for

soluble BOD removal, bearing in mind the

zero-order degradation of the individual substrates making up the overall BOD.

Degradation of particulate organics follows a

first-order rate expression and is proportional to

the biologically active MLVSS and to the SRT.

Mixed liquor solids consist of fixed SS, non-biological VSS, biological active VSS and biological

non-active VSS.

Nitrate removal in the anoxic zone is controlled

by carbonaceous organic degradation rate. It is

treated in analogy with oxygen utilization in

aerobic systems.

The rate of BOD removal in the anoxic zone is

taken as a fraction of that in the aerobic zone.

REFERENCES

Adams C. E., Eckenfelder W. W., Jr. and Hovious J. (1975)

A kinetic model for design of completely mixed activated

sludge treating variable strength industrial wastewater.

Wat. Res. 9, 37-42.

Argaman Y. (1991) Chemical reaction engineering and

activated sludge---a research note. )Vat. Res. 25,

1583-1586.

Argaman Y. and Papkov G. (1995) A steady-state model for

the single sludge activated sludge system--II. Model

application and sensitivity analysis. Wat. Res. 29,

147-153.

Balmat J. L. (1957) Biochemical oxidation of various particulate fractions of sewage. Sewage Industrial Wastes 29,

757-761.

Barth J. E. (1979) The effect of primary solids on the

activated sludge process. M.Sc. Thesis, Vanderbilt University, Nashville, Tennessee.

Eckenfelder W. W. Jr. (1990) Estimating oxygen requirements and waste sludge from activated sludge with and

without primary clarifiers treating municipal wastewater.

Environ. Technol. 11, 793-798.

Ekama G. A. and Marais G. V. R. (1984) Nitrification.

In "'Theory Design and Operation of Nutrient Removal

Activated Sludge". University of Cape Town, City

Council of Johannesburg, and the National Institute for

Water Research of the CSIR. Pretoria, 1984, South

Africa.

Eliosov B. (1994) The fate of particulate organics in activated sludge systems. M.Sc. Thesis, Technion-Israel Inst.

of Techn., Haifa, Israel.

Goronszy M. C. and Eckenfelder W. W. Jr. (1991) The role

of the degradation of primary solids in activated sludge

plants. Presented at the 64th Annual Conference, WPCF.

Toronto, Oct. 1991.

Steady-state model of activated sludge---I

Grau P., Dohanyos M. and Chudoba J. (1975) Kinetics of

multi-component substrate removal by activated sludge.

War. Res. 9, 637-642.

IAWPRC Task Group on Mathematical Modelling for

Design and Operation of Biological Wastewater Treatment (1987) Activated sludge model No. 1. Scientific and

Technical Report No. 1, IAWPRC, London.

Kayser R. (1993) Comparison of design calculations for the

activated sludge process with regard to nitrogen removal.

Proceedings of the 9th E W P C A - I S W A Symposium, Liquid

Waste Section, Munich, May 1993.

145

Quirk T. P. and Eckenfelder W. W. Jr. (1986) Active mass

in activated sludge analysis and design. J. WPCF 58,

932-936.

Rittman B. E., Bae W., Namkung E. and Lu C. J.

(1987) A critical evaluation of microbial product formation in biological processes. Water Sci. Tech. 19, Rio,

517-528.

Tischler L. F. and Eckenfelder W. W. (1969) Linear

substrate removal in the activated sludge process. In

Advances in Water Pollution Research. Pergamon Press,

Oxford.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- PHY1004L. - Lab 7 - Investigating Static and Kinetic FrictionsДокумент4 страницыPHY1004L. - Lab 7 - Investigating Static and Kinetic Frictionsdiegocely70061533% (3)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Equilibrium Separation ColumnsДокумент18 страницEquilibrium Separation ColumnsWade ColemanОценок пока нет

- Cigre Guidelines For Life Management Techniques For Power Transformers PDFДокумент125 страницCigre Guidelines For Life Management Techniques For Power Transformers PDFJorge Bejarano100% (2)

- Eis Tattoo Proc 052003 enДокумент110 страницEis Tattoo Proc 052003 enPeterDonerОценок пока нет

- Chapter 2 Is Matter Around Us Pure NotesДокумент16 страницChapter 2 Is Matter Around Us Pure NotesManjusha MathewОценок пока нет

- Introduction To ThermodynamicsДокумент66 страницIntroduction To ThermodynamicsMikaela Dela Cruz0% (1)

- Price List For WIKA PDFДокумент110 страницPrice List For WIKA PDFMohammed AbdelsalamОценок пока нет

- Ch.11 Heat and ThermoДокумент10 страницCh.11 Heat and ThermoJoanne Aga EslavaОценок пока нет

- Experiment 3 Emulsion TestДокумент5 страницExperiment 3 Emulsion Testzulkeflee a rahmanОценок пока нет

- Iso Fdis 4484-3 (E)Документ36 страницIso Fdis 4484-3 (E)Светлана ДудуковаОценок пока нет

- Laju Reaksi PDFДокумент9 страницLaju Reaksi PDFHafsemi RapsanjaniОценок пока нет

- Young Scientist PDFДокумент134 страницыYoung Scientist PDFArtyom KoptelovОценок пока нет

- Understanding Solubility: Preparing Spreadsheets & Graphs With ExcelДокумент6 страницUnderstanding Solubility: Preparing Spreadsheets & Graphs With ExcelnandagamersОценок пока нет

- Midterm SolutionДокумент4 страницыMidterm SolutionMabel OngОценок пока нет

- API 653 Effectivity SheetДокумент1 страницаAPI 653 Effectivity SheetIsmail MemonОценок пока нет

- Calculate the cooling capacity of a precooled air handling unitДокумент4 страницыCalculate the cooling capacity of a precooled air handling unitPradeep Sukumaran100% (1)

- Relationship between food sources and consumersДокумент6 страницRelationship between food sources and consumerskhairuzi79Оценок пока нет

- RC Column Design (ACI318-05)Документ5 страницRC Column Design (ACI318-05)Rizwan MirzaОценок пока нет

- Tubing and Casing ConnectionsДокумент2 страницыTubing and Casing ConnectionsYougchu LuanОценок пока нет

- Saep 1146Документ8 страницSaep 1146Ronanki RaviОценок пока нет

- Physics: Investigatory ProjectДокумент22 страницыPhysics: Investigatory ProjectabiОценок пока нет

- Mechanics of FluidsДокумент3 страницыMechanics of Fluidseldhopaul19894886Оценок пока нет

- Catalyst Recovery BrochureДокумент6 страницCatalyst Recovery BrochureborgiamatriceОценок пока нет

- REACTION PATHWAYSДокумент28 страницREACTION PATHWAYSkonstantas100% (2)

- Unit 5 ChemicChemical Kinetics and Equilibriumal Kinetics and Equilibrium Notes (Answers)Документ22 страницыUnit 5 ChemicChemical Kinetics and Equilibriumal Kinetics and Equilibrium Notes (Answers)Muhammad IrfanОценок пока нет

- Design and Analysis of Composite Leaf Spring in Light VehicleДокумент6 страницDesign and Analysis of Composite Leaf Spring in Light VehicleShreyas GiridharanОценок пока нет

- Torchshield Quotation KadapaДокумент2 страницыTorchshield Quotation KadapaYellaturi Siva Kishore Reddy100% (1)

- Hydraulic Jumps (Lind, Mohammed, McCallum)Документ21 страницаHydraulic Jumps (Lind, Mohammed, McCallum)JKalorep100% (1)

- Laboratory Evaporation Solutions BR A4 en CДокумент24 страницыLaboratory Evaporation Solutions BR A4 en CFelipe Marçal MorgantiniОценок пока нет

- Instrumental Analytical Methods Experiment 2 - Turbidimetric Quantitative Analysis of Casein in SolutionДокумент4 страницыInstrumental Analytical Methods Experiment 2 - Turbidimetric Quantitative Analysis of Casein in Solutionapi-235187189Оценок пока нет