Академический Документы

Профессиональный Документы

Культура Документы

XRD

Загружено:

MahadevanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

XRD

Загружено:

MahadevanАвторское право:

Доступные форматы

Lecture 4: X-ray diffraction

Contents

1 Introduction to diffraction

2 Braggs law

3 Braggs law example

4 X-ray spectrometer

Introduction to diffraction

In Lecture 2, we looked at interaction of X-rays with matter - specifically

X-ray absorption. Absorption is a continuous process wrt X-ray wavelength

due to the scattering of the radiation. Along with this background there are

sharp absorption peaks when the energy of the X-rays couples with certain

electronic transitions in the material. In lecture 3, we looked at crystalline

solids and their properties. In X-ray diffraction we focus on a combination on

both, how X-rays interact with crystalline solids, specifically the phenomenon

of diffraction.

Diffraction by light waves is a well known phenomenon. The theory was put

forward by Dutch physicist Christian Huygens and refined by French physicist Augustin-Jean Fresnel. If we have a ruled grating with the spacing of

the order of the wavelength of light (400-700 nm) each point on the grating can be considered to be a source of secondary waves. These secondary

waves can interfere forming alternate maxima and minima i.e. diffraction

pattern. X-rays have wavelength of the order of 01 - 10

A. Crystals have

lattice constants and hence interplanar spacing around 2 - 6

A. Thus a crystalline material naturally serves as a ruled grating with the ability to scatter

X-rays producing maxima and minima i.e. diffraction. Diffraction using Xrays was first shown by German physicist von Laue in 1912 where he used a

1

MM3030: Materials Characterisation

Figure 1: Diffraction of X-rays from a set of planes. For constructive interference the path difference must be a integral multiple of the wavelength.

Taken from http://en.wikipedia.org/wiki/Braggs law

copper sulphate crystal (CuSO4 with a triclinic structure) to get diffraction

patterns from X-rays. This work was carried forward by a father-son scientist

team W.H. Bragg and W.L. Bragg who managed to express the condition for

diffraction in a mathematical form. this was called Braggs law. They were

also able to solve the structure of sodium chloride (with 2 interpenetrating

fcc structures) using X-rays thus proving the power of X-ray diffraction to

solve crystal structures.

Braggs law

Braggs law in the simplest sense gives the condition for constructive interference for X-rays incident on a set of lattice planes. Constructive interference

occurs when the intensities of the waves add to each other while the opposite

is destructive interference where the intensities cancel each other. Braggs

law can be derived from the general set of diffraction conditions derived by

von Laue, which we shall see in the context of electron diffraction. Consider a

set of planes as shown in figure 1 The interplanar spacing between the planes

is denoted by d. If the Miller indices of the plane is (hkl) and the system is

cubic then d is related to a by

h2

k2

l2

1

=

+

+

d2

a2

a2

a2

a

d=

2

h + k 2 + l2

(1)

For a tetragonal system with two lattice parameters a and c the equation is

modified as

1

h2

k2

l2

= 2 + 2 + 2

(2)

d2

a

a

c

2

MM3030: Materials Characterisation

For a hexagonal system where = 120 the relation between d-spacing and

lattice parameters are

1

4 h2 + hk + k 2

l2

(

=

)

+

(3)

d2

3

a2

c2

From figure 1 x-rays are incident at an angle on 2 planes with spacing d. Xrays reflected from the bottom plane have to travel an extra distance, which

is given by 2dsin (from geometry). This is the then the path difference

between the x-rays reflected from the material. For constructive interference

this path length has to be an integral multiple (n)of the wavelength. Thus,

Braggs law can be stated as

2dsin = n

(4)

Here, n is an integer and can take values 1, 2, 3 and so on. This represents

the order of reflection. Braggs law is the most important law in diffraction.

It is not only used for XRD but also when we look at diffraction in an electron microscope. For a given set of planes there are reflected waves in all

possible directions but these are not reinforced (the waves are not in phase)

and hence the intensity is weak. The strongest reflected intensity is when

the angle is equal to the Bragg angle i.e. the diffracted wave. The incident

beam, diffracted beam, and the reflecting planes are coplanar.

Braggs law example

Let us use an example to understand Braggs law. Consider a metal with

fcc crystal structure, Nickel (Ni) with lattice constant a of 3.52

A. Cu K

radiation of wavelength 1.54

A is incident on Ni. Considering only first order

reflection (n=1) equation 4 can be written as

2dsin =

sin =

2d

(5)

The first criteria is that sin cannot be greater than 1 so that 2d or

d 2 . Thus, using Braggs law only those d-spacings greater than half

the wavelength of X-rays used will produce diffraction. This sets a lower

limit on the measurable d-spacing and dictates the choice of X-rays used for

diffraction. On the other hand, if we use too low a wavelength the angles ()

will be very small and hence it will be hard to differentiate one line from the

3

MM3030: Materials Characterisation

Figure 2: Ni XRD pattern taken from a Canadian 5 cents coin. Taken from

http://chemistry.beloit.edu/Edetc/nanolab/nickel2/index.html

other. Typically, for metals Cu K is used as the X-ray source.

If we consider the 100 family of planes for Cu, the d-spacing is the same

A and

as a and using equation 4 = 12.64 . For 110 d = a2 = 2.49

a

= 18.21 . For 111 d = 3 = 2.03

A and = 22.27 . Thus as d-spacing

reduces the diffraction angle increases. The experimental XRD pattern from

Nickel is shown in figure 2 The experimental pattern does not contain all the

d-spacings and actually starts from the 111 family with each line having different intensity. We will see the reason for this when dealing with structure

factors and intensity. Also the the plot is intensity vs. 2. This is the angle between the incident X-ray (source) and the diffracted X-ray (detector).

Thus, if we know the X-ray wavelength and the crystal structure and lattice

constant of the material under investigation we can calculate the positions

(2) of all the lines.

Apart from Cu K another commonly used X-ray source is Mo K with

a wavelength of 0.71

A. Since the wavelength is smaller the angles will also

be smaller, for the same d-spacing. Thus, if we use Mo for the above Ni

example the 111 line will fall at = 10.07 instead of 22.27 . Mo sources

MM3030: Materials Characterisation

Figure 3: Schematic of X-ray spectrometer. Taken from Elements of X-ray

diffraction - B.D. Cullity.

are normally used for small molecules where the d-spacing is smaller and we

need a smaller wavelength to obtain diffraction, see equation 5.

X-ray spectrometer

Experimentally Braggs law can be used in 2 ways:

1. Use X-rays of single (monochromatic) and known wavelength () and

measure the diffraction angle () and use that to calculate the d-spacing

and hence the crystal structure. This is called structure analysis.

2. Alternate is to use planes of known spacing (d), measure and from

this calculate . This technique is called X-ray spectrometry and is a

way of doing chemical analysis with X-rays. We can also use this to

get a true line source for structure analysis.

A schematic of the X-ray spectrometer is shown in figure 3 The source is an

X-ray tube which emits a continuous spectrum of X-rays with some characteristic sharp peaks (depending on the tube voltage being above the threshold).

The X-rays fall on a crystal with known d-spacing. Thus, different X-rays are

5

MM3030: Materials Characterisation

diffracted at different angles which are measured by the detector that is rotated. Thus, we can get a plot of I vs. or I vs. Energy of the X-ray source.

This can be used for calibrating new X-ray sources and chemical analysis. If

instead of the detector we had a narrow exit slit that only the wavelength corresponding to the slit angle will be emitted while the others will be stopped.

Thus using the X-ray spectrometer a very narrow monochromatic source can

be obtained especially for use in high precision X-ray diffractometers.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Technology Development: TowardsДокумент35 страницTechnology Development: TowardsMahadevanОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- 15 ReferencesДокумент9 страниц15 ReferencesMahadevanОценок пока нет

- Arc Ag!Документ5 страницArc Ag!MahadevanОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Tensile and Micro Structural Characteristics AA2219 Aluminum AlloysДокумент7 страницTensile and Micro Structural Characteristics AA2219 Aluminum AlloysMahadevanОценок пока нет

- Materials and Design: M. Joseph Fernandus, T. Senthilkumar, V. BalasubramanianДокумент6 страницMaterials and Design: M. Joseph Fernandus, T. Senthilkumar, V. BalasubramanianMahadevanОценок пока нет

- Solid State Physics: Debye-Scherrer PhotographyДокумент5 страницSolid State Physics: Debye-Scherrer PhotographyMahadevanОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Kathrein 80010681 PDFДокумент4 страницыKathrein 80010681 PDF李微風Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Antenna SystemДокумент30 страницAntenna SystemnghongvyОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Bose-Einstein Statistics: e e G e G NДокумент12 страницThe Bose-Einstein Statistics: e e G e G NRangga TaufiqurahmanОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Electromagnetic Wave Class 12 EamcetДокумент78 страницElectromagnetic Wave Class 12 Eamcetsai mukeshОценок пока нет

- Upper-Room UVGI Leaflet G.L.A.Документ4 страницыUpper-Room UVGI Leaflet G.L.A.MihaiAnastasiuОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Long Quiz 11Документ2 страницыLong Quiz 11Mikee MercadoОценок пока нет

- Experiment 3 Thermal RadiationДокумент7 страницExperiment 3 Thermal RadiationSheila Roselley100% (2)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- KONGURДокумент19 страницKONGURforchat759Оценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Service Manual: Color Television Chassis No. GA-4MДокумент42 страницыService Manual: Color Television Chassis No. GA-4MKennex Trazo50% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- 34 Artikel 65 1 10 20200619Документ8 страниц34 Artikel 65 1 10 20200619Muh Hervian NugrahaОценок пока нет

- Danger of EmfsДокумент5 страницDanger of EmfsAida GaladariОценок пока нет

- Resonant Excitation of Coherent Cerenkov Radiation in Dielectric Lined WaveguidesДокумент3 страницыResonant Excitation of Coherent Cerenkov Radiation in Dielectric Lined WaveguidesParticle Beam Physics LabОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- CV - Adnan JudehДокумент5 страницCV - Adnan JudehAnonymous k4rDHIОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

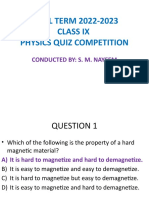

- Class Ix Physics Quiz Competition.Документ11 страницClass Ix Physics Quiz Competition.Nayeem HakimОценок пока нет

- Infrared Spectroscopy RCДокумент22 страницыInfrared Spectroscopy RCSricharanОценок пока нет

- Lecture 5 Vacuum Systems: Z Introduction of VacuumДокумент16 страницLecture 5 Vacuum Systems: Z Introduction of VacuumAlok BaralОценок пока нет

- Aircraft InfraredДокумент129 страницAircraft InfraredTurk SoloОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- And X-RAY Microanalysis: ElectДокумент42 страницыAnd X-RAY Microanalysis: ElectrmsscruzОценок пока нет

- PHS 227 HW 1Документ1 страницаPHS 227 HW 1Zuhair FashinaОценок пока нет

- 2021 Term 1 Grade 12 Science Paper 1 Test 2Документ2 страницы2021 Term 1 Grade 12 Science Paper 1 Test 2Davies MasumbaОценок пока нет

- L18 HornsДокумент28 страницL18 HornsRobert GrubeОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Forensic PhotographyДокумент20 страницForensic PhotographyPrincess Trina Galapon RamosОценок пока нет

- Radiation ProtectionДокумент56 страницRadiation ProtectionYessamae JinangОценок пока нет

- Radiation 2Документ66 страницRadiation 2guna sekaranОценок пока нет

- Principles of Exposure Ch.8Документ42 страницыPrinciples of Exposure Ch.8abdulsalam khalaf100% (1)

- Koheras BOOSTIKДокумент4 страницыKoheras BOOSTIKDahyeon LeeОценок пока нет

- Laboratory Report - Module 2 (Refractometry)Документ37 страницLaboratory Report - Module 2 (Refractometry)Jeremy Kyle Edson AustriaОценок пока нет

- Properties of Light: T E 15 MJ N 5.24Документ17 страницProperties of Light: T E 15 MJ N 5.24077 AgentОценок пока нет

- Analytical Methods: (PART 1)Документ52 страницыAnalytical Methods: (PART 1)Francis ValdezОценок пока нет

- RadiationnДокумент12 страницRadiationnDivisha TahilianiОценок пока нет