Академический Документы

Профессиональный Документы

Культура Документы

Thermocouple

Загружено:

Gustavo PalaciosАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Thermocouple

Загружено:

Gustavo PalaciosАвторское право:

Доступные форматы

T

Exhaust Gas and

Wheel Space Thermocouples

FOR FRAME 5, 6, 7, AND 9 GAS TURBINE APPLICATIONS

THERMOCOUPLE

AMETEK Exhaust Gas (EGT) and Wheel Space

Frame Turbine Thermocouples meet the specific

operational and performance requirements for

REPLACEMENT and RETROFIT Frame

gas turbine applications. AMETEKs

expertise in solving creep, stress,

rupture, corrosion, EMF drift, and other

problems affecting sensor performance

has resulted in a robust line of single and

dual element thermocouple designs. Typical

applications include wheel space and exhaust

gas temperature monitoring.

AMETEK EGT and Wheel Space Thermocouples

use Type K wire with MgO insulation and stainless

steel sheathing. The thermocouple probe tips

and terminations are hermetically sealed against

exposure to operational environments and have

been qualified to ASTM E585 and ASTM E608

standards, with a leak rate of less than

1 x 10 -6 cc/sec.

For exhaust gas applications, AMETEK

manufactures production-qualified radiation

shields. These shields, together with AMETEK

EGT Thermocouples, form a system that controls

thermocouple immersion depth, eliminates

fretting due to vibration, and provides improved

turbine performance.

FEATURES AND BENEFITS

Hermetically-sealed single and dual

junction configurations

Exhaust gas temperature systems prevent:

Mechanical probe damage at installation

Tip vibration during normal operation

Rapid time response

Cost-effective retrofit capability

AMETEK quality, OEM experience, and

worldwide service

AMETEK can provide kits to RETROFIT older

Frame turbines with this improved thermocouple

and radiation shield configuration. Contact

AMETEK for a cross-reference list that contains

hundreds of different thermocouple, radiation

shield, and retrofit kit part numbers.

Experience the Power

SPECIFICATIONS

Time Response

Temperature at Environmental Seal

Below 1.3 sec for 0.125 tip diameters

Below 0.8 sec for 0.0625 tip diameters

-70 to 400F (-57 to 204C)

Lengths

Calibration

Various from 60" to 500"

0.75% for Type K thermocouples

0.4% for all exhaust gas

temperature thermocouples

Sheath Diameters

0.062" to 0.125"

Hermetic Seal

1 x 10 -6 cc/sec

IN

(MM)

NOTE: Dimension (A) varies between 60 and 500 inches

depending on the part number ordered.

For customer support call:

AMETEK

POWER INSTRUMENTS

50 Fordham Road

Wilmington, MA 01887

Tel: 978.988.4903

Fax: 978.988.4990

power.sales@ametek.com

HEADQUARTERS

AMETEK Power Instruments

50 Fordham Road

Wilmington, MA 01887

Tel: 978.988.4903

Fax: 978.988.4990

power.sales@ametek.com

EUROPEAN HEADQUARTERS

Unit 20, Ridgeway

Donibristle Industrial Estate

Dalgety Bay, Dunfermline, KY119JN

Scotland U.K.

Tel: 44.1383.825630

Fax: 44.1383.825715

power.sales@ametek.com

ASIA PACIFIC HEADQUARTERS

10 Ang Mo Kio Street 65

#05-12 Techpoint

Singapore 569059

Tel: 65.6484.2388

Fax: 65.6481.6588

ISO 9001 Certified

2005, by AMETEK, Inc. All rights reserved. 5M1001 (210016)

Qualified Hermetic Exhaust Gas

Temperature Thermocouple Upgrade

FOR NEW AND EXISTING FRAME 5, 6, 7, AND 9 GAS TURBINE APPLICATIONS

THERMOCOUPLE

FIT-IT & FORGET-IT

Eliminate Exhaust Gas

Temperature (EGT)

thermocouple concerns

with AMETEKs new EGT

thermocouple product

offering for Frame turbine

applications. AMETEK has worked

closely with the turbine OEM to design

and engine test this thermocouple as a

direct replacement and upgrade for all new

and existing EGT thermocouples. The new

EGT thermocouples are qualified and meet all

design specifications.

MISTAKE-FREE INSTALLATION

The new EGT design makes it impossible to

over-tighten, while ensuring the proper

immersion depth of the thermocouple into the

radiation shield. Furthermore, the new EGT

design allows the cable leads to be attached to

the thermocouple prior to insertion into the

radiation shield, and also enables a convenient,

stress-free orientation of the thermocouple

junction box and cable leads.

SINGLE EGT THERMOCOUPLES AND

COMPLETE UPGRADE KITS AVAILABLE

Whether you are upgrading from the

302A4010Pxxx, 351A3488Pxxx, or the

362A1102Pxxx EGT thermocouples, AMETEK

can provide either the thermocouples only or the

complete upgrade kit with all the required

fittings, adapters, and cables. A more detailed

description of the many different upgrade

options available, including parts lists,

installation instructions, and drawings, can be

found in AMETEKs EGT THERMOCOUPLE

RETROFIT MANUAL.

FEATURES AND BENEFITS

Foolproof Installationensures proper insertion

depth and eliminates over-tightening induced

open circuit failures

Flexible Installationenables cable leads to be

connected prior to assembly and a stress-free

orientation of the thermocouple junction box and

cable leads

Quick Installationuse of compression fitting

significantly reduces installation time

New Probe Designeliminates thermal

gradient differences that could cause

thermocouple element breakage

Includes the Benefits of the Original

Design100% Hermetic for high

accuracy and long life, Positive Stop to

ensure proper location of the

thermocouple into the radiation shield,

Material Selection eliminates seizure,

Type K Terminal Studs to reduce

secondary junction error, and a

Junction Box that simplifies

installation and makes cable

connection foolproof

Experience the Power

SPECIFICATIONS

Calibration

Environment

Type K, ungrounded

Error: special limits (0.4%)

Approximately 2.9 seconds

-20O to 700OF at thermocouple junction box

(-29O to 371OC)

-20O to 392OF for the cable (-29O to 200OC)

100% humidity for the entire thermocouple

Hermetic Seal

Lengths

1 x 10-6cc/sec for entire thermocouple

For Frame 5, 6, 7, and 9 gas turbine

applications

Time Response

Figure 1: Replacing 362A1102P001, P006, or P011 EGT Thermocouples

THERMOCOUPLE CABLE

AMETEK P/N: 8EH6 SERIES

OEM P/N: 361A2327 SERIES

TYPICAL

FITTING

AMETEK P/N: 3610A40P001

RADIATION SHIELD

AMETEK P/N: 8RS1 SERIES

OEM P/N: 362A1344 SERIES

THERMOCOUPLE

AMETEK P/N: 8TR4D SERIES

OEM P/N: 362A1102 SERIES

TYPICAL

TYPICAL

For details on how to replace 302A4010Pxxx or

351A3488Pxxx EGT Thermocouples, please refer to

AMETEKs EGT THERMOCOUPLE RETROFIT MANUAL.

For customer support call:

POWER INSTRUMENTS

HEADQUARTERS

EUROPEAN HEADQUARTERS

ASIA PACIFIC HEADQUARTERS

50 Fordham Road

Wilmington, MA 01887

Tel: 978.988.4903

Fax: 978.988.4990

power.sales@ametek.com

AMETEK Power Instruments

50 Fordham Road

Wilmington, MA 01887

Tel: 978.988.4903

Fax: 978.988.4990

power.sales@ametek.com

Unit 20, Ridgeway

Donibristle Industrial Estate

Dalgety Bay, Dunfermline, KY119JN

Scotland U.K.

Tel: 44.1383.825630

Fax: 44.1383.825715

power.sales@ametek.com

10 Ang Mo Kio Street 65

#05-12 Techpoint

Singapore 569059

Tel: 65.6484.2388

Fax: 65.6481.6588

ISO 9001 Certified

2005, by AMETEK, Inc. All rights reserved. 5M0303T (210049)

Hermetic Exhaust Gas and Wheel

Space Thermocouple and Cable

FOR FRAME 6, 7, AND 9 GAS TURBINE APPLICATIONS

THERMOCOUPLE

AMETEK Hermetic Exhaust Gas (EGT) and

Wheel Space Frame Turbine Thermocouples

are the latest OEM production qualified design

and incorporate many improvements over

previous thermocouple offerings. AMETEKs

new thermocouple is 100% hermetic which

ensures longer product life, improved

temperature accuracy, and no troublesome

insulation resistance failures during operation.

The junction box mounts directly to the radiation

shield or turbine case and eliminates the

problem of mineral insulated cable extending

outside the turbine. Materials were carefully

selected to ensure long life and to eliminate

vibration and galling failures. This new

thermocouple, used in conjunction with

AMETEKs flexible cable, provides a product

that is not only easier to install and maintain,

but also a product that is more reliable,

accurate, and longer lived.

CABLE

The flexible, stainless steel braided

thermocouple Cable mates directly to the

new Hermetic Thermocouple and creates a

much more reliable thermocouple system

than previous designs. The Cable uses Type

K wire and terminal lugs so no secondary

junction errors are introduced into the

thermocouple circuit. The terminal lugs use

two different sizes of captivated nuts making

it impossible to install incorrectly or to lose

any of the hardware.

FEATURES AND BENEFITS

Thermocouple

100% Hermeticprovides longer life, better

accuracy, and no insulation resistance failures

Positive Stopensures proper location of

thermocouple tip in radiation shield

Material Selectioneliminates seizure of

thermocouple into radiation shield

Type K Terminal Studsreduces secondary

junction errors

Junction Boxsimplifies installation and makes

cable connection foolproof

Cable

Type K Terminal Lugsensures no secondary

junction errors are introduced

Different Sized Terminal Lugsmake it

impossible to cross-wire

Captivated Hardwarenothing to lose and

nothing more to purchase

Stainless Steel Braidprotects Teflon coated

wires from abrasion

Experience the Power

SPECIFICATIONS

Calibration

Environment

Type K, Ungrounded

-20 to 700F at thermocouple junction box

(-29 to 371C)

Error: Standard (0.75%) or Special (0.4%)

limits depending on part number

-20 to 392F for the cable (-29 to 200C)

100% Humidity for the entire thermocouple

Time Response

Varies from 1.7 to 4.0 seconds depending on

tip configuration

Lengths

Hermetic Seal

Tip Diameters

1 x 10 -6 cc/sec for entire thermocouple

Various from 0.062" to 0.125"

Various from 9" to 123"

Sheath Diameters

Various from 0.125" to 0.188"

IN

(MM)

For customer support call:

AMETEK

POWER INSTRUMENTS

50 Fordham Road

Wilmington, MA 01887

Tel: 978.988.4903

Fax: 978.988.4990

power.sales@ametek.com

HEADQUARTERS

AMETEK Power Instruments

50 Fordham Road

Wilmington, MA 01887

Tel: 978.988.4903

Fax: 978.988.4990

power.sales@ametek.com

EUROPEAN HEADQUARTERS

Unit 20, Ridgeway

Donibristle Industrial Estate

Dalgety Bay, Dunfermline, KY119JN

Scotland U.K.

Tel: 44.1383.825630

Fax: 44.1383.825715

power.sales@ametek.com

ASIA PACIFIC HEADQUARTERS

10 Ang Mo Kio Street 65

#05-12 Techpoint

Singapore 569059

Tel: 65.6484.2388

Fax: 65.6481.6588

ISO 9001 Certified

2005 by AMETEK, Inc. All rights reserved. 5M102 (210032)

Individual Exhaust Gas (T5.4)

Thermocouple and Cable System

FOR RETROFIT ON LM2500 AND LM5000 GAS TURBINES

THERMOCOUPLE

AMETEKs Individual EGT Probe System

(AMETEK P/N 8TC34BAG1, GE P/N L44830P01)

is designed for retrofit on LM2500 and LM5000

gas turbines. Exhaust gas temperatures are

measured using a combination of individual

thermocouples mated to a flexible harness

assembly, eliminating the need for rigid harness

systems. Operators and overhaul facilities can

replace a single probe without removing a full

harness quadrant or affecting other serviceable

system components. This results in lower

component and maintenance costs and shorter

turbine downtime cycles.

The Individual EGT System incorporates a

combination of AMETEK thermocouple designs

that are currently qualified and operating on

production gas turbines. Its probe design is

identical to the design presently operating on

production LM2500 and LM5000 turbines, while

its junction box is identical to that utilized on

other industrial and aerospace turbine

thermocouples.

AMETEK can provide either averaging or

individual mating cables. The averaging cables

mimic the output of the rigid harness system

whereas the individual cables provide a separate

output for each of the 11 thermocouples. This

flexibility enables the operator to select the

measurement that best captures turbine

performance.

FEATURES AND BENEFITS

Utilizes AMETEK designs presently operating on

LM2500, LM5000, and LM6000 gas turbines.

Qualified through GE, P/N L44830P01

Eliminates the need for rigid

thermocouple quadrants

Replacement of single probes results in lower

component and maintenance costs and shorter

turbine downtime cycles

Since October, 1993, AMETEKs Individual Probe

Systems have entered field service at numerous

operator sites. The system has accumulated over

250,000 hours of trouble-free operation, and it

continues to demonstrate the quality and

performance of the AMETEK design.

Experience the Power

SPECIFICATIONS

THERMOCOUPLE PROBE ASSEMBLY

FLEXIBLE CABLE ASSEMBLY

Temperature Range

Conductor

- 65 to 1875F (-54 to 1023C)

17 gage thermocouple grade material,

Type K (+ and -)

Accuracy

Outer Jacket

4 to 530F (2.2 to 277C);

0.75% above 530F (277C)

34 gage stainless steel braid

Time Response

Operating Temperature

< 4 sec. for temp. change from 1400

to 1500F (760 to 816C) at 6 lb./sec./sq.ft.

To 1000F (538C)

Insulation

Output

Multi-Layer System:

Primary Insulation

- Mica Tape

Secondary Insulation - Refrasil Braid

- E Type Fiberglass

Type K (millivolts)

Vibration

12 Gs

Leakproof

Hermetically sealed

IN

(MM)

For customer support call:

AMETEK

POWER INSTRUMENTS

50 Fordham Road

Wilmington, MA 01887

Tel: 978.988.4903

Fax: 978.988.4990

power.sales@ametek.com

HEADQUARTERS

AMETEK Power Instruments

50 Fordham Road

Wilmington, MA 01887

Tel: 978.988.4903

Fax: 978.988.4990

power.sales@ametek.com

EUROPEAN HEADQUARTERS

Unit 20, Ridgeway

Donibristle Industrial Estate

Dalgety Bay, Dunfermline, KY119JN

Scotland U.K.

Tel: 44.1383.825630

Fax: 44.1383.825715

power.sales@ametek.com

ASIA PACIFIC HEADQUARTERS

10 Ang Mo Kio Street 65

#05-12 Techpoint

Singapore 569059

Tel: 65.6484.2388

Fax: 65.6481.6588

ISO 9001 Certified

2005, by AMETEK, Inc. All rights reserved. 5M1001 (210020)

Вам также может понравиться

- Exhaust Gas and Wheel Space Thermocouples: ThermocoupleДокумент2 страницыExhaust Gas and Wheel Space Thermocouples: ThermocoupleAmmar KhaleelОценок пока нет

- Gas Turbine Thermocouple SystemsДокумент2 страницыGas Turbine Thermocouple Systemssujit100% (1)

- Ceramic BandДокумент0 страницCeramic BandAsyraf Ahmad SaferiОценок пока нет

- WEG NemapremiumДокумент11 страницWEG NemapremiumGualaОценок пока нет

- Carrier38CKC 50HzДокумент20 страницCarrier38CKC 50HzAaron LeveyОценок пока нет

- Current Transformers (72.5 kV to 420 kV) SpecificationsДокумент4 страницыCurrent Transformers (72.5 kV to 420 kV) SpecificationsPaulo CardosoОценок пока нет

- Heat Treatment Equipment and Spares GuideДокумент16 страницHeat Treatment Equipment and Spares Guidelewgne08Оценок пока нет

- 3M-EMD High Voltage CableAss PBДокумент8 страниц3M-EMD High Voltage CableAss PBLiz Vilela ArízagaОценок пока нет

- SST (GMAW) Welding Process PDFДокумент4 страницыSST (GMAW) Welding Process PDFmudrijasm100% (1)

- Invertec V275-S: For Stick and DC TIG WeldingДокумент4 страницыInvertec V275-S: For Stick and DC TIG WeldingPedro Ernesto Rodriguez RojasОценок пока нет

- ABB Molded Case Circuit Breakers: Technical CatalogДокумент280 страницABB Molded Case Circuit Breakers: Technical Catalogap00Оценок пока нет

- Electrical Conduit - Web PDFДокумент24 страницыElectrical Conduit - Web PDFAlaa RamadanОценок пока нет

- Current Transformers For Out D 040126Документ4 страницыCurrent Transformers For Out D 040126eccos3Оценок пока нет

- Ed5 5Документ8 страницEd5 5Anonymous 4e7GNjzGWОценок пока нет

- Current Transformer Iosk 1Документ8 страницCurrent Transformer Iosk 1Dumitru Tănase0% (1)

- TCJДокумент12 страницTCJThilina Dhanushka GuluwitaОценок пока нет

- 275 S InvertecДокумент4 страницы275 S InverteclokopicОценок пока нет

- Origo™ Tig 3000i AC/DC, TA24 AC/DC: For Demanding TIG Welding ApplicationsДокумент2 страницыOrigo™ Tig 3000i AC/DC, TA24 AC/DC: For Demanding TIG Welding Applicationsandresboy123Оценок пока нет

- Manual em Ingles e Bem Explicado Tig 200 AcdcДокумент16 страницManual em Ingles e Bem Explicado Tig 200 AcdcMarcelo CarnicelliОценок пока нет

- Carrrier Manual 38ckc-c5pdДокумент20 страницCarrrier Manual 38ckc-c5pdAaron LeveyОценок пока нет

- Hyundai Contactors HiMCДокумент12 страницHyundai Contactors HiMCMawaz Khan MirzaОценок пока нет

- Ti 2 516 UsДокумент2 страницыTi 2 516 Uswill_streetОценок пока нет

- AC Mill Duty Motors & SwitchgearДокумент4 страницыAC Mill Duty Motors & Switchgearamol76Оценок пока нет

- Contact TermicДокумент22 страницыContact Termic04hngОценок пока нет

- Crouse Hinds Control StationsДокумент127 страницCrouse Hinds Control StationsLaurence MalanumОценок пока нет

- ABB molded case circuit breakers guideДокумент280 страницABB molded case circuit breakers guideMohammed AbdelsalamОценок пока нет

- Tweco Welding Catalogue 2001Документ84 страницыTweco Welding Catalogue 2001Andrew Schroeder0% (1)

- STRESS RELIEVING EQUIPMENT & ACCESSORIESДокумент9 страницSTRESS RELIEVING EQUIPMENT & ACCESSORIESErick HoganОценок пока нет

- Installation Instructions: - Split System Air ConditionerДокумент45 страницInstallation Instructions: - Split System Air ConditionerpejdewitОценок пока нет

- kc200gt PDFДокумент2 страницыkc200gt PDFYuvarekha SenthilkumarОценок пока нет

- 1MRK513003-BEN C en Connection and Installation Components COMBIFLEXДокумент30 страниц1MRK513003-BEN C en Connection and Installation Components COMBIFLEXthomaswangkoroОценок пока нет

- M-Line Series Multi-Pin MN Series Appleton CatalogДокумент25 страницM-Line Series Multi-Pin MN Series Appleton CatalogAndrea SeguraОценок пока нет

- Exhaust Gas Thermocouples: Product Features and BenefitsДокумент2 страницыExhaust Gas Thermocouples: Product Features and Benefitsdris mahmoudiОценок пока нет

- Servicemanual PanasonicДокумент62 страницыServicemanual PanasonicYsabelle Tagaruma100% (1)

- NAM Cat CombinedCh1Документ16 страницNAM Cat CombinedCh1Thanh Do VanОценок пока нет

- HV Circuit Breaker Dead Tank TypeДокумент4 страницыHV Circuit Breaker Dead Tank TypeEsproОценок пока нет

- Kem Tc101 STDДокумент51 страницаKem Tc101 STDnalasekaranОценок пока нет

- Design A KEMET Ceramic Capacitor Into Your Next Project - . .Документ4 страницыDesign A KEMET Ceramic Capacitor Into Your Next Project - . .s-adi-putro-1442Оценок пока нет

- MEPF BOQ - AZURE TargetДокумент33 страницыMEPF BOQ - AZURE TargetUpendra ChariОценок пока нет

- Jak 0cДокумент4 страницыJak 0cOliver MendozaОценок пока нет

- Watlow Air HeatersДокумент32 страницыWatlow Air HeatersEliasОценок пока нет

- Brosura Aparate MMAДокумент10 страницBrosura Aparate MMARogo CatalinОценок пока нет

- Air HeatersДокумент34 страницыAir HeatersNaveen KamatОценок пока нет

- Eng DS Epp-0608 1410Документ2 страницыEng DS Epp-0608 1410Douglas FernandoОценок пока нет

- Totally Enclosed Tube Ventilated High Voltage Induction MotorsДокумент7 страницTotally Enclosed Tube Ventilated High Voltage Induction MotorsAbhay JhaОценок пока нет

- OTEF Voltage Transformers 100 KV To 800 KV - Brochure GBДокумент4 страницыOTEF Voltage Transformers 100 KV To 800 KV - Brochure GBjoseandres999Оценок пока нет

- Jad AcДокумент2 страницыJad AcFrancisco LeonОценок пока нет

- Echipamente de Sudare EWMДокумент148 страницEchipamente de Sudare EWMRogo CatalinОценок пока нет

- En PyrotenaxSystem2000 DS H57049 Tcm432 26219Документ5 страницEn PyrotenaxSystem2000 DS H57049 Tcm432 26219thanna9783Оценок пока нет

- GE Pegasus MHV MotorДокумент6 страницGE Pegasus MHV MotoridontlikeebooksОценок пока нет

- GIS and Oil Immersed Transformer Terminations 69kV-245kVДокумент4 страницыGIS and Oil Immersed Transformer Terminations 69kV-245kVSavitha RajitОценок пока нет

- Eaton Series G Circuit BreakerДокумент59 страницEaton Series G Circuit BreakerWilliam PinzonОценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionОт EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Marine Electrical Practice: Marine Engineering SeriesОт EverandMarine Electrical Practice: Marine Engineering SeriesРейтинг: 4 из 5 звезд4/5 (8)

- Nox Rust1100 PDFДокумент2 страницыNox Rust1100 PDFGustavo PalaciosОценок пока нет

- Carbon Steel ThreadoletДокумент5 страницCarbon Steel ThreadoletMohd AzrinОценок пока нет

- 9.1 Attributes-Vs-Properties PDFДокумент1 страница9.1 Attributes-Vs-Properties PDFGustavo PalaciosОценок пока нет

- Adoption GuideДокумент16 страницAdoption GuideGustavo PalaciosОценок пока нет

- Brennan Thread ChartДокумент1 страницаBrennan Thread ChartraulguardaОценок пока нет

- Er-56 02Документ3 страницыEr-56 02Gustavo PalaciosОценок пока нет

- Thermo Gau RDДокумент9 страницThermo Gau RDGustavo PalaciosОценок пока нет

- TL Contrastsensors Manual Rev G EngДокумент1 страницаTL Contrastsensors Manual Rev G EngGustavo PalaciosОценок пока нет

- Optimizing Oil Change IntervalsДокумент8 страницOptimizing Oil Change IntervalsRigaud Fajardo GuzmanОценок пока нет

- WM 2004 New FeaturesДокумент8 страницWM 2004 New FeaturesDoris CamargoОценок пока нет

- StrawberryДокумент65 страницStrawberryGustavo PalaciosОценок пока нет

- 2286 3253 1 PBДокумент16 страниц2286 3253 1 PBGustavo PalaciosОценок пока нет

- Strawberry Cultivation Production TechnologyДокумент9 страницStrawberry Cultivation Production TechnologyAnkugadhiyaОценок пока нет

- Replacement Coils and Spark Plug Wires - FlierДокумент1 страницаReplacement Coils and Spark Plug Wires - FlierGustavo PalaciosОценок пока нет

- Shaviv Directory 2014 EE 150714 WebДокумент20 страницShaviv Directory 2014 EE 150714 WebGustavo PalaciosОценок пока нет

- 2286 3253 1 PBДокумент16 страниц2286 3253 1 PBGustavo PalaciosОценок пока нет

- WD Black: PC Hard DrivesДокумент3 страницыWD Black: PC Hard DrivesGustavo PalaciosОценок пока нет

- Random ForestsДокумент35 страницRandom ForestseasymakeleleОценок пока нет

- T 001733 eДокумент8 страницT 001733 eGustavo PalaciosОценок пока нет

- Inconel Alloy 625Документ18 страницInconel Alloy 625Gustavo Palacios100% (1)

- To Gas Turbines and ApplicationsДокумент34 страницыTo Gas Turbines and Applicationstanojpatro1985100% (1)

- Om 3Документ15 страницOm 3akilshaikhОценок пока нет

- MaintenanceДокумент9 страницMaintenanceKumar GaneshОценок пока нет

- Vibrations DR BertoliniДокумент168 страницVibrations DR BertoliniGustavo PalaciosОценок пока нет

- Catalogo 7Документ105 страницCatalogo 7Gustavo PalaciosОценок пока нет

- 5th-Order, Lowpass, Switched-Capacitor Filters: General Description FeaturesДокумент12 страниц5th-Order, Lowpass, Switched-Capacitor Filters: General Description FeaturesGustavo PalaciosОценок пока нет

- Expert Profile & Qualifications: Amusement Ride Inspector/Expert WitnessДокумент8 страницExpert Profile & Qualifications: Amusement Ride Inspector/Expert WitnessGustavo PalaciosОценок пока нет

- String Games (Juegos de Cuerda)Документ52 страницыString Games (Juegos de Cuerda)Ares Javier0% (1)

- Operation & Maintenance: A160-Om-C-May15Документ66 страницOperation & Maintenance: A160-Om-C-May15Gustavo PalaciosОценок пока нет

- S 8-Bit ADC With Track/Hold: LC MOS 5 AD7575Документ13 страницS 8-Bit ADC With Track/Hold: LC MOS 5 AD7575Fabio DiazОценок пока нет

- Structural Design PDFДокумент100 страницStructural Design PDFDennoh Mbuthia100% (1)

- Faculty EBIT Full PDFДокумент966 страницFaculty EBIT Full PDFBrendon Gova100% (1)

- Complete Standard Detail Drawings PDFДокумент97 страницComplete Standard Detail Drawings PDFabhishek581067% (15)

- Distribution System Grounding FundamentalsДокумент17 страницDistribution System Grounding FundamentalsJose Alberto RodriguezОценок пока нет

- 45th Dredging Engineering Short CourseДокумент4 страницы45th Dredging Engineering Short Courseرعد العكيليОценок пока нет

- Upgrading the DigitalFilipino Engineer for World PracticeДокумент71 страницаUpgrading the DigitalFilipino Engineer for World PracticesedexxОценок пока нет

- ECS448 - Topic 1Документ28 страницECS448 - Topic 1dixn__Оценок пока нет

- Monthly Progres Report - Feb-2016Документ40 страницMonthly Progres Report - Feb-2016Akshata Patil ParvatikarОценок пока нет

- MCA TANCET Cutoff 2020Документ7 страницMCA TANCET Cutoff 2020Sundaresan MunuswamyОценок пока нет

- AN18.01 Achieving Best Price Performance Parallel Power SuppliesДокумент5 страницAN18.01 Achieving Best Price Performance Parallel Power SuppliesFarhan ShahОценок пока нет

- John+Smith Summary+of+contributionsДокумент5 страницJohn+Smith Summary+of+contributionsmaxor4242Оценок пока нет

- VSL News 1997 1Документ16 страницVSL News 1997 1DrPadipat ChaemmangkangОценок пока нет

- Flexible Pipe Systems: France Brazil MalaysiaДокумент2 страницыFlexible Pipe Systems: France Brazil MalaysiajiokoijikoОценок пока нет

- Abbrivation List 10001246905Документ7 страницAbbrivation List 10001246905hemant_durgawaleОценок пока нет

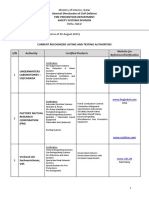

- MOI QCDD-FPD Recognized Listing Testing AuthoritiesДокумент9 страницMOI QCDD-FPD Recognized Listing Testing AuthoritiessynkanОценок пока нет

- Ecoshield PДокумент2 страницыEcoshield PBaugh Graphic DesignОценок пока нет

- Weld FatigueДокумент143 страницыWeld FatigueJim Gray100% (1)

- Engineering Geology FundamentalsДокумент76 страницEngineering Geology FundamentalsDORINОценок пока нет

- Project Handover Record Information Rev 2Документ29 страницProject Handover Record Information Rev 2Antonio GalvezОценок пока нет

- Castable RefractoryДокумент4 страницыCastable RefractorySarbajitMannaОценок пока нет

- Allowable Deflection of PipesДокумент4 страницыAllowable Deflection of PipesTAMER RAGAAОценок пока нет

- Steel Design Calculation For Bridge False WorksДокумент10 страницSteel Design Calculation For Bridge False Worksnelvar2005Оценок пока нет

- Bridge Manual (Metric)Документ501 страницаBridge Manual (Metric)Anonymous PjmE9RJcghОценок пока нет

- Curriculum Vitae: Personal InformationДокумент4 страницыCurriculum Vitae: Personal InformationRabeea AhmadОценок пока нет

- Safety Standard For Belt Manlifts: ASME A90.1-2009Документ34 страницыSafety Standard For Belt Manlifts: ASME A90.1-2009Marko's Brazon'Оценок пока нет

- MQ SP P 5024Документ16 страницMQ SP P 5024jaseel kОценок пока нет

- Sen Answer Class Test 1Документ14 страницSen Answer Class Test 1zayankhan368369Оценок пока нет

- Design and Modelling of a ForkliftДокумент5 страницDesign and Modelling of a Forkliftjyothi karnatiОценок пока нет

- Software CrisisДокумент4 страницыSoftware CrisisJee AlmanzorОценок пока нет