Академический Документы

Профессиональный Документы

Культура Документы

201409005es 141103063255 Conversion Gate01 PDF

Загружено:

choksi himanshuИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

201409005es 141103063255 Conversion Gate01 PDF

Загружено:

choksi himanshuАвторское право:

Доступные форматы

Kumar et al. 2014. International J Ext Res.

1:36-40

http://www.journalijer.com

International

Journal of Extensive Research

Open Access

Research Article

Efficient Production Methodology For Biodiesel From Non-Edible

Karanja Oil and Its Fuel Characterization Study

Kumar Vinod, Jahan Firdaus and Saxena RK*

Department of Microbiology, University of Delhi South Campus

New Delhi 110021 India

Abstract

Biodiesel production is the transesterification reaction which could be catalyzed either chemically or enzymatically. Enzymatic

transesterification has certain advantages over the chemical catalysis of transesterification, as it is less energy intensive, allows

easy recovery of glycerol and the transesterification of glycerides with high free fatty acid contents. In the present study, transesterification reaction of karanja oil was carried out by using Pseudomonas aeruginosa lipase. Effects of important process parameters were optimized conventionally. Enhanced conversion 85.9% of fatty acid to fatty acid methyl ester within 48 h at 45 C was

achieved by using lipase at concentration of 5% (w/v of oil), molar ratio of 1:4 (oil: methanol), methanol acyl donor, n-hexane

solvent and temperature 45 C. This approach might pave the way for industrial production of biodiesel equivalents from renewable resources by employing enzyme, enabling a broader use of biodiesel like fuel in the near future.

Keywords: lipase, biodiesel, transesterification, karanja oil, FAME.

Introduction

Diesel fuel consumption has been continuously increasing over

the past few decades resulting in the depletion of world petroleum

reserves and increased pollution. In recent decades, researches are

being focused on developing renewable raw materials as sources

of sustainable energy (Gog et al. 2012). The biodiesel fuel from

vegetable oil does not produce sulfur oxide and minimize the soot

particulate one-third times in comparison with the existing one

from petroleum (Gog et al. 2012). Because of these environmental

advantages, biodiesel fuel can be expected as a substitute for conventional diesel fuel (Fan et al., 2012).

In this context, the concept of using vegetable oil as a fuel

source in diesel engines is known, however, its development and

utilization as biodiesel fuel has been limited until recently. Technically, biodiesel is defined as the mono alkyl esters of long fatty

acids derived from renewable lipid feedstock such as vegetable oils

or animal fats (Meka et al. 2007). Karanja oil (Millettia pinnata) is

one of such non-edible oils, which has an estimated annual production potential of 200 metric tons in India and it can be grown

in waste land (Shikha and Rita, 2012). The karanja seed kernel

contains 40-60% (w/w) oil, which is constituted of 20 % saturated

and 80 % unsaturated fatty acids. Oleic acid is the most abundant

(44.8 %) followed by linoleic acid (34 %), palmitic acid (12.8 %),

and stearic acid (7.3 %) (Shikha and Rita, 2012). While composition of karanja oil is similar to other oils, which are used for

non-edible purposes, the presence of some anti-nutritional factors

*Corresponding authors email: rksmicro@yahoo.co.in;

vinodudsc@gmail.com

Copyright IJER 2014. All rights reserved.

such as toxic phorbol esters renders this oil unsuitable for use in

cooking (Gbitz et al. 1999).

Although biodiesel is at present produced chemically at industrial level (Kamini & Iefuji, 2001), the disadvantages of using

chemicals of either acid or alkaline catalysts for the transesterification of karanja oil (such as pre-treatment of feedstock, glycerol

recovery, catalyst removal wastewater treatment and high energy

requirement in the process) have drawn many researchers to seek

for more environ- mental friendly approach. Enzymatic approach

is likely to over- come the problems of a chemical-catalyzed process. Enzyme catalyzed reaction is more efficient, highly selective,

involves less energy consumption, produces less waste and it is

recyclable as enzymes can be immobilized onto a support medium

(Robles-Medina et al. 2009). Glycerol recovery in enzymatic process is easier as it would produce high grade glycerol as compared

to an alkaline process (Robles-Medina et al. 2009). It is reported

that the enzymatic reactions are insensitive to FFA and water content in the raw material (Kulkarni & Dalai, 2006).

In this paper karanja oil was studied, but there are no technical

restrictions to the use of other kinds of vegetable oils, although

biodiesels coming from some vegetable oils may not fulfil quality standards (Chang et al. 2005; Garlapati et al. 2013; Kumari et

al. 2007; Soumanou & Bornscheuer, 2003). Our current research

is focussed on the use a cheap lipase preparation from P. aeruginosa was used as the catalyst. The enzymatic transesterification

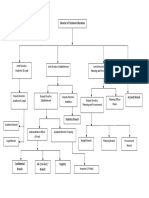

of karanja oil with methanol in solvent system was studied (Fig.

1). The reaction conditions for were optimized and evaluating the

fuel properties of the produced biodiesel.

Page 1 of 5

Kumar et al. 2014. International J Ext Res. 1:36-40

http://www.journalijer.com

Materials and Methods

Materials

Karanja oil was purchased from Adi biotech Pvt, Ltd. New Delhi. All analytical reagents and media components were purchased

from Sisco Research Laboratories, India and Hi-Media, India. All

other chemicals were also obtained commercially and of analytical

grade.

Microorganism and lipase production conditions

P.aeruginosa, was maintained on nutrient agar slants (g/l): Peptone-1.5, Yeast extract-1.5, NaCl-5, Agar-20). Production of lipase

was carried out in 2 L Erlenmeyer flasks containing 400 ml of

optimized production medium (% w/v) : corn oil (emulsified with

2% gum acacia), 0.5; glucose 0.2; Tryptone 1.5%; Ammonium nitrate 0.2%; MgSO4.7H2O 0.60 mM; pH 8.0) inoculated with 2%

inoculum density and incubated at 30 oC, 200 rpm for 36 h. The

crude enzyme obtained after centrifugation of the culture broth

and subsequent four fold concentration was carried out using 10

kDa cellulose acetate membrane (Millipore). This concentrated

culture filtrate was used as lipase source for further transesterification reactions.

Transesterification Reaction

The reactions for biodiesel synthesis were carried out in a 100 ml

round bottom flask. The reaction mixture consisted of 20.0 g of

oil (karanja oil), 5.0% (w/w) crude lipase and 3.0 molar equivalent

of methanol. This reaction was carried out in presence of n-hexane at 45 C and 200 rpm for 48 h. Samples (2.0 ml) were withdrawn from the reaction mixture at regular intervals of 12 h up to

48 h and centrifuged at 12,000 rpm for 10 min. An aliquot of the

upper layer was precisely taken and biodiesel production was measured by TLC. Spectrophotometric analysis at 715 using copper

pyridine regent for residual fatty acid and finally GC analysis was

carried out to determine fatty acid methyl ester (FAME) content.

Spectrophotometric analysis of fatty acid methyl estyers.

The reaction (Sample size 0.5 ml) was terminated using 0.1 ml

of 6 M HCl. n-hexane (0.5 ml) was added to it and the mixture

was centrifuged at 10,000 rpm for 10 min at 4 C. Now, 0.1 ml

of copper pyridine reagent (50 g copper acetate dissolved in 1.0

L distilled water with pH adjusted to 6.0 using pyridine) was added to 0.5 ml of supernatant. This mixture was homogenized and

absorbance was recorded at 715 nm with a UV/VIS spectrophotometer (Shimada et al. 1999).

The percentage of conversion of fatty acid (FA) at definite

time (t) was determined according to the following formula:

Fatty acid conversion(t ) ( % )

Initial conc. of FA Conc. of FAat time ( t )

100

Intial conc. of FA

GC analysis of fatty acid methyl esters

After the reaction, samples were withdrawn and the product was

analyzed by a gas chromatography. A GC-2014 gas chromatography (Shimadzu, Japan) equipped with a capillary column (Stablewax DA, 30 m x 0.25 mm, 0.2 m film thickness) and flame

ionizing detector (FID) was used. Nitrogen gas was used as the

carrier gas at a flow rate 0f 6.21 mL / min. Injection was done in

split mode (1/5) and the injector and detector temperatures were

at 250 oC and 260 oC, respectively. Samples (1 L) were injected at

an oven temperature of 160 oC, then the oven was heated at 3 oC

/min to 250 oC (holding for 10 min) (Lowry and Tinsley, 1975).

Biodiesel fuel characteristics

Fuel characteristics were checked by American Society for Testing Materials (ASTM) methods. Specific gravities of pure samples were tested (ASTM 1996)with specific gravity bottle. Around

40 ml of sample was taken for viscosity (ASTM 2006), and flash

point testing (ASTM 2002), 80 ml of pure sample was used. Flash

point was not tested for blended sample. The experiments were

repeated two times and the average values were presented.

Fig. 1 Schematic representation of biodiesel produciton via

enzymatic route from non-edible oil

Results and Discussion

Effect of enzyme concentration on transesterification

The transesterification reactions were carried out using different

concentrations (5 15%) of P. aeruginosa lipase to produce maximum FAME production. As presented in (Fig. 2), results show

that the maximum FAME conversion (74.5%) was obtained using

5 % lipase. Use of lipase in lower concentration (1-2.5%) did not

show any significant FAME conversion. However further increase

in the enzyme concentration did not yield in any further enhancement in FAME conversion after 48 h. At a higher enzyme concentration (3%), percentage conversion was very low. The reason

might be due to unavailability of sufficient quantity of substrate

to enzyme for reaction (Nie et al., 2006). The maximum methyl

ester yield was reported by Kose et al., 2002 with the 30% Novozyme based on oil weight in transesterification of cottonseed oil

(Kse et al. 2002). Similar results were in case of methanolysis of

rice bran oil using Cryptococcus sp. S-2 lipase (Kamini & Iefuji,

2001). In another study, Garlapti et al., (2013) also reported the

optimal molar conversion of 62.23% was observed at 10 U of

lipase activity.

Effect of different acyl acceptors on transesterification

The most important factors affecting the transesterification reaction is the different acyl acceptor of solvent. The synthesis of

biodiesel was studied in the methanol, ethanol, propane 2-ol, nbutanol. The result showed that, the maximum conversion (74.8

%) was observed on using methanol as an acyl acceptor in 48 h.

Page 2 of 5

Kumar et al. 2014. International J Ext Res. 1:36-40

http://www.journalijer.com

Effect of molar ratio of acyl acceptors on transesterification

One of the most important factors affecting the transesterification reaction is the molar ratio of triglycerides to methanol. The

synthesis of biodiesel was studied in the range of molar ratio

of 1:3 to 1:12. With 5 % (w/w) lyophilized lipase the maximum

FAME conversion (79.9 %) was obtained at 1:6 molar ratio after

the incubation of 48 h (Fig. 4). However, at higher molar ratio,

there was a decline in the FAME conversion with only 43.3 %

FAME conversion obtained at 1:12 molar ratio.

From the results presented in Fig. 3, it is clear that one mole

of oil is completely esterified by six mole of methanol when crude

lipase is used and approximately similar results were obtained using lipase from Pseudomonas fluorescens. Shimada et al. (1999)

reported the methanolysis of canola oil and methanol for biodiesel production using immobilized lipase from Candida antarctica

(Novozyme 435). Maximum conversion was achieved using subFig. 2 Effect of enzyme concentrations for biodiesel production.

Error bar represents std deviation.

Fig. 3 Effect of acyl acceptor for biodiesel production.

Error bar represents std deviation.

Minimum conversion was observed in case of n-butanol (40.2 %)

(Fig. 3).

In order for the lipase to maintain its activity for repeated reactions, either the enzyme or the entire cell must be immobilized.

One major problem of lipase-catalyzed transesterification is that

glycerol competitively inhibits lipase activity by blocking the active

sites site (Nie et al. 2006). Since glycerol is a byproduct of the

reaction of triglycerides with methanol, new acyl acceptors that

produce other more useful and less detrimental byproducts are

under investigation. Methanol also has a negative impact on the

stability of the enzyme for repeated use because prolonged exposure causes denaturation of lipase. An acyl acceptor functions

as the new attachment of fatty acid chains, in place of glycerol.

The byproduct of this reaction is triacetylglycerol, which has no

negative effects on the reaction, can easily be separated from the

biodiesel product, and has a higher value than glycerol for later use

(Mallory, 2007).

Fig. 4 Effect of molar ratio of oil to methanol on biodiesel

production. Error bar represents std deviation.

Fig. 5 Effect of solvents on biodiesel production.

Error bar represents std deviation.

Page 3 of 5

Kumar et al. 2014. International J Ext Res. 1:36-40

http://www.journalijer.com

strate molar ratio of 3.5:1 and enzyme concentration of 42.3%.

However, in the present investigation, lower concentration of enzyme (5%) was used for biodiesel production.

Effect of organic solvents on transesterification

The transesterification reactions were carried out using different

organic solvents to observe their effect on the FAME conversion.

A suitable solvent system can improve the miscibility of substrates,

which in turn enhance the conversion and rate of the reaction. It

was observed that polar solvents like acetonitrile and acetone did

not favour the reaction, whereas non polar solvents like hexane

(Chang et al. 2005). These values indicate the polarity of the solvents. The higher the value of log P, the lower is the polarity of the

solvent. It is quite obvious that polar solvents cannot solubilize the

non-polar substrates like vegetable oils and hence, result in lower

conversions. In recent years the focus was shifted from non-polar

solvents to a partially polar solvent like tbutanol, which has a log

P value lying between those of polar and non-polar solvents and

hence, it is widely used for transesterification reactions involving

different oils (Kumar et al. 2007; Kumar et al. 2009).

As visible from the results presented in Fig. 5, the maximum

FAME conversion (79.90%) was observed while using n-hexane

as a solvent. Whereas, minimum conversion was observed with

iso-amylalcohol (53.20%). However, n-propanol and n-butanol

showed the average FAME conversion.

Biodiesel Fuel characteristics

The physico-chemical properties of the karanja, based biodiesel

(B100) were evaluated as per the ASTM standards and the experimental procedures for evaluating physico-chemical properties

were followed. The fuel properties data of karanja methyl esters

with diesel are summarized in a tabular form as shown in Table

1. The karanja methyl esters have fuel property values relatively

closer to that of regular petroleum diesel. GC profile of reaction

mixture also presented in the Fig. 6.

Table 1. Fuel properties of biodiesel made from

karanjia oil

Biodiesel

(Enzymatic)

Biodiesel standard

(ASTM D 6751 08)

Density, kg/m3

0.8785

0.85 - 0.95

Kinematic viscosity

at 40 C cSt

8.972

25

Acid value mg

KOH/g

0.82

<0.8

Properties

Pour point C

0 0C

< 9 0C

Water content

<0.05

< 0.1 %

Conclusions

In the present investigation, biodiesel was synthesized using

karanja oil via transesterification reaction using P. aeruginosa lipase.

The optimal conditions determined were as follows: enzyme concentration 5 %, molar ratio 1:6, acyl accepter methanol and temperature 45 C. We report highest yield of biodiesel after transesterification (85.9 %) was achieved after 48 h incubation using

karanja oil. However, in the batch system, the conversion yield of

the biodiesel could not be increased above 85.9% might due to

activity loss of enzyme. Therefore, a stepwise reaction could be

conducted to increase the biodiesel production. This method is

a feasible method for an industrial biodiesel production. However, further research and development on some advanced methods

such as supercritical methanol process could be performed.

Acknowledgement

The authors gratefully acknowledge financial support from the

Ministry of New and Renewable Energy (MNRE) to Vinod

Kumar and from Council of Scientific and Industrial Research

(CSIR) to Firdaus Jahan. The authors would also like to thank

Technology Based Incubator, UDSC New Delhi for providing the

infrastructure support.

Fig. 7 Gas chromatography profile of (a) Fatty acid profile in karanja oil and (b) fatty acid methy esters synthesis during

transesterification reaction

Page 4 of 5

Kumar et al. 2014. International J Ext Res. 1:36-40

http://www.journalijer.com

Conflict of interests

The authors declare that they have no direct financial relation with

any commercial identity above mentioned in this paper that might

lead to a conflict of interests. The authors also declare that they

have no competing interests.

References

1. Gog A, Roman M, Tosa M, Paizs C, Irimine FD: Biodiesel

production using enzymatic transesterification current

state and perspectives. Renew Energy 2012, 39(1): 10-16.

2. Fan X, Niehus X, Sandoval G: Lipases as biocatalyst for

biodiesel production. Method Mol Boil 2012, 861:471-483.

3. Meka PK, Tripathi V, Singh RP: Synthesis of biodiesel fuel

from safflower oil using various reaction parameters. J Oleo

Sci 2007, 56: 9-12.

4. Shikha, K. and Rita, C. Y., (2012). Biodiesel production

from non-edible-oils: A Review. J. Chem. Pharm. Res.

4:4219-4230.

5. Gubitz GM, Mittelbach M, Trabi M: Extraction of oil from

Jatropha curcas L. seed by Enzyme. Bioresour Technol

1998, 67:73-77.

6. Kumar S, Gupta AK, Naik SN: Conversion of non-edible

oil into biodiesel. J Sci Ind Res 2003, 62:124-132.

7. Ma F, Hanna MA: Biodiesel Production: A Review. Bioresour Technol1999, 70:115.

8. Fukuda H, Kondo A, Noda H: Biodiesel fuel production by

transesterification of oils. J Biosci Bioeng 2001, 92:405416.

9. Ramadhas AS, Jayaraj S, Muraleedharan C:2005). Biodiesel production from high FFA rubber seed oil. Fuel 2005,

84:335340.

10. Wu H, Zong MH, Luo Q, Wu HC: Enzymatic conversion

of waste oil to biodiesel in a solvent-free system. J Am

Chem Soc 2003, 48:533534.

11. Shimada Y, Watanabe Y, Samukawa T, Sugihara A, Noda

H, Fukuda H, Tominaga Y: Conversion of vegetable oil to

biodiesel using immobilized Candida antarctica lipase. J Am

Oil Chem Soc 1999, 76:789793.

12. Lowry RR, Tinsley IJ: Rapid Colorimetric Determination of

Free Fatty Acids. J Am Oil Chem Soc 1975, 53: 470-473.

13. ASTM D 4052-96, Standard test method for density and

relative density of liquids by digital density meter, Philadelphia; 1996.

14. ASTM D 445-06, Standard test method for kinematic viscosity of transparent and opaque liquids (and calculation of

dynamic viscosity), Philadelphia; 2006.

15. ASTM D 93-02, Standard test methods for flash point by

pensky-martens closed cup tester, Philadelphia; 2002.

16. Nie K, Xie F, Wang F, Tan T: Lipase catalyzed methanolysis

to produce biodiesel: Optimization of the biodiesel production. J Mol Catal B: Enz 2006, 43:142147.

17. Kose O, Tuter M, Aksoy HA: Immobilized Candida antarctica lipasecatalyzed alcoholysis of cotton seed oil in a

solvent-free medium. Bioresource Technol 2002, 83(2):125

129.

18. Kamini NR, Iefuji H: Lipase catalyzed methanolysis of

vegetable oils in aqueous medium by Cryptococcus spp. S-2.

Process Biochem 2001, 37(4):405410.

19. Garlapti VK, Kant R, Kumari A, Mahapatra P, Das P, Banerjee R: Lipase mediated transesterification of simarouba

20.

21.

22.

23.

24.

25.

26.

27.

28.

glauca oil: a new feedstock for biodiesel production. Sustain

Chem Processes, 2013, 1:1-6

Soumanou MM, Bornscheuer UT: Lipase-catalyzed alcoholysis of vegetable oils. Eur J Lipid Sci Technol 2003,

105:656660.

Mallory P: Transesterification of Vegetable Oils to Produce

Biodiesel Fuel MMG 445. Basic Biotechnol e J. 2007, 3:5761.

Chang HM, Liao HF, Lee CC, Shieh CJ: Optimized synthesis of lipase-catalyzed biodiesel by Novozym 435. J Chem

Technol Biotechnol 2005, 80:307-312.

Kumari V, Shah S, Gupta MN: Preparation of biodiesel by

lipase-catalyzed transesterification of high free fatty acid

containing oil from Madhuca indica. Energy Fuels 2007,

21:36872.

Kumari A, Mahapatra P, Garlapati VK, Banerjee R: Enzymatic transesterification of Jatropha oil. Biotechnol Biofuel

2009, 2:17.

Jeong GT, Park DH: Lipase-catalyzed transesterification of

rapeseed oil for biodiesel production with tert-butanol. Appl

Biochem Biotechnol 2008, 148:1319.

Mittelbach M: Lipase catalyzed alcoholysis of sunflower oil.

J Am Oil Chem Soc 1990, 67:168170.

Pizarro AVL, Park E: Lipase catalyzed production of biodiesel fuel from vegetable oils contained in waste activated

bleaching earth. Process Biochem 2003, 38:1077-1082.

Soham C, Ankush K., Sancharini D, Asoke D, Ramkrishna

S: Biocatalytic production of biodiesel from cottonseed oil:

Standardization of process parameters and comparison of

fuel characteristics. Appl Energy 2011, 88:12511256.

**********

Article Information:

Received: 08 August 2014

Accepted: 14 September 2014

Published: 19 September 2014

Cite this article as:

Vinod et al. 2014. Efficient production methodology for biodiesel from

non-edible oil and its fuel characterization study. International Journal

of Extensiv Research. Vol. 1:36-40.

Page 5 of 5

Вам также может понравиться

- Dimethyl Carbonate PaperДокумент9 страницDimethyl Carbonate Paperchoksi himanshuОценок пока нет

- NIRF 2021 Overall ReportДокумент24 страницыNIRF 2021 Overall Reportchoksi himanshuОценок пока нет

- Biodiesel Feedstock and Production TechnДокумент26 страницBiodiesel Feedstock and Production Technchoksi himanshuОценок пока нет

- Course Structure of B.Voc. (CPE)Документ10 страницCourse Structure of B.Voc. (CPE)choksi himanshuОценок пока нет

- Director of Technical EducationДокумент1 страницаDirector of Technical Educationchoksi himanshuОценок пока нет

- Field Sales JDДокумент2 страницыField Sales JDchoksi himanshuОценок пока нет

- Zeppelin Systems India Pvt. LTD (Responses)Документ2 страницыZeppelin Systems India Pvt. LTD (Responses)choksi himanshuОценок пока нет

- Appr BE 2016Документ14 страницAppr BE 2016choksi himanshuОценок пока нет

- Polymer CharacterizationДокумент3 страницыPolymer Characterizationchoksi himanshuОценок пока нет

- Faculty Mentors ExpectationsДокумент5 страницFaculty Mentors Expectationschoksi himanshuОценок пока нет

- Petroleum QuizДокумент62 страницыPetroleum Quizchoksi himanshu100% (1)

- Pandit Deendayal Petroleum University School of Technology No Dues FormДокумент1 страницаPandit Deendayal Petroleum University School of Technology No Dues Formchoksi himanshuОценок пока нет

- Basic Property Definitions of BiodieselДокумент5 страницBasic Property Definitions of Biodieselchoksi himanshuОценок пока нет

- HP-5MS Column AnalysisДокумент3 страницыHP-5MS Column Analysischoksi himanshuОценок пока нет

- Taguchi Method Calculation & AnalysisДокумент96 страницTaguchi Method Calculation & Analysischoksi himanshu100% (1)

- Coalbed Methane Extraction: Landowner RightsДокумент44 страницыCoalbed Methane Extraction: Landowner Rightschoksi himanshuОценок пока нет

- BD From Tobacco Seed Oil PDFДокумент9 страницBD From Tobacco Seed Oil PDFchoksi himanshuОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Biodiesel Lab7Документ20 страницBiodiesel Lab7Karla LopezОценок пока нет

- Properties of AlgaeДокумент25 страницProperties of AlgaeHemal Patel Sam50% (2)

- Biodiesel Production Using Second-Generation Feedstocks: A ReviewДокумент18 страницBiodiesel Production Using Second-Generation Feedstocks: A ReviewPadelisgiОценок пока нет

- Production of Vegetable Oil Fatty Acid Methyl Este PDFДокумент10 страницProduction of Vegetable Oil Fatty Acid Methyl Este PDFSagar DhuriОценок пока нет

- Biodisel OdfДокумент6 страницBiodisel OdfMari AlvesОценок пока нет

- Watson's Internship Report (Mic Rev)Документ41 страницаWatson's Internship Report (Mic Rev)dinesh93Оценок пока нет

- Polygel Titanates BrochureДокумент12 страницPolygel Titanates BrochureMenoddin shaikhОценок пока нет

- Report On BiodieselДокумент32 страницыReport On BiodieselEmmanuelОценок пока нет

- Wang 2007Документ10 страницWang 2007sri murti astutiОценок пока нет

- Abstract BiodieselДокумент6 страницAbstract BiodieseljahmanОценок пока нет

- Developement of Biolubricants From Vegetable Oils Via Chemical Modification 2015Документ34 страницыDevelopement of Biolubricants From Vegetable Oils Via Chemical Modification 2015Anshul KumarОценок пока нет

- Assignment by Manish Chaudhary (32016313)Документ15 страницAssignment by Manish Chaudhary (32016313)Manish ChaudharyОценок пока нет

- Transesterifikasi Menggunakan NaOHДокумент12 страницTransesterifikasi Menggunakan NaOHDanar AdityaОценок пока нет

- Laboratory Manual and Record: ChemistryДокумент67 страницLaboratory Manual and Record: ChemistryAnil GugulothОценок пока нет

- Process Production of PETДокумент7 страницProcess Production of PETDhiyyah MardhiyyahОценок пока нет

- Chemical Engineering Science: Saeikh Z. Hassan, Madhu VinjamurДокумент11 страницChemical Engineering Science: Saeikh Z. Hassan, Madhu VinjamurkarpanaiОценок пока нет

- Kinetic and Thermodynamic Study of Methanolysis of Poly (Ethylene Terephthalate) Waste PowderДокумент6 страницKinetic and Thermodynamic Study of Methanolysis of Poly (Ethylene Terephthalate) Waste PowderMaria ElaineОценок пока нет

- Optimization of Novel Lepidium Perfoliatum Linn Biodiesel Using Zirconium Modified Montmorillonite Clay CatalystДокумент17 страницOptimization of Novel Lepidium Perfoliatum Linn Biodiesel Using Zirconium Modified Montmorillonite Clay CatalystGanesh T NaikОценок пока нет

- Modern Heterogeneous Catalysts For Biodiesel Production PDFДокумент22 страницыModern Heterogeneous Catalysts For Biodiesel Production PDFFabricio Uliana0% (1)

- Biodiesel Application NoteДокумент1 страницаBiodiesel Application NoteMohamad MukharirОценок пока нет

- Chemistry Project On Green Chemistry: Bio-Diesel and Bio-PetrolДокумент18 страницChemistry Project On Green Chemistry: Bio-Diesel and Bio-PetrolFerry Sofat82% (17)

- Menggunakan Katalis Basa Homogen: Pilot Plant Proses Produksi BiodieselДокумент7 страницMenggunakan Katalis Basa Homogen: Pilot Plant Proses Produksi Biodiesel20-027 Ranaf SitumorangОценок пока нет

- ch12 PDFДокумент7 страницch12 PDFAkash ThummarОценок пока нет

- Fat Splitting: Fatty Acid Isolation and Glycerine RecoveryДокумент41 страницаFat Splitting: Fatty Acid Isolation and Glycerine RecoveryAzhan FikriОценок пока нет

- Transesetrification ProcessДокумент33 страницыTransesetrification Processdark knightОценок пока нет

- Synthesis of BiodieselДокумент11 страницSynthesis of BiodieselMohamed Abd ElraoofОценок пока нет

- Current Advances in Catalysis Toward Sustainable Biodiesel ProductionДокумент12 страницCurrent Advances in Catalysis Toward Sustainable Biodiesel Productionfitri rowiyahОценок пока нет

- Print FamesДокумент6 страницPrint FamesnabilaОценок пока нет

- Waste Cooking Oil PDFДокумент6 страницWaste Cooking Oil PDFRichard ObinnaОценок пока нет

- A Technology and Entrepreneurship InterfДокумент239 страницA Technology and Entrepreneurship InterfOheneba AboagyeОценок пока нет