Академический Документы

Профессиональный Документы

Культура Документы

Firing Estonian Oil Shale in CFB Boilers - Ash Balance and Behaviour of Carbonate Minerals

Загружено:

salkan_rahmanovic810Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Firing Estonian Oil Shale in CFB Boilers - Ash Balance and Behaviour of Carbonate Minerals

Загружено:

salkan_rahmanovic810Авторское право:

Доступные форматы

Oil Shale, 2011, Vol. 28, No. 1, pp.

5867

doi: 10.3176/oil.2011.1.07

ISSN 0208-189X

2011 Estonian Academy Publishers

FIRING ESTONIAN OIL SHALE IN CFB BOILERS

ASH BALANCE AND BEHAVIOUR OF CARBONATE

MINERALS

K. PLAMUS*, A. OTS, T. PIHU, D. NESHUMAYEV

Department of Thermal Engineering, Tallinn University of Technology

116 Kopli St., Tallinn 11712, Estonia

The ash balance and the extent of carbonate decomposition (ECD) for

circulating fluidised-bed (CFB) boilers depending on oil shale lower heating

value (8.5 and 11.1 MJ/kg) were analysed. As for the ash balance, ash mass

flow rates (kg/s) for each ash separation port were determined. In calculations

the ECD methodology developed at the Department of Thermal Engineering

(DTE) on the basis of ash composition was used. Changes in the boiler ash

balance occurred when firing oil shale of different quality. Additionally, the

reduction of the CO2 emission by 7% and of the total ash mass flow by 23%

was obtained when firing upgraded oil shale instead of low-grade oil shale.

Introduction

Oil shale is the main energy resource in Estonia. Around 90% of the

electricity in the country is produced from oil shale at the Narva Power

Plants (NPP). The lower heating value (LHV) of oil shale used for electricity

production is 8.38.4 MJ/kg. This is a low-grade fuel with a high content of

carbonate minerals. Burning that kind of fuel is associated with several

problems concerning dissociation of carbonate minerals, high CO2 emission

levels, ash handling and storing. In the context of minimising the environmental impact of power production, the question has arisen about utilisation

of oil shale of higher quality. The application of the modern CFB technology

at the NPP provides advantages in utilisation of upgraded oil shale with the

LHV at up to 11.0 MJ/kg.

Several positive aspects of using oil shale of higher quality can be highlighted: decreased concentration of CO2 in flue gas, reduction of fuel consumption per kWh of produced power, and the improvements in ash

handling and storing. Considering these aspects, the energy unit efficiency

increases, which also improves cost efficiency.

*

Corresponding author: e-mail plamus@sti.ttu.ee

Firing Estonian Oil Shale in CFB Boilers Ash Balance and Behaviour of Carbonate Minerals

59

However, firing of oil shale of higher quality could cause changes in the

CFB boiler operating conditions. Considering the fact that the carbonate

minerals (mainly limestone) in oil shale are mechanically harder (compressive strength range of 4080 MPa) and heavier by density (2200

2600 kg/m3) than the organic and sandy-clay part (compressive strength

range of 2040 MPa and density at 15001800 kg/m3), firing of oil shale

containing reduced amount of carbonate minerals could cause redistribution

of the CFB boiler ash mass flows and changes in the behaviour of mineral

matter in the furnace during the combustion process.

To investigate the distribution of ash mass flows and the behaviour of the

mineral matter depending on oil shale quality, the boiler ash balance was

determined and the extent of carbonate decomposition for the boiler ash was

calculated. The investigation is based on the full-scale oil shale firing tests

carried out by the DTE and the NPP during 20062007.

Experimental part

Arrangement of the tests and collection of the process data

The oil shale firing tests were carried out in the CFB boiler No. 1 of the Balti

Power Plant energy unit No. 11. The capacity of the energy unit was

215 MWe and it was commissioned in 2004 by Foster Wheeler Energia OY.

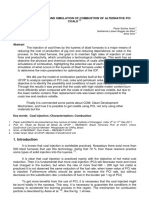

The main parameters of the boiler (Fig. 1) used were as follows:

steam capacity (primary/secondary) 95/76 kg/s;

primary/secondary steam pressure 12.7/2.4 MN/m2;

steam temperature 535/535 C.

The detailed description of the boiler is provided in [1].

Several fuel classes of various composition and the LHV at 8.211.5 MJ/kg

were fired. A total of 17 tests were carried out in accordance with EVS-EN

12952 15:2003 [2]. The upgraded oil shale fuel was specially prepared. The

tests were run at boiler loads of 90% of nominal power.

During each test run several process data sets were collected. As regards

the investigation of the ash mass balance and the behaviour of carbonate

minerals in the CFB boiler, the fuel and ash sampling from the separation

ports was performed as described below, followed by averaging and dividing

procedures for achieving the representative average sample of the test run.

The locations of the ports used to collect solid samples are indicated in

Fig. 1. The fuel samples (A) before and (B) after the secondary fuel crusher

were taken to determine the granular composition of the fuel fed into the

boiler. The secondary fuel crushers are located at the end of each fuelfeeding line before fuel entering the furnace and are used to ensure the most

suitable granular composition of the fuel for the CFB boiler. The fuel

samples for the ultimate and proximate analysis were taken from the main

fuel conveyor (not shown in Fig.1). Additionally, several ash samples were

taken. The furnace ash samples were taken from the following collection

ports (Fig. 1): C bottom ash and D reheater of the second stage

K. Plamus et al.

60

(INTREX). Small and light ash particles (d < 50 m) [1] not separated by the

separators of solids comprise fly ash. The fly ash samples were taken from

the following collection ports: E convective cage of superheater and

reheater of first stages (SH-RH), F economizer (ECO), G air preheater

(APH) and from four fields in the electrostatic precipitator (ESP: H, I, J, K).

The fuel and ash samples were analysed by the chemistry laboratory of the

DTE. The granular composition analyses of the fly ash samples were performed by ENAS OY, Finland.

Fig. 1. Oil shale-fired CFB boiler (sample ports).

1 raw fuel silo, 2 fuel feeder, 3 grate, 4 furnace chamber, 5 separating

chamber, 6 fluidised bed internal heat exchanger (INTREX), 7 separator of

solids, 8 convective superheater and reheater, 9 economizer, 10 air preheater,

11 electrostatic precipitator, 12 secondary fuel crusher

Processing test data

Determination of the ash mass flow rates

The ash formed during the combustion process is removed from the boiler

by several separation ports as shown in Fig. 1 (C to K). For the ash balance,

the ash mass flow rates for each separation port were calculated. The ash

from the separation ports is directed to the common ash silo by the ash

senders via the mechanical and pneumatic conveying lines. The calculation

was performed on the basis of the ash senders operation frequency (except

convective cage (E) and INTREX (D)) and the ash bulk density. The data of

the ash senders operation frequencies was registered by the data logging

Firing Estonian Oil Shale in CFB Boilers Ash Balance and Behaviour of Carbonate Minerals

61

system of the plant. For the calculation it was assumed that 2/3 of the total

ash senders volumes was effective.

Considering the circumstance that the ash mass flow from the SH-RH (E)

is directed to the bottom ash silo, a specially prepared valve was installed on

the ash tube under the convective cage to determine the ash mass flow rate

from SH-RH (E). The ash mass flow rate (E) was calculated on the basis of

the ash bulk volume in the tube and the time spent on the tube fulfilment in

the case of the closed valve. The valve was closed cyclically during the tests

for measurements. The ash mass flow from the INTREX (D) is included in

the bottom ash mass flow (C).

Determination of the extent of carbonate decomposition

Regarding CO2 emissions from the CFB boiler, the behaviour of carbonate

minerals during the combustion process plays a significant role. It is well

known that calcite and dolomite during the combustion process dissociate

according to the following reactions [3]:

CaCO3CaO+CO2

(1)

CaMg(CO3)2CaO+MgO+2CO2

(2)

CaCO3+SO2+1/2O2CaSO4+CO2.

(3)

Carbon dioxide formed during the dissociation (reactions 13) of such

carbonate minerals is added to the amount of CO2 formed during the burning

of carbon. It results in an increased amount of CO2 in the flue gas. The share

of mineral CO2 in the total CO2 emission depends on the oil shale mineral

CO2 content and the ECD.

It is possible to determine the ECD for the CFB boiler ash on the basis of

the ash composition alone [4]. In order to determine the ECD, it is important

to know the CaO and MgO content of the ash. The initial amount of CO2

bound with CaO and MgO before the decomposition of carbonates occurs

can be established using the formulas below:

CO2 CaO = 0.7785 CaOash

(4)

CO2 MgO = 1.0555 MgOash

(5)

CO2 sum = CO2 CaO + CO2 MgO,

(6)

where CO2 CaO and CO2 MgO CO2 bound accordingly with CaO and MgO

and calculated in percentages of the ash mass, and CaOash and MgOash CaO

and MgO content of ash. If the carbonaceous CO2 content of ash (CO2 ash) is

also determined by the chemical analysis, the ECD is calculated with Eq. 7:

kCO2 = 1 (CO2 ash /CO2 sum).

(7)

K. Plamus et al.

62

CO2 emission from the CFB boiler

As mentioned above, the total amount of CO2 discharged into the atmosphere when firing oil shale depends on these two aspects: burning of carbon

and decomposition of carbonates. The calculation of the CO2 emission per

one kilogram of fuel as received is performed according to the formulas

below [3]:

The amount of CO2 arising from the burning of carbon, in nm3/kg:

VCO2 carbon = 0.01853 Cr,

(8)

where Cr carbon content of oil shale, %.

The amount of the CO2 arising from the decomposition of carbonates,

nm3/kg:

VCO2 carb = 0.00509 kCO2 (CO2)rc,

(9)

where kCO2 extent of carbonate decomposition;

(CO2)rc content of mineral CO2 in oil shale, %.

The total amount of the CO2 emission from the CFB boiler is calculated

as follows, in nm3/kg:

VCO2 = VCO2 carbon + VCO2 carb.

(10)

This is the specific emission of CO2 from the CFB boiler per produced

thermal energy, in t/MWhth:

CO2 = 3.6 VCO2 B / Qheat,

(11)

where = 1.977 density of CO2, kg/nm3;

B fuel consumption rate, kg/s;

Qheat boiler heat output, MWth.

Results and discussion

Investigation of the ash balance

The investigation of the CFB boiler ash balance is based on the tests in

which oil shale with the LHV 8.5 MJ/kg (Test 1) and 11.1 MJ/kg (Test 2)

were fired. For Test 1 the boiler operated continuously for three days and

five days for Test 2. A short characterisation of the fuels is provided in

Table 1.

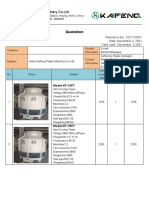

The results for the CFB boiler ash balance when firing oil shale of

different quality can be viewed in Fig. 2. As it was expected, the firing of oil

shale of different quality resulted in changes in the distribution of the ash

mass flows. The main difference can be noticed in the bottom ash mass

flows.

63

Firing Estonian Oil Shale in CFB Boilers Ash Balance and Behaviour of Carbonate Minerals

Table 1. Characterisation of oil shale fuel as received (mass %)

Symbol

Description, unit

Qir

Wr

Ar

Cr

(CO2)rc

R[0.5]A

R[0.5]B

60

Test 2

11.1

11.3

42.3

26.1

14.1

0.75

0.41

49.3

50

46.7

40

30

8.5

11.1

44.1

21.1

18.7

1.2

0.57

Total ash mass flow 12.6 kg/s

Total ash mass flow 16.3 kg/s

Relative ash mass flows, %

Test 1

Lower heating value, MJ/kg

Moisture, %

Ash (815 C), %

Organic carbon, %

Mineral CO2, %

Median size of fuel before crusher (Fig. 1, A), mm

Median size of fuel after crusher (Fig. 1, B), mm

37.4

29.3

20

11.0

10

6.9

3.2

6.1

1.4

6.8

0.9 0.6

0.14 0.16 0.02 0.01

0

Bottom

SH-RH

ECO

APH

LHV 11.1 MJ/kg

ESP 1

ESP 2

ESP 3

ESP 4

LHV 8.5 MJ/kg

Fig. 2. Ash balance for CFB boiler.

The shares of bottom and fly ash were 37% and 63% when burning lowgrade (8.5 MJ/kg) oil shale, but 30% and 70% in the case of firing upgraded

(11.1 MJ/kg) oil shale. This denotes a reduced bottom ash ratio when firing

upgraded fuel. One of the reasons for the reduced bottom ash mass flow

when firing upgraded oil shale could be in the reduction of the content of

carbonate minerals in the fuel. When firing oil shale at 8.5 MJ/kg (higher

content of carbonate minerals), carbonate minerals (relatively large limestone particles) during the combustion process in the furnace subside

through the fluidised bed due to their substantial density and can be removed

from the boiler along with the bottom ash, resulting in a higher share of the

bottom ash mass flow. On the other hand, the reduced bottom ash mass flow

when firing upgraded fuel can be explained by the granular composition of

the fuel. More precisely, as it can be seen in Table 1, the upgraded fuel used

in Test 2 was finer, with the median size of particles at R[0.5]B = 0.41 mm.

When firing low-grade oil shale, the fuel median size was R[0.5]B = 0.57 mm.

The finer granular composition of the upgraded fuel in Test 2 was caused by

the finer initial fuel entering the secondary fuel crusher. The finer granular

64

K. Plamus et al.

composition of the initial fuel was caused by the higher crushing rate of the

fuel due to better conditions in the primary fuel crusher (not shown in

Fig. 1). The primary crushers new hammers were installed during operation

one month before the firing tests with the upgraded fuel. Due to finer fuel

particles, limestone decomposes to a larger extent and the organic part burns

quicker, resulting in reduction of the bottom ash mass flow rate.

The firing of oil shale of higher quality also affected the boiler total ash

mass flow (Fig. 2). To summarise the ash mass flows from the separation

ports, the total ash mass flow discharged from the boiler was 16.3 kg/s for

Test 1 and 12.6 kg/s for Test 2, meaning a reduction of the total ash mass

flow by 23% when firing oil shale of higher quality. The reduction of the

total ash mass flow was achieved by the reduction of both fuel consumption

due to the increased LHV and ash content of oil shale (Table 1).

The sulphate- and carbonate-free ash balance

For estimating the accuracy of the measurements of boiler ash mass flows,

the sulphate- and carbonate-free ash balance was composed. The sulphateand carbonate-free ash balance is based on the ash components which form

oxides during the combustion process: SiO2, Fe2O3, Al2O3, CaO, MgO, K2O

and Na2O. These components are bound totally into the ash and they do not

proceed partly or totally into the combustion gases such as SO2, CO2 and Cl.

The boiler ash which contains only these elements is called sulphate- and

carbonate-free ash.

For composing the sulphate- and carbonate-free ash balance, the flow rate

of sulphate-free ash mass into the boiler with the fuel was calculated. The

calculation is based on the laboratory data on ash content of the fuel, fuel

consumption rate (calculated via boiler heat balance) and chemical

composition of the fuel ash. The sulphate- and carbonate-free ash mass flow

discharged from the boiler is calculated on the basis of the ash composition

and the measured ash mass flows. If the ash balance is correct, the sulphatefree ash mass flow fed into the boiler with the fuel should be equal to the

sulphate- and carbonate-free total ash mass flow discharged from the boiler.

The calculation showed that the sulphate- and carbonate-free total ash

mass flow discharged from the boiler was 8% greater than the sulphate-free

ash mass flow fed into boiler when firing oil shale with the LHV 8.5 MJ/kg

and 16% greater when firing oil shale with the LHV 11.1 MJ/kg (see also

Table 2).

Investigation of the behaviour of carbonate minerals and CO2 emissions

The results of the analyses of the ash samples and determined kCO2 values

are presented in Table 3. It can be seen in Table 3 that median sizes and

densities of the fly ash samples (E-K) are quite similar when firing oil shale

(8.5 MJ/kg or 11.1 MJ/kg). Determined kCO2 values for the fly ash samples

are also quite similar, being in the range of 0.700.88.

65

Firing Estonian Oil Shale in CFB Boilers Ash Balance and Behaviour of Carbonate Minerals

However, concerning the kCO2 value for the bottom ash samples, it can

be seen in Table 3 that when firing low-grade (8.5 MJ/kg) oil shale it is 0.47

and when firing upgraded (11.1 MJ/kg) oil shale it is 0.68. The reason for the

lower kCO2 value when firing low-grade fuel could be explained by the

coarser granular composition of the ash. As it can be seen in Table 3, the

bottom ash median size when firing the low-grade fuel is 1.13 mm and when

firing the upgraded fuel it is 0.43 mm. The coarser granular composition of

the bottom ash when firing low-grade fuel was caused by the coarser fuel

(coarser limestone particles in the fuel) fired.

While the CFB boiler is equipped with a separator of solids, the granular

composition of fly ash leaving separator does not depend on the fuel

granular composition. Coarser and heavier fuel and ash particles are captured

by the separator and directed to the circulating medium for burnout.

Taking into account the ash mass flow rates (kg/s) for each separation

port (Fig. 2), the kCO2 for the CFB boiler total ash is calculated (weighted

average). It can be seen from Table 3 that the total kCO2 for the CFB boiler

when burning upgraded oil shale (Test 2) is 0.78 and when firing low-grade

oil shale (Test 1) it is 0.69. As the boiler was operated at the same load and

furnace temperatures, the reason for the higher kCO2 value when firing

upgraded fuel can be explained by the fuel granular composition. As

mentioned above, the upgraded fuel used was finer. Indeed finer limestone

particles in the fuel during the combustion process can be heated up quickly

and thus decompose to a larger extent.

The specific CO2 emission results for the CFB boilers useful heat rate

are presented in Table 2. According to the test results, the total CO2 emission

when firing low-grade oil shale was 0.384 t/MWhth and when firing

upgraded oil shale it was 0.356 t/MWhth. When firing oil shale of higher

quality, a reduction of the CO2 emission by ~7% was achieved as compared

to firing of low-grade oil shale. As regards the CO2 emission from the

decomposition of carbonates when firing low-grade fuel, it was 14.1%, and

when firing upgraded fuel, it was 10.4% of the total CO2 emission.

Table 2. Results for CFB boiler CO2 emissions and sulphate- and carbonate-free

ash balance

Indicator

LHV

8.5 MJ/kg

LHV

11.1 MJ/kg

Total CO2 emission, t/MWhth

CO2 emission from burning of carbon, t/MWhth

CO2 emission from decomposition of carbonates, t/MWhth

Sulphate-free ash mass flow fed into the boiler with fuel, kg/s (1)

Sulphate- and carbonate-free total ash mass flow from the boiler,

kg/s (2)

Difference between (1) and (2), %

0.384

0.330

0.054

12.42

0.356

0.319

0.037

8.94

13.51

10.68

8.1

16.3

K. Plamus et al.

66

Table 3. Characteristics of the ash samples and results of ECD calculation

Separation

port

(Fig. 1)

LHV 8.5 MJ/kg

LHV 11.1 MJ/kg

Density R[0.5] CO2 CaO MgO kCO2 Density R[0.5] CO2 CaO MgO kCO2

%

%

%

g/cm3 m

%

%

%

g/cm3 m

Bottom (C) 1.483 1133 24.04 53.55

INTREX (D) 1.280 108.76 1.52 53.82

SH-RH (E) 0.787 20.77 6.94 36.39

ECO (F)

0.668

6.24 33.93

APH (G)

0.841

5.44 38.77

ESP 1 (H)

0.652 10.99 5.61 32.94

ESP 2 (I)

0.666 7.93 5.04 31.84

ESP 3 (J)

0.564

4.29 29.43

ESP 4 (K)

0.431

5.43 31.74

kCO2 for CFB boiler total ash

(weighted average),

3.00

4.45

4.45

3.60

5.11

3.73

3.36

3.49

3.98

0.47

0.97

0.79

0.80

0.85

0.82

0.83

0.84

0.81

0.69

1.647 430 14.46 50.57 5.60 0.68

1.300 118.12 1.42 47.25 6.56 0.97

0.758 19.49 5.26 30.52 5.14 0.82

0.710

4.67 29.48 4.76 0.83

0.841

3.95 34.41 5.36 0.88

0.598 10.83 4.33 25.52 4.23 0.82

0.565 7.99 4.01 24.88 4.51 0.83

0.515

3.40 22.74 4.81 0.85

0.447

7.36 25.73 4.34 0.70

0.78

Conclusions

The following general conclusions can be drawn from the investigation of

the CFB boiler ash balance and of the mineral matter behaviour when firing

oil shale of different quality:

1. When firing low-grade oil shale, the share of the bottom ash mass

flow in the total ash was 37% instead of 30% when firing upgraded

oil shale. The reduced bottom ash mass flow when firing upgraded oil

shale could be explained by the reduced content of the carbonate

minerals in the fuel and by the finer granular composition of such

fuel.

2. The kCO2 value for the CFB boilers total ash when firing upgraded

oil shale was 0.78, and 0.69 when firing low-grade oil shale. The

reason for the higher kCO2 value when firing upgraded fuel could be

explained by the finer granular composition of the fuel used in the

test.

3. In the context of the environmental impact of power production, we

should note the reduction of the CO2 emission by ~7% achieved

when firing upgraded oil shale. As CO2 emissions depend on the kCO2

value and the latter depends on the fuel granular composition,

theoretically, taking the boiler kCO2 value for the boiler total ash at

0.69 as it was when low-grade oil shale was fired, an additional

reduction of the total CO2 emission by more than 1% can be achieved

when firing upgraded fuel.

Firing Estonian Oil Shale in CFB Boilers Ash Balance and Behaviour of Carbonate Minerals

67

Acknowledgements

The authors express their gratitude to the Estonian Science Foundation

(Grant No. 6661) for the financial support, to the Narva Power Plants for the

technical assistance with performance of the firing tests and to Mr. Teet

Parve, Mr. Rein Rootamm, Mr. Illar Viilmann and Mr. Arvi Prikk for their

help during the firing tests.

REFERENCES

1. Hotta, A., Parkkonen, R., Hiltunen, M., Arro, H., Loosaar, J., Parve, T., Pihu, T.,

Prikk, A., Tiikma, T. Experience of Estonian oil shale combustion based on CFB

technology at Narva Power Plants // Oil Shale. 2005. Vol. 22, No. 4S. P. 381

397.

2. EVS-EN 12952-15:2003, Water-tube boilers and auxiliary installations Part

15: Acceptance tests.

3. Ots, A. Oil Shale Fuel Combustion. Tallinn, 2006, 833 p.

4. Arro, H., Prikk, A., Pihu, T. Calculation of CO2 emission from CFB boilers of oil

shale power plants // Oil Shale. 2006. Vol. 23, No. 4. P. 356365.

Received August 31, 2010

Вам также может понравиться

- PR-1078 - Hydrogen Sulphide Management ProcedureДокумент22 страницыPR-1078 - Hydrogen Sulphide Management Procedureromedic360% (1)

- Coal Gasification Using AspenДокумент6 страницCoal Gasification Using AspenTaniadi Suria100% (1)

- Methanol Synthesis (Safety)Документ16 страницMethanol Synthesis (Safety)furqankausarhaiderОценок пока нет

- The Principles of Sizer Technology PDFДокумент13 страницThe Principles of Sizer Technology PDFsalkan_rahmanovic810Оценок пока нет

- Rock-Eval Pyrolysis: Lab AssignmentДокумент10 страницRock-Eval Pyrolysis: Lab AssignmentHamza Masood100% (1)

- Heat ConductionДокумент11 страницHeat ConductionAlex Samuel SilvaОценок пока нет

- BPQ REV. 0 Interactive FormДокумент2 страницыBPQ REV. 0 Interactive FormcosmicbunnyОценок пока нет

- EAF Energy OptimizationДокумент7 страницEAF Energy OptimizationAron LopezОценок пока нет

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsОт EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerОценок пока нет

- Coal To Methanol Conversion GasificationДокумент10 страницCoal To Methanol Conversion GasificationUmesh Kumar Sharma RamamoorthiОценок пока нет

- Vortex Tube: Fundamental Approach: The PhysicsДокумент6 страницVortex Tube: Fundamental Approach: The Physicssalkan_rahmanovic810Оценок пока нет

- Alp Mineral Sizers ProjectsДокумент12 страницAlp Mineral Sizers Projectssalkan_rahmanovic810Оценок пока нет

- Autothermal Reforming ProcessДокумент9 страницAutothermal Reforming ProcessOliver Everett EspinoОценок пока нет

- Coal AnalysisДокумент7 страницCoal AnalysisManigandan ChinnasamyОценок пока нет

- Power Powders: The inДокумент6 страницPower Powders: The insalkan_rahmanovic810Оценок пока нет

- Design, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed CombustionДокумент9 страницDesign, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed Combustionapi-3799861Оценок пока нет

- Rock Eval 6Документ24 страницыRock Eval 6bellebelal100% (1)

- Manitou MT 1740 SLTДокумент2 страницыManitou MT 1740 SLTsalkan_rahmanovic810100% (3)

- Coal To Coke PDFДокумент9 страницCoal To Coke PDFVenkata Krishnan RamanujamОценок пока нет

- Waste CFB CombustionДокумент15 страницWaste CFB CombustionmihugirОценок пока нет

- CO2 Emmision Calculation in CFB BoilerДокумент10 страницCO2 Emmision Calculation in CFB BoilerNakkolopОценок пока нет

- Vol41 1Документ509 страницVol41 1Gaurav AcharyaОценок пока нет

- Synthesis GasДокумент8 страницSynthesis GasTotok IswantoОценок пока нет

- Appl of TGA For Fossil Fuels PDFДокумент509 страницAppl of TGA For Fossil Fuels PDFPondok HudaОценок пока нет

- Co-Gasification of Colombian CoalДокумент7 страницCo-Gasification of Colombian Coalwcamilo015Оценок пока нет

- Coal To Methanol p2Документ8 страницCoal To Methanol p2moeeezОценок пока нет

- Simulation of A Circulating Fluidized Bed Combustor With Shrinking Core and Emission ModelsДокумент10 страницSimulation of A Circulating Fluidized Bed Combustor With Shrinking Core and Emission ModelsAzharuddin_kfupmОценок пока нет

- Representation of Coal and Coal Derivatives in Process ModellingДокумент16 страницRepresentation of Coal and Coal Derivatives in Process ModellingPrateek PatelОценок пока нет

- 09 Combustion (Burners, Combustion Systems)Документ1 страница09 Combustion (Burners, Combustion Systems)ahmed1581973Оценок пока нет

- Oil-Shale Gasification For Obtaining of Gas For Synthesis of Aliphatic HydrocarbonsДокумент4 страницыOil-Shale Gasification For Obtaining of Gas For Synthesis of Aliphatic HydrocarbonsBobbyfrank UmehОценок пока нет

- Combustion Analysis of Coal-Water Slurry Fuel Prepared From Plant Coal and Recovered Coal FinesДокумент7 страницCombustion Analysis of Coal-Water Slurry Fuel Prepared From Plant Coal and Recovered Coal Finesarsalan322Оценок пока нет

- Chemical-Looping Combustion of Solid Fuels in A 10 KW Pilot - Batch Tests With Five FuelsДокумент8 страницChemical-Looping Combustion of Solid Fuels in A 10 KW Pilot - Batch Tests With Five FuelsAzharuddin Ehtesham FarooquiОценок пока нет

- Ecp 17138011Документ7 страницEcp 17138011SrashmiОценок пока нет

- Ref11 - SP10 - Danloy1 - Essen - New PDFДокумент3 страницыRef11 - SP10 - Danloy1 - Essen - New PDFCofe MilkОценок пока нет

- Temperature ControlsДокумент10 страницTemperature Controlsmashaikh898470Оценок пока нет

- Evaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresДокумент5 страницEvaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresjulianapohlmannufrgsОценок пока нет

- Evaluation of Response of Brown Coal To Selective Oild Agglomeration by Zeta Potential MeasurementДокумент6 страницEvaluation of Response of Brown Coal To Selective Oild Agglomeration by Zeta Potential MeasurementdelycocukОценок пока нет

- 1 s2.0 S0140670199982565 MainДокумент1 страница1 s2.0 S0140670199982565 MainAtiqah AuliaОценок пока нет

- India Kharagpur PCI - 2011Документ12 страницIndia Kharagpur PCI - 2011Carlos Frederico Campos de AssisОценок пока нет

- Cement Manufacturing Using Alternative Fuels and The Advantages of Process ModellingДокумент6 страницCement Manufacturing Using Alternative Fuels and The Advantages of Process ModellingStefan StrutzОценок пока нет

- (First Author) 2010 Fuel and Energy AbstractsДокумент71 страница(First Author) 2010 Fuel and Energy AbstractsalyaxandrОценок пока нет

- CMS JournalДокумент20 страницCMS JournalRaheem MomohОценок пока нет

- (143170606) 12 - PettinauДокумент2 страницы(143170606) 12 - PettinauKiki Maria NababanОценок пока нет

- 3syngas in Perspective - Rostrup-Nielsen, J. R. Catalysis Today, 2002, 71, (3-4), 243-247 (2003) (10.1016 - s0140-6701 (03) 90583-2) - Libgen - LiДокумент1 страница3syngas in Perspective - Rostrup-Nielsen, J. R. Catalysis Today, 2002, 71, (3-4), 243-247 (2003) (10.1016 - s0140-6701 (03) 90583-2) - Libgen - Liamerico molinaОценок пока нет

- Autothermal Reforming of Methane Design and PerforДокумент7 страницAutothermal Reforming of Methane Design and Perforromi moriОценок пока нет

- Thermogravimetric Analysis of The Combustion Characteristics of Oil Shale Semi-Coke/Biomass BlendsДокумент12 страницThermogravimetric Analysis of The Combustion Characteristics of Oil Shale Semi-Coke/Biomass BlendsRajendraОценок пока нет

- Coking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneДокумент7 страницCoking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneAndres PeñaОценок пока нет

- v30 365 374 PDFДокумент10 страницv30 365 374 PDFMárcia CardosoОценок пока нет

- Hong AnalysisДокумент38 страницHong AnalysisleovenuОценок пока нет

- Lowtemp Didari2009Документ8 страницLowtemp Didari2009Zia Ru'ya HilalОценок пока нет

- Combustion and Emission Characteristics of Rice Husk in A Rectangular Fluidized Bed CombustorДокумент4 страницыCombustion and Emission Characteristics of Rice Husk in A Rectangular Fluidized Bed CombustorfelramОценок пока нет

- Combustibles LiquidosДокумент7 страницCombustibles LiquidosVictor Hugo CarreÓnОценок пока нет

- Catalyst PreparationДокумент7 страницCatalyst PreparationAulia RahmanОценок пока нет

- 49 1 Anaheim 03-04 0837Документ2 страницы49 1 Anaheim 03-04 0837castelo_grandeОценок пока нет

- Heat and Mass Balances in The ULCOS Blast FurnaceДокумент3 страницыHeat and Mass Balances in The ULCOS Blast FurnaceakshukОценок пока нет

- Pilar Gayán, Iñaki Adánez-Rubio, Alberto Abad, Luis F. de Diego, Francisco García-Labiano, Juan AdánezДокумент13 страницPilar Gayán, Iñaki Adánez-Rubio, Alberto Abad, Luis F. de Diego, Francisco García-Labiano, Juan AdánezRobert MyersОценок пока нет

- Energy in Warm Mix AsphaltДокумент11 страницEnergy in Warm Mix AsphaltSuraj GuptaОценок пока нет

- Fluidized Bed Gasification As A Means of Converting Waste To EnergyДокумент28 страницFluidized Bed Gasification As A Means of Converting Waste To Energyoscop2009Оценок пока нет

- AC Catalst PTДокумент5 страницAC Catalst PTJarretОценок пока нет

- Modeling and Analysis of Offshore Energy Systems On North Sea Oil and Gas PlatformsДокумент16 страницModeling and Analysis of Offshore Energy Systems On North Sea Oil and Gas PlatformsMossad Khôi NguyênОценок пока нет

- S C A CДокумент3 страницыS C A CAjaya Kumar SahooОценок пока нет

- TMAXДокумент5 страницTMAXLaura PutrivoОценок пока нет

- A Comparative Analysis of Methanol Production Routes: Synthesis Gas Versus CO2 HydrogenationДокумент10 страницA Comparative Analysis of Methanol Production Routes: Synthesis Gas Versus CO2 HydrogenationMohanad El-HarbawiОценок пока нет

- Influence Biomass MontianoДокумент30 страницInfluence Biomass MontianoPRATYUSH PRAKASHОценок пока нет

- Production of Synthesis Gas: Caalysis Today, 18 (1993) 305-324Документ20 страницProduction of Synthesis Gas: Caalysis Today, 18 (1993) 305-324ainmnrhОценок пока нет

- Oil 2014 3 238 249Документ12 страницOil 2014 3 238 249Fatin FatehaОценок пока нет

- A Mathematic Model With Total Differential Equations of Combustion in ThermobalanceДокумент5 страницA Mathematic Model With Total Differential Equations of Combustion in ThermobalanceAnonymous PkeI8e84RsОценок пока нет

- 2461 2 EnglishДокумент2 страницы2461 2 Englishsalkan_rahmanovic810Оценок пока нет

- EjektorДокумент1 страницаEjektorsalkan_rahmanovic810Оценок пока нет

- Generalized Maxwell ModelДокумент10 страницGeneralized Maxwell Modelsalkan_rahmanovic810Оценок пока нет

- Decision-Support System For Bearing Failure Mode Analysis: Read More atДокумент4 страницыDecision-Support System For Bearing Failure Mode Analysis: Read More atsalkan_rahmanovic810Оценок пока нет

- The Advantages of Dynamic Stiffness Parameters Over Classical Bearing CoefficientsДокумент6 страницThe Advantages of Dynamic Stiffness Parameters Over Classical Bearing Coefficientssalkan_rahmanovic810Оценок пока нет

- DThe FFT Analyzer 55Документ16 страницDThe FFT Analyzer 55salkan_rahmanovic810Оценок пока нет

- How To Create A Table of Contents in Microsoft Word - ShaunaKellyДокумент5 страницHow To Create A Table of Contents in Microsoft Word - ShaunaKellysalkan_rahmanovic810Оценок пока нет

- 1110 6022 PDFДокумент11 страниц1110 6022 PDFsalkan_rahmanovic810Оценок пока нет

- Defrosting Technologies of Frozen Raw Materials in Defrosting TunnelsДокумент3 страницыDefrosting Technologies of Frozen Raw Materials in Defrosting Tunnelssalkan_rahmanovic810Оценок пока нет

- Periodic Force: Number of Blades of The AssemblyДокумент1 страницаPeriodic Force: Number of Blades of The Assemblysalkan_rahmanovic810Оценок пока нет

- Asphalt - Cement & Soil ReclamationДокумент53 страницыAsphalt - Cement & Soil Reclamationsalkan_rahmanovic810Оценок пока нет

- ResumeДокумент3 страницыResumeabreddy2003Оценок пока нет

- Pds Luxathane 5000 VocДокумент2 страницыPds Luxathane 5000 Vocmuthukumar100% (1)

- Trodat Standard Self Inking Stamp and Accessory Mini CatalogДокумент12 страницTrodat Standard Self Inking Stamp and Accessory Mini CatalogpromotesourceОценок пока нет

- KAIFENG Quotation For 150T Cooling TowerДокумент13 страницKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyОценок пока нет

- Implementing The IBM Storwize V7000 V6.3: Front CoverДокумент630 страницImplementing The IBM Storwize V7000 V6.3: Front CoverMimiLakicОценок пока нет

- Solucionario Libro Infotech 4th EditionДокумент32 страницыSolucionario Libro Infotech 4th EditionGisella Espinoza BarberenaОценок пока нет

- Richard Feynman BiographyДокумент5 страницRichard Feynman Biographyapi-284725456100% (1)

- 3.14. TR-069 WAN Management...Документ6 страниц3.14. TR-069 WAN Management...duculeteОценок пока нет

- Drive List BoxДокумент3 страницыDrive List BoxLuis Carlos VillegasОценок пока нет

- Chapter 1 Introduction To PSoCДокумент32 страницыChapter 1 Introduction To PSoCtptuyen2246Оценок пока нет

- Hitman Contracts PC ManualДокумент14 страницHitman Contracts PC ManualChernoll MendoncaОценок пока нет

- MARTA: 2012 KPMG Phase II Final DraftДокумент114 страницMARTA: 2012 KPMG Phase II Final DraftthomaswheatleyОценок пока нет

- Global Cardiac Catheters - 2012-2018Документ4 страницыGlobal Cardiac Catheters - 2012-2018Axis Research MindОценок пока нет

- Final Project Miguel Santana GallegoДокумент44 страницыFinal Project Miguel Santana GallegoDaniel PereiraОценок пока нет

- Glenair Connector Terms - SummaryДокумент4 страницыGlenair Connector Terms - SummarybenОценок пока нет

- Dutypoint BrochureДокумент24 страницыDutypoint Brochuremh wОценок пока нет

- Answers of Chapter (8) : Course: Operating SystemДокумент7 страницAnswers of Chapter (8) : Course: Operating SystemasdОценок пока нет

- Paranormal Activity 3Документ5 страницParanormal Activity 3alexОценок пока нет

- The Scientist PDFДокумент68 страницThe Scientist PDFPetcu Adrian100% (1)

- TDS 9-11SA Mechanical TroubleshootingДокумент34 страницыTDS 9-11SA Mechanical Troubleshootingahmed.kareem.khanjerОценок пока нет

- Ems2348x User Manual Id IdДокумент104 страницыEms2348x User Manual Id IdGod GamerОценок пока нет

- MSS - Manual Bernoulli FilterДокумент3 страницыMSS - Manual Bernoulli FilterFLTR PURPLE E.Оценок пока нет

- Lab - 17-WAN ConfigurationДокумент12 страницLab - 17-WAN ConfigurationMuhammad Asghar Khan100% (1)

- 100124119Документ175 страниц100124119mkeiwuaОценок пока нет

- DPP Series 1 PDFДокумент1 страницаDPP Series 1 PDFsukainaОценок пока нет

- Kevin D Thomas - Activated Carbon and Lemon Peels As Adsorbent For Removing Oil From Waste WaterДокумент37 страницKevin D Thomas - Activated Carbon and Lemon Peels As Adsorbent For Removing Oil From Waste WaterRejinОценок пока нет

- BX Tuner ManualДокумент4 страницыBX Tuner ManualdanielthemanОценок пока нет