Академический Документы

Профессиональный Документы

Культура Документы

EcoWarn 12VDC o M Ecotechnic English New

Загружено:

modОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

EcoWarn 12VDC o M Ecotechnic English New

Загружено:

modАвторское право:

Доступные форматы

Wavin-Labko Oy

Labkotie 1

FI-36240 KANGASALA

FINLAND

Tel:

+ 358 20 1285 200

Fax:

+ 358 20 1285 530

Email: level@wavin-labko.fi

Internet: www.wavin-labko.fi

28.09.2004

D15285_e

1/12

Labko SET-2000 Hi Level/Oil (12 VDC)

Alarm Device for Oil Separators

Installation and Operating Instructions

Copyright 2004 Wavin-Labko Oy

We reserve the right for changes without notice

Labko SET-2000 Hi Level/Oil (12 VDC)

Installation and Operating Instructions

D15285_e

TABLE OF CONTENTS

1 GENERAL............................................................................................................ 3

2 INSTALLATION ................................................................................................... 4

2.1 SET-2000 Hi Level/Oil (12 VDC) Control Unit ............................................. 4

2.2 Probe installation.......................................................................................... 5

2.3 Cabling ......................................................................................................... 5

2.4 Cable extension using junction box ............................................................. 5

3 OPERATION AND SETTINGS............................................................................ 6

3.1 Operation ..................................................................................................... 7

3.2 Factory settings............................................................................................ 8

4 TROUBLE-SHOOTING ..................................................................................... 10

5 REPAIR AND SERVICE .................................................................................... 11

6 SAFETY INSTRUCTIONS................................................................................. 11

7 TECHNICAL SAFETY DATA............................................................................. 12

SYMBOLS

Warning / Attention

Pay attention to installations at potentially explosive atmospheres

Copyright 2004 Wavin-Labko Oy

2/12

We reserve the right for changes without notice

Labko SET-2000 Hi Level/Oil (12 VDC)

Installation and Operating Instructions

D15285_e

GENERAL

SET-2000 Hi Level/Oil (12 VDC) is a DC-powered alarm device for

monitoring the thickness of the oil layer accumulating in the oil

separator and blocking of the separator. Depending on the order, the

delivery consists of SET-2000 Hi Level/Oil (12 VDC) control unit, SET

DM/3 probe, SET/OS2-O probe, junction box and installation supplies.

System components:

(depending on the order)

3

2

SET DM/3 probe

SET/OS2-O probe

Junction box LJB3

SET-2000 Hi Level/Oil

(12 VDC) control unit

Installation supplies

OIL

Figure 1. Oil separator alarm system with OilSET-2000 Hi

Level/Oil (12 VDC).

The SET DM/3 probe is installed into the light liquid storage chamber

and gives an alarm when the chamber is filled to a pre-determined

degree. The function is based on the measurement of the electrical

conductivity of the surrounding liquid water conducts electricity

much better than oil. The probe is normally immersed in water.

SET/OS2 probe is installed above separators outlets upper level. It

monitors the total level of the separator, regardless of existence of the

oil layer. The principle of the measurement is capacitive. The probe is

normally in the air.

Oil separator is regarded as a potentially explosive (Ex) atmosphere.

The probes can be installed in zone 0, 1 or 2 potentially explosive

atmosphere but the control unit must be mounted in a safe area.

The LED indicators, push buttons and interfaces of the device are

described in figure 2.

SET-2000 Hi Level/Oil (12 VDC)

user interface features:

LED indicator for mains

LED indicators of alarm and

fault for both probes

Reset button for alarm and fault

Test button

Connectors for two Labko SET

level probes [EEx ia]

Potential-free relay outputs for

monitoring and control purposes

Figure 2. SET-2000 Hi Level/Oil (12 VDC) features.

Copyright 2004 Wavin-Labko Oy

3/12

We reserve the right for changes without notice

Labko SET-2000 Hi Level/Oil (12 VDC)

Installation and Operating Instructions

2

2.1

D15285_e

INSTALLATION

SET-2000 Hi Level/Oil (12 VDC) Control Unit

The SET-2000 Hi Level/Oil (12 VDC) control unit can be wallmounted. The mounting holes are located in the base plate of the

enclosure, beneath the mounting holes of the front cover.

The connectors of the external conductors are isolated by separating

plates. The plates must not be removed. The plate covering the

connectors must be installed back after executing cable connections.

The cover of the enclosure must be tightened so, that the edges touch

the base frame. Only then do the push buttons function properly and

the enclosure is tight.

Before installation, please read the safety instructions in chapter 6!

Mounting dimension 160 mm

SET-2000

Hi Level

Alarm

Device/ Oil

Mounting dimension 110 mm

Mains

Alarm

Fault

Alarm

Fault

Reset

Test

HI LEVEL

OIL

OIL

OIL

RELAY 2

SHIELD

SHD

RELAY 1

11- 17 VDC

VAROITUS!

Luonnostaan vaaraton virtapiiri.

Kiinnit suojalevy kun kaapelit

ovat kytketyt.

Ei saa avata jnnitteisen !

SHIELD

SHD

FUSE

315 mAT

WARNING!

Intrinsically safe circuits.

Close protection plate when

the cables are connected.

Do not open when energized !

PROBE 1

Supply voltage 11 - 17 VDC

- = negative supply voltage pole

+ = positive supply voltage pole

Fuse 315 mAT

RELAY 1 (Channel 1)

3 = common pole

4 = opening pole when alarm

5 = closing pole when alarm

RELAY 2 (Channel 2)

6 = common pole

7 = opening pole when alarm

8 = closing pole when alarm

Relays are in alarm positions,

when the mains voltage is off.

PROBE 2

5

Mounting holes diameter 4.5 mm

Enclosure depth 75 mm

315

mAT

4 5

RELAY 1

7 8

CHANNEL 1

+ -

9 10 11

CHANNEL 2

SHD

SHD

+ -

12 13 14

RELAY 2

3 1 2

3 1 2

CHANNEL 1

9 = auxiliary connection (SHD)

10 = + supply pole to probe

11 = - supply pole to probe

CHANNEL 2

12 = auxiliary connection (SHD)

13 = + supply pole to probe

14 = - supply pole to probe

Cover plate

Terminal for equipotential grounding

Separating plates of the connectors, 3 pcs.

Shield of

probe cable

To equipotential

ground

SAFE AREA

HAZARDOUS AREA

SET/OS2-O

PROBE

Check the correct

installation depth

from the instructions

of the separator.

The lowest tip of the probe has

to be always installed above the

lowest level of the separator's

outlet pipe.

SET DM/3

OIL

PROBE

The probe alarms latest when

it is totally immersed in a nonconductive liquid; in other

words: it is totally away from

the water.

Figure 3. Installation of SET-2000 Hi Level/Oil (12 VDC) alarm device.

Copyright 2004 Wavin-Labko Oy

4/12

We reserve the right for changes without notice

Labko SET-2000 Hi Level/Oil (12 VDC)

Installation and Operating Instructions

2.2

D15285_e

Probe installation

The probe installation should be done as described in figure 3.

SET DM/3 probe gives an alarm earliest when the upper electrode is

in oil and latest when the probe is totally immersed in a nonconductive liquid in other words, it is totally away from the water.

SET/OS2-O probe gives an alarm when - of the probe is

immersed into oil or when 5 10 mm of the probe is in water. The

trigger level can be adjusted with the SENSITIVITY setting in the

control unit (See chapter 3.2).

Both probes can be mounted suspended from the ceiling of the

separator by their cable.

Please check the correct installation depth also from the instructions

of the oil separator.

2.3

Cabling

When probe cable extension is not necessary, connect the wires and

shield as described in figure 3.

Resistance of the wire used for equipotential grounding must be less

than 1 and cross section at least 4 mm or 2 x 1.5 mm.

2.4

Cable extension using junction box

If the probe cable must be extended, it can be done with the cable

junction box. The cabling between the SET-2000 control unit and the

junction box should be done with a shielded twisted pair instrument

cable.

The cabling in figure 4 can be done with a two-pair shielded twisted

pair cable, whereupon both pairs are equipped with their own shields.

Make sure that the signal wires of the cables can never be

connected to each other.

Labko LJB3 junction box enables cable extension in potentially

explosive atmospheres.

In figure 4 the shields and excess wires have been connected to the

same point in galvanic contact with metallic frame of the junction box.

This point can be connected to equipotential ground thru the ground

terminal. Other components of the system that need to be grounded

can also be connected to the same ground terminal. The wire used for

equipotential grounding must be min. 2.5 mm mechanically protected

or, when not mechanically protected, the minimum cross section is 4

mm.

SET-2000 Hi Level/Oil (12 VDC) control unit is connected to

equipotential ground thru its own terminal and resistance of the wire

must be less than 1 and cross section at least 4 mm or 2 x 1.5

mm.

Please make sure, that the probe and the cable between SET-2000

control unit and the probe do not exceed the maximum allowed

electrical parameters see chapter 7 Technical and safety data.

Detailed cabling instructions can also be found in the installation

instructions of SET DM/3 and SET/OS2 probes.

Copyright 2004 Wavin-Labko Oy

5/12

We reserve the right for changes without notice

Labko SET-2000 Hi Level/Oil (12 VDC)

Installation and Operating Instructions

D15285_e

Junction box of type LJB3 includes light alloy parts. When installing in

explosive atmosphere, make sure, that the junction box is located so,

that it can not be mechanically damaged or it will not be exposed to

external impacts, friction etc. causing ignition of sparks.

Make sure, that the junction box is closed properly.

Channel 2

SHD

10 11

SET-2000

Hi Level /Oil (12 VDC)

SHD

Channel 1

12 13 14

To equipotential

ground

LJB3-78-83

Common shield

Pair shield

To equipotential

ground

Shield of

probe

cable

All shields and excess wires

to be connected to the same

point.

SET DM/3 probe:

Wires 1 and 3

are connected

together.

SET/OS2-O

PROBE

SET DM/3

PROBE

Figure 4. Cabling with a junction box for cable extension.

OPERATION AND SETTINGS

SET-2000 Hi Level/Oil (12 VDC) is initialized at the factory. The

operation of the device should always be checked after the

installation. The operation should also be checked always when

emptying the separator or at least once every six months.

Functionality test

Hi level alarm (SET/OS2-O probe)

1. Lift the probe up in the air. The device should be in normal mode (see

chapter 3.1).

2. Immerse the probe into water or oil. Hi level alarm should occur (see

chapter 3.1).

3. Lift the probe up in the air again. The alarm should go off after 5 sec

delay.

Functionality test

Oil alarm (SET DM/3 probe)

1. Immerse the probe into water. The device should be in normal mode

(see chapter 3.1).

2. Lift the probe up in the air or oil. Oil alarm should occur. (see chapter

3.1).

3. Immerse the probe back into water. Alarm should go off after 5 sec

delay.

Copyright 2004 Wavin-Labko Oy

6/12

We reserve the right for changes without notice

Labko SET-2000 Hi Level/Oil (12 VDC)

Installation and Operating Instructions

D15285_e

Clean up the probes before placing them back into the separator.

A more detailed description of the operation is provided in chapter 3.1.

If the operation is not as described here, check the factory settings

(chapter 3.2) or contact a representative of the manufacturer.

3.1

Operation

The operation of a factory-initialized SET-2000 Hi Level/Oil (12 VDC)

is described in this chapter.

Normal mode no alarms

SET DM/3 probe is totally in water and SET/OS2-O probe is in the air.

Mains LED indicator is on.

Other LED indicators are off.

Relays 1 and 2 are energized.

High level alarm

The level has hit the SET/OS2 high level probe. Alarm takes place when

- of the probe is immersed in oil or 5-10 mm of the probe is in water.

Mains LED indicator is on.

Hi level alarm LED indicator is on.

Buzzer on after 5 sec delay.

Relay 1 de-energizes after 5 sec delay.

Relay 2 remains energized.

Oil alarm

SET DM/3 probe is in oil. The probe gives an alarm earliest when the

upper electrode is in oil and latest when the probe is totally immersed in a

non-conductive liquid, in other words, totally away from water.

(Note! The same alarm takes place when SET DM/3 probe is in the air)

Mains LED indicator is on.

Oil Alarm LED indicator is on.

Buzzer on after 5 sec delay.

Relay 1 remains energized.

Relay 2 de-energizes after 5 sec delay.

After removal of an alarm, the respective alarm LED indicators and

buzzer will be off and respective relay will be energized after 5 sec delay.

Fault alarm

Reset of an alarm

Copyright 2004 Wavin-Labko Oy

A broken probe, probe cable break or short circuit, i.e. too low or too high

probe signal current.

Mains LED indicator is on.

Probe circuit Fault LED indicator is on after 5 sec delay.

The relay of the respective channel de-energizes after 5 sec delay.

Buzzer is on after 5 sec delay.

When pressing the Reset push button.

Buzzer will go off.

Relays will not change their status before the actual alarm or fault is off.

7/12

We reserve the right for changes without notice

Labko SET-2000 Hi Level/Oil (12 VDC)

Installation and Operating Instructions

D15285_e

TEST FUNCTION

Test function provides an artificial alarm, which can be used to test the

function of the SET-2000 Hi Level/Oil (12 VDC) and the function of

other equipment, which is connected to SET-2000 via its relays.

Attention ! Before pressing Test button, make sure that the change of

relay status does not cause hazards elsewhere !

Normal situation

When pressing the Test push button:

Alarm and Fault LED indicators are immediately on.

Buzzer is immediately on.

Relays de-energize after 2 sec of continuous pressing.

When the Test push button is released:

LED indicators and buzzer go immediately off.

Relays energize immediately.

High level or Oil alarm on

When pressing the Test push button:

Fault LED indicators are immediately on.

The Alarm LED indicator of the alarming channel remains on and the

respective relay remains de-energised.

Alarm LED indicator of the other channel is on and the relay de-energizes.

Buzzer remains on. If it has been reset earlier, it will return to be on.

When the Test push button is released:

The device returns without delay to the preceding status.

Fault alarm on

3.2

When pressing Test push button:

The device does not react with regards to the faulty channel.

The device reacts as described above with regards to the functional

channel.

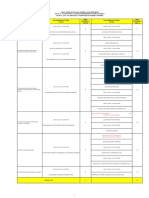

Factory settings

If the operation of SET-2000 Hi Level/Oil (12 VDC) is not as described

in the previous chapter, check that the device settings are as in figure

4. Change the settings according to the following instructions if

needed

The following tasks must only be executed by a person with proper

education and knowledge of Exi devices.

Type plate

R41

VTT 04 ATEX 031X

II (1) G [EEx ia] IIC

Um=23 V Uo= 14,7 V Io= 55 mA

Po=297 mW

R= 404

O

11 - 17 VDC

The settings of channel 2 are

made with switches S3 and S4

and potentiometer in the right.

Probe selection:

S3 S4

DELAY

S1 S2

MODE

DELAY

R38

MODE

DELAY

SENSITIVITY

The settings of channel 1 are

made with switches S1 and S2

and potentiometer in the left.

MODE

SENSITIVITY

MODE

DELAY

We recommend, that when altering the settings the mains voltage is

off or the device is initialized before the installation is executed.

SET DM/3 -probe, channel 2

other SET -probe, channel 1

315

mAT

0537

Serial number

Figure 4. Factory settings of SET-2000 Hi Level / Oil.

Copyright 2004 Wavin-Labko Oy

8/12

We reserve the right for changes without notice

Labko SET-2000 Hi Level/Oil (12 VDC)

Installation and Operating Instructions

D15285_e

The settings are made with switches (MODE and DELAY) and

potentiometers (SENSITIVITY) located in the upper printed circuit

board (figure 4) and with the jumpers located in the lower board.

Switches in figure 4 are as set in the factory.

TRIGGER LEVEL SETTING (SENSITIVITY)

(Only for SET/OS2 probe. The trigger level of SET DM/3 probe cannot

be changed with this setting, but a false setting may cause problems.

See chapter 4 Trouble-shooting.)

When rotating teh trimmer

clockwise the trigger level

moves upwards.

When rotating

the trimmer

anti-clockwise the

trigger level moves

downwards.

SENSITIVITY

Trigger level setting is executed as follows:

1. Immerse the probes sensing element to the medium

to the desired height see probe instructions, if

needed.

2. Rotate the potentiometer so, that the Alarm LED is

on and the relay de-energizes please pay attention

to the operational delay.

3. Check the function by lifting the probe to the air and

immersing it back to the medium.

OPERATIONAL DELAY SETTING (DELAY)

Switches S2 and S4 are used to set the operational delay of the device.

When the switch is in low position relays de-energize and buzzer is on after

5 seconds after the level reaches trigger level, and if the level still remains

on the same side of the trigger level.

When the switch is in high position, the delay is 30 seconds.

Delays are operational in both directions (energizing, de-energizing). Alarm

LEDs follow the probe current value and trigger level without delay. Fault

alarm takes place after a fixed delay of 5 sec.

Copyright 2004 Wavin-Labko Oy

9/12

We reserve the right for changes without notice

Labko SET-2000 Hi Level/Oil (12 VDC)

Installation and Operating Instructions

D15285_e

TROUBLE-SHOOTING

Problem:

Possible reason:

To do:

MAINS LED indicator is off

Supply voltage is too low or the fuse is blown or MAINS ON LED indicator is faulty.

1. Check the fuse.

2. Measure the voltage between poles - and +. It should be 11 17 VDC.

Problem:

Possible reason:

To do:

No alarm when SET DM/3 probe in oil or air, or the alarm will not go off

The SENSITIVITY setting is wrong in the control unit (see figure 4), or probe dirty.

1. Clean-up the probe and lift it up in the air or immerse it into oil.

2. Turn the SENSITIVITY potentiometer slowly anticlockwise until the probe gives

an alarm.

3. Immerse the probe into water and wait until the alarm goes off. If the alarm does

not go off, turn the potentiometer slowly clockwise until the alarm goes off.

4. Lift the probe up in the air or oil. The probe should give an alarm again.

Problem:

Possible reason:

To do:

FAULT LED indicator is on

Current in probe circuit too low (cable break) or too high (cable in short circuit).

The probe might also be broken.

1. Make sure, that the probe cable has been connected correctly to the SET-2000

control unit. See probe specific instructions.

2. Measure the voltage separately between the poles 10 and 11 as well as 13 and

14. The voltages should be between 10,3.11,8 V.

3. If the voltages are correct, measure the probe current one channel at a time.

Do as follows:

3.1 Disconnect probes [+] wire from probe connector (poles 11 and 13).

3.2 Measure short circuit current between [+] and [-] poles.

3.3 Connect mA-meter as in figure 5.

Make a comparison to the values in Table 1.

3.4. Connect the wire/wires back to respective connector(s).

If the problems can not be solved with the above instructions, please contact

Wavin-Labko Oys local distributor or Wavin-Labko Oys service.

Attention ! If the probe is located in an explosive atmosphere, the multimeter must

be Exi-approved !

Figure5. Probe current measurement.

Copyright 2004 Wavin-Labko Oy

SET/OS2-O, Channel 1

SET DM/3, Channel 2

Poles 10 [+] and 11 [-]

Poles 13 [+] and 14 [-]

Shortcircuit

20 mA 24 mA

20 mA 24 mA

Probe in the air

5 7 mA

9 10 mA

Probe in the oil

9 12 mA

9 10 mA

Probe in the water

12 16 mA

2 3 mA

Factory setting for

alarm point

approx. 8.5 ma

approx. 6.5 mA

Table 1. Probe currents.

10/12

We reserve the right for changes without notice

Labko SET-2000 Hi Level/Oil (12 VDC)

Installation and Operating Instructions

D15285_e

REPAIR AND SERVICE

The probes should be cleaned and the operation of the alarm device

should be tested when emptying the oil storage chamber or at least

once every six months. The easiest way to check the operation is to

lift the probes up in the air and put them back to the separator. The

operation is described in chapter 3.

For cleaning, a mild detergent (e.g. washing-up liquid) and a

scrubbing brush can be used.

The mains fuse (marked 315 mAT) can be changed to another glass

tube fuse 5 x 20 mm / 315 mAT complying EN 60127-2/3 . Any other

repair and service works on the device may be carried out only by a

person who has received training in Exi devices and is authorized by

the manufacturer.

In case of queries, please contact Wavin-Labko Oys service:

service@wavin-labko.fi.

SAFETY INSTRUCTIONS

SET-2000 Hi Level/Oil (12 VDC) must not be installed in potentially

explosive atmosphere. Probes connected to it may be installed in zone

0, 1 or 2 potentially explosive atmosphere. The maximum input voltage

(Um) which can be applied to supply voltage connection without

invalidating the intrinsic safety of the apparatus is 23 V.

In case of installations in explosive atmospheres the national

requirements and relevant standards as EN 50039 and/or EN 6007914 must be taken into account.

If electrostatic discharges can cause hazards in the operating

environment, the device must be connected into equipotential ground

according to requirements with regards to explosive atmospheres.

Equipotential grounding is made by connecting all conductive parts

into same potential e.g. at the cable junction box. Equipotential ground

must be earthed.

When executing service, inspection and repair in explosive

atmosphere, the rules in standards EN 60079-17 and EN 60079-19

about instructions of Ex-devices must be obeyed.

Copyright 2004 Wavin-Labko Oy

11/12

We reserve the right for changes without notice

Labko SET-2000 Hi Level/Oil (12 VDC)

Installation and Operating Instructions

D15285_e

7 TECHNICAL AND SAFETY DATA

SET DM/3 probe (Oil alarm)

Labko SET-2000 Hi Level/Oil (12 VDC)

Dimensions

175 mm x 125 mm x 75 mm (L x H x D)

Enclosure

IP 65, material polycarbonate

Ambient temperature

-25 C+50 C

Supply voltage

11 17 VDC

Fuse 5 x 20 mm 315 mAT (EN 601272/3)

The device is not equipped with a power

switch

Principle of operation

Measurement of conductivity

Enclosure

IP68, materials: AISI 316 and PVC

Ambient temperature

-20 C+70 C

Supply voltage

Approx. 12 VDC from SET control unit

Cable

Fixed oil resistant PVC cable 3 x 0,5

mm2, standard length 5 m.

EMC

Emission

Immunity

Power consumption

Max 2,3 VA

Typical (no alarms) 1,5 VA

Ex-classification

Probes

Labko SET/OS2 and SET DM/3

Electrical parameters

Max. impedance of the

current loop between the

control unit and a probe

75 .

Relay outputs

Two potential-free relay outputs

250 V, 5 A, 100 VA

Operational delay 5 sec or 30 sec.

Relays de-energize at trigger point.

Operation mode selectable for increasing

or decreasing level.

EN 50081-1

EN 50082-1

II 1 G EEx ia IIA T4

VTT 02 ATEX 012X

Ui = 16,5 V

Pi = 330 mW

Li = 10 H

Ii = 80 mA

Ci = 700 pF

Special conditions concerning Ex-classification (X):

- Ambient temperature -20 C+70 C

- Shielded probe cable shall be connected to equipotential ground

- If probe cable have to be extended, please use Labko LJB2-78-83

junction box. The junction box shall also be connected to

equipotential ground.

EMC

Emission

Immunity

EN 61000-6-3

EN 61000-6-2

Ex-classification

II (1) G [EEx ia] IIC

VTT 04 ATEX 031X

(Ta = -25 C+50 C)

Special conditions (X)

Electrical parameters

SET/OS2 probe (Hi level alarm)

Um = 23 V

Uo = 14,7 V

Io = 55 mA

Po = 297 mW

R = 404

Characteristic curve of the

output voltage is trapezoidal

See table 2.

Max. permissible value

Co

Lo

II B

Capacitive

Enclosure

IP68, materials: AISI 316 and PVC

Ambient temperature

-20 C+60 C

Supply voltage

Approx. 12 VDC from SET control unit

Cable

Fixed oil resistant PVC cable 3 x 0,5

mm2, standard length 5 m.

EMC

Emission

Immunity

Due to non-linear characteristics of the probe voltage, the interaction of

both, capacitance and inductance, must be taken into account. The

table below indicates the connecting values in explosion groups IIC and

IIB. In explosion group IIA the values of the group IIB can be applied.

II C

Principle of operation

608nF

3,84F

10 mH

30 mH

EN 50081-1

EN 61000-6-2

Ex-classification

Electrical parameters

Combined Co and Lo

Co

Lo

568nF

0,15 mH

458 nF

0,5 mH

388 nF

1,0 mH

328 nF

2,0 mH

258 nF

5,0 mH

3,5 F

0,15 mH

3,1 F

0,5 mH

2,4 F

1,0 mH

1,9 F

2,0 mH

1,6 F

5,0 mH

II 1 G EEx ia IIA T5

VTT 03 ATEX 009X

Ui = 18 V

Pi = 297 mW

Li = 30 H

Ii = 66 mA

Ci = 3 nF

Special conditions concerning Ex-classification (X):

- Ambient temperature -25 C+60 C

- Shielded probe cable shall be connected to equipotential ground.

- If probe cable have to be extended, please use Labko LJB2-78-83

junction box. The junction box shall also be connected to

equipotential ground.

Lo/Ro = 116,5 H/ (IIC) and 466 H/ (IIB)

Table 2. SET-2000 Hi Level/Oil electrical parameters

214 mm

81 mm

82 mm

25 mm

Figure 6. Dimensional drawings of SET/OS2 (left) and SETDM3 (right).

Copyright 2004 Wavin-Labko Oy

12/12

We reserve the right for changes without notice

Вам также может понравиться

- New Government Advisory On Ammonium Nitrate HandlingДокумент19 страницNew Government Advisory On Ammonium Nitrate HandlingJason TrahanОценок пока нет

- API 580 Questions Practice Exam 2Документ10 страницAPI 580 Questions Practice Exam 2Mohammed Abdul Sayeed100% (4)

- ACA Corrosion Technology GuideДокумент174 страницыACA Corrosion Technology Guidetridatyl100% (1)

- Long document contents listДокумент40 страницLong document contents listkaldjdsjkaОценок пока нет

- As 3735-2001 Concrete Structures Retaining LiquidsДокумент27 страницAs 3735-2001 Concrete Structures Retaining Liquidsmod67% (3)

- Flow Metering InformationДокумент6 страницFlow Metering InformationmodОценок пока нет

- Kpipe UsersmanualДокумент540 страницKpipe UsersmanualmodОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- ComAp Marine Brochure 2011-11 CPCEMARIДокумент52 страницыComAp Marine Brochure 2011-11 CPCEMARIsdiaman100% (1)

- Principles of Electronic Communication Systems: Second Edition Louis FrenzelДокумент41 страницаPrinciples of Electronic Communication Systems: Second Edition Louis FrenzelSwaminathan RajaramОценок пока нет

- Nature of Electrical Supply CharacteristicsДокумент27 страницNature of Electrical Supply CharacteristicsDrPrashant M. MenghalОценок пока нет

- C&MI - Lecture 1Документ12 страницC&MI - Lecture 1Mourougapragash Subramanian0% (1)

- S6 Sub Maths SBДокумент186 страницS6 Sub Maths SBFlorence UfituweОценок пока нет

- SJ-20200929135033-015-ZXA10 C680&C600&C650&C620 (V1.2.1) Optical Access Aggregation Equipment Routine Maintenance - 996110Документ44 страницыSJ-20200929135033-015-ZXA10 C680&C600&C650&C620 (V1.2.1) Optical Access Aggregation Equipment Routine Maintenance - 996110paulo gadelhaОценок пока нет

- AC Circuits Knowledge Bank ExplainedДокумент34 страницыAC Circuits Knowledge Bank ExplainedMalak SamirОценок пока нет

- Measurements & Electronic Instruments Laboratory Experiment ManualДокумент3 страницыMeasurements & Electronic Instruments Laboratory Experiment Manualfirst lastОценок пока нет

- Auo B140XW01 V.8Документ30 страницAuo B140XW01 V.8shareatorОценок пока нет

- Op-Amp Cookbook - Part 4: Electronic Rectifier CircuitsДокумент18 страницOp-Amp Cookbook - Part 4: Electronic Rectifier Circuitsamit281276Оценок пока нет

- P54d en 2048 PDFДокумент8 страницP54d en 2048 PDFSi DidiksОценок пока нет

- The Smart Grid - Enabling Energy Efficiency and Demand Response - C5Документ20 страницThe Smart Grid - Enabling Energy Efficiency and Demand Response - C5Kiên PhạmОценок пока нет

- S Cubed DatasheetДокумент2 страницыS Cubed DatasheetGulf JobzОценок пока нет

- Properties Of Nλ/2 LinesДокумент12 страницProperties Of Nλ/2 LinesJunar JohnОценок пока нет

- DGPS Trimble BD950Документ2 страницыDGPS Trimble BD950aitopesОценок пока нет

- 6 16Документ2 страницы6 16Indira KarimovaОценок пока нет

- Bersemuka LДокумент7 страницBersemuka LPK K0% (1)

- Elevator Disconnect RequirementsДокумент10 страницElevator Disconnect Requirementssuresh7234Оценок пока нет

- MOELLER DF4-341-55k PDFДокумент173 страницыMOELLER DF4-341-55k PDFWilliam SanabriaОценок пока нет

- GV-2 Guv'nor Plus: Owners ManualДокумент5 страницGV-2 Guv'nor Plus: Owners ManualDaniel CardiaОценок пока нет

- pdp8 DocДокумент18 страницpdp8 DocalmeviОценок пока нет

- 487.4-2013 Standard For The Electrical Protection of Communication Facilities Serving Electric Supply Locations Through The Use of Neutralizing TransformersДокумент55 страниц487.4-2013 Standard For The Electrical Protection of Communication Facilities Serving Electric Supply Locations Through The Use of Neutralizing Transformersjose eduardo mejia sanchezОценок пока нет

- Manual CL-3022WKДокумент11 страницManual CL-3022WKDario ZainОценок пока нет

- PROFIBUS Standard for Fieldbus Communication in AutomationДокумент1 страницаPROFIBUS Standard for Fieldbus Communication in AutomationhenrytolentinoОценок пока нет

- Chapter 2 Computer EvolutionДокумент28 страницChapter 2 Computer EvolutionmillerОценок пока нет

- Aim: To Test Differentiator and Integrator Circuits Using Ua741op-AmpДокумент8 страницAim: To Test Differentiator and Integrator Circuits Using Ua741op-AmpAvinash Nandakumar100% (1)

- Test and Burn-In Sockets PDFДокумент27 страницTest and Burn-In Sockets PDFKSОценок пока нет

- FactSheet TPS Controllers ORION enДокумент2 страницыFactSheet TPS Controllers ORION enlacda83Оценок пока нет

- Dell G15 5515: Service ManualДокумент75 страницDell G15 5515: Service ManualMohitОценок пока нет

- List of Parts RequiredДокумент3 страницыList of Parts RequiredRoberto PasicОценок пока нет