Академический Документы

Профессиональный Документы

Культура Документы

Dynamometer

Загружено:

Shang Divina Ebrada0 оценок0% нашли этот документ полезным (0 голосов)

342 просмотров3 страницыdyna

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документdyna

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

342 просмотров3 страницыDynamometer

Загружено:

Shang Divina Ebradadyna

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

A dynamometer or "dyno" for short, is a device for measuring force,

torque, or power.

For example, the power produced by an engine, motor or other rotating

prime mover can be calculated by simultaneously measuring torque and

rotational speed (RPM).

A dynamometer that is designed to be driven is called an absorption or

passive dynamometer. A dynamometer that can either drive or absorb is

called a universal or active dynamometer.

Detailed dynamometer description

Electrical dynamometer setup showing engine, torque measurement

arrangement and tachometer

Tachometer-A tachometer (revolution-counter, tach, rev-counter, RPM

gauge) is an instrument measuring the rotation speed of a shaft or disk,

as in a motor or other machine.

Rotor-The rotor is a moving component of an electromagnetic system in

the electric motor, electric generator, or alternator.

Trunnion- a pin or pivot forming one of a pair on which something is

supported.

A dynamometer consists of an absorption (or absorber/driver) unit, and

usually includes a means for measuring torque and rotational speed. An

absorption unit consists of some type of rotor in a housing. The rotor is

coupled to the engine or other equipment under test and is free to rotate

at whatever speed is required for the test. Some means is provided to

develop a braking torque between the rotor and housing of the

dynamometer. The means for developing torque can be frictional,

hydraulic, electromagnetic, or otherwise, according to the type of

absorption/driver unit.

Types of dynamometer systems

A 'brake' dynamometer applies variable load on the Prime Mover (PM) and measures the PM's

ability to move or hold the RPM as related to the "braking force" applied. It is usually connected

to a computer that records applied braking torque and calculates engine power output based on

information from a "load cell" or "strain gauge" and a speed sensor.

An 'inertia' dynamometer provides a fixed inertial mass load, calculates the power required to

accelerate that fixed and known mass, and uses a computer to record RPM and acceleration rate

to calculate torque. The engine is generally tested from somewhat above idle to its maximum

RPM and the output is measured and plotted on a graph.

A 'motoring' dynamometer provides the features of a brake dyne system, but in addition, can

"power" (usually with an AC or DC motor) the Prime Mover (PM) and allow testing of very

small power outputs (for example, duplicating speeds and loads that are experienced when

operating a vehicle traveling downhill or during on/off throttle operations).

Вам также может понравиться

- ME5506 Make-Up Quiz 2Документ6 страницME5506 Make-Up Quiz 2Wai-Yen Chan100% (1)

- DC Machines Solved Problems CharulathaДокумент59 страницDC Machines Solved Problems CharulathaShang Divina Ebrada88% (80)

- Chlorine Theory & MeasurementДокумент6 страницChlorine Theory & Measurementjfisher2534Оценок пока нет

- Predictive Maintenance CourseДокумент2 страницыPredictive Maintenance Courseamhosny2010Оценок пока нет

- Skill-Lync Project Ideas Part - 1Документ53 страницыSkill-Lync Project Ideas Part - 1prasanthme34Оценок пока нет

- EvaporationДокумент37 страницEvaporationVimal KumarОценок пока нет

- Dynamometer Operation PrincipleДокумент4 страницыDynamometer Operation PrincipleAngel OfrenОценок пока нет

- MEC322 Chapter 7 - TORQUE & POWER MEASUREMENTДокумент19 страницMEC322 Chapter 7 - TORQUE & POWER MEASUREMENTAiman ArhamОценок пока нет

- Basic Tools 1Документ48 страницBasic Tools 1palaniОценок пока нет

- 101 Ways Extract Modal Parameters Which Is One Me PDFДокумент13 страниц101 Ways Extract Modal Parameters Which Is One Me PDFValentino de GeorgeОценок пока нет

- Ansys NVH Solutions For Electric Vehicles Whitepaper PDFДокумент6 страницAnsys NVH Solutions For Electric Vehicles Whitepaper PDFRajeshОценок пока нет

- Engine Modeling For Real-Time Control Using SimulinkДокумент15 страницEngine Modeling For Real-Time Control Using SimulinkAhmed El-wench100% (1)

- MPC Based Yaw and Lateral Stabilisation Via Active Front Steering and Braking PDFДокумент19 страницMPC Based Yaw and Lateral Stabilisation Via Active Front Steering and Braking PDFKiran KoneОценок пока нет

- Engineering S Ym Bology, Prints, and Draw Ings: Key WordsДокумент200 страницEngineering S Ym Bology, Prints, and Draw Ings: Key WordsMurtuza DehgamwalaОценок пока нет

- Automotive Systems: Vehicle Performances Parameters PFI Gasoline EnginesДокумент36 страницAutomotive Systems: Vehicle Performances Parameters PFI Gasoline EnginesAmanda MoraraОценок пока нет

- Diagnosis For in Vehicle NetworksДокумент26 страницDiagnosis For in Vehicle NetworksSayyedОценок пока нет

- Me322 Cep 2018144 2018297Документ77 страницMe322 Cep 2018144 2018297Hassan Ayub KhanОценок пока нет

- 2008 BevanphdДокумент194 страницы2008 Bevanphdrajm100% (1)

- Parametric Design Analysis and Fea Simulation of A Chisel Plow For An Agriculture UseДокумент14 страницParametric Design Analysis and Fea Simulation of A Chisel Plow For An Agriculture UseAnonymous pKuPK3zUОценок пока нет

- Unit 2-AEEДокумент128 страницUnit 2-AEEChidananda BasavannaОценок пока нет

- Real-Time Systems in Automotive Applications: Vehicle Stability ControlДокумент13 страницReal-Time Systems in Automotive Applications: Vehicle Stability ControlSEP-PublisherОценок пока нет

- Machine Learning A-Z: All The Answers To Your Questions, Section by SectionДокумент52 страницыMachine Learning A-Z: All The Answers To Your Questions, Section by Sectionhari krishnanОценок пока нет

- Introduction To R.T.P.P: 1.1 GeneralДокумент12 страницIntroduction To R.T.P.P: 1.1 GeneralSairam Kumar ChowdaryОценок пока нет

- Motor Condition MonitorДокумент25 страницMotor Condition MonitorVirgilioОценок пока нет

- AVL Guia de InstalaçãoДокумент36 страницAVL Guia de InstalaçãohenevilОценок пока нет

- Esp32-Wroom-32 Datasheet enДокумент27 страницEsp32-Wroom-32 Datasheet enSichzeugОценок пока нет

- ECU Mount-On-Engine Vibration StudyДокумент6 страницECU Mount-On-Engine Vibration StudyElroy LeeОценок пока нет

- What Is MatlabДокумент5 страницWhat Is Matlabyash143565Оценок пока нет

- Integrated Thermal Management of Hybrid Electric VehicleДокумент18 страницIntegrated Thermal Management of Hybrid Electric VehicleSachin SinghalОценок пока нет

- Automotive TVET ProgramДокумент70 страницAutomotive TVET Programlucky javellanaОценок пока нет

- Tuning of PID Controller Using Ziegler-Nichols Method For Speed Control of DC MotorДокумент6 страницTuning of PID Controller Using Ziegler-Nichols Method For Speed Control of DC Motoreubis_machado4370Оценок пока нет

- Engine Testing TechniqueДокумент8 страницEngine Testing TechniqueNur YakhinОценок пока нет

- Modelling and Simulation of Automatic TransmissionДокумент11 страницModelling and Simulation of Automatic TransmissionInternational Journal of Innovative Science and Research Technology100% (1)

- Introduction DynamometerДокумент5 страницIntroduction DynamometerJohn Paul CabreraОценок пока нет

- Factors Affecting Car Fuel ConsumptionДокумент23 страницыFactors Affecting Car Fuel ConsumptionScribd898989100% (1)

- Mechatronics ScafoundaryДокумент299 страницMechatronics Scafoundaryirfan deshmukhОценок пока нет

- Uqm Powerphase 75Документ6 страницUqm Powerphase 75Mihai BairacОценок пока нет

- Pneumatic SymbolsДокумент23 страницыPneumatic SymbolsPirate_KillerОценок пока нет

- 4 - Engine Performance ParametersДокумент20 страниц4 - Engine Performance ParametersWHO IS ITОценок пока нет

- Tire ModelsДокумент274 страницыTire Modelsdebendra128nitrОценок пока нет

- A New Cell-to-Cell Fast Balancing Circuit For Lithium-Ion Batteries in Electric Vehicles and Energy Storage SystemДокумент5 страницA New Cell-to-Cell Fast Balancing Circuit For Lithium-Ion Batteries in Electric Vehicles and Energy Storage SystemSanjana RoseОценок пока нет

- Fuel Flow MetersДокумент7 страницFuel Flow MetersAMIYA SHANKAR PANDAОценок пока нет

- Modeling and Simulation For Application Engineers: Hydraulic Systems Volume 7Документ21 страницаModeling and Simulation For Application Engineers: Hydraulic Systems Volume 7Tejas MahadikОценок пока нет

- Información Training Lab For Automotive Electrics PDFДокумент10 страницInformación Training Lab For Automotive Electrics PDFjuanОценок пока нет

- An Overview of Brake Noise and Vibration ProblemsДокумент7 страницAn Overview of Brake Noise and Vibration ProblemsChangbum YuОценок пока нет

- Improvement of Strain Gauges Micro-Forces Measurement Using Kalman Optimal FilteringOriginal Research ArticleДокумент6 страницImprovement of Strain Gauges Micro-Forces Measurement Using Kalman Optimal FilteringOriginal Research ArticlehmtuanbkОценок пока нет

- Ecosimpro Brochure Library TurboДокумент2 страницыEcosimpro Brochure Library TurboEfikos NewsОценок пока нет

- Solutions Manual Internal Combustion Engines: Applied Thermosciences ch08Документ17 страницSolutions Manual Internal Combustion Engines: Applied Thermosciences ch08swastik jenaОценок пока нет

- Graz Virtual Vehicle Symposium CI SIL Conference 2019 PDFДокумент20 страницGraz Virtual Vehicle Symposium CI SIL Conference 2019 PDFbnd1uОценок пока нет

- Bosch Fuel LubricityДокумент4 страницыBosch Fuel LubricityvictorpoedeОценок пока нет

- 024 - MathWorks Automotive Advisory Board Control AlgorithmДокумент265 страниц024 - MathWorks Automotive Advisory Board Control AlgorithmJAMER OSWALDO CHALA RAMIREZОценок пока нет

- Automotive Components LabДокумент63 страницыAutomotive Components LabBarathkannan PalanichamyОценок пока нет

- Engine ParametersДокумент27 страницEngine ParametersahmedОценок пока нет

- 2 Dual - Fuel - Tutorial - r170 PDFДокумент16 страниц2 Dual - Fuel - Tutorial - r170 PDFmohanОценок пока нет

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationОт EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationОценок пока нет

- Power Electronics and Electric Drives for Traction ApplicationsОт EverandPower Electronics and Electric Drives for Traction ApplicationsОценок пока нет

- Plug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideОт EverandPlug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideОценок пока нет

- Structural Health MonitoringОт EverandStructural Health MonitoringDaniel BalageasОценок пока нет

- Automotive Safety Integrity Level A Complete Guide - 2020 EditionОт EverandAutomotive Safety Integrity Level A Complete Guide - 2020 EditionОценок пока нет

- Introduction to Hybrid Vehicle System Modeling and ControlОт EverandIntroduction to Hybrid Vehicle System Modeling and ControlРейтинг: 4 из 5 звезд4/5 (1)

- How To Solve Worded Problems: G.M.R, Rce, Me1, RMPДокумент35 страницHow To Solve Worded Problems: G.M.R, Rce, Me1, RMPShang Divina EbradaОценок пока нет

- Common Mistakes Electrical Grounding and Bonding - JAIME V MENDOZA PDFДокумент103 страницыCommon Mistakes Electrical Grounding and Bonding - JAIME V MENDOZA PDFShang Divina EbradaОценок пока нет

- Electrical High Voltage BushingsДокумент49 страницElectrical High Voltage BushingsShang Divina EbradaОценок пока нет

- Managing Across Borders: Chapter 3: Global ManagementДокумент13 страницManaging Across Borders: Chapter 3: Global ManagementShang Divina EbradaОценок пока нет

- Mathletics - Multiplications and Divisions - Series E StudentДокумент73 страницыMathletics - Multiplications and Divisions - Series E StudentShang Divina Ebrada100% (1)

- EET306 Tutorial 3 2018 SolutionДокумент11 страницEET306 Tutorial 3 2018 SolutionShang Divina EbradaОценок пока нет

- Physics NotesДокумент6 страницPhysics NotesShang Divina EbradaОценок пока нет

- 24 It Is Use To Disconnect B) : PracticeДокумент1 страница24 It Is Use To Disconnect B) : PracticeShang Divina EbradaОценок пока нет

- Inventory Management & Inventory ModelsДокумент27 страницInventory Management & Inventory ModelsShang Divina EbradaОценок пока нет

- RME PEC Reviewer PDFДокумент96 страницRME PEC Reviewer PDFShang Divina EbradaОценок пока нет

- DRB Urm PDFДокумент1 страницаDRB Urm PDFShang Divina EbradaОценок пока нет

- DRB Urm PDFДокумент1 страницаDRB Urm PDFShang Divina EbradaОценок пока нет

- RME PEC Reviewer PDFДокумент96 страницRME PEC Reviewer PDFShang Divina EbradaОценок пока нет

- MP PDFДокумент2 страницыMP PDFShang Divina EbradaОценок пока нет

- Portable Power Factor Meters: FeaturesДокумент1 страницаPortable Power Factor Meters: FeaturesShang Divina EbradaОценок пока нет

- Rish Whiteline 90 Deg Power Factor Meter LF DatasheetДокумент4 страницыRish Whiteline 90 Deg Power Factor Meter LF DatasheetShang Divina EbradaОценок пока нет

- Figure 3.10.3 Impedance Diagram of 2Документ1 страницаFigure 3.10.3 Impedance Diagram of 2Shang Divina EbradaОценок пока нет

- AdU - 1S1718 - Tradis - 501 - ALAMILLO ND - Final Term Assign. No. 1 - Objective Type QuestionsДокумент3 страницыAdU - 1S1718 - Tradis - 501 - ALAMILLO ND - Final Term Assign. No. 1 - Objective Type QuestionsShang Divina EbradaОценок пока нет

- AdU - 1S1718 - Tradis - 501 - CONCEPCION MDM - Final Term Assignment No. 4Документ8 страницAdU - 1S1718 - Tradis - 501 - CONCEPCION MDM - Final Term Assignment No. 4Shang Divina EbradaОценок пока нет

- Martinez Trinidad Trinanes PowerpointДокумент20 страницMartinez Trinidad Trinanes PowerpointShang Divina EbradaОценок пока нет

- Basic in ElectricityДокумент26 страницBasic in ElectricityShang Divina EbradaОценок пока нет

- Martinez, Jan Carlos A. Code of Ethics Bsee August 17, 2018Документ2 страницыMartinez, Jan Carlos A. Code of Ethics Bsee August 17, 2018Shang Divina EbradaОценок пока нет

- TM 10 4310 392 13 and PДокумент43 страницыTM 10 4310 392 13 and PVitor FreitasОценок пока нет

- Degassed Acid Conductivity (DAC) : - The Fast Way To The TurbineДокумент12 страницDegassed Acid Conductivity (DAC) : - The Fast Way To The TurbinesivamОценок пока нет

- Hilti X-U NailsДокумент10 страницHilti X-U NailsLightninWolf32Оценок пока нет

- Roy-Mandal2020 Article Thermo-economicAnalysisAndMultДокумент15 страницRoy-Mandal2020 Article Thermo-economicAnalysisAndMultAhmed RagabОценок пока нет

- Enhancing The Seismic Performance of Batter Piles in Pile-Supported Wharves Using Fluid Viscous Dampers - P - 2018Документ15 страницEnhancing The Seismic Performance of Batter Piles in Pile-Supported Wharves Using Fluid Viscous Dampers - P - 2018Halil Can EryasarОценок пока нет

- In-Situ Rock StressesДокумент16 страницIn-Situ Rock StressesAslam KhanОценок пока нет

- What Is Tribology - Bearing Design, Lubrication & Friction by GGB PDFДокумент8 страницWhat Is Tribology - Bearing Design, Lubrication & Friction by GGB PDFMohan AyyappanОценок пока нет

- Presentation NanofluidДокумент23 страницыPresentation NanofluidnitaicheОценок пока нет

- Introduction To Inorganic Chemistry (Skt1013) Solid State Chemistry 3Документ38 страницIntroduction To Inorganic Chemistry (Skt1013) Solid State Chemistry 3izz isalahОценок пока нет

- Atmospheric Water Water VapourДокумент6 страницAtmospheric Water Water VapourBrian chunguliОценок пока нет

- Study of The Degradation Mechanisms of Polyethylene During ReprocessingДокумент9 страницStudy of The Degradation Mechanisms of Polyethylene During ReprocessingJoselyn GaliciaОценок пока нет

- Tacheometry Surveying IIДокумент25 страницTacheometry Surveying IINAJA MOHAMEDОценок пока нет

- Carbonic Hydronium Conc - PDFДокумент2 страницыCarbonic Hydronium Conc - PDFbencleeseОценок пока нет

- AAPL Capability StatementДокумент41 страницаAAPL Capability StatementjsmnjasminesОценок пока нет

- De Saint VenantДокумент13 страницDe Saint VenantSinthya Nlend djikeОценок пока нет

- Shallow Foundation - SettlementДокумент31 страницаShallow Foundation - SettlementDelina TedrosОценок пока нет

- Efa FitnetДокумент20 страницEfa FitnetQuoc VinhОценок пока нет

- Micromeritics 3Документ27 страницMicromeritics 3novi_lingga100% (1)

- PG Test Procedure For ACCДокумент3 страницыPG Test Procedure For ACCMadhu BediguthuОценок пока нет

- Nitrogen RejectionДокумент7 страницNitrogen RejectionOmar TocmoОценок пока нет

- Unit Operations of Chemical Engineering: (7th Edition)Документ3 страницыUnit Operations of Chemical Engineering: (7th Edition)HennessysОценок пока нет

- Me2121 2Документ12 страницMe2121 2Wei QuanОценок пока нет

- Determining Wicking of Fibrous Glass Fiber Blanket Insulation (Aircraft Type)Документ3 страницыDetermining Wicking of Fibrous Glass Fiber Blanket Insulation (Aircraft Type)Ahmed AlzubaidiОценок пока нет

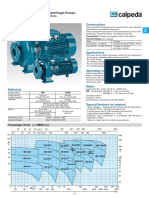

- Construction: Close Coupled Centrifugal PumpsДокумент11 страницConstruction: Close Coupled Centrifugal PumpsAhmed AbarchidОценок пока нет

- Calculation of Air Duct Pressure Loss (Rectangular)Документ15 страницCalculation of Air Duct Pressure Loss (Rectangular)Phyu Mar Thein KyawОценок пока нет

- P5 Q1 Experimental Design Updated To MJ22 ALL TOPICSДокумент6 страницP5 Q1 Experimental Design Updated To MJ22 ALL TOPICSSaad NahraОценок пока нет

- Digital Assignment 2Документ13 страницDigital Assignment 2Goutham ReddyОценок пока нет

- CIP25-Corrosion of Steel in ConcreteДокумент2 страницыCIP25-Corrosion of Steel in Concrete7774R105Оценок пока нет