Академический Документы

Профессиональный Документы

Культура Документы

Composite Beam Design

Загружено:

Sunil PulikkalАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Composite Beam Design

Загружено:

Sunil PulikkalАвторское право:

Доступные форматы

Job No: IA-PB-****

Design By : ***

Checked By : ***

Page # : 1

Design Calculation

Reference Codes

IRC-22

IRC-24

IRC-21

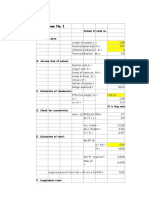

GIVEN DATA

Span (L)

Concrete slab width (cbf)

Thickness of slab (cth)

=

=

=

fck, Grade of concrete

Live Load (LL)

Super imposed dead load = 20% slab wt

Steel Beam I- Section

dw, Web Depth

tw, Web Thickness

18 m

2000.00 mm

300.00 mm

2

40 N/mm

700.00 kN

=

=

1000

10

bf, Flange Width

500

mm

tfo, Flange Thickness

30

mm

bf, Bottom Flange Width

500

mm

tfi, Bottom Flange Thickness

D, Total Depth

=

=

30

1060

mm

mm

mm

mm

Type of Construction : Unshored

DATA ASSUMED

2

Ec

32500 N/mm

Density of Concrete

24 kN/m

Es, Modulus of Elasticity

211000 N/mm

Density of steel

Yield strength of steel

78.5 kN/m

250 Mpa

2

3

Y

Concrete Flange = 2000 x 300

Z

Web =1000x10

Top & Bottom Flange=500x30

Y

Load Calculation

Dead Loads

Self weight of slab

Self weight of beam

Super imposed dead load ( 20% slab wt )

Total Dead Load (DL)

=

=

=

=

DL moment ( wl^2/8)

LL moment ( Wl / 8)

=

=

DL Shear

LL Shear

(IRC-21:2000, Table-9)

14.40

3.14

2.88

20.42

kN/m

kN/m

kN/m

kN/m

827.01 kN.m

1575.00 kN.m

183.78 kN

350.00 kN

(IRC-24:2001, 505.1.1)

Job No: IA-PB-****

Design By : ***

Checked By : ***

Page # : 2

Design Calculation

M, Moment

= wL /8

V, Shear Force

=

=

Modular Ratio

For Permenant Loads, m = Es / ( Kc x Ec )

For Transient Loads, m = Es / ( Ec )

=

=

583.2 kN.m

129.6 kN

12.98461538

6.492307692

Properties of I - Beam (STEEL)

2

A, Area

yg, centroid of section from bottom flange

=

=

40000 mm

530 mm

Iz, Inertia about major axis

8,792,333,333 mm

Iy, Inertia about minor axis

625,083,333 mm

125

ry Radius of gyration about yy

Z, Section Modulus

Composite proerties for Transient Loads

transformed Effective width of flange ( cbf/m)

transformed Area for concrete flange ()

16,589,308 mm3

=

=

308.06 mm

92417 mm2

Job No: IA-PB-****

Design By : ***

Checked By : ***

Page # : 3

Design Calculation

Combined Properties of I-beam + Concrete flange

Total Depth

Total area

C. G. of section from bottom flange

=

=

=

Iz, for combined section

1360 mm

132417 mm2

1005 mm

4

22,394,265,877 mm

Zzbottom

3

22,291,981 mm

63,009,384 mm

flange,

for combined section

Z top, for combined section

Calculation of elastic Critical stress fcb

fcb = k1 ( X + k2 Y ) ( c2 / c1 )

X = Y sqrt ( 1 + 1/20 ( l T / ( ry D )^ 2 )

Y = 26.5 x 10 ^ 5 / ( l / ry ) ^ 2 Mpa

c1, c2 = lesser & greater distance of of extreme

fiber from N.A

k1

k2

sigma bc

1) Checking of the stress

CONSTRUCTION STAGE

During construction stage, since

Due to Dead Loads ( Unshored condition )

bending compressivestress @ top flange

Allowable stress

bending tensile stress @ bottom flange

Allowable bending stress = 0.62 * Fy

Unity Check

Shear stress (average)

Allowable shear stress = 0.38 * Fy

Unity Check

Deflection check

Allowable deflection ( span /

Deflection ((5/384)*w*L /(E*I)

span / deflection

Composite action for additional live load

Additional tesile stress in steel

Total tensile stress in steel

Allowable bending stress = 0.62 * Fy

Unity Check

Compressive stress in concrete

Allowable stress

191.72

127.814206

127.81411

530.0 Mpa

1

0.50

87 Mpa

49.85

=

=

=

=

=

=

=

=

=

=

=

=

Vertical Shear

Total Vertical shear is assumed to be resisted by steel beam

Total Vertical shear

= 533.78

Shear stress (average)

=

Allowable shear stress = 0.38 * Fy

=

Unity Check

=

49.85

155

0.32

18.38

95

0.19

N/mm2

N/mm2

< 1.0 Hence ok

N/mm2

N/mm2 ( Table 6.2, IRC-24-2001 )

< 1.0 Hence ok

600

5.9070 mm

3047 O.K.

71

121

155

0.78

3.85

15.00

N/mm2

N/mm2

N/mm2

< 1.0 Hence ok

N/mm2

N/mm2 ( Table - 9 of IRC 21)

kN

53.38 N/mm2

95 N/mm2 ( Table 6.2, IRC-24-2001 )

0.56 < 1.0 Hence ok

Design of shear connectors

High tensile shear Connector from fatigue strength consideration

IRC:22-2000: Cl 611.4.1.2

VR

Area of transformed concrete salb = Ac

Y bar

I

Vr

P = Spacing of connectors required

= 350.00

= 92417

= 205

=

22,394,265,877

0.2967

kn

mm2

mm4

kN/mm

Job No: IA-PB-****

Design By : ***

Checked By : ***

Page # : 4

Design Calculation

dia of shear stud, d

stud height , h

h/d

No of shear studs / cross section

Qr = Alpha. A. 10^-2

25

120

5 >4

2

27 kN

182 mm

High tesile shear Connector from the consideration of ultimate flexural strength

Maximum horizontal force based on CL 611.4.1.2.1

H1 = Ast . Fy . 10-3

10000 kN

-3

H2 = 0.85 fc. bf. hf. 10

Maximum horizontal force in the slab

20400 kN

=minimim of H1 & H2

10000

kN

The ultimate strength of shear connector Qu = 0.5A sqrt (fck.Ec) x 10^-3

279.84

number of shear connectors between the mid span and end support, n = H/ ( lamda Qu ), Lamda = 0.85

42.04

The number of shear connecters based on fatigue

98.91 Hence the fatigue strength requirement governs

Design of transverse reinforcement

VL = V . Ac . Y / I

Since it is unshored construction, the V is the shear from Live load & super imposed dead load

350.00

VL

0.30

kN/mm

0.4 Ls sqrt (fck)

Ls, length of shear plane 1-1 as per Fig 5a of IRC 22

600

mm

Ls, for shear plane 2-2 as per Fig 5a of IRC 22

740 mm

0.4 Ls sqrt (fck)

1517.89

0.7 As sigma y + 0.08 Ls sqrt (fck)

486.01

Reinforcement provided = 0.2% in each direction

600.00 mm^2 / m length

Diameter of reinforcement

10.00

mm

spacing of top & bottom bar

0.26 m

Provide 10mm dia bars @ 250k=mm spacing at top & bottom in both directions

Вам также может понравиться

- Design Example ASD Beam CompositeДокумент9 страницDesign Example ASD Beam Compositecrealraj100% (1)

- Design of Rectangular Footing Col at Edge - 3Документ27 страницDesign of Rectangular Footing Col at Edge - 3Glenn SarneОценок пока нет

- CompositeДокумент11 страницCompositeluuvandong48xf396100% (1)

- Counter Fort Retaining Walls Penul TPT CounterfortДокумент23 страницыCounter Fort Retaining Walls Penul TPT Counterfortcoreteam100% (3)

- Design of WingwallДокумент29 страницDesign of WingwallMar MartillanoОценок пока нет

- Design of Composite Floor System Using Profiled SheetsДокумент2 страницыDesign of Composite Floor System Using Profiled SheetsArya AsokanОценок пока нет

- Crackwidth For Wall (Combined Bending and Tension)Документ3 страницыCrackwidth For Wall (Combined Bending and Tension)mukhleshОценок пока нет

- Crack Width Calculation For Rectangular RC BeamДокумент1 страницаCrack Width Calculation For Rectangular RC BeamRomyMohanОценок пока нет

- Composite Beam Design ExampleДокумент7 страницComposite Beam Design Exampledgreally1gmailcom100% (1)

- CD Perp1Документ6 страницCD Perp1dovi01Оценок пока нет

- Deck SlabДокумент22 страницыDeck SlabMahendra SuryavanshiОценок пока нет

- Retaining Wall Counterfort PDFДокумент48 страницRetaining Wall Counterfort PDFSilver Olguín CamachoОценок пока нет

- Design of Composite BeamДокумент7 страницDesign of Composite BeamMohammed SumerОценок пока нет

- Slab Design FFДокумент17 страницSlab Design FFSivaAgathamudiОценок пока нет

- Column at Node No. A. General DataДокумент9 страницColumn at Node No. A. General DataTarkeshwar Lal SrivastavaОценок пока нет

- Retaining WallДокумент41 страницаRetaining Wallp_ignatiusОценок пока нет

- Method of Design Cantilever ErectionДокумент62 страницыMethod of Design Cantilever Erectionzieq72Оценок пока нет

- RC Pilecap Design (Beam Method)Документ27 страницRC Pilecap Design (Beam Method)Thaung Myint OoОценок пока нет

- T Girder Bridge Deck Diaphragm-20 MДокумент14 страницT Girder Bridge Deck Diaphragm-20 MAmitabha DebОценок пока нет

- Composite Column DesignДокумент3 страницыComposite Column DesignEngDbt50% (2)

- 3bow-String Girder - Design Construction Aspects PDFДокумент12 страниц3bow-String Girder - Design Construction Aspects PDFankur mundraОценок пока нет

- Warehouse A: ProjectДокумент145 страницWarehouse A: ProjectCHEA VANNAIОценок пока нет

- Staircase Design 1Документ365 страницStaircase Design 1Vanu VamalaiОценок пока нет

- Design of Splice ConnectionДокумент4 страницыDesign of Splice ConnectionJustinОценок пока нет

- Column Design ExampleДокумент1 100 страницColumn Design ExampleDon RathnayakaОценок пока нет

- Design Moment For Column To BS8110Документ1 страницаDesign Moment For Column To BS8110Pranote PuapermpoonsiriОценок пока нет

- Wall - Shear Rebar Design - SumanДокумент2 страницыWall - Shear Rebar Design - Sumansuman_civil100% (1)

- Loading On CanopyДокумент9 страницLoading On CanopyanbuaedОценок пока нет

- RCC Rect Col-Dsn Kns 176Документ7 страницRCC Rect Col-Dsn Kns 176nvnrevОценок пока нет

- Steel Bridge DesignДокумент56 страницSteel Bridge Designnavin263Оценок пока нет

- Circular Water Tank Design: Capacity of Tank Free Board Total HeightДокумент2 страницыCircular Water Tank Design: Capacity of Tank Free Board Total HeightyasirjurabaОценок пока нет

- Check For Requirement of Boundary ElementДокумент9 страницCheck For Requirement of Boundary ElementJai ThakkarОценок пока нет

- Design of Lift Footing MKD. F8Документ3 страницыDesign of Lift Footing MKD. F8Nitesh SinghОценок пока нет

- Super Composite ColumnДокумент2 страницыSuper Composite ColumnCheng Por EngОценок пока нет

- Base Plate DesignДокумент3 страницыBase Plate DesignVinayak MadiОценок пока нет

- Connection DesignДокумент14 страницConnection DesignarjunОценок пока нет

- Circular Section Crack Width Under Pure TensionДокумент1 страницаCircular Section Crack Width Under Pure TensionAbinash ModakОценок пока нет

- Shear Wall DesignДокумент9 страницShear Wall DesignJai ThakkarОценок пока нет

- Design of Concrete CorbelДокумент2 страницыDesign of Concrete CorbelUttam Kumar GhoshОценок пока нет

- Circular Pier With Circular Footing.Документ25 страницCircular Pier With Circular Footing.Balaji Rao Ch100% (5)

- 16 Selection of Concrete Filled Steel Pipe Columns 23052014Документ1 страница16 Selection of Concrete Filled Steel Pipe Columns 23052014Ahmad Badsha QuadriОценок пока нет

- Flat Slab 6 X 6 Ext PNLДокумент5 страницFlat Slab 6 X 6 Ext PNLDarshan Shah100% (1)

- StaircaseДокумент2 страницыStaircaseMAGED MOHMMED AHMED QASEMОценок пока нет

- Design of Square Footing F2Документ18 страницDesign of Square Footing F2Mohammed Sumer100% (1)

- Concrete Pier (Isolated Deep Foundation) Design Based On ACI 318-14Документ6 страницConcrete Pier (Isolated Deep Foundation) Design Based On ACI 318-14Matiur Rahman BasumОценок пока нет

- TCC33 Flat Slabs (A&D)Документ47 страницTCC33 Flat Slabs (A&D)Nazar Shafiq100% (1)

- Design of BeamДокумент17 страницDesign of BeamAbhinav Chowdary100% (2)

- Method of RCC Slab Design As Per Is 456Документ2 страницыMethod of RCC Slab Design As Per Is 456Shruti Shah67% (3)

- Masonry Wall Design - 2Документ3 страницыMasonry Wall Design - 2Michael AbandeОценок пока нет

- Numerical Analysis: Chapter - 6Документ30 страницNumerical Analysis: Chapter - 6Pranay ReddyОценок пока нет

- Design of T Beam Using SP16 Economic Depth and CheckДокумент10 страницDesign of T Beam Using SP16 Economic Depth and CheckRiazahemad B JagadalОценок пока нет

- Raft Footing DesignДокумент7 страницRaft Footing DesignPrakash ShresthaОценок пока нет

- Design of T-BeamДокумент6 страницDesign of T-BeamDineshОценок пока нет

- Sachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Документ5 страницSachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Costas SachpazisОценок пока нет

- Problem Statment DARSHANДокумент10 страницProblem Statment DARSHANMayuresh NalawadeОценок пока нет

- BS 8110 Data Given: Calculation SheetДокумент8 страницBS 8110 Data Given: Calculation SheetLee See VoonОценок пока нет

- Steel Composite 1 VERY GOOD MahfuzДокумент5 страницSteel Composite 1 VERY GOOD MahfuzLivian TeddyОценок пока нет

- DG Consulting Engineers: Job NoДокумент52 страницыDG Consulting Engineers: Job NosthakshyОценок пока нет

- Design of Box Culvert DataДокумент3 страницыDesign of Box Culvert DataHemant SonawadekarОценок пока нет

- Strap Beam: Analysis and Design of Strap (Cantilever) Footing According To ACI 318Документ12 страницStrap Beam: Analysis and Design of Strap (Cantilever) Footing According To ACI 318aamiri.shamloo100% (1)

- Fatigue CheckДокумент1 страницаFatigue CheckSunil PulikkalОценок пока нет

- Is 800-2007 Interpretation by INSDAGДокумент15 страницIs 800-2007 Interpretation by INSDAGnilesh_yerawar100% (1)

- Drainage DesignДокумент1 страницаDrainage DesignSunil PulikkalОценок пока нет

- Brick Masonry Walls Book PDFДокумент117 страницBrick Masonry Walls Book PDFPremalatha Jeyaram100% (1)

- Analysis and Design of Base Plate and Anchor Bolt For Pinned BaseДокумент4 страницыAnalysis and Design of Base Plate and Anchor Bolt For Pinned BaseSunil PulikkalОценок пока нет

- Base Plate Andf Anchor Bolt Design For Minor Axis MomentДокумент2 страницыBase Plate Andf Anchor Bolt Design For Minor Axis MomentSunil Pulikkal100% (1)

- Crane DataДокумент1 страницаCrane DataSunil PulikkalОценок пока нет

- Effective Length of Stepped ColumnДокумент1 страницаEffective Length of Stepped ColumnSunil PulikkalОценок пока нет

- Comparison of Tolerances - Is 7215 - AWS - MBMAДокумент1 страницаComparison of Tolerances - Is 7215 - AWS - MBMASunil Pulikkal100% (2)

- CFДокумент1 страницаCFSunil PulikkalОценок пока нет

- Torsional PropertiesДокумент19 страницTorsional PropertiesAndrés Felipe HernándezОценок пока нет

- Multistorey BuildingДокумент6 страницMultistorey BuildingSunil PulikkalОценок пока нет

- Cold Forms Section Tolerances As Per MbmaДокумент1 страницаCold Forms Section Tolerances As Per MbmaSunil PulikkalОценок пока нет

- Innovations in PlatДокумент26 страницInnovations in PlatSunil PulikkalОценок пока нет

- Guide Line For Inspection of Overhead Crane StructureДокумент43 страницыGuide Line For Inspection of Overhead Crane StructurePranoy Barua100% (1)

- Pinned Base As Per AISC-Detail-A-R0Документ5 страницPinned Base As Per AISC-Detail-A-R0Sunil Pulikkal100% (1)

- Is Standard ListДокумент11 страницIs Standard ListSunil PulikkalОценок пока нет

- Cssbi 57Документ69 страницCssbi 57jachoijachoiОценок пока нет

- Rayleigh RitzДокумент23 страницыRayleigh Ritzjmam1992Оценок пока нет

- Astm Standard List PDFДокумент4 страницыAstm Standard List PDFSunil Pulikkal0% (1)

- Light Weight BricksДокумент4 страницыLight Weight BricksSunil PulikkalОценок пока нет

- Building Insulation BulletinДокумент4 страницыBuilding Insulation BulletinSarath ChukkapalliОценок пока нет

- STEEL STRUCTURE MAGAZINE, Article About Pipe StructureДокумент3 страницыSTEEL STRUCTURE MAGAZINE, Article About Pipe StructureSunil PulikkalОценок пока нет

- Bolt Spec ReviewДокумент2 страницыBolt Spec ReviewAnonymous Re62LKaACОценок пока нет

- Safe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFДокумент36 страницSafe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFFarid RezaeianОценок пока нет

- Rules of Thumb For Steel StructuresДокумент5 страницRules of Thumb For Steel StructuresLincs lincoln100% (1)

- Safe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFДокумент36 страницSafe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFFarid RezaeianОценок пока нет

- OL-1 Failure of Steel StructureДокумент0 страницOL-1 Failure of Steel StructureSunil PulikkalОценок пока нет

- General Safety Rules For Steel Fabricators AISCДокумент55 страницGeneral Safety Rules For Steel Fabricators AISCEdison BecerraОценок пока нет

- Floating Pontoon BridgesДокумент26 страницFloating Pontoon BridgestitieОценок пока нет

- Egyption Code of Practice For Steel ConstructionДокумент142 страницыEgyption Code of Practice For Steel ConstructionYousab CreatorОценок пока нет

- Linkway - Bishan - Stretch D - T-PL1963-BSN-CS-105Документ4 страницыLinkway - Bishan - Stretch D - T-PL1963-BSN-CS-105parathasiОценок пока нет

- Dennis LamДокумент302 страницыDennis Lamlucianolimauerjrm4Оценок пока нет

- RCC-Conc Objective QuestionsДокумент34 страницыRCC-Conc Objective QuestionsAlok Jha88% (8)

- Basics of Cold Form - INsdag PDFДокумент21 страницаBasics of Cold Form - INsdag PDFCharu Sharma100% (1)

- DuraFuse Design Guide Z FoldДокумент2 страницыDuraFuse Design Guide Z FoldHussain ZaranwalaОценок пока нет

- (La Poutre, D.B.) Strength and Stability of Channel Sections Used As Beam PDFДокумент201 страница(La Poutre, D.B.) Strength and Stability of Channel Sections Used As Beam PDFoubiОценок пока нет

- Struktur Baja II Part 03-Lentur 02Документ31 страницаStruktur Baja II Part 03-Lentur 02RatihОценок пока нет

- INTERTEK Diaphragm Shear Test Report FinaДокумент43 страницыINTERTEK Diaphragm Shear Test Report FinarycproyectistaОценок пока нет

- Applsci 13 00778 v3Документ12 страницApplsci 13 00778 v3Doan Nguyen VanОценок пока нет

- No.: Wide Flange Crane Bracket Design Page: of Date: LocationДокумент13 страницNo.: Wide Flange Crane Bracket Design Page: of Date: LocationmaheshbandhamОценок пока нет

- EuroCode 4Документ420 страницEuroCode 4Mohamed Tahar Allagui100% (3)

- Behaviorof Castellated Steel Beams Stateofthe Art ReviewДокумент11 страницBehaviorof Castellated Steel Beams Stateofthe Art Reviewvijaykrishna kotapatiОценок пока нет

- EEVEELUTION - Project Assignment 5 6Документ31 страницаEEVEELUTION - Project Assignment 5 6ANGELA YSABELLE ESTRADAОценок пока нет

- Lira Calculation Report: Ship Name: Builder: JobДокумент27 страницLira Calculation Report: Ship Name: Builder: JobJesus Raul Osco TrujilloОценок пока нет

- Beam Design Notes Nzs 3404Документ24 страницыBeam Design Notes Nzs 3404sdewss100% (3)

- Distribution of Stresses in I BeamДокумент11 страницDistribution of Stresses in I BeambharatОценок пока нет

- Worked Example 01 Semi ContinuousДокумент17 страницWorked Example 01 Semi Continuousnurul adilahОценок пока нет

- 5 TorsionДокумент6 страниц5 TorsionDem Austria EspinoОценок пока нет

- LFMModeller V3.97.0.0Документ26 страницLFMModeller V3.97.0.0Latifat quadriОценок пока нет

- Catalogo Perfiles AISC en mm9Документ30 страницCatalogo Perfiles AISC en mm9Jhandry JimenezОценок пока нет

- Lecture 4B.5: Calculation Examples: Example 1 Critical Temperature of Tension MemberДокумент4 страницыLecture 4B.5: Calculation Examples: Example 1 Critical Temperature of Tension MemberTest NameОценок пока нет

- Integral Bridge Design ExampleДокумент33 страницыIntegral Bridge Design ExampleRussel Odendaal100% (1)

- Steel 2022 BeamДокумент26 страницSteel 2022 BeamRaven Von DizonОценок пока нет

- Structural System For Tall Buildings PDFДокумент222 страницыStructural System For Tall Buildings PDFAravind Bhashyam50% (2)

- Basic Properties of SectionДокумент83 страницыBasic Properties of SectionkarthicksipОценок пока нет

- RCC & Steel & Current 30-Jul-2021Документ9 страницRCC & Steel & Current 30-Jul-2021soham trivediОценок пока нет

- Through Bolt Connection PDFДокумент197 страницThrough Bolt Connection PDFAkhil VNОценок пока нет

- 21910-CAL-01 Tank Design Calculation For NMA TankДокумент56 страниц21910-CAL-01 Tank Design Calculation For NMA TankShayan Hasan KhanОценок пока нет

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!От EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Рейтинг: 4 из 5 звезд4/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignОт EverandTo Engineer Is Human: The Role of Failure in Successful DesignРейтинг: 4 из 5 звезд4/5 (138)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОт EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОценок пока нет

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsОт EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsОценок пока нет

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresОт EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresРейтинг: 1 из 5 звезд1/5 (2)

- Artificial Intelligence: From Medieval Robots to Neural NetworksОт EverandArtificial Intelligence: From Medieval Robots to Neural NetworksРейтинг: 4 из 5 звезд4/5 (3)

- Structural Cross Sections: Analysis and DesignОт EverandStructural Cross Sections: Analysis and DesignРейтинг: 4.5 из 5 звезд4.5/5 (19)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureОт EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.От EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Рейтинг: 4 из 5 звезд4/5 (5)

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesОт EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Dark Aeon: Transhumanism and the War Against HumanityОт EverandDark Aeon: Transhumanism and the War Against HumanityРейтинг: 5 из 5 звезд5/5 (1)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsОт EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsОценок пока нет

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsОт EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsРейтинг: 5 из 5 звезд5/5 (3)

- Pile Design and Construction Rules of ThumbОт EverandPile Design and Construction Rules of ThumbРейтинг: 4.5 из 5 звезд4.5/5 (15)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionОт EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionРейтинг: 3.5 из 5 звезд3.5/5 (129)