Академический Документы

Профессиональный Документы

Культура Документы

Fixed and Variable Cost Analysis for Highway Paving Project

Загружено:

Aileen May Santillan Herrera0 оценок0% нашли этот документ полезным (0 голосов)

122 просмотров8 страницPractice Problems.

Оригинальное название

Chapter 2 Engg Eco Reviewer

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPractice Problems.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

122 просмотров8 страницFixed and Variable Cost Analysis for Highway Paving Project

Загружено:

Aileen May Santillan HerreraPractice Problems.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

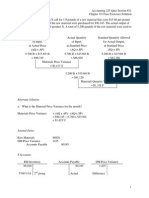

Fixed and Variable Costs

In connection with surfacing a new highway, a contractor

has a choice of two sites on which to set up the asphaltmixing plant equipment. The contractor estimates that it will

cost $1.15 per cubic yard mile (yd 3-mile) to haul the asphaltpaving material from the mixing plant to the job location.

Factors relating to the two mixing sites are as follows

(Production costs at each sites are the same):

Cost factor

Site A

Site B

Average hauling

6 miles

4.3 miles

distance

Monthly rental of site

$1,000

$5,000

Cot set up and

$15,000

$25,000

remove equipment

Hauling expense

$1.15/yd3-mile $1.15/yd3-mile

Flagperson

Not required

$96/day

The job requires 50,000 cubic yards of mixedasphalt-paving material. It is estimated that four months (17

weeks of five working days per week) will be required for

the job. Compare the two sites in terms of their fixed,

variable and total costs. Assume that the cost of the return

trip is negotiable. Which is the better site? For the selected

site, how many cubic yards of paving material does the

contractor have to deliver before starting to make a profit if

paid $8.05 per cubic yard delivered to the job location?

Optimal Demand When Demand Is a Function of Price

A company produces an electronic timing switch that is used

in consumer and commercial products. The fixed cost (CF) is

$73,000 per month, and the variable cost (cv) is $83 per unit.

The selling price per unit is p = $180 0.02(D), based on

equation. For this situation, (a) determine the optimal

volume for this product and confirm that a profit occurs

(instead of a loss) at this demand; (b) find the volumes at

which breakeven occurs; that is, what is the range of

profitable demand?

Breakeven Point When Price Is Independent of Demand

An engineering consulting firm measures its output in a

standard service hour unit, which is a function of the

personnel grades levels in the professional staff. The

variable cost (cv) is $62 per standard service hour. The

charge-out rate [i.e., selling price (p)] is $85.56 per hour.

The maximum output of the firm is 160,000 per year, and its

fixed cost (CF) is $2,024,000 per year. For this firm, (a) what

is the breakeven point in standard service hours and in

percentage of total capacity? (b) What is the percentage

reduction in the breakeven point (sensitivity) if fixed costs

are reduced 10%; if variable cost per hour is reduced 10%;

and if the selling price per unit is increased by 10%?

How Fast Should the Airplane Fly?

The cost of operating a jet-powered commercial (passengercarrying) airplane varies as the three-halves power of its

velocity; specifically, CO = knv3/2, when n is the trip length in

miles, k is a constant of proportionality, and v is velocity in

miles per hour. It is known that at 400 miles per hour, the

average cost of operation is $300 per mile. The company

that owns the aircraft wants to minimize the cost of

operation, but that cost must be balanced against that cost of

passengers time (CC), which has been set at $300,000 per

hour. (a) At what velocity should the trip be planned to

minimize the total cost, which is the sum of the cost of

operating the airplane and the cost of passengers time? (b)

How do you know that your answer for the problem in Part

A minimizes the total cost?

Energy Savings through Increased Insulation

This example deals with a discrete optimization problem of

determining the most economical amount of attic insulation

for a large single-story home in Virginia. In general, the heat

lost through the roof of a single-story home is

In southwest Virginia, the number of heating days

per year is approximately 230, and the annual heating

degree-days equals 230 (65F-46F) = 4370 degree-days per

year. Here, 65F is assumed to be the average inside

temperature and 46F is the average outside temperature

each day.

Consider a 2,400-ft2 single-story house in

Blacksburg. They typical annual space-heating load for this

size of a house is 100 x 106 BTU. That is, with no insulation

in the attic, we lose about 100 x 106 BTE per year.*

Common sense dictates that the no insulation alternative is

not attractive and is to be avoided.

With insulation in the attic, the amount of heat lost

each year will be reduced. The value of energy savings that

results from adding insulation and reducing heat loss is

dependent on what type of residential heating furnace is

installed. For this example, we assume that an electrical

resistance furnace is installed by the builder, and its

efficiency is near 100%.

Now were in a position to answer the following

question: What amount of insulation is most economical?

An additional piece of data we need to involves the cost of

electricity, which is $0.0074 per kWh. This can be converted

to dollars per 10^6 BTU as follows (1kWh = 3,413 Btu):

The cost of several insulation alternatives and

associated space-heating loads for this house are given in the

following table

Amount of Insulation

R11

R19

R30

R38

Investmen

600

900

1300

1600

t cost ($)

Annual

heating

74x106 69.8x106 67.2x106 66.2x106

load

(Btu/year)

In view of these data, which amount of attic

insulation is most economical? The life of the insulation is

estimated to be 25 years.

To Produce or Not to Produce?

A manufacturing plant consists of three departments: A, B,

and C. Department A occupies 100 square meters in one

corner of the plant. Product X is one of the several products

being produced in Department A. The daily production of

Product X is 576 pieces. The cost accounting records show

the following average daily production costs for Product X:

The department foreman has recently learned about an

outside company sells X at $0.35 per piece. Accordingly, the

foreman figured a cost per day of $0.35(576) = $201.60,

resulting in a daily savings of $288.40-$201.60=$86.80.

Therefore, a proposal was submitted to the plant manager

for shutting down the production line of Product X and

buying it from the outside company.

However, after examining each component

separately, the plant manager decided not to accept the

foremans proposal based on the unit cost of product X:

1. Direct labor: because the foreman was supervising

the manufacture of the other products in

Department A in addition to Product X, the only

possible savings in labor wound occur if the

operator working 4 hours per days on Product X

were not reassigned after this line is shut down.

That is, a maximum savings of $90.00 per day

would result.

2. Materials: The maximum savings on direct material

will be $86.40. However, this figure could be lower

if some of the material for Product X is obtained

from scrap of another product.

3. Overhead: Because other products are made in

Department A, no reduction in total floor space

requirements will probably occur. Therefore, no

reduction in overhead costs will result from

discontinuing Product X. It has been estimated that

there will be daily savings in the variable overhead

costs traceable to Product X of about $3.00 due to a

reduction in power costs and in insurance

premiums.

PROBLEMS

Вам также может понравиться

- Test Bank For Engineering Economy 16Th Edition by Sullivan Wicks Koelling Isbn 0133439275 9780133439274 Full Chapter PDFДокумент25 страницTest Bank For Engineering Economy 16Th Edition by Sullivan Wicks Koelling Isbn 0133439275 9780133439274 Full Chapter PDFmindy.sorrell339100% (13)

- Test Bank For Engineering Economy 16th Edition by Sullivan Wicks Koelling ISBN 0133439275 9780133439274Документ35 страницTest Bank For Engineering Economy 16th Edition by Sullivan Wicks Koelling ISBN 0133439275 9780133439274AshleyParksegn100% (23)

- Week 9-10Документ26 страницWeek 9-10Raja Umair RaufОценок пока нет

- Week 7-9Документ28 страницWeek 7-9Sohaib IrfanОценок пока нет

- Engineering Economy 16th Edition Sullivan Test BankДокумент5 страницEngineering Economy 16th Edition Sullivan Test BankDanielThomasxjfoq100% (15)

- Engineering Economy 16th Edition Sullivan Test BankДокумент5 страницEngineering Economy 16th Edition Sullivan Test BankThomas Seamon100% (40)

- Engineering Economy 16th Edition Sullivan Test BankДокумент36 страницEngineering Economy 16th Edition Sullivan Test Bankfoxysolon8cfh5100% (20)

- Dwnload Full Engineering Economy 16th Edition Sullivan Test Bank PDFДокумент36 страницDwnload Full Engineering Economy 16th Edition Sullivan Test Bank PDFserenafinnodx100% (11)

- Breakeven and EOQ Exercises (With Answers)Документ6 страницBreakeven and EOQ Exercises (With Answers)Charlene ChorОценок пока нет

- Engineering Economy (Lecture 2)Документ26 страницEngineering Economy (Lecture 2)Anonymous d6Etxrtb100% (2)

- CH #3 NumericalsДокумент3 страницыCH #3 NumericalsMs Noor ul AinОценок пока нет

- Eco BreakevenДокумент32 страницыEco Breakevenkhen026Оценок пока нет

- Assignment1 2016Документ3 страницыAssignment1 2016Youssef LebroОценок пока нет

- Sheet 2 Engineering Economy 2018-2019Документ3 страницыSheet 2 Engineering Economy 2018-2019حسن علي جاسمОценок пока нет

- CH #2 NumericalsДокумент3 страницыCH #2 NumericalsMs Noor ul AinОценок пока нет

- ENGINEERING-ECONOMY_2Документ7 страницENGINEERING-ECONOMY_2Jefrey M. ButilОценок пока нет

- Tutorial 1 EME 3056 Industrial ManagementДокумент4 страницыTutorial 1 EME 3056 Industrial ManagementSivanesh KumarОценок пока нет

- Industrial Organization SolutionsДокумент89 страницIndustrial Organization SolutionsDavide Rossetto80% (5)

- Lecture 3-Linear ProgrammingДокумент40 страницLecture 3-Linear ProgrammingadmiremukureОценок пока нет

- Class Work For Chapter 10Документ3 страницыClass Work For Chapter 10Madiha Abu Saied Tazul Islam 1721217Оценок пока нет

- Alternatives to Replace Coal Power Plant CapacityДокумент38 страницAlternatives to Replace Coal Power Plant Capacitylennahfe19Оценок пока нет

- Annual Worth, Capitalized, RorДокумент11 страницAnnual Worth, Capitalized, RorNaveen KumarОценок пока нет

- Replacement Analysis: SolutionДокумент10 страницReplacement Analysis: Solutionthawatchai112225120% (1)

- 201B Exam 2 PrepДокумент9 страниц201B Exam 2 PrepChanel NguyenОценок пока нет

- Breakeven and Payback Analysis: Parameter or Decision VariableДокумент5 страницBreakeven and Payback Analysis: Parameter or Decision VariableZoloft Zithromax ProzacОценок пока нет

- Marginal and Absorption CostingДокумент10 страницMarginal and Absorption CostingSandip GhoshОценок пока нет

- Make or Buy Analysis and Target CostingДокумент14 страницMake or Buy Analysis and Target CostingGloriana FokОценок пока нет

- Assignment5 1st MechanicalДокумент3 страницыAssignment5 1st Mechanicallapepeng2067Оценок пока нет

- Assignments Eco PDFДокумент7 страницAssignments Eco PDFKaman LuitelОценок пока нет

- Literature Review 1 PageДокумент9 страницLiterature Review 1 PageMahbub HussainОценок пока нет

- Evaluate Alternatives and Make Optimal DecisionsДокумент5 страницEvaluate Alternatives and Make Optimal DecisionsGene Justine SacdalanОценок пока нет

- Chapter 2 - Examples - SolutionsДокумент11 страницChapter 2 - Examples - SolutionsAhmed walidОценок пока нет

- Rashmi's CMA P1 homework evaluationДокумент6 страницRashmi's CMA P1 homework evaluationRaman AОценок пока нет

- Present EconomyДокумент21 страницаPresent EconomyKhryz Anne AvilaОценок пока нет

- Sample Final 11BДокумент11 страницSample Final 11Bjosephmelkonian1741100% (1)

- Cash Flow Estimation Models: Estimating Relationships and ProblemsДокумент30 страницCash Flow Estimation Models: Estimating Relationships and ProblemsSenthil RОценок пока нет

- QS11 - Class Exercises SolutionДокумент8 страницQS11 - Class Exercises Solutionlyk0tex100% (2)

- Satwinder Singh Gill 197046 0Документ4 страницыSatwinder Singh Gill 197046 0Prithpal SinghОценок пока нет

- Final Case Analysis - CostconДокумент7 страницFinal Case Analysis - CostconDheine Maderazo100% (1)

- Revision Exercise IДокумент2 страницыRevision Exercise IDayangku Nur Hamiza Awang KedariОценок пока нет

- Tugas Konsep Dasar Manajemen Biaya (Irga Ayudias Tantri - 12030121410004)Документ5 страницTugas Konsep Dasar Manajemen Biaya (Irga Ayudias Tantri - 12030121410004)irga ayudiasОценок пока нет

- Solutions To Relevant Cost ProblemsДокумент13 страницSolutions To Relevant Cost ProblemsAndrian VillanuevaОценок пока нет

- Comparing excavator and tiller options for irrigation ditch preparationДокумент5 страницComparing excavator and tiller options for irrigation ditch preparationtarekОценок пока нет

- 19 Process CostingДокумент30 страниц19 Process Costingsabinaeghan1Оценок пока нет

- Chapter 10 5eДокумент4 страницыChapter 10 5eym5c2324Оценок пока нет

- Capacity Problem1Документ3 страницыCapacity Problem1Ahmed ZamanОценок пока нет

- GDB3023 Assignment Analyzes Costs, Benefits of Gas Station TripДокумент3 страницыGDB3023 Assignment Analyzes Costs, Benefits of Gas Station TripDanish ZabidiОценок пока нет

- Material, Direct Labor, and OverheadДокумент3 страницыMaterial, Direct Labor, and OverheadrobertОценок пока нет

- ComaДокумент21 страницаComamanojОценок пока нет

- Assignment Standard Costing SolutionsДокумент13 страницAssignment Standard Costing SolutionsMartha MasalangkayОценок пока нет

- EEE Assignment 1Документ8 страницEEE Assignment 1Hamizan Fuad100% (2)

- The Economics of Hardfacing: Home PageДокумент10 страницThe Economics of Hardfacing: Home PageJR ZookОценок пока нет

- F5 - LCT-1Документ6 страницF5 - LCT-1Amna HussainОценок пока нет

- The Home Owner's Guide to HVAC: The Envelope and Green TechnologiesОт EverandThe Home Owner's Guide to HVAC: The Envelope and Green TechnologiesОценок пока нет

- Reducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemОт EverandReducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemОценок пока нет

- Making Your Home More Energy Efficient: A Practical Guide to Saving Your Money and Our PlanetОт EverandMaking Your Home More Energy Efficient: A Practical Guide to Saving Your Money and Our PlanetОценок пока нет

- Southern Marine Engineering Desk Reference: Second Edition Volume IОт EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IОценок пока нет

- Navi Lab Front Page SoloДокумент1 страницаNavi Lab Front Page SoloAileen May Santillan HerreraОценок пока нет

- ScheduleДокумент3 страницыScheduleAileen May Santillan HerreraОценок пока нет

- Adamson University: College of Engineering Electronics Engineering DepartmentДокумент1 страницаAdamson University: College of Engineering Electronics Engineering DepartmentAileen May Santillan HerreraОценок пока нет

- Schedule For Pre-Registration: Monday TuesdayДокумент2 страницыSchedule For Pre-Registration: Monday TuesdayAileen May Santillan HerreraОценок пока нет

- Lecture Radio Wave PropagationДокумент7 страницLecture Radio Wave PropagationAileen May Santillan HerreraОценок пока нет

- Ece Block Sections - Schedule of ClassesДокумент8 страницEce Block Sections - Schedule of ClassesAileen May Santillan HerreraОценок пока нет

- Trans Front Page Expt 2Документ1 страницаTrans Front Page Expt 2Aileen May Santillan HerreraОценок пока нет

- Antenna LectureДокумент20 страницAntenna LectureAileen May Santillan HerreraОценок пока нет

- Frenzel Self Test Chapter 9Документ6 страницFrenzel Self Test Chapter 9Aileen May Santillan HerreraОценок пока нет

- Trans Attendance SheetДокумент2 страницыTrans Attendance SheetAileen May Santillan HerreraОценок пока нет

- Calendar SY 1617Документ18 страницCalendar SY 1617Aileen May Santillan HerreraОценок пока нет

- For Oral RecitationДокумент2 страницыFor Oral RecitationAileen May Santillan HerreraОценок пока нет

- Numerical Methods Laboratory ExerciseДокумент8 страницNumerical Methods Laboratory ExerciseAileen May Santillan HerreraОценок пока нет

- Numerical Methods Sample QuizДокумент6 страницNumerical Methods Sample QuizAileen May Santillan HerreraОценок пока нет

- Energy Conversion Lec 1Документ5 страницEnergy Conversion Lec 1Aileen May Santillan HerreraОценок пока нет

- Sample For Energy ConversionДокумент1 страницаSample For Energy ConversionAileen May Santillan HerreraОценок пока нет

- Block Diagram of 2-Input Intruder AlertДокумент1 страницаBlock Diagram of 2-Input Intruder AlertAileen May Santillan HerreraОценок пока нет

- Energy Conversion Expt1Документ1 страницаEnergy Conversion Expt1Aileen May Santillan HerreraОценок пока нет

- Print For Pcomms NotesДокумент2 страницыPrint For Pcomms NotesAileen May Santillan HerreraОценок пока нет

- Narrative Report (Amplifier Kit)Документ3 страницыNarrative Report (Amplifier Kit)Aileen May Santillan HerreraОценок пока нет

- Time MON TUE WED THU FRI SATДокумент10 страницTime MON TUE WED THU FRI SATAileen May Santillan HerreraОценок пока нет

- Engg Eco Intro SummaryДокумент5 страницEngg Eco Intro SummaryAileen May Santillan HerreraОценок пока нет

- Socialization Second Sem 14-15Документ27 страницSocialization Second Sem 14-15Aileen May Santillan HerreraОценок пока нет

- Adamson University Electronics Engineering Discrete and Continuous Time Signal GenerationДокумент8 страницAdamson University Electronics Engineering Discrete and Continuous Time Signal GenerationAileen May Santillan HerreraОценок пока нет

- Sleepyhead AwardДокумент2 страницыSleepyhead AwardAileen May Santillan HerreraОценок пока нет

- AM Transmission Chapter SummaryДокумент7 страницAM Transmission Chapter SummaryAileen May Santillan HerreraОценок пока нет

- PatternДокумент2 страницыPatternAileen May Santillan HerreraОценок пока нет

- Schedule 41Документ1 страницаSchedule 41Aileen May Santillan HerreraОценок пока нет

- Amway Final ReportДокумент74 страницыAmway Final ReportRadhika Malhotra75% (4)

- Bolt Jul 201598704967704 PDFДокумент136 страницBolt Jul 201598704967704 PDFaaryangargОценок пока нет

- How To Install Windows XP From Pen Drive Step by Step GuideДокумент3 страницыHow To Install Windows XP From Pen Drive Step by Step GuideJithendra Kumar MОценок пока нет

- Robotic End Effectors - Payload Vs Grip ForceДокумент8 страницRobotic End Effectors - Payload Vs Grip ForcesamirОценок пока нет

- TelanganaДокумент16 страницTelanganaRamu Palvai0% (1)

- Parking Garage LED Retrofit - 1 - Lighting-Guide - Rev.082015 PDFДокумент2 страницыParking Garage LED Retrofit - 1 - Lighting-Guide - Rev.082015 PDFmonsОценок пока нет

- Falling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsДокумент18 страницFalling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsEdisson Eduardo Valencia Gomez100% (1)

- S 212 Pre Course WorkДокумент5 страницS 212 Pre Course Workafiwierot100% (2)

- L P 10Документ13 страницL P 10Bình Minh HoàngОценок пока нет

- Digital MarketingДокумент70 страницDigital MarketingTarun N. O'Brain Gahlot0% (2)

- T Cells & Autoimmunity, s3Документ21 страницаT Cells & Autoimmunity, s3LiaAriestaОценок пока нет

- SPSS-TEST Survey QuestionnaireДокумент2 страницыSPSS-TEST Survey QuestionnaireAkshay PatelОценок пока нет

- PPC2000 Association of Consultant Architects Standard Form of Project Partnering ContractДокумент5 страницPPC2000 Association of Consultant Architects Standard Form of Project Partnering ContractJoy CeeОценок пока нет

- Gantt Chart Engr110 - Gantt Chart Template 3Документ1 страницаGantt Chart Engr110 - Gantt Chart Template 3api-375485735Оценок пока нет

- Occupant Load CalculationsДокумент60 страницOccupant Load CalculationsKAIVALYA TIWATNEОценок пока нет

- Serto Up To Date 33Документ7 страницSerto Up To Date 33Teesing BVОценок пока нет

- Current Developments in Testing Item Response Theory (IRT) : Prepared byДокумент32 страницыCurrent Developments in Testing Item Response Theory (IRT) : Prepared byMalar VengadesОценок пока нет

- Arts9 q4 Mod1 Theatricalforms v5Документ30 страницArts9 q4 Mod1 Theatricalforms v5Harold RicafortОценок пока нет

- Ceeshsworkingstudents Abm Group2Документ18 страницCeeshsworkingstudents Abm Group2kzz9c5hqrwОценок пока нет

- Self ReflectivityДокумент7 страницSelf ReflectivityJoseph Jajo100% (1)

- Template - Time in ManufacturingДокумент2 страницыTemplate - Time in ManufacturingVero RoaОценок пока нет

- Telegra Manual - DatasheetДокумент79 страницTelegra Manual - DatasheetNilanjan Chakravortty100% (1)

- New Japa Retreat NotebookДокумент48 страницNew Japa Retreat NotebookRob ElingsОценок пока нет

- Rock Laboratory PricelistДокумент1 страницаRock Laboratory PricelistHerbakti Dimas PerdanaОценок пока нет

- WBC Study Reveals God's NatureДокумент11 страницWBC Study Reveals God's NatureSherwin Castillo DelgadoОценок пока нет

- Seminar 6 Precision AttachmentsДокумент30 страницSeminar 6 Precision AttachmentsAmit Sadhwani67% (3)

- Department of Education Doña Asuncion Lee Integrated School: Division of Mabalacat CityДокумент2 страницыDepartment of Education Doña Asuncion Lee Integrated School: Division of Mabalacat CityRica Tano50% (2)

- PHILHIS Executive Summary - EditedДокумент7 страницPHILHIS Executive Summary - EditedMaxy Bariacto100% (1)

- Business Plan1Документ38 страницBusiness Plan1Gwendolyn PansoyОценок пока нет

- Jeremy Hughes ReviewДокумент5 страницJeremy Hughes ReviewgracecavОценок пока нет