Академический Документы

Профессиональный Документы

Культура Документы

Effect of Numbers of Fringing Electric Field (FEF) Fingers On The Performance of Sensor For Water Content in Soil

Загружено:

อภิฌาน กาญจนวาปสถิตย์Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Effect of Numbers of Fringing Electric Field (FEF) Fingers On The Performance of Sensor For Water Content in Soil

Загружено:

อภิฌาน กาญจนวาปสถิตย์Авторское право:

Доступные форматы

International Journal of Materials, Mechanics and Manufacturing, Vol. 1, No.

1, February 2013

Effect of Numbers of Fringing Electric Field (FEF) Fingers

on the Performance of Sensor for Water Content in Soil

Mohd Farizul Azman, Azmi Yahya, and Hadi Purwanto

= VW/VT

AbstractThe Fringing Electric Field (FEF) element design

consideration has been discussed in this paper. This type of

sensor is planned to be used for the Non-Destructive Test (NDT)

measurement of a moisture level in soil for irrigation system in

the field and green house. The effect of soil type and its

moisture level has been taken into account by preparing several

types of soil moisture level in the lab by performing

measurement and calculation as proposed by several papers. It

has been shown that the FEF parameters such as the dielectric

constant, numbers of finger for FEF design and the working

frequency played an important role for FEF design

considerations. The performance of the FEF element sensor

had been compared with the commercial sensor for

benchmarking.

(1)

where VW is the volume of water and VT = V soil + V water + V air

is the total volume. The operating principle of a fringing

electric field (FEF) sensor can be understood in terms of the

more conventional parallel plate capacitor (PPC), which is

commonly used to measure dielectric properties of materials.

Fig. 2 shows a gradual transition from the PPC to a fringing

field capacitor. The electrodes of the fringing field capacitor

are open up to provide one sided access to material under test

(MUT). Therefore the sensor can be fabricated on PCB and it

can access the soil from single side.

Index TermsFEF, fringing electric field, MUT, material

under test, NDT, non-destructive test, PCB, printed circuit

board, PPC, parallel plate capacitor, VWC, volumetric water

content.

Fig. 2. Transition from PPC to fringing filed capacitor.

I. INTRODUCTION

Fringing electric field (FEF) soil moisture sensor use

printed circuit board (PCB) technology as the sensor platform

and is fabricated on the selected PCB material. The electrical

capacitance of sensor uses the soil as a dielectric which

depends on the soil water content. The measurement is done

at a fixed frequency. Soil consists of air, water and solids as

shown in Fig. 1.

Soil moisture would change the relative permittivity of the

capacitor. Therefore, changes in VWC of the soil would

change the capacitance of the sensor. The FEF sensor in this

study is comprised of two set coplanar electrodes which are

excitation electrode and sensing electrode. The electric fields

originating from the driving electrodes will penetrate through

the soil and then terminate on the sensing electrodes. The

dielectric properties of the soil will alter the distribution of

the electric field lines. The capacitance on the sense

electrodes is then measured using precision LCR meter.

Because the electric field of the sensors is non-uniform, the

measurement sensitivity becomes position-dependent. The

signal strength of the sensor changes exponentially with its

distance to the soil. Measurement also depends on the

penetration depth of the field which is mainly affected by the

geometry parameter used in the sensor design. The fringing

electric field distributed beyond the penetration depth is

weak. Therefore the sensor only measures the property of the

adjacent soil.

This work will discuss the effect of the numbers of FEF

fingers and excitation frequency when designing the FEF

elements for measuring soil moisture level.

Fig. 1. Elements of soils.

Volumetric water content (VWC) of soil is the ratio of the

volume of water over the total value of soil. Volumetric water

content, , is defined mathematically as:

Manuscript received December 5, 2012; revised February 6, 2013.

Mohd Farizul Azman and Azmi Yahya are with the Department of Green

Technology and Engineering Support in MIMOS Berhad, Technology Park

Malaysia, 57000 Kuala Lumpur, Malaysia (e-mail: {farizul.azman,

azmiya}@mimos.my).

Hadi Purwanto is with the Faculty of Engineering, International Islamic

University of Malaysia, Jalan Gombak, 53100 Kuala Lumpur, Malaysia

(e-mail: hadi@iium.edu.my).

DOI: 10.7763/IJMMM.2013.V1.10

II. RESEARCH SUMMARY

The capacitance value from FEF element can be calculated

from the formula derived by the conformal mapping method

produced by the Schwarz-Christoffel transform [1], [2]. This

mapping method shows the transition from parallel plate

46

International Journal of Materials, Mechanics and Manufacturing, Vol. 1, No. 1, February 2013

capacitor to fringing field capacitor as shown in Fig. 2. From

this mapping, the FEF capacitance value is consist of two

external capacitance (Ce) and (N-2) internal capacitance (Ci)

as shown in Fig. 3 below. Thus, the calculation will be:

CFEF = 2

Ce + (N-2)

Ci

In this work, we prepared five types of FEF element which

consists of 5 to 9 finger patterns. The signal pattern from

SMA connector to electrodes are kept as 50 ohm as possible

to maintain the signal integrity to avoid any loss or distortion

[6]. Due to that, the PCB impedance is designed by

controlling the PCB thickness, track width and adding GND

plane underneath the track to keep 50 ohm impedance.

The preparation of soil with pre-define VWC is almost

impossible without a proper preparation and procedure.

Proper procedure will help to reduce the error in the prepared

soil. There are three steps detailed below:

(2)

A. Calculate the Bulk Density of Dry Soil

To calculate the bulk density of dry soil, the soil need to be

bake to ensure it is 100% dry and the weight (W) is measured.

Then measure the area (A) of the container being use and

measure the height (H) of soil in the container after it been

compressed. With the (A) and (H) value, the volume (V) of

dry soil is calculated. The bulk density (BD) of dry soil is

then calculated as:

Fig. 3. Capacitance inner (Ci) and external (Ce).

The capacitance also is calculated for FEF element that has

more than one finite dielectric layer as shown in Fig. 4 below.

Thus, the calculation Ci and Ce when more than one finite

layer is taking into consideration will be:

Ce = Ce (air) + Ce (1) + Ce (substrate)

(3)

Ci = Ci (air) + Ci (1) + Ci (substrate)

(4)

and

BD (DrySoil) = W (DrySoil) / V (DrySoil)

(5)

B. Preparing Wet Soil for VWC Test

The amount of water, V (Water) needed to prepare target

VWC can be calculate as:

These calculations method was derived from the

Schwarz-Christoffel transform to FEF capacitance as

discussed on [3]-[5].

V (Water) = Target VWC W (DrySoil) / BD (DrySoil) (6)

C. Actual VWC Measurement

The actual VWC measurement is conducted and recorded

by an external device to know the current VWC value of soil

before it can be used.

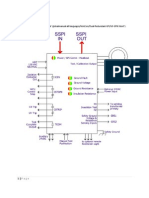

The measurement setup is consist of five types FEF

elements (5-9 finger FEF elements), five types MUT, LCR

meter and two coaxial cable to supply excitation signal and

read the capacitance.

Fig. 4. Multi-dielectric layer on FEF elements.

To make this capacitance work, the drive electrode will be

supplied with frequency. In this work, 100 kHz to 2 MHz will

be supplied to the electrode. The behavior of both parameters

will be studied in this work by using Cocopeat soil as the

material under test (MUT).

III. MATERIAL AND METHOD

The two electrodes that perform as FEF element are design

and printed on FR-4 type PCB material. The electrode

pattern is design to achieve the optimum capacitance value

with the given outlines. The parameter that is important for

the FEF design is the pattern width (W), length (L), spacing

(S), and the numbers of fingers (N) as shown in Fig. 5.

Fig. 6. Test setup for measuring capacitance versus soil VWC

In this work, assumption has been made that the

moisture of dry soil is an equal with the moisture on air.

Thus, the measurement of each FEF elements for 0% VWC is

by measuring the moisture content of the air. For 100%

VWC, the FEF elements are tested by put it into the DI water

and the prepared MUT was used to test FEF elements under

20%, 30% and 40% VWC. The FEF elements are inserted

into five different area of soil with remain the same height.

Then, the average value was plotted on the graph to show the

relation of different VWC for each FEF samples.

Fig. 5. FEF element.

47

International Journal of Materials, Mechanics and Manufacturing, Vol. 1, No. 1, February 2013

IV. RESULT AND DISCUSSION

During the testing, changes in VWC would change the

capacitance. These changes are recorded from 100 kHz to 2

MHz for each type of FEF elements that have a different

numbers of FEF fingers design. Result for the experiment

conducted is as shown in Fig.7-11 below.

Along the frequency range, the capacitance value of #5,

#6, and #7 fingers FEF elements on air is almost linear and it

is at the lowest capacitance level in the graph. The

capacitance value for a 100% VWC MUT is the highest level.

While the others moisture level, it is populated in between

dry soil and 100% VWC except for #8 and #9 fingers FEF

elements. At some frequency, the capacitance lines is very

close to each other and the measurement of soil moisture will

be difficult because there is no room for tolerance.

The calculation discussed in (1), (2) and (3) suggested that

the capacitance value should increase from 0%, 20%, 30%,

40% VWC until archived it saturation point proportionally.

From the result, this can be seen at 900 kHz frequency value

for #5, #6 and #7 fingers FEF elements, but the tolerance is

very small. In the other hand, the results for #8 and #9

fingers FEF element does not achieve that and some of it

reading a negative capacitance value. This is related to the

complex dielectric constant of soil mixture. In general, it is a

function of: 1) frequency, temperature and salinity, 2) the

total VWC, 3) the relative fractions of bound and free water

(related to the soil surface area per unit volume), 4) the bulk

soil density, 5) the shape of the soil particles, and 6) the shape

of water inclusions [8]. The dielectric behaviors of soil are

represented by:

= ' + j ''

Fig. 9. Results for #7 fingers FEF.

Fig. 10. Results for #8 fingers FEF.

(7)

where imaginary part '' is known as dielectric loss, ''/ ' =

tan is the loss tangent, and the loss angle.

Fig. 11. Results for #9 fingers FEF.

The numbers of study carried out by Hoekstra and Delaney

(1974), Wang and Schmugge (1980), Hallikainen et al.

(1985) showed that soil texture have an effect on dielectric

constant behavior over frequency. The study also showed

that the dielectric constant is related to the behavior of water

being added to the dry soil. This behavior was explained by

the transition of bound water to free water of the dry soil

when water is added into it. In a dry soil, absorbed cations are

tightly held by negatively charged particle surfaces

composed predominantly of clay. When water is slowly

added into the system, salt precipitates go into the solution,

and the adsorbed cations partially diffuse into the solution

adjacent to the particle surfaces. In a low frequency, the ionic

conductivity of saline water may effect on the loss factor ''.

Consequently, high soil salinity may significantly influence

the dielectric properties of wet soils.

This may happened to the result of #8 and #9 fingers FEF

element because when the numbers of fingers increase, the

Fig. 7. Results for #5 fingers FEF.

Fig. 8. Results for #6 fingers FEF.

48

International Journal of Materials, Mechanics and Manufacturing, Vol. 1, No. 1, February 2013

sensing area become larger. Due to the gravity effect, water

content in each high of the MUT is not uniform. Thus, the

soil might have higher salinity contain in the bottom side

compared to the higher side. The high soil salinity may

significantly influence the dielectric properties of wet soil

that may results a negative capacitance value for the higher

VWC as shown in Fig. 10 and Fig. 11.

Fig. 12 shows the relation between capacitance versus

VWC for the best result in this study which is #6 fingers FEF

element. At 900 kHz, the increase of capacitance value is

proportional with the VWC value. This result shows two

different slope gradients: 1) 0% to 6% VWC and 2) 6% to

100% VWC. The first slope is when the moisture in soil is in

bond water stage and the other one is when in free water stage

where the water content in soil is above the transition level

WT.

Manufacturing in Islamic International University of

Malaysia and sponsored by MIMOS Berhad.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

N. Eidenberger and B. G. Zagar, Capacitive sensor design utilizing

conformal mapping methods, International Journal on Smart Sensing

and Intelligent Systems, vol. 5, no. 1, pp. 36-56, March 2012.

T. Sun, N. G. Green, and H. Morgan, Electric field analysis using

Schwarz-Christoffel mapping, Journal of Physics: Conference Series

142, pp. 1-6, 2008, DOI:10.1088/1742-6596/142/1/012029.

S. S. Gevorgian, T. Martinsson, P. L. J. Linner, and E. L. Kollberg,

CAD models for multilayered substrate interdigital capacitors, IEEE

Trans. on Microwave Theory and Technique, vol. 44, no. 6, June 1996.

R. Igreja and C. J. Dias, Analytical evaluation of the interdigital

electrodes capacitance for a multi-layered structure, Sensors and

Actuators A, vol. 112, pp. 291-301, 2004.

E. Chen and S. Y. Chou, Characteristics of coplanar transmission lines

on multilayer substrates: Modeling and experiments, IEEE Trans. on

Microwave Theory and Techniques, vol. 45, no. 6, pp. 939-944, June.

1997.

H. W. Johnson and M. Graham, High-Speed digital design: A

handbook of black magic, 1st ed. Prentice-Hall PTR, 1993, pp. 133-188.

J. Behari, Microwave dielectric behavior of wet soils, Remote

Sensing and Digital Image Processing, Springer, vol. 8, pp. 10, 2005.

Chukhlantsev, A. Alexander, Microwave radiometry of vegetation

canopies, Advances in Global Change Research Series, vol. 24,

Chapter 2, pp. 23-29, 2006.

Mohd Farizul Azman was born in Malaysia, in 1976. He

received an Advanced Diploma at Nagano National

Technology College in Japan in 1999. He is working at

MIMOS Berhad as a Senior Engineer and responsible for

PCB design and fabrication for MIMOS product. He is

currently studying a Master of Manufacturing in

International Islamic University of Malaysia. He is

certified PCB designer from IPC from 2011.

Fig. 12. Graph for #6 fingers FEF (Capacitance vs. VWC).

Azmi Yahya was born in Malaysia, in 1972. He received

a Degree in Electrical Engineering at Nagano University

Technology of Malaysia in 2012. He is working at

MIMOS Berhad as a Technician and responsible for PCB

design and fabrication for MIMOS product.

V. CONCLUSION

This study shows the relationship of the numbers of FEF

element fingers and operating frequency at low frequency

with regard to the VWC of soil. In this work, the suitable

frequency to be used to excite FEF element is at 900 kHz and

the element that is good for this application is #6 fingers FEF

element. Results at Fig. 12 shows there is a small tolerance

with the numbers of test on the same MUT. The soil moisture

measurement will take the second slope as it shows the real

water content in soil.

Hadi Purwanto was graduated from Institute

Technology Sepuluh Nopember, Indonesia and

completed his PhD in Metallurgy at Tohoku University,

Japan. He is currently a lecturer at the Department of

Manufacturing and Materials Engineering, International

Islamic University Malaysia. His research area of interest

are Iron making, Non-destructive testing, Biomass, Waste

materials and energy processing.

ACKNOWLEDGMENT

The author would like to thank the staff members that

fabricate the prototypes and advices along this process. This

work is for Master Degree completion in Master of

49

Вам также может понравиться

- Dragon SPSL-HF 4.0 Manual de Servicio PDFДокумент222 страницыDragon SPSL-HF 4.0 Manual de Servicio PDFAbraham Elias Sarquis Luna100% (2)

- Testing and Commissioning of MVHV CablesДокумент7 страницTesting and Commissioning of MVHV CablesFernando Patiño GuevaraОценок пока нет

- Frequency Electrical Conductivity and Te PDFДокумент12 страницFrequency Electrical Conductivity and Te PDFZhraa NorОценок пока нет

- Frequency, Electrical Conductivity and Temperature Analysis of A Low-Cost Capacitance Soil Moisture SensorДокумент12 страницFrequency, Electrical Conductivity and Temperature Analysis of A Low-Cost Capacitance Soil Moisture SensorandrewОценок пока нет

- Measurements of Soil Redox PotentialДокумент7 страницMeasurements of Soil Redox PotentialMehedi HasanОценок пока нет

- Efficient Soil Moisture Measurement Using Microwave Surface Reflection MethodДокумент6 страницEfficient Soil Moisture Measurement Using Microwave Surface Reflection MethodGarudaOzoОценок пока нет

- An Empirical Model For The Complex Dielectric Permittivity of Soils As A Function of Water Content PDFДокумент8 страницAn Empirical Model For The Complex Dielectric Permittivity of Soils As A Function of Water Content PDF조성철Оценок пока нет

- Modeling The Compression Index For Fine Soils Using An Intelligent MethodДокумент8 страницModeling The Compression Index For Fine Soils Using An Intelligent MethodInternational Network For Natural SciencesОценок пока нет

- AGU - IPoster Printed v8 FINAL Presented at ConferenceДокумент16 страницAGU - IPoster Printed v8 FINAL Presented at ConferenceLeopoldoОценок пока нет

- Wet Soil DielectricДокумент12 страницWet Soil DielectricCollier LuntОценок пока нет

- Measuring and Modeling: Soil Hydraulic Characteristics: Moisture Content MeasurementДокумент43 страницыMeasuring and Modeling: Soil Hydraulic Characteristics: Moisture Content MeasurementLokesh KОценок пока нет

- Measurement and Simulation of Grounding Resistance With Two and Four Mesh GridsДокумент6 страницMeasurement and Simulation of Grounding Resistance With Two and Four Mesh GridscphcricriОценок пока нет

- Measuring and Modeling: Soil Hydraulic Characteristics: Moisture Content MeasurementДокумент41 страницаMeasuring and Modeling: Soil Hydraulic Characteristics: Moisture Content MeasurementDipankar nathОценок пока нет

- Soil Moisture MeasurementsДокумент7 страницSoil Moisture MeasurementsbdromeiraОценок пока нет

- Adv - Sci.Lett. 19 (3) 858-861, 2013Документ4 страницыAdv - Sci.Lett. 19 (3) 858-861, 2013pachisjovОценок пока нет

- EN 1991-1-4 NA enДокумент4 страницыEN 1991-1-4 NA enanuj3936100% (1)

- Mitigation of Installation Related EffecДокумент36 страницMitigation of Installation Related EffecABBA MALLAОценок пока нет

- Ijeee 15-18 - 1 - 1Документ4 страницыIjeee 15-18 - 1 - 1AmitKumarОценок пока нет

- Paper4-Estimation of Soil Moisture in Paddy Field Using Artificial Neural NetworksДокумент5 страницPaper4-Estimation of Soil Moisture in Paddy Field Using Artificial Neural NetworksIjarai ManagingEditorОценок пока нет

- A Rectangular Patch Antenna Technique For The Determination of Moisture Content in SoilДокумент6 страницA Rectangular Patch Antenna Technique For The Determination of Moisture Content in Soilsanthosh kОценок пока нет

- Design of Earthing SystemДокумент4 страницыDesign of Earthing SystemhughgossОценок пока нет

- Resume Jurnal GeolistrikДокумент6 страницResume Jurnal GeolistrikbidaraaaОценок пока нет

- Dielectric Properties and Influence of Conductivity in Soils at One To Fifty MegahertzДокумент10 страницDielectric Properties and Influence of Conductivity in Soils at One To Fifty MegahertzDani AliquintuiОценок пока нет

- Multimodeling With Pedotransfer Functions. Documentation and User Manual For PTF Calculator (Calcptf)Документ26 страницMultimodeling With Pedotransfer Functions. Documentation and User Manual For PTF Calculator (Calcptf)Fábio MathiasОценок пока нет

- Soilsystems 04 00061Документ20 страницSoilsystems 04 00061franco123456novОценок пока нет

- L. Weiherm Uller, J.A. Huisman, S. Lambot, M. Herbst and H. VereeckenДокумент9 страницL. Weiherm Uller, J.A. Huisman, S. Lambot, M. Herbst and H. VereeckenhanifnafriОценок пока нет

- Horton Model: Recirculating Furrow InfiltrometerДокумент7 страницHorton Model: Recirculating Furrow InfiltrometerMaria ConceptionОценок пока нет

- On-Site Diagnosis of Transformers Case StudiesДокумент15 страницOn-Site Diagnosis of Transformers Case Studiestsogbadrakh ArvanОценок пока нет

- Hydrogeophysical Model PDFДокумент13 страницHydrogeophysical Model PDFvan huu tranОценок пока нет

- Numerical Modeling On Vibro Otation Soil Improvement Techniques Using A Densi Cation Constitutive LawДокумент10 страницNumerical Modeling On Vibro Otation Soil Improvement Techniques Using A Densi Cation Constitutive LawPiotr ZielińskiОценок пока нет

- Frequency-Dependent Equivalent Linearized TechniqueДокумент8 страницFrequency-Dependent Equivalent Linearized Techniquetimoss74Оценок пока нет

- Fluent Help Evaporation TutorialДокумент5 страницFluent Help Evaporation TutorialsidyantОценок пока нет

- Ement As A Moisture .TR RansДокумент4 страницыEment As A Moisture .TR RansAldo Sempértegui TapiaОценок пока нет

- Parametrization of Soil Thermal Conductivity in THДокумент9 страницParametrization of Soil Thermal Conductivity in THantog06Оценок пока нет

- Calibration of A Frequency Domain Reflectometry Sensor For Humid Tropical Soils PDFДокумент5 страницCalibration of A Frequency Domain Reflectometry Sensor For Humid Tropical Soils PDFthiagoduarteОценок пока нет

- SMOS L2 Algorithm Over Forests: Description and Generation of Global MapsДокумент22 страницыSMOS L2 Algorithm Over Forests: Description and Generation of Global MapsprabhuОценок пока нет

- Mukesh Paper 30mДокумент22 страницыMukesh Paper 30mABDELLAH AATTARОценок пока нет

- CE6405-Soil Mechanics 2Документ10 страницCE6405-Soil Mechanics 2Sekar DineshОценок пока нет

- Soil IonisationДокумент14 страницSoil IonisationVKPMОценок пока нет

- Journal of Hydrology: Heidi Mittelbach, Irene Lehner, Sonia I. SeneviratneДокумент11 страницJournal of Hydrology: Heidi Mittelbach, Irene Lehner, Sonia I. Seneviratneandrew100% (1)

- Scholar Search: A Simple Polysilicon Thin-Film Transistor SPICE ModelДокумент5 страницScholar Search: A Simple Polysilicon Thin-Film Transistor SPICE ModelBojan MilojevicОценок пока нет

- ECE+412+ECE+5513+Project Antenna+Height-Gain+FactorДокумент2 страницыECE+412+ECE+5513+Project Antenna+Height-Gain+Factorsuman.k.das83Оценок пока нет

- Time Domain: Miftakhur Rahmat 3714100052 Tugas Eksplorasi GeolistrikДокумент6 страницTime Domain: Miftakhur Rahmat 3714100052 Tugas Eksplorasi GeolistrikMiftakhur RahmatОценок пока нет

- Testing Procedure (Zaihashraf)Документ11 страницTesting Procedure (Zaihashraf)Aiman DanishОценок пока нет

- Evaluation of A Microclimate Model For PДокумент12 страницEvaluation of A Microclimate Model For Pandhy batoОценок пока нет

- Evaluation of A Microclimate Model For PДокумент12 страницEvaluation of A Microclimate Model For Pandhy batoОценок пока нет

- MERJ-Vol-9, 2013, Page 1-6 PDFДокумент6 страницMERJ-Vol-9, 2013, Page 1-6 PDFWunkey WunkruОценок пока нет

- 05 Bellan 01Документ9 страниц05 Bellan 01shotlubОценок пока нет

- Evaporation Crete 2011Документ12 страницEvaporation Crete 2011MauroОценок пока нет

- TR321Документ54 страницыTR321Phani KumarОценок пока нет

- Triangle Models and MisconceptionsДокумент4 страницыTriangle Models and MisconceptionsSEP-PublisherОценок пока нет

- Purdue University: Time Domain Reflectometry Tests of Multilayered SoilsДокумент17 страницPurdue University: Time Domain Reflectometry Tests of Multilayered SoilsCSEngineerОценок пока нет

- Evaluation of Some Assumptions Used in Multizone Airflow Network ModelsДокумент26 страницEvaluation of Some Assumptions Used in Multizone Airflow Network Modelsshosh82Оценок пока нет

- Using Machine Learning To Predict Optimal ElectromДокумент28 страницUsing Machine Learning To Predict Optimal ElectromAbdulrahman ElwafiОценок пока нет

- Combining Near-Field Measurement and Simulation For EMC Radiation AnalysisДокумент5 страницCombining Near-Field Measurement and Simulation For EMC Radiation AnalysisLOUKILkarimОценок пока нет

- Valve Control System On A Venturi To Control FiO2 A Portable Ventilator With Fuzzy Logic Method Based On MicrocontrollerДокумент10 страницValve Control System On A Venturi To Control FiO2 A Portable Ventilator With Fuzzy Logic Method Based On MicrocontrollerIAES IJAIОценок пока нет

- SensorsДокумент23 страницыSensorsmythriОценок пока нет

- Amt 2020 479Документ27 страницAmt 2020 479Bùi Thanh AnОценок пока нет

- Soil Moisture Measurement InstrumentationДокумент8 страницSoil Moisture Measurement InstrumentationNguyen Di KhanhОценок пока нет

- CDEGS Versus WinIGS in Soil Modelling ApplicationsДокумент14 страницCDEGS Versus WinIGS in Soil Modelling ApplicationssanibubaОценок пока нет

- Fluid Dynamics in Complex Fractured-Porous SystemsОт EverandFluid Dynamics in Complex Fractured-Porous SystemsBoris FaybishenkoОценок пока нет

- OPNET STK Modeling UAV NetworkДокумент63 страницыOPNET STK Modeling UAV Networkอภิฌาน กาญจนวาปสถิตย์Оценок пока нет

- 1 s2.0 S1877042813026360 MainДокумент9 страниц1 s2.0 S1877042813026360 MainHemanth KrishnaОценок пока нет

- Image Stitching Using MatlabДокумент5 страницImage Stitching Using Matlabอภิฌาน กาญจนวาปสถิตย์Оценок пока нет

- High Speed PCB LayoutДокумент41 страницаHigh Speed PCB Layoutizzati_2607Оценок пока нет

- Nmos and Pmos PspiceДокумент15 страницNmos and Pmos PspiceshreenandanraoОценок пока нет

- Models - Acdc.capacitor DCДокумент16 страницModels - Acdc.capacitor DCFrancisco Rafael CerónОценок пока нет

- Principles of Communication Systems by Taub & SchillingДокумент119 страницPrinciples of Communication Systems by Taub & SchillingInsane Clown Prince40% (5)

- Pspice Mos Tut5Документ20 страницPspice Mos Tut5Dhanesh MuraliОценок пока нет

- PSpice TutorialДокумент30 страницPSpice TutorialMurali SriramОценок пока нет

- A MA TLAB-based Simulation Program For Indoor Visible Light Communication SystemДокумент5 страницA MA TLAB-based Simulation Program For Indoor Visible Light Communication Systemอภิฌาน กาญจนวาปสถิตย์Оценок пока нет

- Electromechanical InstrumentsДокумент17 страницElectromechanical Instrumentsอภิฌาน กาญจนวาปสถิตย์Оценок пока нет

- NCS1Документ186 страницNCS1getter2Оценок пока нет

- Sanwa YX-360TR MultitesterДокумент14 страницSanwa YX-360TR Multitestersupun_tharanga100% (1)

- Chap 02Документ41 страницаChap 02อภิฌาน กาญจนวาปสถิตย์Оценок пока нет

- 5990 5197enДокумент15 страниц5990 5197enSunu PradanaОценок пока нет

- Digital Key Coded LockДокумент11 страницDigital Key Coded LockEngr. Zeeshan mohsin100% (1)

- Pr1613adf PDFДокумент2 страницыPr1613adf PDFhaerulamriОценок пока нет

- UV Charger Retrofit Kit 25500365A0 - 1216Документ20 страницUV Charger Retrofit Kit 25500365A0 - 1216Carlos VélizОценок пока нет

- Paribhashik ShabdawaliДокумент5 страницParibhashik Shabdawalisgangwar2005sg100% (1)

- ATP EMTP Model of TPX, TPY and TPZ Current Transformers For RealisticДокумент4 страницыATP EMTP Model of TPX, TPY and TPZ Current Transformers For RealisticBalajiОценок пока нет

- Control Solenid Main Mod Control Circuit High P0963Документ4 страницыControl Solenid Main Mod Control Circuit High P0963Christian Ramos Alarcon100% (1)

- Narayana: Common Practice Test-7Документ13 страницNarayana: Common Practice Test-7AshutoshОценок пока нет

- 5 THДокумент20 страниц5 THbertovalenОценок пока нет

- Artemide. 5 Years WarrantyДокумент126 страницArtemide. 5 Years Warrantysalah eddine derkaouiОценок пока нет

- Typical Noise Levels in Power SubstationДокумент2 страницыTypical Noise Levels in Power SubstationRobert GalarzaОценок пока нет

- GCL-P6/72: High Efficiency Multicrystalline ModuleДокумент2 страницыGCL-P6/72: High Efficiency Multicrystalline ModuleNetoHolandaОценок пока нет

- University of Engineering and Technology Lahore (Narowal Campus) Experiment No. 9 Frequency Modulation & Demodulation Using MATLABДокумент7 страницUniversity of Engineering and Technology Lahore (Narowal Campus) Experiment No. 9 Frequency Modulation & Demodulation Using MATLABMuhammad Hanan AsgharОценок пока нет

- Boss rv6 Manual PDFДокумент1 страницаBoss rv6 Manual PDFwplaisОценок пока нет

- Basics For The GFMДокумент6 страницBasics For The GFMReno BoilardОценок пока нет

- CSMP67: en Es FRДокумент41 страницаCSMP67: en Es FRGerson FelipeОценок пока нет

- Check List and Testing ProcedureДокумент3 страницыCheck List and Testing ProcedureSheikh Shoaib RezaОценок пока нет

- Battery Specification: Document Number & RevisionДокумент23 страницыBattery Specification: Document Number & RevisionEricОценок пока нет

- Lightning Strike and Surge CounterДокумент2 страницыLightning Strike and Surge Countersampath muthunayakeОценок пока нет

- 3 Phase Transformer Vector GroupsДокумент35 страниц3 Phase Transformer Vector GroupsAbhishek Modak100% (2)

- MDoor Indicators EN 2013 PDFДокумент3 страницыMDoor Indicators EN 2013 PDFRudy IndrawanОценок пока нет

- Comparator Design and Analysis For Comparator-Based Switched-Capacitor CircuitsДокумент182 страницыComparator Design and Analysis For Comparator-Based Switched-Capacitor CircuitsAMSA84Оценок пока нет

- Tutorial Sheet - 3 2020Документ2 страницыTutorial Sheet - 3 2020guddu guptaОценок пока нет

- Annex 2 - Delivery Format - Task 2Документ13 страницAnnex 2 - Delivery Format - Task 2david giraldo lopezОценок пока нет

- Energy StorageДокумент146 страницEnergy StorageGuillermo Lopez-FloresОценок пока нет

- Centro-Matic Automated Lubrication Systems: System ControlsДокумент8 страницCentro-Matic Automated Lubrication Systems: System ControlsAlex Rivera RiveraОценок пока нет

- S60-ch3 Ddeciv PDFДокумент184 страницыS60-ch3 Ddeciv PDFAlex BravoОценок пока нет

- Lecture 2Документ8 страницLecture 2Mustafa Khider100% (1)

- DMX LED RGB Crystal Magic Ball ManualДокумент4 страницыDMX LED RGB Crystal Magic Ball ManualImporta de ChinaОценок пока нет