Академический Документы

Профессиональный Документы

Культура Документы

AISC Sections

Загружено:

raymondАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AISC Sections

Загружено:

raymondАвторское право:

Доступные форматы

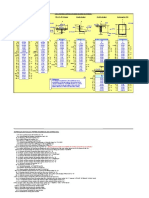

AISC MEMBER DIMENSIONS AND PROPERTIES VIEWER

W, S, M, HP Shapes

C, MC Shapes

Single Angles

Double Angles

Y

Y

Y

b=8

tf=8.128

bf=

x=0.773

t=0.25

d=3.5

tf=

d=127

tw=6.223

X

X

d=

tw=4.826

t=0.116

t=1

y=

x(bar)=0.484

d=201.422

Rectangular HSS

Y

k1=0.5625

tf=10.16

k=0.794

WT, ST, MT Shapes

d=8

H=6

y=1.02

tw=

b=3

(0, 3/8, or 3/4

bf=165.1

A=

d=

tw =

bf =

tf =

T=

k=

k1 =

gage =

rt =

d/Af =

Ix =

Sx =

rx =

Iy =

Sy =

ry =

Zx =

Zy =

J=

Cw =

a=

Wno =

Sw =

Qf =

Qw =

W8x24

7.08

201.42

6.22

165.10

10.16

6-1/8

0.79

0.56

3-1/2

1.76

3.05

34422338.90

342489.64

3.42

18.30

5.63

1.61

23.10

8.57

0.35

259

44.03

12.20

7.94

4.71

11.30

bf=44.45

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

A=

d=

tw =

bf =

tf =

T=

k=

gage =

x(bar) =

eo =

d/Af =

Ix =

Sx =

rx =

Iy =

Sy =

ry =

J=

Cw =

a=

ro(bar) =

H=

C5x6.7

1.97

127.000

4.826

44.450

8.128

3-1/2

0.7500

1

0.484

0.552

8.93

7.48

2.99

1.950

0.47

0.37

0.489

0.05

2.22

10.23

2.26

0.790

B=3

gap)

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

A=

d=

tw =

bf =

tf =

k=

Ix =

Sx =

rx =

y=

Iy =

Sy =

ry =

J=

Cw =

a=

ro(bar) =

H=

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

d=

b=

t=

k=

wt./ft. =

A=

Ix =

Sx =

rx =

y=

Iy =

Sy =

ry =

x=

rz =

TAN() =

J=

Cw =

a=

ro(bar) =

H=

L3-1/2x3x1/4

3.5

3

0.25

0.6250

5.38

1.58

1.92

0.77

1.100

1.020

1.30

0.59

0.908

0.773

0.628

0.725

0.036

0.027

1.39

1.81

---

in.

in.

in.

in.

plf.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

2L8x8x1

8

8

1

1.6250

103.00

30.20

178.00

31.60

2.430

2.360

3.390

3.520

3.660

4.56

0.834

d=

b=

t=

k=

wt./ft. =

A=

Ix =

Sx =

rx =

y=

ry(0) =

ry(3/8) =

ry(3/4) =

ro(bar) =

H=

in.

in.

in.

in.

plf.

in.

in.

in.

in.

in.

in.

in.

in.

in.

d=

b=

t=

wt./ft. =

A=

Ix =

Sx =

rx =

Iy =

Sy =

ry =

Zx =

Zy =

J=

HSS6x3x1/8

6

3

0.116

7.30

2.00

9.43

3.14

2.170

3.23

2.15

1.270

3.87

2.40

7.73

in.

in.

in.

plf.

in.

in.

in.

in.

in.

in.

in.

in.

in.

in.

Round HSS & Pipes

Y

in.

in.

in.

in.

Plates

Y

t=0.875

t=0.25

O.D.=8.63

b=12

I.D.=6.88

Reference:

The shapes contained in this database are a

compilation of those listed in the current AISC

"Shapes Database" CD-ROM Version 3.0 (June,

2001), as well as those listed in the AISC 9th

Edition Manual of Steel Construction (1989).

t=

b=

wt./ft. =

A=

Ix =

Sx =

rx =

Iy =

Sy =

ry =

1/ 4

12

10.21

3.000

0.016

0.125

0.072

36.000

6.000

3.464

in.

in.

plf.

in.

in.

in.

in.

in.

in.

in.

O.D. =

I.D. =

t=

wt./ft. =

A=

I=

S=

r=

PIPE8XXS

8.63

6.88

0.875

72.50

21.30

162.00

37.60

2.760

in.

in.

in.

plf.

in.

in.

in.

in.

J=

36.016

in.

J=

324.00

in.

NOMENCLATURE FOR AISC MEMBER PROPERTIES AND DIMENSIONS:

A=

d=

tw =

bf =

tf =

T=

k=

k1 =

gage =

rt =

d/Af =

Ix =

Sx =

rx =

Iy =

Sy =

ry =

Zx =

Zy =

J=

Cw =

a=

E=

G=

W no =

Sw =

Qf =

Qw =

x(bar) =

eo =

xo =

yo =

ro(bar) =

H=

LLBB =

SLBB =

STD =

XS =

XXS =

Cross-sectional area of member (in.^2)

Overall depth of member, parallel to X-axis (in.)

Thickness of web of member (in.)

Width of flange of member (in.)

Thickness of flange of member (in.)

Distance between fillets for wide-flange or channel shape (in.) = d-(2*k)

Distance from outer face of flange to web toe of fillet (in.)

Distance from web centerline to flange toe of fillet (in.)

Standard gage (bolt spacing) for member (in.) (Note: gages for angles are available by viewing comment box at cell K18.)

Radius of gyration of compression flange plus 1/3 of compression web area, taken about an axis in plane of web (in.)

Ratio of of total depth of member to area of compression flange of member = d/(b f*tf)

Moment of inertia of member taken about X-axis (in.^4)

Elastic section modulus of member taken about X-axis (in.^3)

Radius of gyration of member taken about X-axis (in.) = SQRT(I x/A)

Moment of inertia of member taken about Y-axis (in.^4)

Elastic section modulus of member taken about Y-axis (in.^3)

Radius of gyration of member taken about Y-axis (in.) = SQRT(Iy/A)

Plastic section modulus of member taken about X-axis (in.^3)

Plastic section modulus of member taken about Y-axis (in.^3)

Torsional constant of member (in.^4)

Warping constant (in.^6)

Torsional property, a = SQRT(E*Cw/G*J)

Modulus of elasticity of steel = 29,000 ksi

Shear modulus of elasticity of steel = 11,200 ksi

Normalized warping function at a point at the flange edge (in.^2)

Warping statical moment at a point on the cross section (in.^4)

Statical moment for a point in the flange directly above the vertical edge of the web (in.^3)

Statical moment at the mid-depth of the section (in.^3)

Distance from outside face of web of channel shape to Y-axis (in.)

Horizontal distance from the outer edge of a channel web to its shear center (in.) = (approx.) t f*(d-tf)^2*(bf-tw/2)^2/(4*Ix)-tw/2

x-coordinate of shear center with respect to the centroid of the section (in.)

y-coordinate of shear center with respect to the centroid of the section (in.)

Polar radius of gyration about the shear center (in.) = SQRT(xo^2+yo^2+(Ix+Iy)/A)

Flexural constant, H = 1-(xo^2+yo^2)/ro(bar)^2)

Long legs back-to-back for double angles

Short legs back-to-back for double angles

Standard weight (Schedule 40) pipe section

Extra strong (Schedule 80) pipe section

Double-extra strong pipe section

Вам также может понравиться

- AISC Properties ViewerДокумент4 страницыAISC Properties ViewerMáryuri CriadoОценок пока нет

- AISC Properties ViewerДокумент4 страницыAISC Properties ViewerJorge Luis Borghes CepedaОценок пока нет

- Aisc Member Dimensions and Properties ViewerДокумент4 страницыAisc Member Dimensions and Properties ViewercoolkaisyОценок пока нет

- Propiedades de Perfiles de Acero EstructuralДокумент5 страницPropiedades de Perfiles de Acero EstructuralmandomendoОценок пока нет

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationОт EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationОценок пока нет

- Aisc Properties Viewer Perfiles Estruct UsaДокумент30 страницAisc Properties Viewer Perfiles Estruct Usacristhian mayoОценок пока нет

- Aisc 13-0 Properties ViewerДокумент4 страницыAisc 13-0 Properties ViewerErnesto RQОценок пока нет

- Manual of Engineering Drawing: British and International StandardsОт EverandManual of Engineering Drawing: British and International StandardsРейтинг: 3.5 из 5 звезд3.5/5 (4)

- AISC 13.0 Properties ViewerДокумент12 страницAISC 13.0 Properties ViewerRam ValОценок пока нет

- Engineering Vibroacoustic Analysis: Methods and ApplicationsОт EverandEngineering Vibroacoustic Analysis: Methods and ApplicationsStephen A. HambricОценок пока нет

- AISC 14.1 Properties ViewerДокумент2 страницыAISC 14.1 Properties ViewerDivina Teja Rebanal-Glino0% (1)

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesОт Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesОценок пока нет

- Aisc 13.0 Properties RodrigoДокумент25 страницAisc 13.0 Properties RodrigoJosé Carlos TorrezОценок пока нет

- AISC 14.1 Properties ViewerДокумент2 страницыAISC 14.1 Properties ViewerJay GalvanОценок пока нет

- Aisc 13.0 Properties RodrigoДокумент21 страницаAisc 13.0 Properties RodrigoJavier Alejandro AñazgoОценок пока нет

- Aisc Edition Member Dimensions and Properties ViewerДокумент2 страницыAisc Edition Member Dimensions and Properties ViewerRoberto CatalaniОценок пока нет

- AISC Properties ViewerДокумент6 страницAISC Properties ViewerEriksson GillmarОценок пока нет

- Differential Forms on Electromagnetic NetworksОт EverandDifferential Forms on Electromagnetic NetworksРейтинг: 4 из 5 звезд4/5 (1)

- PERFILES Programa para Flexion y CorteДокумент16 страницPERFILES Programa para Flexion y CortePaolo Ordoñez SangaОценок пока нет

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsОт EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsОценок пока нет

- Diseño de Vigas A FlexionДокумент12 страницDiseño de Vigas A FlexionDaniel Peña FarfanОценок пока нет

- LRFD TablasДокумент3 страницыLRFD TablasFlorencio SandovalОценок пока нет

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОт EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОценок пока нет

- AISC 13th Edition Member Dimensions and Properties Viewer (2005) .Документ2 страницыAISC 13th Edition Member Dimensions and Properties Viewer (2005) .Jalal Naser FaqiryarОценок пока нет

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsОт EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikОценок пока нет

- AISC 13.0 Properties ViewerДокумент2 страницыAISC 13.0 Properties ViewerHenri Johonel Mejia VilchezОценок пока нет

- Aceros - AISCДокумент4 страницыAceros - AISCFreddy Gallo SanchezОценок пока нет

- Cylindrical Compression Helix Springs For Suspension SystemsОт EverandCylindrical Compression Helix Springs For Suspension SystemsОценок пока нет

- AISC Properties ViewerДокумент2 страницыAISC Properties ViewerHaris LeeОценок пока нет

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityОт EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityОценок пока нет

- Borrador A MomentoДокумент16 страницBorrador A MomentoDaniel Peña FarfanОценок пока нет

- AISC 13.0 Properties ViewerДокумент18 страницAISC 13.0 Properties ViewerramilianОценок пока нет

- Aisc Tabla PerfilesДокумент2 страницыAisc Tabla PerfilesRiky Ayala63% (8)

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsОт EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsОценок пока нет

- AISC (MM) PropertiesДокумент7 страницAISC (MM) PropertiesasrhaelОценок пока нет

- CALCULOSДокумент227 страницCALCULOSLuisHuamanQuilicheОценок пока нет

- AISC Properties MMДокумент31 страницаAISC Properties MMManuel JuanОценок пока нет

- Design of pile cap - PC2 (For 750x300 column) a Φ/5 a: cu 2 m y 2 mДокумент8 страницDesign of pile cap - PC2 (For 750x300 column) a Φ/5 a: cu 2 m y 2 mtheunknown076Оценок пока нет

- Aisc Shape W M S and HP Metric SeriesДокумент26 страницAisc Shape W M S and HP Metric SeriesJustine MagnayeОценок пока нет

- AISC Properties ViewerДокумент2 страницыAISC Properties ViewerNoeBongaОценок пока нет

- Single Shear Steel ConnectionДокумент36 страницSingle Shear Steel ConnectionNatalie WestОценок пока нет

- Double Angle Connection V2Документ13 страницDouble Angle Connection V2runkirОценок пока нет

- Aisc Shapes Database v16.0Документ7 страницAisc Shapes Database v16.0Mohsen GhiasiОценок пока нет

- Continuation of Machne DesignДокумент38 страницContinuation of Machne DesignHalley Mayer TorresОценок пока нет

- DEFINITIONSДокумент2 страницыDEFINITIONSRowell BeranaОценок пока нет

- Aashto Shear and TorsionДокумент4 страницыAashto Shear and Torsion3cesОценок пока нет

- Lecture Three - Welded ConnectionsДокумент30 страницLecture Three - Welded ConnectionsAhmedОценок пока нет

- Giant-Kelana Jaya First FLR Storage Area 500 1035 30 77 7.8: Bars Links Locat'n Mark Dia Nos Length Volume (MM) (M) (m3)Документ1 страницаGiant-Kelana Jaya First FLR Storage Area 500 1035 30 77 7.8: Bars Links Locat'n Mark Dia Nos Length Volume (MM) (M) (m3)raymondОценок пока нет

- Uniform Building Code Volume 21997Документ545 страницUniform Building Code Volume 21997raymond100% (1)

- Consumer Education: VCO Processing MethodsДокумент23 страницыConsumer Education: VCO Processing MethodsraymondОценок пока нет

- FoundationДокумент2 страницыFoundationraymondОценок пока нет

- AustraliaBoltingpage53 58Документ6 страницAustraliaBoltingpage53 58qaz111wsx222Оценок пока нет

- Description Applied Capacity % of Cap. Status: Job Number Job Title Punching Shear Check To BS 8110-1: 1985Документ3 страницыDescription Applied Capacity % of Cap. Status: Job Number Job Title Punching Shear Check To BS 8110-1: 1985raymondОценок пока нет

- Cantilever Retaining Wall - Metric PDFДокумент16 страницCantilever Retaining Wall - Metric PDFJebin JacobОценок пока нет

- m1911 A1 ReduxДокумент59 страницm1911 A1 ReduxPehr HedströmОценок пока нет

- Strength Analysis of Resistance Spot Weld-627Документ10 страницStrength Analysis of Resistance Spot Weld-627raymondОценок пока нет

- Connection Weld Bolt (06!06!2016)Документ21 страницаConnection Weld Bolt (06!06!2016)raymond100% (1)

- Girder DesignДокумент4 страницыGirder DesignraymondОценок пока нет

- Eurocode Side BarsДокумент6 страницEurocode Side BarsraymondОценок пока нет

- Base Plate and Anchor Bolt EurocodeДокумент45 страницBase Plate and Anchor Bolt Eurocoderaymond0% (1)

- AISC SectionsДокумент3 страницыAISC SectionsraymondОценок пока нет

- CE 632 Earth PressureДокумент18 страницCE 632 Earth PressureBala Sutharshan100% (1)

- Changes - ACI 318 - 05 PDFДокумент6 страницChanges - ACI 318 - 05 PDFraymondОценок пока нет

- Beam GravityДокумент11 страницBeam GravitylucianduОценок пока нет

- Elena Papadopoulos - Design of Column Base PlatesДокумент31 страницаElena Papadopoulos - Design of Column Base PlatesNoé InzunzaОценок пока нет

- Pile Cap DesignДокумент228 страницPile Cap Designraymond80% (5)

- Girder DesignДокумент4 страницыGirder DesignraymondОценок пока нет

- Math 6110 Pset 2Документ4 страницыMath 6110 Pset 2Miguel Antonio Leonardo SepulvedaОценок пока нет

- Advantages of Vedic MathsДокумент5 страницAdvantages of Vedic MathsPrem Kumar SОценок пока нет

- PV Row SpacingДокумент2 страницыPV Row Spacingpandi27100% (1)

- Rordam ICMДокумент18 страницRordam ICMusyoussef ufsОценок пока нет

- Levi-Civita and Christoffel Symbols - 2Документ4 страницыLevi-Civita and Christoffel Symbols - 2Asraf AliОценок пока нет

- Areas and Volumes of Similar ShapesДокумент6 страницAreas and Volumes of Similar ShapesTrúc HồОценок пока нет

- TBO Problem Solving Booklet SolutionsДокумент23 страницыTBO Problem Solving Booklet Solutionsyy100% (1)

- ScaraДокумент8 страницScararwurdigОценок пока нет

- Chapter 2 Application of DifferentiationДокумент21 страницаChapter 2 Application of Differentiationfaiz jojoОценок пока нет

- PhysicsSE 10 Ch03 PowerPointsДокумент42 страницыPhysicsSE 10 Ch03 PowerPointsmkdatosОценок пока нет

- Centre of Mass - (Step-2 - 3) - JEE 22-FinalДокумент36 страницCentre of Mass - (Step-2 - 3) - JEE 22-FinalAditya PahujaОценок пока нет

- Matrikulasi Malaysia: Matematik Kertas SesiДокумент7 страницMatrikulasi Malaysia: Matematik Kertas SesiNandОценок пока нет

- Maths 11 3Документ17 страницMaths 11 3api-230427224Оценок пока нет

- Mats College of Technology Modified Course Syllabus Math 107 - Teaching Math in The Primary GradesДокумент2 страницыMats College of Technology Modified Course Syllabus Math 107 - Teaching Math in The Primary GradesDiosdado II MarimonОценок пока нет

- St. Line PDFДокумент40 страницSt. Line PDFNeerraj YadavОценок пока нет

- A Warp Drive' With More Reasonable Total Energy RequirementsДокумент9 страницA Warp Drive' With More Reasonable Total Energy RequirementsCarlos BorrОценок пока нет

- Cambridge IGCSEДокумент16 страницCambridge IGCSEVivaan KothariОценок пока нет

- Fundamental of Financial MathematicsДокумент4 страницыFundamental of Financial MathematicsSin WeiОценок пока нет

- Kinematics: Grade 7 PhysicsДокумент68 страницKinematics: Grade 7 PhysicsHaryanti Putri RizalОценок пока нет

- Angeles City Science High School: First Quarterly Examinations Pre-CalculusДокумент3 страницыAngeles City Science High School: First Quarterly Examinations Pre-CalculusSyrus Dwyane RamosОценок пока нет

- Geometry and TrigonometryДокумент17 страницGeometry and Trigonometrychotumotu131111Оценок пока нет

- Geometry Set 2Документ5 страницGeometry Set 2Albert Thaw TunОценок пока нет

- Class 10 Maths Notes Chapter 3 Studyguide360Документ10 страницClass 10 Maths Notes Chapter 3 Studyguide360Magesh wari100% (1)

- Dynamics of Rigid Bodies Merian Book 2005Документ122 страницыDynamics of Rigid Bodies Merian Book 2005Denis PAОценок пока нет

- Nat Reviewer: Bagong Barrio National High School - Annex MathematicsДокумент3 страницыNat Reviewer: Bagong Barrio National High School - Annex MathematicsYuvey Josh DiskОценок пока нет

- TOS 1 Unit 4 Centre of Gravity and Moment of InertiaДокумент14 страницTOS 1 Unit 4 Centre of Gravity and Moment of Inertiaflower lilyОценок пока нет

- Jee Main 2022 - Coordinate Geometry & Conics SprintДокумент178 страницJee Main 2022 - Coordinate Geometry & Conics Sprints KUMARОценок пока нет

- Eiffel Tower Final RuffДокумент4 страницыEiffel Tower Final Ruffapi-208377715Оценок пока нет

- M - SC - (Mathematics) - 311 14 - Topology - I PDFДокумент264 страницыM - SC - (Mathematics) - 311 14 - Topology - I PDFLishii Ðë Lä Callë100% (1)

- Chapter Project03Документ2 страницыChapter Project03Dalia Al-dairyОценок пока нет