Академический Документы

Профессиональный Документы

Культура Документы

2raw Material

Загружено:

Ivana HalingkarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2raw Material

Загружено:

Ivana HalingkarАвторское право:

Доступные форматы

FAO Corporate Document Repository

2. RAW MATERIALS

2.1 Fish and Other Marine Foods

Many types of fish, and other marine foods are suitable for canning, the size of the

individual fish varying from that of the smallest sardines to that of the largest tuna

species. For some species like tuna and sardines canning is the most important

processing method. Other species, suitable for canning are salmon, mackerel, herring,

clams, oysters, shrimps, octopus, crab and white fish paste products.

The Codex Alimentarius Commission recommends the following species of Tuna,

Bonito, Salmon and Shrimps to be canned:

Canned Tuna and Bonito (CODEX STAN 70-1981)

Thunnus alalunga

Thunnus albacares

Thunnus atlanticus

Thunnus obesus

Thunnus thynnus maccoyii

Thunnus thynnus orientalis

Thunnus thynnus thynnus

Thunnus tongoll

Euthynnus affinis

Euthynnus alletteratus

Euthunnus lineatus

Euthynnus pelamis (syn: Katsuwonus pelamis)

Sarda chiliensis

Sarda orientalis

Sarda Sarda

Sarda velox

Canned Sardines (CODEX STAN 94-1981)

Sardinops melanosticta

Sardinops neopilchardus

Sardinops ocellata

Sardinops Sagax or Sardinops caerulea

Sardina pilchardus (Walbaum)

Clupea harengus

Clupea antipodum

Clupea bassensis or

Clupea fuegensis

Sprattus sprattus

(Clupea sprattus)

Sardinella aurita

Sardinella anchovia

Sardinella brasiliensis or

Sardinella maderensis

Hyperlophus vittatus

Nematolosa vlaminghi

Etrumeus microps

Ethmidium maculatus

Engraulis anchoita

Engraulis ringens

Canned Pacific Salmon (CAC/RS 3-1969. Rev.1)

Oncorhynchus nerka

Oncorhynchus kisutch

Oncorhynchus tschawytscha

Oncorhynchus gorbuscha

Oncorhynchus keta

Oncorhynchus masou

Species of the families

Penaeidae

Pandalidae

Crangonidae and

Palaemonidae

A variety of products can be made using minced fish as main raw material.

Fish Canning Process

FAO Corporate Document Repository

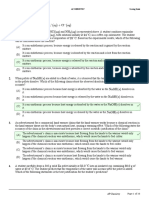

Unutilized or underutilized species (so called trashfish) with a nutritional value

comparable to that of valued food species can be an excellent source of raw material.

To plan the handling and processing of fish and to manage problems connected with all

operations from transport and processing through storage, it is essential to know the

physical and chemical properties of the species involved; these properties include

shape and size. thermal conductivity, chemical composition of fish and conditions

regarding post mortem changes. See Table 4.

Table 4. Various parts of the fish expressed in percentage of total weight and total fish

weight per cubic metre, for some important species used in canning

Percentage of total weight

Species

ton/m

Head

Skin &

flesh

Bones

Fins

Viscera

Atlantic

herring

12.5

62.2

6.5

1.5

15.0

0.91

Sardines

21.0

58.0

6.5

2.5

9.5

0.85

Atlantic

mackerel

22.5

52.0

8.0

1.0

19.5

0.96

Tuna

18.0

64.0

8.0

2.0

8.0

Pink

salmon

16.0

71.0 1/

5.0

8.0

0.95

1/ Including bones and gonads

2.2 fish handling

2.2.1 General

Information about fish handling prior to canning is given in detail in Planning and

Engineering Data, Fresh Fish Handling, FAO Fish. Circ. 735. In this context these data

are of most value where they concern operations of special importance for canning.

2.2.2 Fish handling on board

After washing, the raw material should be chilled as soon as possible, and kept chilled

until unloading. Depending on the type of fishing vessel the catch can be iced in boxes,

containers, or shallow bins.

In practice, however, methods for handling fish on board vary from doing little or

nothing, to chilling or freezing, depending on the type of vessels, area of catching and

fish species.

With large fish like tuna the most common method of handling on board smaller

vessels is washing and chilling with water and/or ice. Larger vessels are equipped with

tanks in which the fish is chilled. These tanks are either chilled sea water (CSW) tanks

or refrigerated sea water (RSW) tanks. The CSW- tanks are chilled with ice, and the

RSW- tanks are chilled by refrigeration. Air blast and brine freezing methods are also

commonly used. For more details concerning freezing methods, see "Freezing in

Fisheries". FAO Fisheries Technical Paper no. 167.

Fish Canning Process

FAO Corporate Document Repository

Smaller species are chilled in CSW or RSW- tanks, and when in small quantities, iced

in boxes.

Industrial species intended for mincing must be handled (as with any high valued food

fish) according to good handling practice. The fish must be washed, and if the raw

material is by-catch from bottom trawling, all mud, sand, etc. must be rinsed away. If

possible, the fish must be sorted, but in some areas this is difficult as the catch consists

of several species, each in small quantities.

2.2.3 Unloading fishing vessels

Care must be taken during unloading and handling in order to avoid bruised fish and/or

skin abrasions. Allhough systems for unloading and handling fish depend on various

factors, the most common methods are as follows:

i.

Fresh fish is humped from the fish hold through scales or volume measuring

equipment to rolling conveyors for further -transport, or directly to tanks, bins,

etc.

ii.

Fresh or frozen fish is loaded into baskets or cases, heaved to the quay, by

either electrical dock hoists or by use of the vessel's own winch. and then

tipped into containers, before transport, or into bins before gutting or transport.

When the fish is iced into boxes, J or containers. on board. it is unloaded in a

similar way. When the boxes are stacked on pallets the entire pallet load is

heaved up.

iii.

Fish kept in CSW or RSW-tanks is heaved from the fish tank by use of nets.

Fish in bulk may also unloaded this way.

iv.

A conveyor system may be used for unloading fresh and frozen fish.

2.2.4 Fish handling on land

The processes and principles involved in preparing fresh fish for canning are, for the

most part, similar to those that would be involved in preparing them for marketing as

fresh fish. Therefore the general instructions described in the Recommended

International Code of Practice should be used as a guide for the handling and

preparation of fresh fish for canning (CAC/RCP 9-1976 and CAC/RCP 10-1976).

For information concerning icing, CSW, RSW, chill storage, containers for raw

materials, materials, freezing and frozen storage, readers are referred to planning and

Engineering Data I - Fresh Fish handling, FAO, Fish. Circ. 735, and freezing in

Fisheries, FAO Fisheries "-"' Technical Paper no. 167".

If the fish consists of industrial species, and sorting is not practical, the raw material

can be stored in containers and mixed with ice until use. If possible, the fish should be

kept in the same boxes or containers, without emptying and reicing, as this will be the

best means of maintaining quality;. sometimes however this is not possible, especially

in cases where the fishermen want their catches weighed immediately after landing.

The less the handling of the iced and boxed/containerized raw material, the longer will

quality be maintained.

It is not recommended to freeze fish which is to be used as a minced raw material.

Fish Canning Process

FAO Corporate Document Repository

Frozen fish can be thawed by immersion in chilled water (temperatures above 15 C

are not advisable), water spraying or air current exposure. Thawing of frozen fish is an

important step in canned fish manufacture. For larger species, like tuna, thawing up to

12 hours or more is not unusual. As thawing of the fish is progressive, smaller species,

and exterior parts of larger species may reach the desired state of thaw while the inner

parts of larger species remain frozen.

Deterioration of fresh fish, especially whole uneviscerated tuna, is rapid at

temperatures sufficient to hasten thawing. The quality of the fresh tuna begins to

diminish before the last thawed portions have become unfrozen.

2.3 Ingredients and Additives

2.3.1 Quality requirements for water

All water available for use in those parts of an establishment where fish and shell fish

are received, kept, processed, packaged and stored should be potable water or clean

sea water and should be supplied at pressure of no less than 1.4 kg/cm.

An adequate supply of hot water of potable quality at a minimum temperature of 82C

should be available at all times during the plant operation (CAC/RCP 9-1976).

The cold water supply used for cleaning purposes should be fitted with an in-line

chlorination system allowing the residual chlorine content of the water to be varied at

will in order to reduce multiplication of micro-organisms and prevent the build-up of fish

odours.

Water used for washing or conveying raw materials should not be recirculated unless it

is restored to a level of potable quality.

Non-potable water may be used for such purposes as producing steam, cooling heat .

exchangers and fire protection. It is very important that both-systems of storage and

distribution of potable and non-potable water are entirely separate and there is no

possibility for cross-contamination or for inadvertent usage of non-potable water in the

fish or shellfish processing areas. Only potable water should be used for the supply of

hot water. The same requirements for the separation of systems would apply to clean

sea water when it is used in the processing of fish (CAC/RCP 9-1976).

2.3.2 Quality requirements for other ingredients and additives

Salt used for making brine or other purposes should be pure and not contain

appreciable quantities of magnesium chloride, a common contaminant of unrefined

salt. If the salt contains too much magnesium chloride the risk of struvite formation

increases; this may concern consumers as struvite can form crystals resembling glass

in the canned fish.

Salt should comply with the "Codex Alimentarius Specifications for Food Grade Salt"

(being-developed by the Codex Committee on Food Additives).

Olive oil intended for canning has to be one of the two following categories (Research

Laboratory of the Norwegian Canning Industry):

Fish Canning Process

FAO Corporate Document Repository

i.

Virgin olive oil produced by mechanical processes, or:

ii.

Olive oil produced by blending of virgin olive oil with chemically refined virgin

olive oil which is produced from pure virgin olive oil.

Olive oil intended for canning Norwegian sardines may be blended to a maximum of 35

% with chemically refined oil. For canned fish other than Norwegian sardines,

chemically refined virgin oil as such is accepted in addition to the olive oil specified.

Olive oil should be extracted from sound olives, without any admixture of other oils

(fat). Further, the oil must be free from any admixture of refined solvent-extracted olive

oil. Synthetic olive oil is strictly forbidden.

The oil shall be clear, free from mucilage, mould or other impurities. The oil shall also

be free from moisture.

The colour of the oil shall be yellow to golden with only a slight tinge of green.

Odour and taste of the oil shall be pure, good and natural, not acrid, bitter or too strong.

The oil must be resistant to cold.

Soya bean oil should be free from foreign and rancid odour and taste. Colour additives

are permitted for the purpose of restoring natural colour lost in processing or for the

purpose of standardizing colour, as long as the added colour does not deceive or

mislead the consumer by concealing damage or inferiority or by making the product

appear to be of greater than actual value.

Maximum level of use is not limited for such additives.

Natural flavours and their identical synthetic equivalents, except those which are known

to represent a toxic hazard, and other synthetic flavours approved by the Codex

Alimentarius Commission, are permitted if they fullfill the limitations mentioned in the

text above.

Other additives as antioxidants, antioxidant synergists and crystallization inhibitors are

permitted in soya bean oil.

Tomato sauce should be made from sound raw materials without any decomposition by

mould, yeast or bacteria. The canned tomato sauce should not contain microbes which

can develop at a normal storage temperature. The colour should be red, even with a

faint tinge of yellow, but never brownish. Odour and taste should be pure and natural.

The tomato sauce should be heterogeneous and not contain too much seeds or skin.

The total solids shall not exceed 30% (Tripple concentrated tomato sauces are not be

permitted). The content of sugar is not permitted to be reduced below 40% of. the total

amount of solids.

The tomato sauce must not contain any extraneous matters (such as carrots etc.).

Artificially colouring or any kind of preservatives, except salt are not permitted.

(Research Laboratory of the Norwegian Canning Industry).

Examples of other ingredients and additives used in the canning process are:

Fish Canning Process

FAO Corporate Document Repository

Pepper (Piper nigrum l.)

Cardemon (Elletria cardamomum)

Ginger (Zingiber officinale roscae)

Onion (Allium cepa allium ascalonicum)

Spirit vinegar (Solution containing vinegar acid, CH3

concentrate from 4 to 12 %)

Ground mustard seed (Brassica species)

Curry powder

Starch (potatoes flour)

Mono Sodium Glutamate (MSG)

Stabilizing agents as sodium alginate and gum tragacanth

Milk

Sugar

Wine

Beer

COOH,

The ingredients should be suitable for human consumption and be free from abnormal

taste, flavour and odour.

2.4 Packaging Materials

The most common material used for manufacturing containers for fish products are tin

plate, aluminium and lacquered steel plate (TFS). Flexible packaging as an alternative

to metal cans has become more common during the last years and glass jars are

sometimes used for speciality packs.

2.4.1 Tin plate

Tin plate is steel sheet coated with a thin layer of tin on each surface. Because of its

strength and rigidity tin plate forms an ideal material for food containers. In addition to

the benefits of its bright appearance and ease of soldering, the major function of the tin

layer is to protect the base steel from corrosion. Mechanical properties such as

strength, stiffness, etc., are controlled in the manufacturing process to suit the

specifications of the can maker. Minimum thickness of tin plate for can making is 0.15

mm (Palling, 1980). The main factors of importance are chemical composition and

physical properties of the base plate, thickness of tin coating, application of protective

coatings and relative corrosivity of the product which is to be canned.

Low carbon steel is used for can manufacture. The chemical composition of the base

steel plate is of primary importance in obtaining adequate service-life for corrosive,

products; the most critical element is phosphorus, but other elements such as copper

nickel, chromium and silicon may also affect the corrosion resistance of the plate. 'Two

basic types of stell (L and MR) are used for different food products and a third type (D)

is used for unusual drawing operations. For low-acid products, such as fish the steel

type has no important influence on corrosion and any of the available types may be

used, nevertheless MR steel is usually required. Originally tin plate coating weight

specifications were expressed in terms of the "base box" which was an industry

measure. Tin plate was sold in only one size sheet (356 x 508 mm), and bundled 112

sheets to a package. The total area of plate in such a package (20.22 m2) came to be

known as a base box, the weight of which varied with the thickness of the steel (Ellis,

1979).

Fish Canning Process

FAO Corporate Document Repository

Formerly, tin plate was made by immersing sheets of "black" plate in molten tin (hence

this plate was known as hot dip plate) .Nowadays electrolytic plating techniques are

used to apply tin to the base steel plate. This method permits thinner tin coatings (0.38

to 2.03 microns) on each side of the plate surface. The electrolytic tinning process

permits also a close control over deposition of the tin coating layer. The most common

coating weights are 0.25, 0.50, 0.75 and 1.00 lb per base box which corresponds to

5.6, 11.2, 16.8 and 22.4 g/m, respectively (when considering both plate surfaces). In

the metric system coating weight is expressed as the weight of tin on each surface.

Thus a total tin coating weight of 5.6 g/m is listed as 2.8/2.8 g/m (Ellis 1979), which

signifies that on each surface the tin coating weight is 2.8 g/m. Differentially coated tin

plate has different tin coating weights on each surface; the heavier coating usually

being on the inside of the container.

2.4.2 Tin-free steel (TFS)

The tin-free steel is one of the newer can-making materials. Untinned steel on which

very thin layers of chromium-oxide have been electrodeposited is resistance to

corrosion and discolouration. Disadvantages are that the plate must be, coated on both

sides and that it cannot be soldered. It is principally used for the ends of the cans.

2.4.3 Aluminium alloys

Aluminium alloys are finding increasing use in the can making industry. Advantages of

aluminium include the light weight of the material resistance to atmospheric corrosion

and to sulfide-bearing products (commonly found in fish products) and versatility for

making containers by different methods. Disadvantages include difficulties in closing

the body seam by soldering and the necessity for heavier gauges which are required to

obtain strength comparable with tin plate. Sheet made with pure aluminium has

mechanical and physical properties which limit its use as a can-making material.

Increased strength is obtained by alloying aluminium with one or more other metals

such magnesium and manganese. Minimum thickness of aluminium for use in fish cans

is 0.28 mm.

2.4.4 Enamel coatings

Enamel coatings are used to protect tin plate, aluminium alloys and TFS, The coatings

can be applied to sheets and coils either before and after cans are made. In some

cases, coatings make it possible to use more lightly coated grades of tin plate or tinfree steel. The enamels or lacquers were originally prepared from polymerized fish oil

but today lacquers are made from synthetic materials which provide better

performance.

2.4.5 Retortable pouches

Retortable pouches for thermoprocessed food as an alternative to metal cans and

glass jars have found increased use during recent years. The pouches are heat

sterilized in retorts and the sterility maintained by the impermeability of the material and

the hermetic seals of the pouches. Characteristics for their use include (Lampi, 1979)

convenience fore-heating by immersion in boiling water. rapid sterilization as the flat.

thin cross section of the pouch permits rapid heat transfer to the contents. energy

conservation. and space utilization.

Fish Canning Process

FAO Corporate Document Repository

Retortable pouches are made from rigid or flexible materials. Rigid pouches are

constructed with high density polyethylene (HDPE), whereas flexible pouches may be

made from a lamination which consists of an outer polyester ply, an aluminium foil, as

the primary material. and an inner ply which is made of modified polyolefin (medium to

high density polyethylene modified with polyisobutylene) or cast polypropylene.

Products are being commercially packed in a film described as 12 microns polyester, 9

microns aluminium oil, 15 microns nylon and 50 microns polypropylene, and processed

at temperatures up to 135 C for times ranging from 2.7 to 9 minutes (Lampi, 1979).

2.4.6 Glass

The principles of processing with glass are substantially the same as for cans, except

that there are some modifications necessary because of the sealing mechanism used

and the thermal characteristics of the glass. As with cans, glass containers must be

hermetically sealed; this is achieved by using a metal closure into which has been

placed a plastisol lining compound that acts as a sealant between the glass and the

metal cap.

Glass containers are processed under water in a counter-balanced retort. The water

prevents thermal shock breakage as steam enters the retort while the counterbalancing air transmits pressure through the water ensuring that at all times the

pressure in the retort is greater than that in the sealed container.

As glass is resistant to all food products no internal surface treatment is required. The

metal closures however must be protected from corrosion and for this reason are

internally and externally lacquered.

Table 5 Size of 2-piece cans for different types of the most important fish products

Type of

can

Material

Volume

(ml)

Length

(mm)

Width

(mm)

Height

(mm)

Product

Net

weight

(g)

Fish

weight

(g)

1/4 dingley

aluminium

tin plate

112

105

76

21.5

sardines,

small fish

106

85

1/4 club *

aluminium

tin plate

115

105

60

29

sardines,

small

fish, tuna

125

95

1/2 hansa *

aluminium

tin plate

200

148

81

26

herrings

195

130

1/2 oblong

aluminium

tin plate

212

154.7

61

30

kippers

225

225

1/3 oval

tin plate

200

149

81

25

mackerel

195

130

1/2 oval

tin plate

270

149

81

25

mackerel

250

180

* Noblikk-Sannem A/S standards.

Table 6 Size of 2- and 3-piece cans for different types of the most important fish

products

Type of

can

Material

Volume

(ml)

Diameter

(mm)

Height

(mm)

Product

Net

weight

(g)

Fish

weight

(g)

2-piece

round

aluminium

225

90

40

shrimp

217

150

2-piece

round

aluminium

115

78

32

shrimp

111

75

Fish Canning Process

FAO Corporate Document Repository

Type of

can

Material

2-piece

1/2 pound

round

aluminium

tin plate

Volume

(ml)

Diameter

(mm)

245

90

Height

(mm)

Product

Net

weight

(g)

Fish

weight

(g)

44

fish with

vegetables,

herring,

tuna

230

460

2-piece 1

pound

round

tin plate

490

120

49

fish with

vegetables,

herring,

tuna

3-piece

round

tin plate

212

83.8

46

tuna

200

155

3-piece

round

tin plate

400

99.5

60

tuna

377

292

3-piece

round

tin plate

450

72

119

cod roe in

brine

425

300

3-piece

round

tin plate

450

101

64

fish cakes

400

260

3-piece

round

tin plate

900

101

121

fish balls

800

520

3-piece 5

kg round

tin plate

4 250

218

123

tuna,

sardine

4 000

3 100

3-piece 10

kg round

tin plate

8 500

218

245

tuna

8 000

6 200

* Depends on amount of vegetables.

2.4.7 Construction of metal containers

Metal containers are normally divided into two groups:

2-piece cans (square, oval or round).

3-piece cans with soldered or welded body (square, oval or round).

Specifications for the most common metal containers are shown in Tables 5 and 6.

Fish Canning Process

Вам также может понравиться

- Mendelssohn Variation SerieusesДокумент2 страницыMendelssohn Variation SerieusesIvana HalingkarОценок пока нет

- Boy's Round Dance - Niels GadeДокумент3 страницыBoy's Round Dance - Niels GadeIvana HalingkarОценок пока нет

- Fountain in The Rain - GillockДокумент3 страницыFountain in The Rain - GillockIvana Halingkar33% (3)

- Sinfonia: For Other Uses, SeeДокумент4 страницыSinfonia: For Other Uses, SeeIvana HalingkarОценок пока нет

- Bach Partita For KeyboardsДокумент3 страницыBach Partita For KeyboardsIvana HalingkarОценок пока нет

- Music PeriodsДокумент20 страницMusic PeriodsIvana HalingkarОценок пока нет

- ToccataДокумент4 страницыToccataIvana HalingkarОценок пока нет

- Jazz TheoryДокумент82 страницыJazz Theorytouchofclass56291% (47)

- Oscar PetersonДокумент9 страницOscar PetersonIvana HalingkarОценок пока нет

- Gabriel FauréДокумент15 страницGabriel FauréIvana HalingkarОценок пока нет

- Music in My Mother's HouseДокумент13 страницMusic in My Mother's HouseIvana HalingkarОценок пока нет

- Solomons TempleДокумент2 страницыSolomons TempleIvana HalingkarОценок пока нет

- Francis PoulencДокумент16 страницFrancis PoulencIvana Halingkar0% (1)

- List of Transcriptions For Piano Four HandsДокумент14 страницList of Transcriptions For Piano Four HandsIvana Halingkar100% (1)

- George GershwinДокумент11 страницGeorge GershwinIvana HalingkarОценок пока нет

- Microstructure of Cheese (Journal)Документ7 страницMicrostructure of Cheese (Journal)Ivana HalingkarОценок пока нет

- Stravinsky - Petrushka 3mvtsДокумент37 страницStravinsky - Petrushka 3mvtsMarcos Vinicius VieiraОценок пока нет

- Aram KhachaturianДокумент13 страницAram KhachaturianIvana HalingkarОценок пока нет

- Secret - Time Travel Theme (Fast) - Jay Chou PDFДокумент4 страницыSecret - Time Travel Theme (Fast) - Jay Chou PDFIvana HalingkarОценок пока нет

- Chopsticks Very Easy VersionДокумент1 страницаChopsticks Very Easy VersionIvana HalingkarОценок пока нет

- Long Legged SailorДокумент1 страницаLong Legged SailorIvana HalingkarОценок пока нет

- Fly Me To The Moon - Jazz Piano SoloДокумент3 страницыFly Me To The Moon - Jazz Piano Solopartition48100% (1)

- Impact of Xylitol Replacement On Physicochemical, Sensory & Microbial Quality of CookiesДокумент6 страницImpact of Xylitol Replacement On Physicochemical, Sensory & Microbial Quality of CookiesIvana HalingkarОценок пока нет

- WunderKeys Parent Information GuideДокумент2 страницыWunderKeys Parent Information GuideIvana HalingkarОценок пока нет

- Six Little Kittens: Teaching Piano Adventures® - Primer LevelДокумент1 страницаSix Little Kittens: Teaching Piano Adventures® - Primer LevelIvana HalingkarОценок пока нет

- Review of Faber and Faber Piano Adventures Basic Piano MethodДокумент11 страницReview of Faber and Faber Piano Adventures Basic Piano MethodIvana Halingkar0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Dowex Optipore V503Документ2 страницыDowex Optipore V503SunnyОценок пока нет

- Chapter 2Документ9 страницChapter 2Behar AbdurahemanОценок пока нет

- Swimming Pool BOQ - Water ProofingДокумент2 страницыSwimming Pool BOQ - Water ProofingStephen RajОценок пока нет

- GE SSG4000 UltraGlaze DatasheetДокумент8 страницGE SSG4000 UltraGlaze DatasheetTomОценок пока нет

- Riopipeline2019 1112 FM 1112 FinalДокумент10 страницRiopipeline2019 1112 FM 1112 FinalMarcelo Varejão CasarinОценок пока нет

- MAKINO U Series Doc ButtonДокумент12 страницMAKINO U Series Doc ButtonBharath SaravananОценок пока нет

- Volume Changes of Cast Irons During CastingДокумент14 страницVolume Changes of Cast Irons During CastingwenceslaoОценок пока нет

- Chem Exp. 6 Chemical EquilibriumДокумент15 страницChem Exp. 6 Chemical EquilibriumRachel MaguireОценок пока нет

- V2500 Capability ListДокумент11 страницV2500 Capability ListVuppala RavitejaОценок пока нет

- Cost Effective Integrated Gas Plant Design Sulfinol MДокумент2 страницыCost Effective Integrated Gas Plant Design Sulfinol Mamirho3ein100% (1)

- 157 - OreOre Deposit Geology (John Ridley, 2013)Документ3 страницы157 - OreOre Deposit Geology (John Ridley, 2013)hugoluis_hОценок пока нет

- What Is Neutralization? A Reaction Between An Acid and A Base, Usually Making A Salt and WaterДокумент3 страницыWhat Is Neutralization? A Reaction Between An Acid and A Base, Usually Making A Salt and Watersomeone someoneОценок пока нет

- Hertz's Contact Pressures in Friction DrivesДокумент8 страницHertz's Contact Pressures in Friction DrivesZahir KhiraОценок пока нет

- Ec Clean - SdsДокумент5 страницEc Clean - SdsMary JosephineОценок пока нет

- Zamak-3 XometryДокумент1 страницаZamak-3 XometryFrancisco BocanegraОценок пока нет

- Penetration and Softening PointДокумент34 страницыPenetration and Softening PointLaxmikantОценок пока нет

- Determination of Saponification ValueДокумент2 страницыDetermination of Saponification Valuetrs22Оценок пока нет

- Grade 11 - w2 - Earth and Life ScienceДокумент7 страницGrade 11 - w2 - Earth and Life ScienceLeslie MermeloОценок пока нет

- Brosur Genteng M ClassДокумент6 страницBrosur Genteng M Classanon_795575819Оценок пока нет

- SG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323Документ10 страницSG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323vDraqОценок пока нет

- E-Mail: Ernst - Burke@falw - Vu.nl E-Mail: Giovanni - Ferraris@unito - ItДокумент16 страницE-Mail: Ernst - Burke@falw - Vu.nl E-Mail: Giovanni - Ferraris@unito - Itjuan25.103761Оценок пока нет

- Chave Emergência ZS73SДокумент6 страницChave Emergência ZS73SAdilsonОценок пока нет

- BOQ - Secondary ContainmentДокумент3 страницыBOQ - Secondary Containmentrehan7777Оценок пока нет

- Introduction and History of - Docx PenetrantДокумент56 страницIntroduction and History of - Docx PenetrantHamydОценок пока нет

- Atoms, Elements & Compounds 1 MS PDFДокумент8 страницAtoms, Elements & Compounds 1 MS PDFClinton ChikengezhaОценок пока нет

- Flange Bolting Torque Values API 6AДокумент1 страницаFlange Bolting Torque Values API 6Aparthameister100% (1)

- Copper Mountain Mine TR 09012020Документ233 страницыCopper Mountain Mine TR 09012020Thibaut LeconteОценок пока нет

- Hydrogen and Synthesis Gas by Steam - and C02 ReformingДокумент75 страницHydrogen and Synthesis Gas by Steam - and C02 Reformingzorro21072107Оценок пока нет

- Jitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetДокумент23 страницыJitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetabhishekОценок пока нет

- Af 163-2Документ10 страницAf 163-2lacsmm982Оценок пока нет