Академический Документы

Профессиональный Документы

Культура Документы

Ol190led PDF

Загружено:

Mahmoud Mohamed NagiebАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ol190led PDF

Загружено:

Mahmoud Mohamed NagiebАвторское право:

Доступные форматы

POINT OBSTRUCTION LIGHTS

POL LED v3

POINTSPEC SERIES

Compliances:

ETL Listed to UL 1598 USA

ETL Listed to CSA C22.2 No.250.0-04 Canada

ETL Listed to UL 1598A Marine Vessels

ETL Verified FAA L-810 to FAA Advisory Circular 150/5345-43F

ETL Verified ICAO Annex 14 Low Intensity Types A (10 cd) & B (32 cd)

Compliance to Transport Canada CAR 621.19. Table 5-1

IMO 2009 MODU Code (2010) paragraphs 13.5.24 & 13.5.25

American Bureau of Shipping (ABS) Type Approved Product

The POL POINTSPEC series of red LED aviation obstruction lights presents the highest grade technical features

and the most options available in the industry. POL steady-burning obstruction lights are used to mark tall

structures that present hazards to air navigation. Use with an FAA photoelectric controller.

See important alarms note on specifications page.

Point Type Power

& Color

Supply*

POL-21003-R

1:

2:

3:

4:

5:

Photometric

Specification

120v

F:

220v

12v DC A:

24v DC

48v DC

FAA & ICAO

Type B (32 cd)

ICAO

Type A (10 cd)

Note: FAA certified with FAA lamp number 281

Intertek ETL SEMKO Control Number 3030033

Mounting

& Entries

Style

34B: -inch, Bottom S: Single

10B: 1-inch, Bottom

D: Double

34F: -in, Feed-thru See Styles

M25B: M25, Bottom

Selection Chart

SF: Slipfitter 2.375-in (60 mm)

*AC voltages are nominal. See pages 3-4 for operating range; suitable for 50 or 60 Hz.

Options

P:

Photoelectric

Controller

CF: Cable Fitting

E:

Emissions

MT: Marine

Treatment

277: 277v (use -2F)

For mounting options and plan details, see file 0MOUNTINGS

All details are available as AutoCAD files for insertion into project plans

POL-21003-R-1F-34B-D

DOUBLE OBSTRUCTION LIGHT

OL-1.9.0 March, 2012

POINT OBSTRUCTION LIGHTS

POL LED v3

POINTSPEC SERIES

SELECTION CHART

Style

Transfer

Alarm

Alarm

Non-Isolated Isolated

Pilot

Light

Flashing

Description

-S

-S1

Single: flashing

-S1.3

Single with junction box: flashing

-S2

Single: non-isolated alarm

-S2.1

DC only; same as Style S2 for use with POC

-S3

-S4

-S5

Standard Single

-D

(Note 1)

(Note 1)

Single: integral junction box & cover

Single: isolated failure alarm

(Note 1)

(Note 1)

Dual Mode Single: flashing, but may be set in

the field to be steady-burning

Double: both heads operating

-DT

-D1

-D2

-D2.2

-D3

-D4

Double: operating head & standby with transfer

Double: transfer & non-isolated alarm

Double: both heads operating &

non-isolated alarm

Double: both heads operating & isolated alarm

-D6

-D13

-D18

-D19

Double: both heads flashing

Double: primary head flashes and transfer to

standby head which flashes; no alarm

Same as Style D8 with alarm line

Double: transfer, primary head alarm, standby

head alarm & power failure alarm; tagged wires

-D16

Double: both heads flashing with isolated alarm

Double: both heads flashing; non-isolated alarm

(Note 2)

-D14

-D15

Same as Style D4 with pilot light

(Note 2)

Same as Style D4 prewired with six (6) wires

-D7

-D10

Double: transfer, non-isolated alarm & pilot light

Double: transfer & isolated alarm

(Note 2)

-D5

-D8

Double: transfer & pilot light

-D4.2

Note 1:

Note 2:

(no junction box)

Double: primary head flashes and transfer to

standby head flashes; pilot light on transfer

Double: transfer, primary head alarm, standby

head alarm; non-isolated alarms

Double: primary head flashes and transfer to

standby head flashes; with isolated alarm line

This single has a J-box & cover below the LED head assembly; box is required for any single with option P.

Alarm activates on transfer

POINT OBSTRUCTION LIGHTS

POL LED v3

POINTSPEC SERIES

LED ILLUMINATION ILLUSTRATED

TURN IT ON!

POL-21003-R-1F-34B-S

SINGLE OBSTRUCTION LIGHT

THE DIFFERENCE IS LIKE DAY AND NIGHT!

Note: Alarm options must be selected at time of initial order. Alarms cannot be added in the field or retrofitted.

Note: The POL optical subassembly is factory sealed to prevent moisture penetration and it is not serviceable.

Option OS:

Override Switch. For use with photoelectric controller option P. Cover mounted 3-position

switch ON-OFF-AUTO. Requires a double or single with junction box.

For remote override switch, add item PL40110-3.

Option CF[B]:

Through holes with 1.5-inch long -20 hex head stainless steel screws and sealing washers.

Metal cable compression fitting for outside diameter: 0.5 to 0.625-inch (12.7 to 15.9-mm).

Available for 34L unilet style single lights.

Option CF[C]:

Through holes with 1.5-inch long -20 hex head stainless steel screws and sealing washers.

Metal cable compression fitting for outside diameter: 0.5 to 0.625-inch (12.7 to 15.9-mm).

Available for all doubles and junction box style single lights.

Option E:

Certified compliant for radiated and conducted radio emissions (EMC) per EU EMC Directive

89/336/EEC to EN55022 Class A and FCC Class A as required for CE labeling per Chomerics

Test Services reports TR4849A.07 & TR4849B.07.

POWER CONSUMPTION

PER POL LED LIGHT HEAD

Code

Type

Voltage

Frequency

Watts*

mA

VA*

-1F

FAA & ICAO B

120 AC

50/60 Hz

9.7

91

10.8

-2F

FAA & ICAO B

220 AC

50/60 Hz

9.7

49

10.8

-3F

FAA & ICAO B

12 DC

---

13.0

960

13.0

-4F

FAA & ICAO B

24 DC

---

13.0

540

13.0

-5F

FAA & ICAO B

48 DC

---

8.6

180

8.6

-1A

ICAO A

120 AC

50/60 Hz

4.7

48

5.8

-2A

ICAO A

220 AC

50/60 Hz

4.7

26

5.9

-3A

ICAO A

12 DC

---

4.7

390

4.7

-4A

ICAO A

24 DC

---

4.6

190

4.6

-5A

ICAO A

48 DC

---

3.4

70

3.4

*Power consumption for AC units includes the effect of the units power factor which accounts for the

difference between watts and volt-amperes. Measurements were made at the nominal AC voltages.

The operating range for 120v units is 93 - 144v. The operating range for 220v units is 176 - 250v.

POINT OBSTRUCTION LIGHTS

POL LED v3

POINTSPEC SERIES

POL LED SPECIFICATIONS

SPECIFICATIONS COMMON TO ALL POL LED VERSIONS

The red LED lighted (specify: voltage) aviation obstruction light shall be tested and certified FAA L-810 (ICAO low intensity Type B).

The obstruction light shall operate properly at 50 or 60 Hz at an input voltage supply of 120V +/-20% (93V to 144V) or, for 220V

units, 176V to 250V. Within the preceding ranges, the output to the LED board shall be a controlled, stabilized constant current. AC

lights shall not exceed 11 VA power consumption per head.

The AC obstruction lights shall be listed Suitable for Use in Wet Locations to UL1598A Marine Vessels, UL1598 2nd Edition Luminaries;

CSA C22.2 No. 250.0-04, 2nd Edition; UL50 11th Edition Standard for Enclosures for Electrical Equipment and CSA C22.2 No. 94M91 Special Purpose Enclosures. Sealed to IP66 ingress protection.

Special Technical Note*: DC light fixtures shall be reverse polarity protected.

* Competitors units will fail if installed with reverse polarity.

The unit shall have passed the FAA certification tests: the constant high temperature test to +130 deg F (+55 deg C) and the constant

low temperature test to -67 deg F (-55 deg C) conducted in accordance with US MILSTD-810E, Method 501.3, Procedure II; the windblown rain test conducted in accordance with US MIL-STD-810E, Method 506.3, Procedure I; and the humidity test shall be in

accordance with US MIL-STD-810E, Method 507.3, Procedure I. The complete test regime shall exceed the requirements of NEMA 4X

and IP 65. The light head shall be powdercoat painted aviation yellow for corrosion resistance certified by the manufacturer to comply

with the US Military Standard Salt Fog Test conducted per MIL-STD-810E, Method 509.3, Procedure I.

The red lens shall be strong soda lime glass with the wave-length matched to the LEDs to permit the fullest light transmission. The lens

shall be smooth and rounded to reduce the adhesion of dirt, ice and snow.

The red emitting LEDs shall meet the chromaticity requirements of US MIL-C-25050. The high output LEDs shall not exceed eight (8)

in number and shall be the latest technology providing uniform light output over the range required by the governing standard. The

LED average life shall exceed 100,000 hours.

The LEDs shall be soldered in a factory set position to insure consistent light output. Wire mounted raised LEDs that can be bent out of

position shall be unacceptable and cause for rejection. The LED board shall be treated with a protective dielectric conformal coating

for protection from moisture and corrosion.

The power supply board shall include short circuit and open circuit protection and the unit shall be protected from line surges by

metal oxide varistors (MOVs). All v3 units shall have the power supply and flasher board (if any) potted in the fixture (head

subassembly) casting. There shall be a clear design element for the dissipation of LED heat to insure the LEDs do not fail prematurely.

The double LED light unit shall have an integral cast aluminum junction box with a minimum of 100 cubic inches of enclosed wiring

space accessible from the front of the light unit. The wiring access cover shall be gasketed to be watertight, shall have captive screws

and shall be secured to the unit with a tether. The cast enclosure and cover shall be powdercoat painted aviation yellow for corrosion

resistance certified by the manufacturer to comply with the US Military Standard Salt Fog Test conducted per MIL-STD-810E, Method

509.3, Procedure I. The cover tether and all hardware shall be stainless steel.

Option -E: Certified compliant for radiated and conducted radio emissions (EMC) per EU EMC Directive 89/336/EEC to

EN55022 Class A and FCC Class A.

The red LED aviation obstruction light shall be POINTSPEC Series POL-21003 manufactured by Point Lighting Corporation.

Important Note: Alarm options must be selected at time of initial order. Alarms cannot be added in the field or retrofitted.

POL LED lights cannot be monitored by 3rd party systems or controllers without selecting an alarm version of the POL LED.

Myth: All LEDs have a useful life of 100,000 hours

Myth: LEDs do not create heat

The amount of useable lightabout 70% of original light

outputfrom some LED's has been shown to be very short

depending on the color and manufacturer of the LED. That

is why the quality of the LED array and power supply is

very important and they should be of the latest technology

as used by Point Lighting Corporation.

LEDs do create heat, but the heat generated is retained

within the LED array and needs to be dissipated. Without a

proper design, the LED will fail very early in life. The POL

LED array design incorporates an aluminum heat sink to

dissipate the heat. Some competitors lightsby design

cannot handle the heat.

POINT OBSTRUCTION LIGHTS

POL LED v3

POINTSPEC SERIES

PHOTOMETRIC DATA

FAA VERSION

FAA L-810 requires 32.5 candelas minimum over 10-deg vertical beam spread

Exceeds the recommendation of ICAO Low Intensity Type B (32 candelas)

25

Vertical

20

15

50.0

40.0

10

32.5

5

0

-180

-150

-120

-90

-60

-30

30

60

90

120

150

180

Horizontal

REPLACEMENT PARTS

Note: Single POLs and the fixture heads of double POLs are permanently sealed. In the event of failure, the fixture

must be returned to the factory for evaluation and repair.

PL210R3-R-xx-xx Replacement Light Head Double

PL10237A

Photoelectric Socket (-P)

PL10236-120

Photoelectric Subassembly 120v

PL10236-230

Photoelectric Subassembly 230v

PL10462

Cover & Tether Double All Styles

PL10496

Cover & Tether Single (with box)

WEIGHT, DIMENSIONS & SHIPPING DATA

inches (mm)

Weight

Height

Width

Depth

Qty

Multi-Pack Carton

Weight

Dim (inches)

POINTSPEC Single:

3.8 lbs 1.7 kg

8.6 (217)

6.0 (152)

5.0 (127)

12

47 lbs

21.3 kg 22 x 15 x 17

POINTSPEC Double:

12.4 lbs 5.6 kg

13.3 (337)

14.9 (378)

5.0 (127)

27 lbs

12.3 kg 19 x 19 x 19

Wind Loading:

Effective Projected Area (EPA) for POINTSPEC Double

0.69 square feet

POINT LIGHTING CORPORATION

Mail: P.O. Box 686, Simsbury, CT 06070

Plant: West Dudley Town Rd, Bloomfield, CT

Tel 01 860.243.0600

USA

Fax 01 860.243.0665

email: Info@PointLighting.com

website: www.PointLighting.com

Вам также может понравиться

- PMP Formulas Cheat SheetДокумент2 страницыPMP Formulas Cheat SheetAn Nguyen100% (12)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- 13 Earned Value ManagementДокумент9 страниц13 Earned Value ManagementAbhinandan Singh100% (1)

- PMP Question Bank PDFДокумент16 страницPMP Question Bank PDFRyan Li67% (15)

- Brother Service Manual 7440NДокумент64 страницыBrother Service Manual 7440NAlicia Smith100% (1)

- PHILIPS LCD Ch-10.1L LLA-32PFL3605D-40PFL3605D PDFДокумент71 страницаPHILIPS LCD Ch-10.1L LLA-32PFL3605D-40PFL3605D PDFAlecsandro BatistaОценок пока нет

- TMC Cable CatalogДокумент71 страницаTMC Cable Cataloglam266Оценок пока нет

- 24 Plait 8ft Bullwhip RecipeДокумент9 страниц24 Plait 8ft Bullwhip RecipeTyler RiceОценок пока нет

- 5-Power & Control Cables PDFДокумент11 страниц5-Power & Control Cables PDFAnonymous ufMAGXcskMОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Process Process Group Inputs Tools & Techniques Outputs: Sno Knowledge AreaДокумент7 страницProcess Process Group Inputs Tools & Techniques Outputs: Sno Knowledge AreaMohamed AfsalОценок пока нет

- Zeroing RobotДокумент44 страницыZeroing RobotArno BothaОценок пока нет

- Lighting Philosphy NTPCДокумент8 страницLighting Philosphy NTPCHarpreet SinghОценок пока нет

- MS150093 01e PDFДокумент181 страницаMS150093 01e PDFAntonio MartinОценок пока нет

- SUPER Final ImportДокумент41 страницаSUPER Final ImportronaldОценок пока нет

- 11 Create WBS PDFДокумент10 страниц11 Create WBS PDFKhanh Dinh Duy100% (1)

- Material Submittal R0-BMS - 10 Schools PDFДокумент216 страницMaterial Submittal R0-BMS - 10 Schools PDFElektrikal InhinyeroОценок пока нет

- Aislador Epoxi Catalogo 2011 ENG PDFДокумент56 страницAislador Epoxi Catalogo 2011 ENG PDFWalter CataldoОценок пока нет

- 06-POWER AND CONTROL CABLE - Rev5 PDFДокумент14 страниц06-POWER AND CONTROL CABLE - Rev5 PDFSanjay RoutОценок пока нет

- Cost, Time and Quality, Two Best Guesses and A Phenomenon, Its Time To Accept Other Success CriteriaДокумент6 страницCost, Time and Quality, Two Best Guesses and A Phenomenon, Its Time To Accept Other Success Criteriaapi-3707091100% (2)

- Seipl Profile and CapabilitiesДокумент32 страницыSeipl Profile and CapabilitiesAbhishek GuptaОценок пока нет

- European Chains & Hotels Report 2019Документ77 страницEuropean Chains & Hotels Report 2019Tatiana100% (1)

- OPTO Coupler Selector Guide MOTДокумент9 страницOPTO Coupler Selector Guide MOTmstgofcoОценок пока нет

- Enclosures TechnicalДокумент16 страницEnclosures TechnicalAnonymous rYZyQQot55Оценок пока нет

- Led Elevated Taxiway Edge Light: CompliancesДокумент4 страницыLed Elevated Taxiway Edge Light: CompliancesanupamkhannaОценок пока нет

- CM Bu9000 Eng Bushings 3Документ36 страницCM Bu9000 Eng Bushings 3ing.dmanriq27100% (1)

- ALC ElectricalДокумент8 страницALC ElectricalmarckalhiОценок пока нет

- At30 130 040f480sxsxaxxx PDFДокумент12 страницAt30 130 040f480sxsxaxxx PDFpepe2xОценок пока нет

- 333 2SDRD S530 A3 DatasheetДокумент6 страниц333 2SDRD S530 A3 Datasheetvikas_ojha54706Оценок пока нет

- Data Sheet L 850c Led L 850d Led Irel L Irte LДокумент3 страницыData Sheet L 850c Led L 850d Led Irel L Irte LyohersonedasaОценок пока нет

- Evt4 LedДокумент4 страницыEvt4 LedGabriela Dominguez BonillaОценок пока нет

- Marine FlexenДокумент67 страницMarine FlexenpayaljeevaОценок пока нет

- Service Manual: Wi-Fi & 3D Ready / DVB-T / T2 / C / S / S2 PAL / Secam System Colour TelevisionДокумент148 страницService Manual: Wi-Fi & 3D Ready / DVB-T / T2 / C / S / S2 PAL / Secam System Colour TelevisionOnet Dorel100% (1)

- Coil Electronics ControlДокумент28 страницCoil Electronics ControlNippur de LagashОценок пока нет

- STAHL Control SwitchesДокумент16 страницSTAHL Control SwitchesLaurence MalanumОценок пока нет

- Catálogo Detector de HumoДокумент2 страницыCatálogo Detector de Humoprufino2Оценок пока нет

- TCW 596Документ4 страницыTCW 596Ben CheungОценок пока нет

- Ap 1600 GetstartДокумент38 страницAp 1600 GetstartFrancisco DiazОценок пока нет

- Luminaria Se'Lux TikalДокумент7 страницLuminaria Se'Lux Tikalelvisjam01Оценок пока нет

- Alk-V Photoelectric Smoke Sensor: ApplicationДокумент2 страницыAlk-V Photoelectric Smoke Sensor: Applicationkofan7Оценок пока нет

- DS Catalogue Fuses Redspot English UkДокумент48 страницDS Catalogue Fuses Redspot English UkSamraj MahalingamОценок пока нет

- Fileshare Filarkivroot Produkt PDF Dokumentasjon Bsd3402 CeДокумент2 страницыFileshare Filarkivroot Produkt PDF Dokumentasjon Bsd3402 CeAndré Albino De OliveiraОценок пока нет

- 38 FLSD enДокумент28 страниц38 FLSD enFlo MircaОценок пока нет

- A.04.251 PvoДокумент4 страницыA.04.251 PvoMuhammad Fadhil FscОценок пока нет

- Ember Led - Vshine Led Flood Light - High PowerДокумент7 страницEmber Led - Vshine Led Flood Light - High Powerjrobins1228Оценок пока нет

- Hadar e BrochureДокумент32 страницыHadar e BrochuremohdОценок пока нет

- AT10.1 Series: Float Battery ChargersДокумент12 страницAT10.1 Series: Float Battery ChargersJ Salvador Calderón BarrancosОценок пока нет

- Cooper Medc Datasheet BG 6ds142 Issue eДокумент2 страницыCooper Medc Datasheet BG 6ds142 Issue eskylarksОценок пока нет

- D5014 Ism0103 enДокумент9 страницD5014 Ism0103 enwaleedusman44Оценок пока нет

- Strato 35 Series and 70 Series :: ROAL Living EnergyДокумент5 страницStrato 35 Series and 70 Series :: ROAL Living EnergyroalscribdОценок пока нет

- In313 PR1Документ35 страницIn313 PR1wellbr123Оценок пока нет

- AM - SS03 - E2 - P1 ZXA10-MSAN Cabinet & Power Module Introduction (Malaysia) V1.1 19pДокумент19 страницAM - SS03 - E2 - P1 ZXA10-MSAN Cabinet & Power Module Introduction (Malaysia) V1.1 19phonestcheaterОценок пока нет

- Logo!: Installation, Connection, Technical SpecificationsДокумент2 страницыLogo!: Installation, Connection, Technical SpecificationsGustavo OrellanaОценок пока нет

- CWDM 1x9 155Mb 120km TransceiverДокумент11 страницCWDM 1x9 155Mb 120km TransceiverdogudoguОценок пока нет

- 1523A Coax - CATV Cable: See Put-Ups and ColorsДокумент4 страницы1523A Coax - CATV Cable: See Put-Ups and ColorslavacagarbuanavirgiawanОценок пока нет

- 0 5 enДокумент70 страниц0 5 enrocket-vtОценок пока нет

- RDSO Specification For LED Based Luminaire (Amdt-2)Документ16 страницRDSO Specification For LED Based Luminaire (Amdt-2)ketan1965Оценок пока нет

- Philips Chassis A02e AaДокумент114 страницPhilips Chassis A02e AajoanОценок пока нет

- Data Sheet: ApplicationДокумент2 страницыData Sheet: ApplicationShamal VidharshaОценок пока нет

- P-2M UserManual V2.2Документ12 страницP-2M UserManual V2.2Mohamed WahidОценок пока нет

- Los FastastiДокумент38 страницLos Fastastialexander RodriguezОценок пока нет

- I7 Gam771pmti2Документ5 страницI7 Gam771pmti2Andres David Nieto FonsecaОценок пока нет

- Fire-Lite B200SR-LF Data SheetДокумент2 страницыFire-Lite B200SR-LF Data SheetJMAC SupplyОценок пока нет

- Philips L04e Aa Chassis TV SMДокумент90 страницPhilips L04e Aa Chassis TV SMSakis GkarasОценок пока нет

- Aislador Epoxi Catalogo 2011 ENGДокумент56 страницAislador Epoxi Catalogo 2011 ENGmk116dОценок пока нет

- TMCX Hazardous Location Cable ConnectorДокумент1 страницаTMCX Hazardous Location Cable ConnectorGolfkung PairojОценок пока нет

- Encoder Mini h9700Документ13 страницEncoder Mini h9700Ramirez ManuelОценок пока нет

- AMLED77YBU1Документ9 страницAMLED77YBU1FaeistenYweОценок пока нет

- How To Google SearchДокумент1 страницаHow To Google SearchMahmoud Mohamed NagiebОценок пока нет

- Project Risk Management TermsДокумент5 страницProject Risk Management TermsSergio AlvesОценок пока нет

- HTTPS://WWW Scribd Com/document/156108189/electromagnetismДокумент19 страницHTTPS://WWW Scribd Com/document/156108189/electromagnetismJean PierreОценок пока нет

- Power of Power BI in Just 10 Different AnalysisДокумент1 страницаPower of Power BI in Just 10 Different AnalysisZubin GeorgeОценок пока нет

- How To Google SearchДокумент1 страницаHow To Google SearchMahmoud Mohamed NagiebОценок пока нет

- Project Risk Management TermsДокумент5 страницProject Risk Management TermsSergio AlvesОценок пока нет

- PMP Ch1Документ5 страницPMP Ch1Mahmoud Mohamed NagiebОценок пока нет

- 14 Controlling QualityДокумент8 страниц14 Controlling QualityMahmoud Mohamed NagiebОценок пока нет

- Technical ReportsДокумент20 страницTechnical ReportsMahmoud Mohamed NagiebОценок пока нет

- PMP Exam SimulatorsДокумент1 страницаPMP Exam SimulatorsMahmoud Mohamed NagiebОценок пока нет

- Find All Paths To Completion. 2. Complete The Forward Pass. 3. Complete The Backward Pass. 4. Expose FloatДокумент5 страницFind All Paths To Completion. 2. Complete The Forward Pass. 3. Complete The Backward Pass. 4. Expose FloatGautam DОценок пока нет

- 2 - DefineДокумент10 страниц2 - DefineMahmoud Mohamed NagiebОценок пока нет

- 10 Mapping Change ControlДокумент5 страниц10 Mapping Change ControlMahmoud Mohamed NagiebОценок пока нет

- Alarm & StatusДокумент11 страницAlarm & StatusEka Suranta Tarigan73% (11)

- Pmpcheatsheetinplainenglishpmbok6 190414214536 PDFДокумент8 страницPmpcheatsheetinplainenglishpmbok6 190414214536 PDFMahmoud Mohamed NagiebОценок пока нет

- LabbbДокумент7 страницLabbbMahmoud Mohamed NagiebОценок пока нет

- Node B Architecture NOKIAДокумент3 страницыNode B Architecture NOKIASokhom TaingОценок пока нет

- 03 - Measure PDFДокумент5 страниц03 - Measure PDFMahmoud Mohamed NagiebОценок пока нет

- 9 Manager Leader PDFДокумент24 страницы9 Manager Leader PDFdonyemjoroОценок пока нет

- How To Write A Good Technical ReportДокумент15 страницHow To Write A Good Technical ReportburraqОценок пока нет

- Annex 19 - RSM Remote Monitoring System PM & CM Check List - V1.0Документ7 страницAnnex 19 - RSM Remote Monitoring System PM & CM Check List - V1.0Mahmoud Mohamed NagiebОценок пока нет

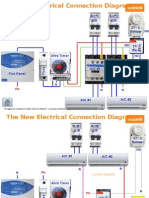

- Air Conditioners ATS Modification - v5Документ6 страницAir Conditioners ATS Modification - v5Mahmoud Mohamed NagiebОценок пока нет

- NEC DC Box ConfigДокумент2 страницыNEC DC Box ConfigMahmoud Mohamed NagiebОценок пока нет

- Seamless Handoff Between Heterogeneous Wireless NetworksДокумент19 страницSeamless Handoff Between Heterogeneous Wireless NetworksMahmoud Mohamed NagiebОценок пока нет

- VEL BS 2001aДокумент20 страницVEL BS 2001aritoh8657Оценок пока нет

- ENSET Buea 2019 - 1ere Annee Du 2nd Cycle - enДокумент5 страницENSET Buea 2019 - 1ere Annee Du 2nd Cycle - enStéphanie Océane NadjiОценок пока нет

- Bittorrent-Like P2P NetworkДокумент41 страницаBittorrent-Like P2P NetworkNguyễn Ngọc GiàuОценок пока нет

- Self Priming Water Lifting Booster PumpДокумент2 страницыSelf Priming Water Lifting Booster PumpzhelipumpОценок пока нет

- Fpga Viva QuestionДокумент4 страницыFpga Viva QuestionManila MathurОценок пока нет

- Non Destructive Testing Tech EnglishДокумент1 страницаNon Destructive Testing Tech Englishvictor hugoОценок пока нет

- Chapter ONE Full PDFДокумент125 страницChapter ONE Full PDFAzimSyahmiОценок пока нет

- Diwali Dhamaka (Gaur City) 21 Gifts W.E.F. 15.09.2018Документ1 страницаDiwali Dhamaka (Gaur City) 21 Gifts W.E.F. 15.09.2018Dev RajОценок пока нет

- Digital Literacy: A Conceptual Framework For Survival Skills in The Digital EraДокумент14 страницDigital Literacy: A Conceptual Framework For Survival Skills in The Digital EraSilvia CarvalhoОценок пока нет

- The Hydraulic Pumping SystemДокумент12 страницThe Hydraulic Pumping SystemCarlos Lopez DominguezОценок пока нет

- Mazda rx7Документ3 страницыMazda rx7Jon WestОценок пока нет

- Kyocera ECOSYS M2030dn M2530dn M2035dn M2535dn SM UK PDFДокумент273 страницыKyocera ECOSYS M2030dn M2530dn M2035dn M2535dn SM UK PDFoleg sokolovОценок пока нет

- 4 Leed Open SpaceДокумент6 страниц4 Leed Open SpaceswapnilupgadeОценок пока нет

- Om Facility LayoutДокумент9 страницOm Facility LayoutBrein Symon DialaОценок пока нет

- TMP 4341Документ2 страницыTMP 4341nithiananthiОценок пока нет

- BCA-529 Linux & Unix PDFДокумент102 страницыBCA-529 Linux & Unix PDFmayur malviyaОценок пока нет

- Ind Mkt. Caselet 1Документ6 страницInd Mkt. Caselet 1harshalОценок пока нет

- A.J Mcdougall: VP Director / Principal ConsultantДокумент27 страницA.J Mcdougall: VP Director / Principal ConsultantDe SambasОценок пока нет

- 07.4 111 FW ML PF WPS 20mm ENGДокумент1 страница07.4 111 FW ML PF WPS 20mm ENGViktorОценок пока нет

- Muhammad Ali - CHRP (Canada)Документ8 страницMuhammad Ali - CHRP (Canada)Muhammad AliОценок пока нет

- GrabBee HD ManualДокумент9 страницGrabBee HD ManualAndrea Lissette Perez FuentesОценок пока нет